Fuel filtration plays a crucial role in vehicle and machinery maintenance. This is a crucial aspect that often determines an engine’s longevity and efficiency. There are many choices available for fuel filters, but brass mesh fuel filters stand out for its remarkable benefits.

At The Mesh Company, we’ve observed a growing trend towards these filters, owing to their superior performance and adaptability. Our blog explores the nuances of brass mesh fuel filters, explaining their importance and how they are revolutionizing fuel filtration.

Let’s get into it..

The mesh fuel filter, as its name implies, is a type of filter used in fuel systems for the purpose of trapping and removing impurities from fuel before it enters the engine in order to provide a cleaner running engine.

There is no doubt that this filtration process is an essential part of preventing contaminants such as dirt, rust, and other particles from damaging the engine in any way. The importance of a mesh fuel filter cannot be understated, as it directly impacts the engine’s performance and longevity.

As these filters ensure that only clean fuel is passing through them, they play a vital role in maintaining the health and efficiency of any fuel-powered system by ensuring that only clean fuel passes through.

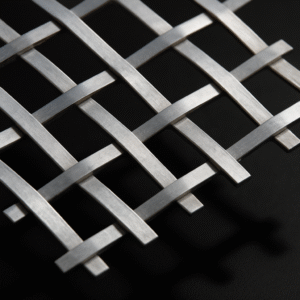

Due to its premium construction material – pure brass wire – The Mesh Company brass mesh fuel filter stands out from the rest.

Choosing brass wasn’t an accident; brass is renowned for its excellent corrosion resistance and mechanical strength, both of which are essential characteristics in harsh fuel environments. The specific design features of our brass mesh fuel filter further enhance its efficiency. The wire thickness is 0.112mm, and the hole size is 0.142mm, striking the perfect balance between strength and filtration. It is also important to note that the mesh has a 31% open area percentage. Fuel flows through the filter efficiently, preventing any significant drop in pressure, which is essential for engine performance.

Summary Points:

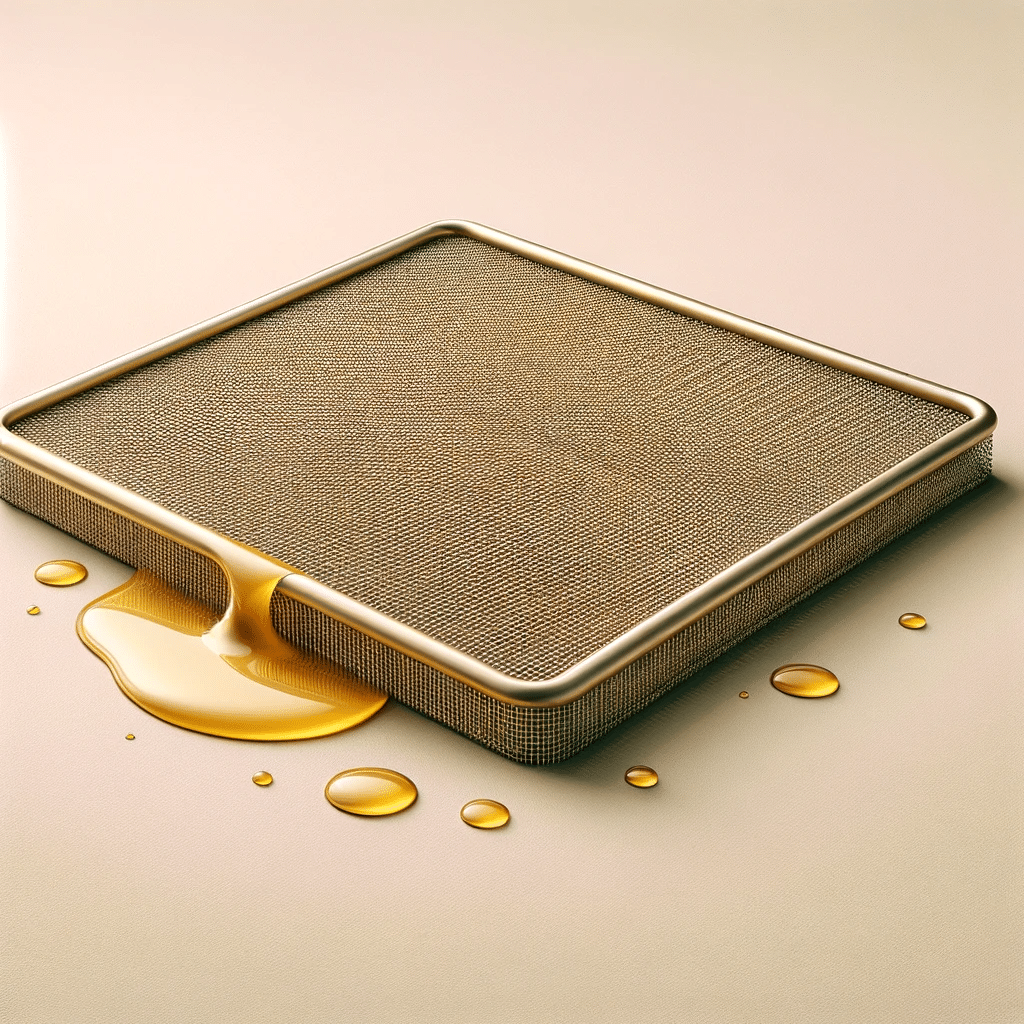

Our brass mesh fuel filter is easy to install, which is one of its key advantages. In addition to being universally compatible, it can be easily integrated into a variety of fuel systems, whether they are in automotive, industrial, marine, or agricultural machinery. A 100mm square filter allows for extensive adaptability. As a result of its malleability, users can cut and shape the filter to meet specific requirements, a feature that is particularly useful for custom or non-standard applications. Due to its flexibility, brass mesh fuel filters can be customized for any type of system, ensuring optimal engine protection and filtration.

Summary Points:

The brass mesh fuel filter from The Mesh Company is more than just a component; it’s a performance enhancer for your engine. It ensures that only clean fuel flows into the engine, thereby increasing efficiency. By weaving the brass mesh so precisely, it is able to trap even the smallest contaminants that could harm your engine. A high level of filtration ensures efficient fuel combustion, which leads to a smoother running engine, increased power output, and reduced engine wear. Furthermore, these filters maintain the engine’s health over time, thus prolonging its lifespan, by facilitating consistent fuel purity.

Summary Points:

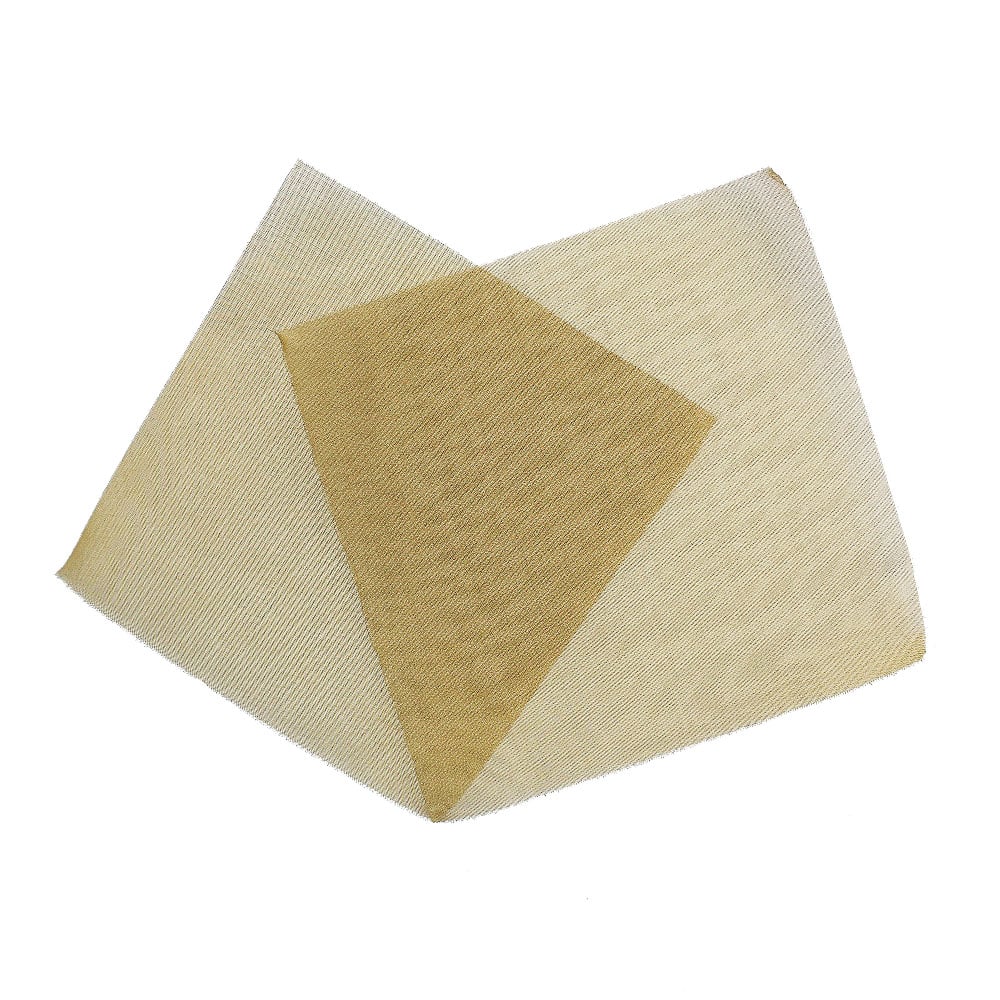

Measure and Cut: Determine the size required for your specific application. Measure and mark the 100 mesh woven wire mesh accordingly. Using appropriate tools, such as wire cutters or scissors, carefully cut the mesh. The flexibility of the brass wire mesh makes it manageable to cut, but it’s important to ensure the edges are even and straight.

