Brass mesh, with its distinctive golden hue and remarkable versatility, can be used for everything from industrial filtering to decorative accents. A copper-zinc alloy, brass is renowned for its unique combination of strength, workability, and corrosion resistance. Brass can be made with specific properties by varying the proportions of copper and zinc, making it extremely versatile.

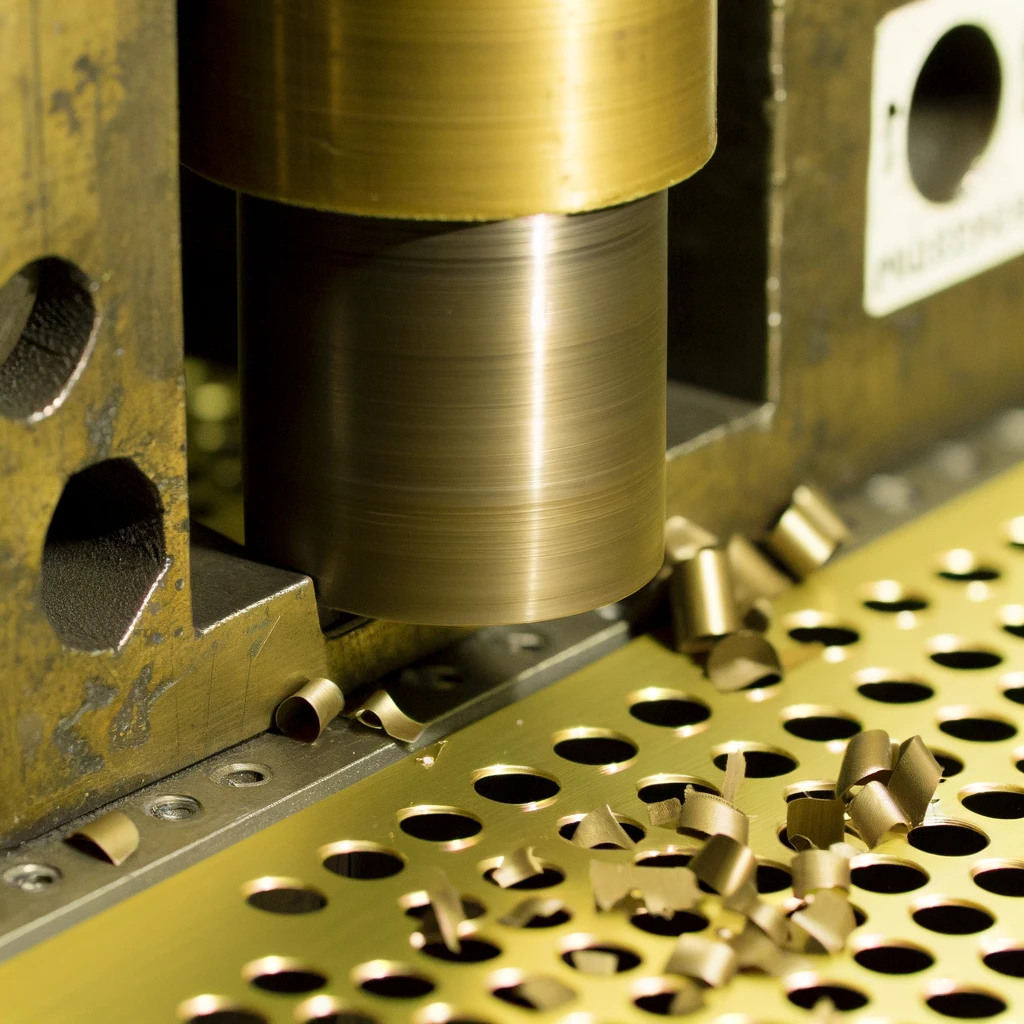

In the world of mesh, brass is primarily fashioned into two types: woven wire mesh and perforated metal mesh. A variety of uses are possible for each type, from protective screens to aesthetic architectural elements. There is a choice between woven and perforated forms depending on the application’s needs, such as fine filtration, electromagnetic interference shielding, or decorative patterns.

The widespread use of brass mesh in various industries is not solely a result of its physical properties. Brass’ warm, inviting luster adds a dimension of beauty to its practicality, making it a popular material for design and architecture. This article delves into the properties of brass mesh that make it such a versatile and desirable material, exploring how its unique blend of aesthetic appeal, durability, and functional properties has cemented its place in numerous fields.

Brass mesh owes its widespread use to a host of intrinsic properties that make it ideally suited for a range of applications. As a result of its copper content, brass is malleable and ductile, allowing it to easily be woven into mesh or stamped into intricate patterns without losing structural integrity. The ease of fabrication is one of the main reasons brass mesh is so popular.

Combined with zinc, brass’ natural corrosion resistance ensures longevity and reliability in environments where moisture and chemicals might damage other materials. Brass mesh is an excellent choice for outdoor architectural features, industrial filtration systems, and even marine applications.

In addition to its functional attributes, brass mesh has an aesthetic quality that is unmatched by other materials. There are many decorative possibilities with its golden appearance, which can range from a bright, polished sheen to a deeper, antiqued patina. Due to its visual appeal and durability, brass mesh can be used in a variety of settings as both a functional element and a decorative feature.

Brass is also antimicrobial, making it a great choice for applications that require a high level of hygiene. Brass’ ability to inhibit the growth of bacteria and other pathogens makes it ideal for use in food processing, medical facilities, and other areas requiring cleanliness and hygienic conditions.

As a result of its malleability, corrosion resistance, aesthetic appeal, and antimicrobial properties, brass mesh is a uniquely versatile material. As a result of these characteristics, brass mesh remains a preferred choice across industries for both practical and decorative applications.

Filtration

As a result of its fine weaves and inherent strength, brass woven wire mesh is widely used in liquid and gas filtration. Non-ferrous materials, such as brass, are ideal in industrial settings due to their resistance to rust or magnetic interference. The mesh’s specific weave patterns allow precise control over particle size retention, ensuring that only substances of desired sizes pass through, which is essential in processes ranging from chemical manufacturing to beverage manufacturing. Brass’ corrosion resistance and its ability to withstand a wide range of temperatures further establish its versatility as a filtration material.

Decorative Applications

Brass woven wire mesh is unmatched in aesthetic appeal, finding its way into architectural and interior design.In addition to adding a touch of elegance, its golden hue also plays with light in enchanting ways, creating warmer, more sophisticated atmospheres.

EMI/RFI Shielding

EMI/RFI shielding is more critical than ever in the age of ubiquitous electronic devices and systems. Due to its electrical conductivity and ability to create a Faraday cage effect, brass woven wire mesh is the ideal material for such applications. From research laboratories to data centers, it ensures the reliability and accuracy of measurements and operations by shielding sensitive electronic equipment from external electromagnetic fields.

Industrial Uses

The utility of brass woven wire mesh extends beyond its more obvious applications. In industries such as mining, pharmaceuticals, and food production, sieves are used for particle sizing, to separate and classify materials according to granule size. Papermakers use brass mesh as a pulp strainer to remove impurities and maintain paper quality. Brass mesh is used in filtration systems in the automotive industry, including oil and air filters, where its durability and resistance to degradation are crucial to vehicle maintenance.

Below are a few selected woven wire specifications and some examples of how they can be used:

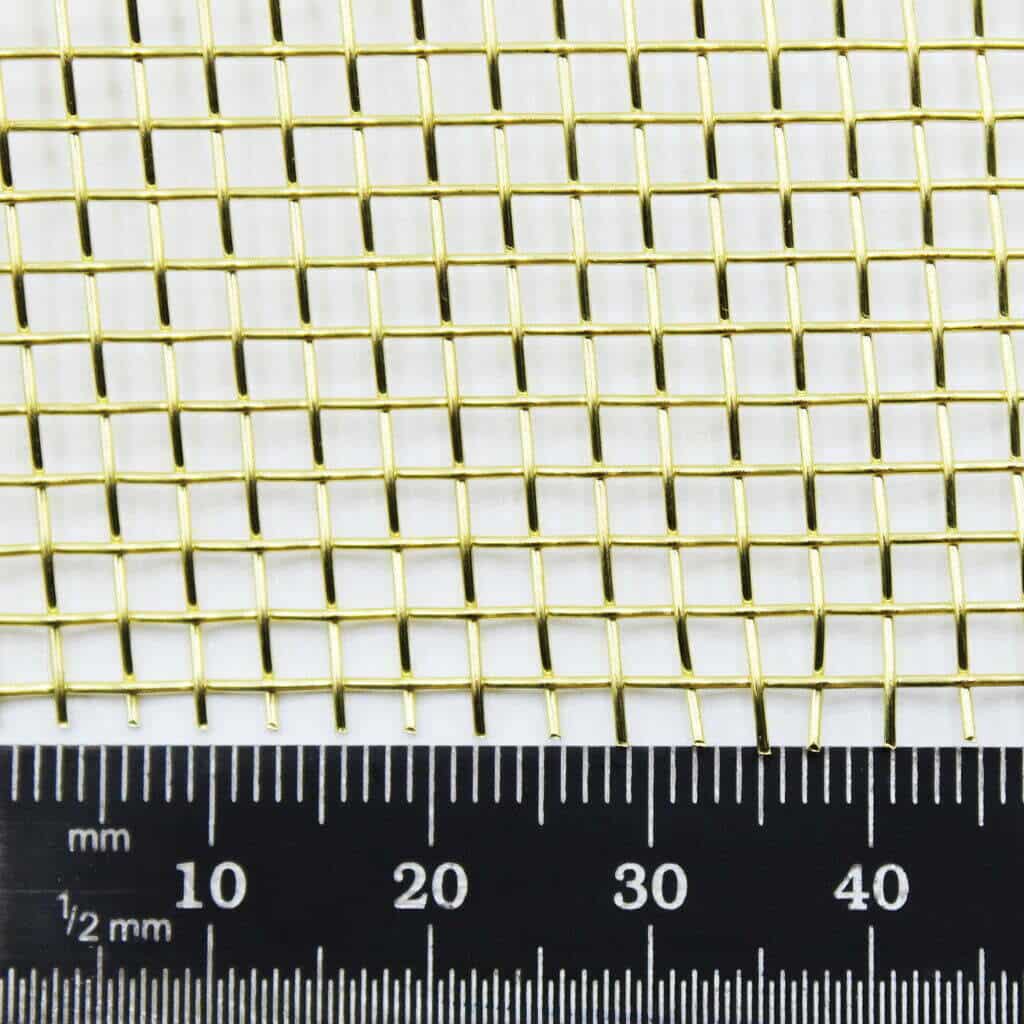

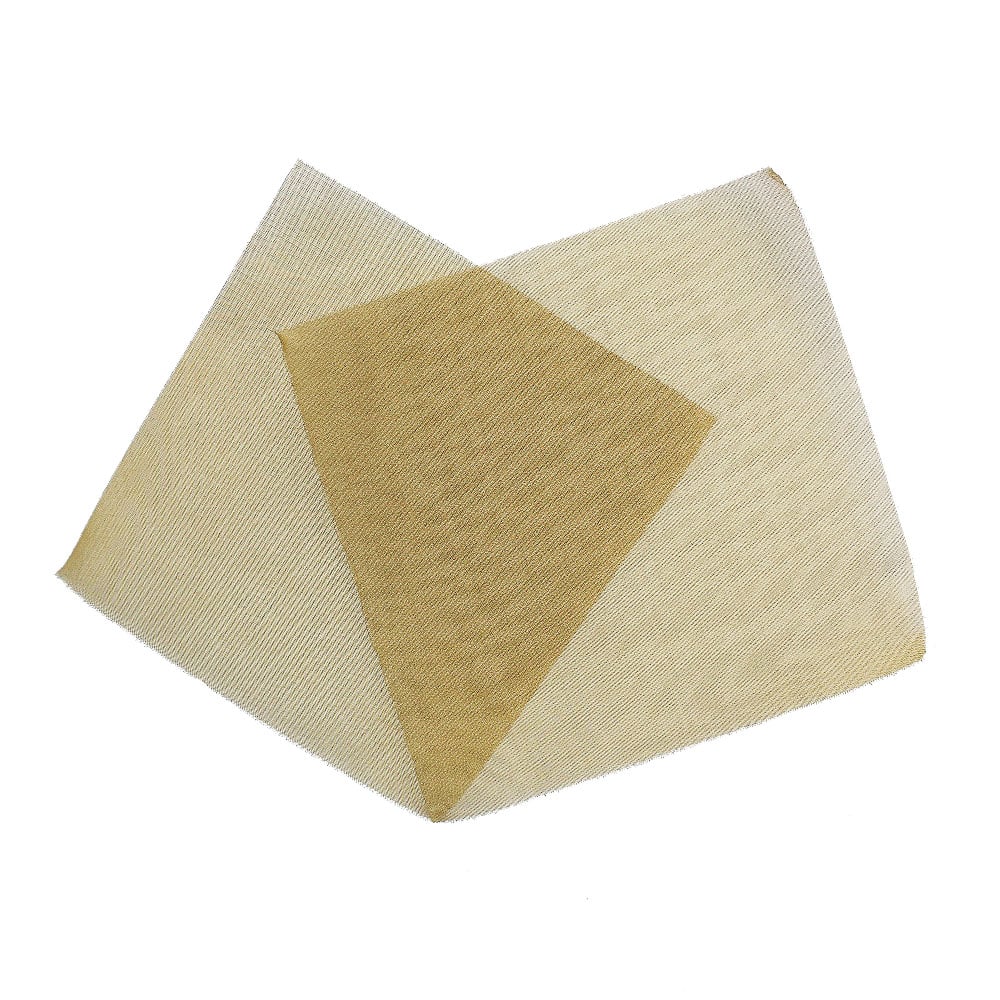

With a wire diameter of 0.63mm and an open area indicative of 8 lines per inch (LPI), this brass heavy-duty wire decorative mesh presents a robust solution for architectural and decorative applications. This mesh combines the timeless aesthetic appeal of brass with functional strength, making it an excellent choice for creating striking facades, room dividers, and feature walls inside and outside. As a result of its large open spaces, it facilitates airflow and light diffusion while maintaining a sense of openness, thus improving environmental comfort and visual interest. Additionally, its heavy-duty nature ensures durability, offering a long-lasting decorative element that can withstand environmental elements, contributing to a sustainable design aesthetic.

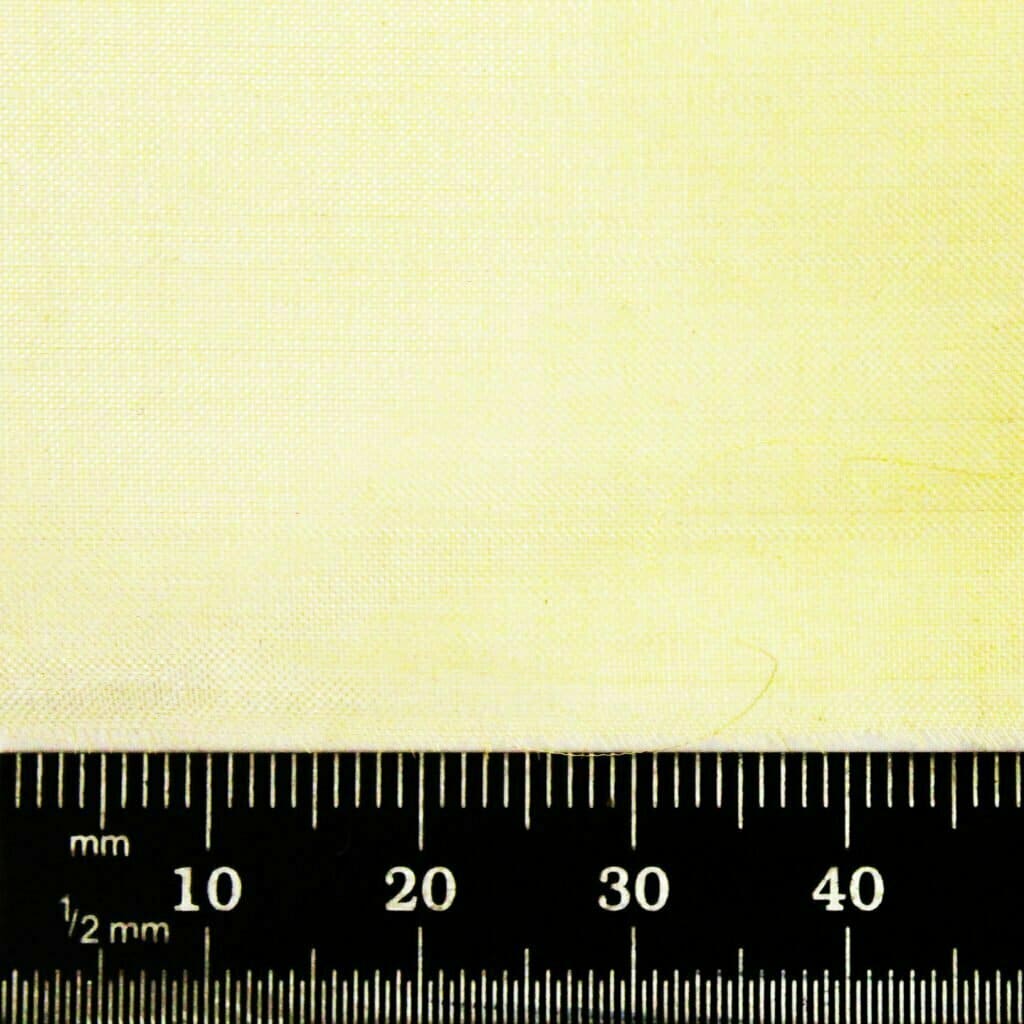

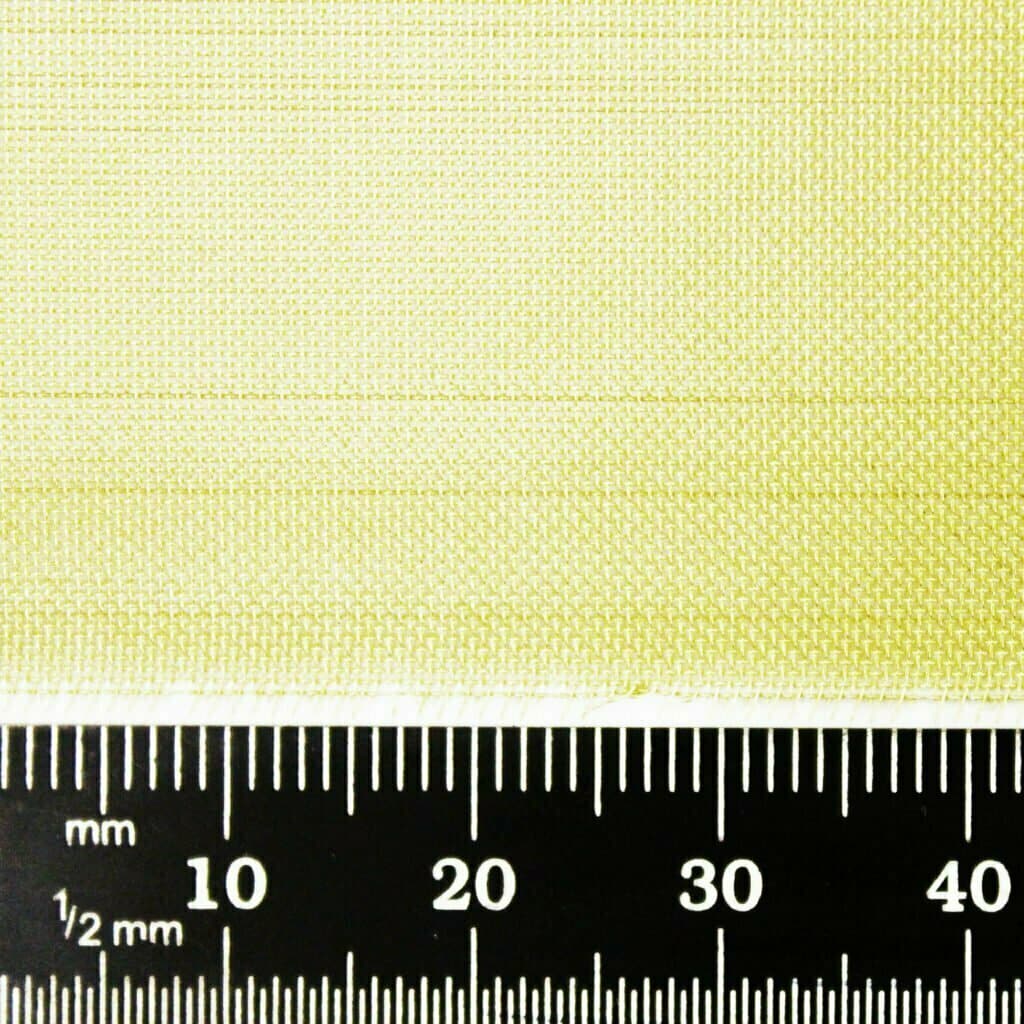

Brass woven fine mesh screen with 0.263mm holes and 0.16mm wire thickness is designed for applications requiring precise filtration and screening. Due to its excellent filtration properties, this finely woven brass mesh is ideal for industrial processes, including the separation and filtration of solids and liquids in the chemical, pharmaceutical, and food and beverage industries. Material properties, such as corrosion resistance and non-magnetic nature, further enhance its utility in sensitive environments, ensuring consistent filter performance without chemical alteration. Also, brass’ aesthetic appeal lends itself well to decorative applications that require a combination of functional and visual properties.

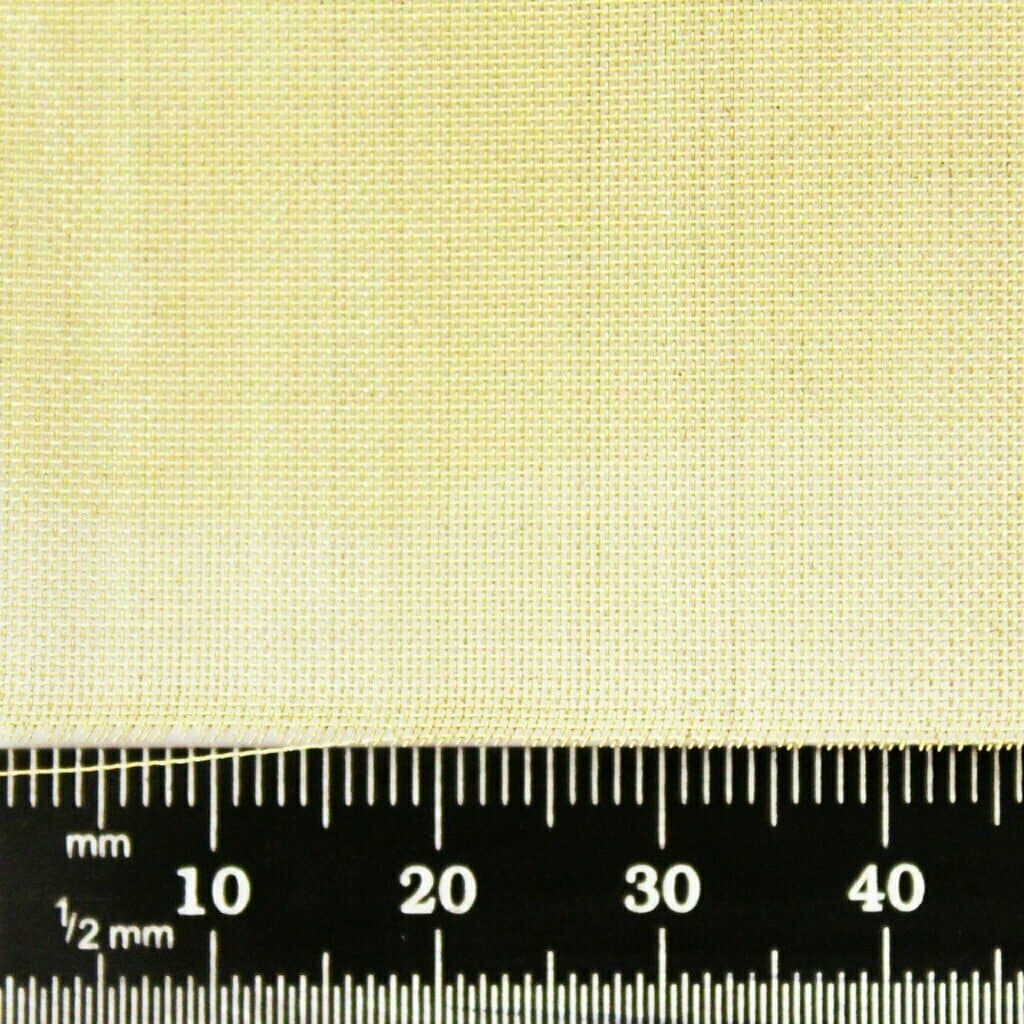

The brass woven fine wire mesh has a hole size of 0.142mm, a wire diameter of 0.11mm, and a density of 100 lines per inch (LPI) to meet the demands of high-precision filtration and separation applications. As a result of its tight weave and fine holes, the mesh is effective in specialised fields such as aerospace, laboratory research, and fine chemical manufacturing, where controlling particulate sizes and protecting against contamination are paramount. Besides offering excellent durability and corrosion resistance, the brass composition also makes the mesh suitable for artistic and decorative projects that require a finer mesh with a subtle sheen. Because of its versatility, it is an invaluable resource across a range of technical and creative fields.

Architectural Features

Brass perforated metal mesh is increasingly in demand in the architectural sector, both for its durability and aesthetic appeal. In addition to serving as a decorative element, this material also contributes to energy efficiency by serving as a functional component. It diffuses natural light, reducing heat gain while softly illuminating interiors. Balustrades, column covers, and privacy screens crafted from brass perforated mesh create standout landmarks by capturing the play of light and shadow.

Acoustic Panels

Brass perforated metal mesh is used in the fabrication of acoustic panels in acoustic engineering. Concert halls, theaters, and venues that prioritise audio clarity and quality use these panels to modulate sound. Brass mesh perforations, when backed with sound-absorbing materials, enhance sound quality by diffusing sound waves, reducing echoes, and reducing reverberation. Additionally, brass’s visual appeal adds sophistication to these spaces, blending functionality with design harmoniously.

Security and Safety

Brass perforated mesh is an ideal candidate for applications requiring security and safety. Radiator guards, vent covers, and machine guards are just a few examples of where this mesh protects from accidental contact or tampering while maintaining airflow and visibility. In such contexts, it underlines the material’s ability to provide protection without compromising the space’s aesthetics or functionality.

Art and Sculpture

Brass perforated metal mesh is frequently used by artists and sculptors due to its malleability and distinctive colour. The mesh serves as both canvas and medium, offering artists the flexibility to shape it into complex forms that play with light, shadow, and perspective. Brass mesh is used in a wide variety of art forms, from large-scale installations to intricate sculptures, to push the boundaries of creativity.

The variety of applications for brass mesh illustrates the material’s remarkable versatility, from precision filtration to elegance in architecture to acoustic design to creativity in art. Its durability, functionality, and aesthetic appeal make brass mesh a material of choice across a wide range of industries, whether it is woven or perforated.

Its versatility, as well as its inherent beauty and practical advantages, make brass mesh a valuable resource for both industrial and creative projects. Brass mesh stands out as a preferred material for enhancing the aesthetic and acoustics of environments, whether enhancing safety and functionality.

Those considering brass mesh for their projects may wish to delve deeper into its application possibilities, recognising its ability to seamlessly blend functionality and beauty.

We hope that this article has contributed to helping you to find the right material for your intended application. As always please contact us if you have any questions whatsoever.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores using brass woven wire mesh as a fuel filter.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.