Shape the Mesh: Once cut to size, the mesh needs to be shaped to fit the filter housing or cartridge. This might involve bending or curving the mesh depending on the design of the filter assembly. The malleability of the brass mesh aids in this process, allowing for shaping without damaging the weave.

Secure the Edges: To prevent fraying and to maintain the integrity of the filter, secure the edges. This can be done through soldering, crimping, or using a binding material. The method chosen will depend on the tools available and the specific requirements of the application.

Test Fit: Before final installation, place the shaped mesh into the filter housing to ensure a proper fit. It should sit snugly within the housing without gaps that could allow unfiltered fuel to pass through.

Final Assembly: Once the fit is confirmed, assemble the filter unit. This might involve placing the mesh into a cartridge or directly into the fuel line, depending on the design.

Quality Check: Conduct a final check to ensure there are no loose wires or sharp edges. Test the filter to make sure it allows adequate fuel flow while effectively trapping impurities.

This brass mesh fuel filter is characterized by exceptional durability, primarily due to its corrosion-resistant nature. In fuel filtration, where a variety of fuels and environmental conditions are common, brass, an alloy of copper and zinc, is highly resistant to rust and corrosion. Consequently, the filter maintains its integrity and functionality for a longer period of time, reducing the need for frequent replacements. Brass mesh fuel filters are reliable and cost-effective fuel system components due to their long-term durability.

Summary Points:

A brass mesh fuel filter’s efficiency is largely determined by the size and density of its holes. This filter offers a meticulous balance between fuel flow and filtration capability, with 100 holes per linear inch and 10,000 holes per square inch. A hole or aperture with a diameter of 0.142mm is small enough to trap fine impurities, yet large enough to ensure that fuel flow is not impeded. By using this design, unwanted particles are effectively removed while maintaining the necessary flow rate for the engine’s optimal performance. The precision in the mesh design is a testament to The Mesh Company’s commitment to quality and efficiency in fuel filtration.

Summary Points:

Due to its versatility, brass mesh fuel filters are not limited to a single application. This includes marine environments, where brass’ corrosion resistance is particularly beneficial, and agricultural machinery, which operates in demanding conditions.

Furthermore, it is suitable for both diesel and gasoline engines, demonstrating its versatility. Because of this versatility, the same high-quality filtration can be applied to a wide range of machinery and vehicles, ensuring engine protection and efficiency in a variety of operating conditions.

Summary Points:

This durable brass construction significantly extends its service life over standard filters due to its inherent corrosion resistance. In order to perform optimally, it requires regular maintenance. To remove any accumulated debris, routine cleaning is recommended. The ease of cleaning these filters – often just requiring a simple rinse – contributes to their user-friendliness. In general, brass mesh filters last longer between replacements than many of their competitors, depending on usage and fuel quality. In order to ensure your engine remains protected at all times, regular inspections are recommended to check for any signs of wear or damage.

Summary Points:

Using a brass mesh fuel filter contributes positively to the environment. Fuel combustion efficiency plays a pivotal role in reducing emissions. A cleaner fuel means more complete combustion, which results in fewer harmful exhaust gases being released into the atmosphere. Additionally, the durability and longevity of brass mesh filters mean less frequent replacements, thereby reducing waste. The efficiency of these filters also contributes to better fuel economy, thereby reducing overall fuel consumption. This dual benefit of environmental friendliness and improved fuel efficiency makes the brass mesh fuel filter an excellent choice for those looking to minimise their ecological footprint while enhancing their engine’s performance.

Summary Points:

A brass mesh fuel filter stands out in terms of its durability and performance when compared to paper or synthetic fuel filters. Despite the fact that paper filters are initially effective, they tend to have a shorter lifespan and can degrade rapidly, especially when they are exposed to moisture. It is true that synthetic filters are more durable than paper filters, but they still fall short of the longevity that brass mesh filters provide. As far as the efficiency of the brass mesh filtration system is concerned, it has been designed in a way to provide superior impurity removal without impacting the flow of fuel. Having this balance of efficiency and durability makes the brass mesh fuel filter a more reliable and robust choice for long-term use due to its robustness and durability.

Summary Points:

Brass mesh fuel filters are the ultimate solution for a wide variety of automotive applications since they combine efficiency, durability, and environmental friendliness in one product.

A superior filtration capability ensures cleaner fuel and better engine performance, while the robust construction of the filter ensures an extended lifespan with minimal maintenance requirements.

When you choose this filter, you’re not only improving the health and efficiency of your engine, but you’re also contributing positively to the environment at the same time. If you are considering upgrading to a brass mesh fuel filter, it is a decision that will bring you a great deal of benefit both to your machinery and the environment at the same time.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores everything that you need to know about woven filter mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions