Brass wire mesh is a niche material that is only available from a select group of producers around the world.

For The Mesh Company it is one of our most popular metal options.

This article will discuss how it is produced, what are the uses and what options are available.

We aim to fill in as many blanks as you may have about this super useful material.

Let’s go…

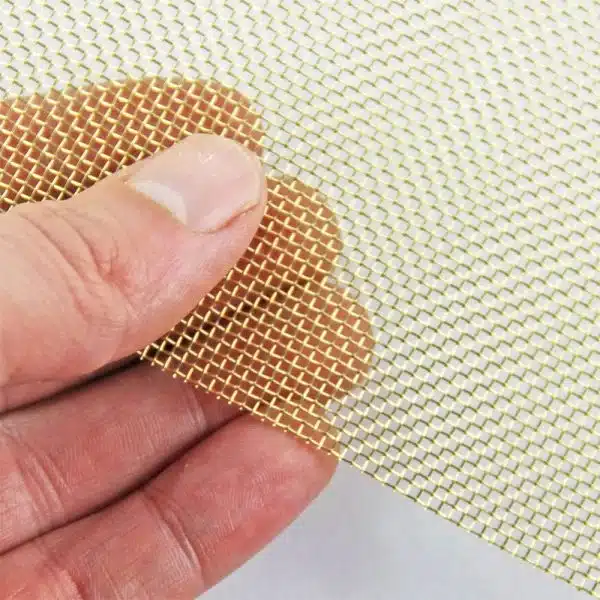

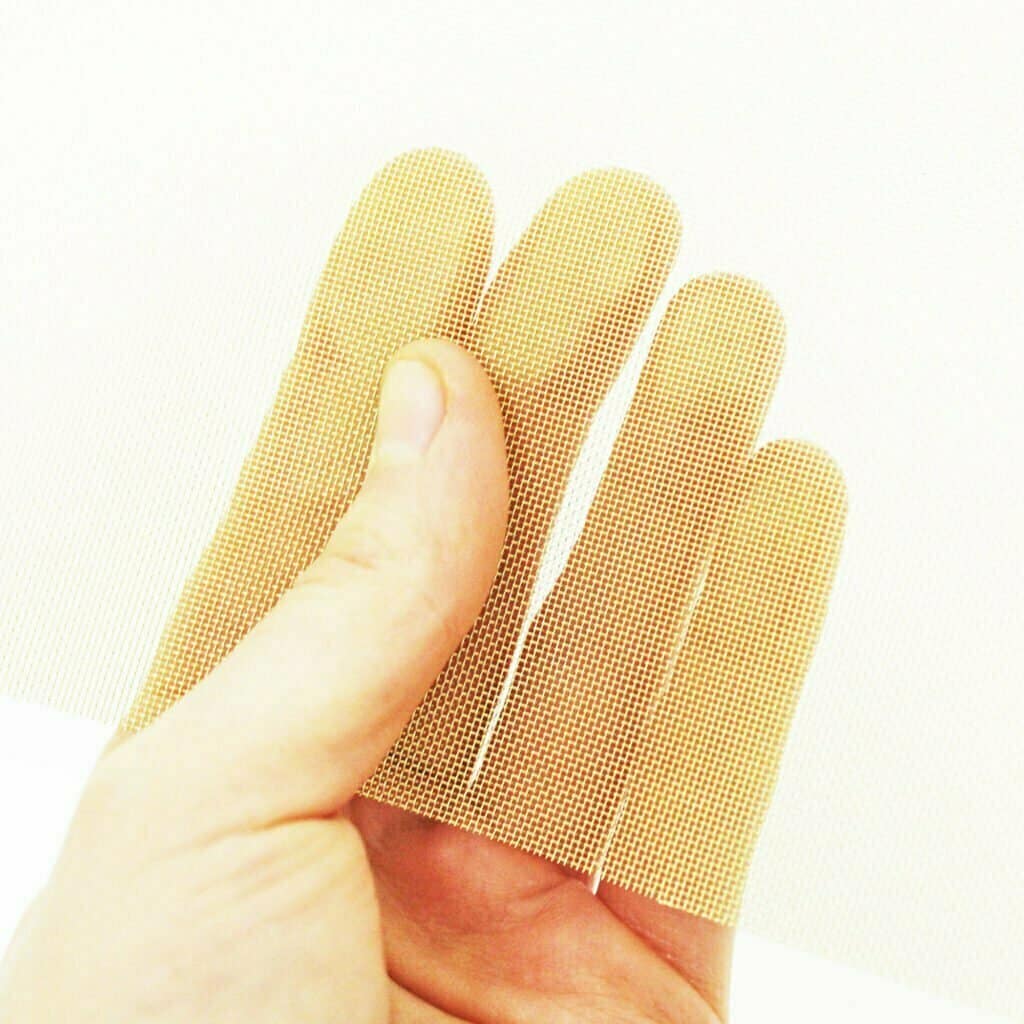

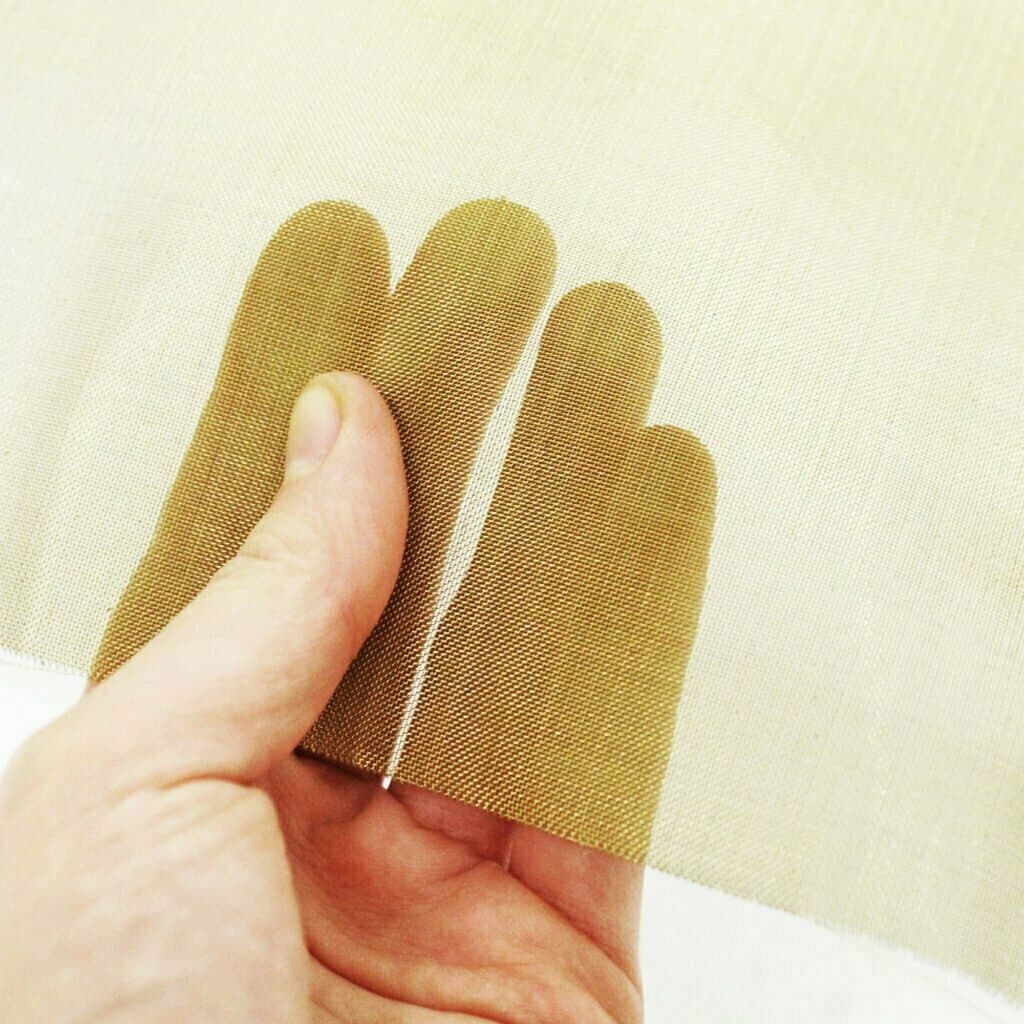

This material is made of ‘pure’ brass. Brass is not actually a natural metal and is made up of 65% copper and 35% zinc It is yellow gold in colour, which many find to be a pleasing appearance, making it ideal for decorative purposes.

As a pure brass this product will become verdigris over time. Brass is a very soft metal, so it is easy to cut and form.

Alloys have been around for thousands of years, and have helped build and create many different things. There are many different alloys out there, but two of the most important and useful are brass and stainless steel.

These are both very useful in many different things, such as construction, transportation, machine building, and plumbing.

Below is a quick breakdown of the key characteristics of this type of brass wire mesh:

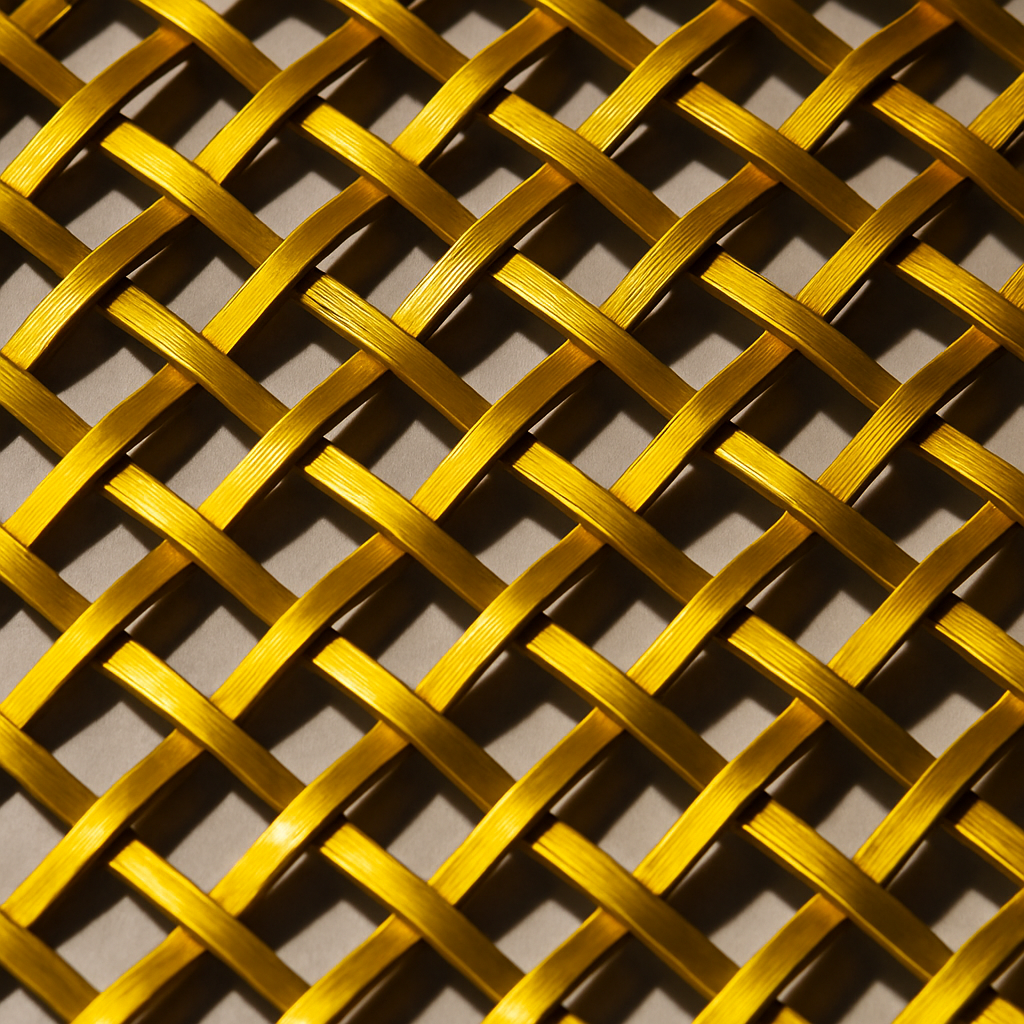

The process of weaving brass to make woven wire mesh is the same as for other metals.

Selection of raw materials: The first step in producing brass woven wire is selecting the raw materials. Brass wire is typically made from a combination of copper and zinc.

Drawing the wire: The brass wire is then drawn through a series of dies to reduce its diameter and increase its strength.

Warping: The wire is then warped onto a beam, which will be used to feed the wire into the weaving machine.

Weaving: The warping beam is mounted on a weaving machine, which uses a shuttle to interlace the wires in a series of over-and-under patterns. The specific pattern used will depend on the desired weave type. See below for an example of a well used loom making a specific stainless steel mesh pattern.

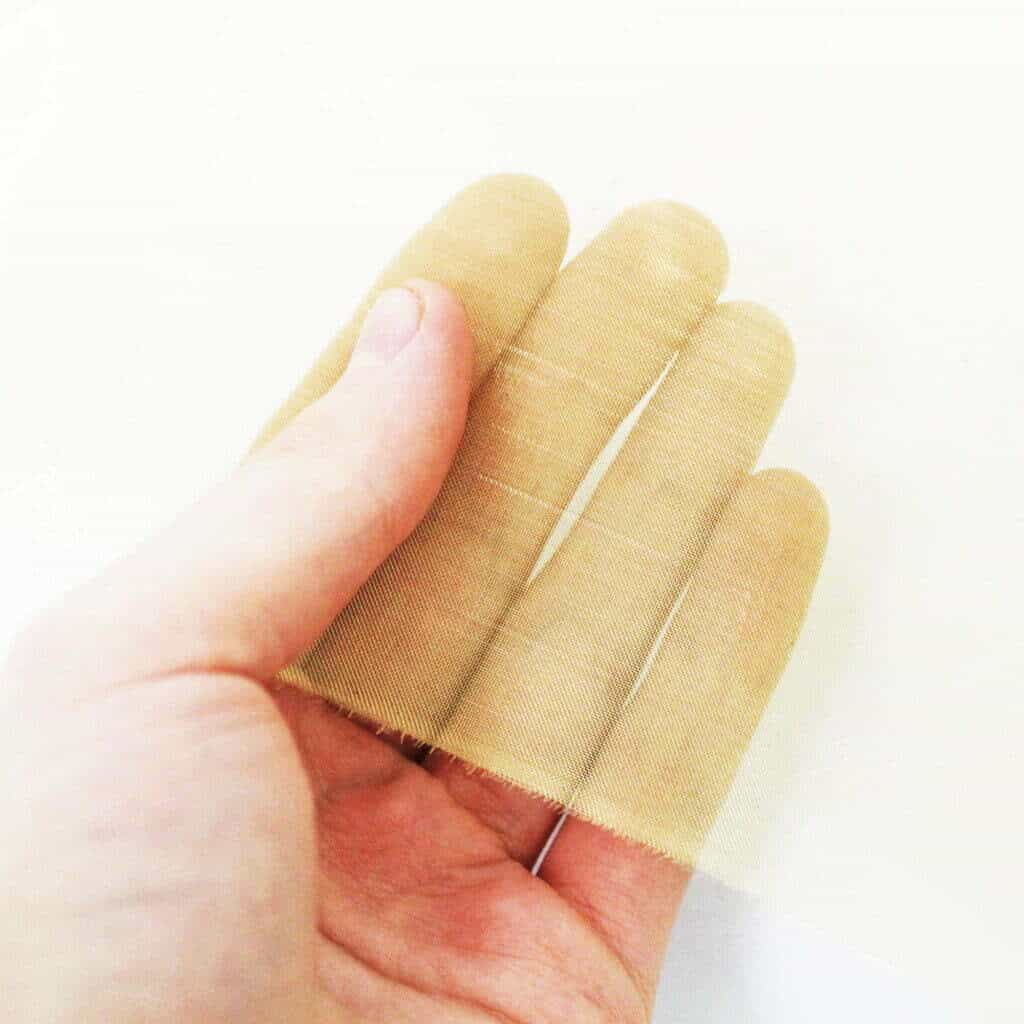

Cutting and finishing: Once the weaving process is complete, the brass woven wire is cut to the desired size and shape. It may also undergo additional finishing processes, such as polishing or coating, depending on the intended application. The standard roll of mesh is usually 30 metres x 1.2 metres, simply because it equates to 100ft x 4ft. This is deemed to be a simple measurement to use as the standard production size.

Brass wire mesh is an incredibly versatile material that offers many benefits for homeowners and businesses alike. Most importantly it’s goldy-yellowy colouring is extremely popular.

Brass wire mesh is corrosion-resistant, which means it does not easily rust or corrode when exposed to moisture or other environmental factors. It does however turn verdigris very quickly.

It is corrosion resistant because it is an alloy made from a combination of copper and zinc, which are both non-ferrous metals and do not contain iron.

In addition to its corrosion resistance, brass wire mesh also has good electrical conductivity, high strength, and excellent ductility, making it a versatile and durable material for various applications.

The strength and durability of brass mesh make it suitable for a range of applications, including security fences and structural support systems. Importantly it’s non-flammable, which makes it ideal for use near open flames or hot surfaces.

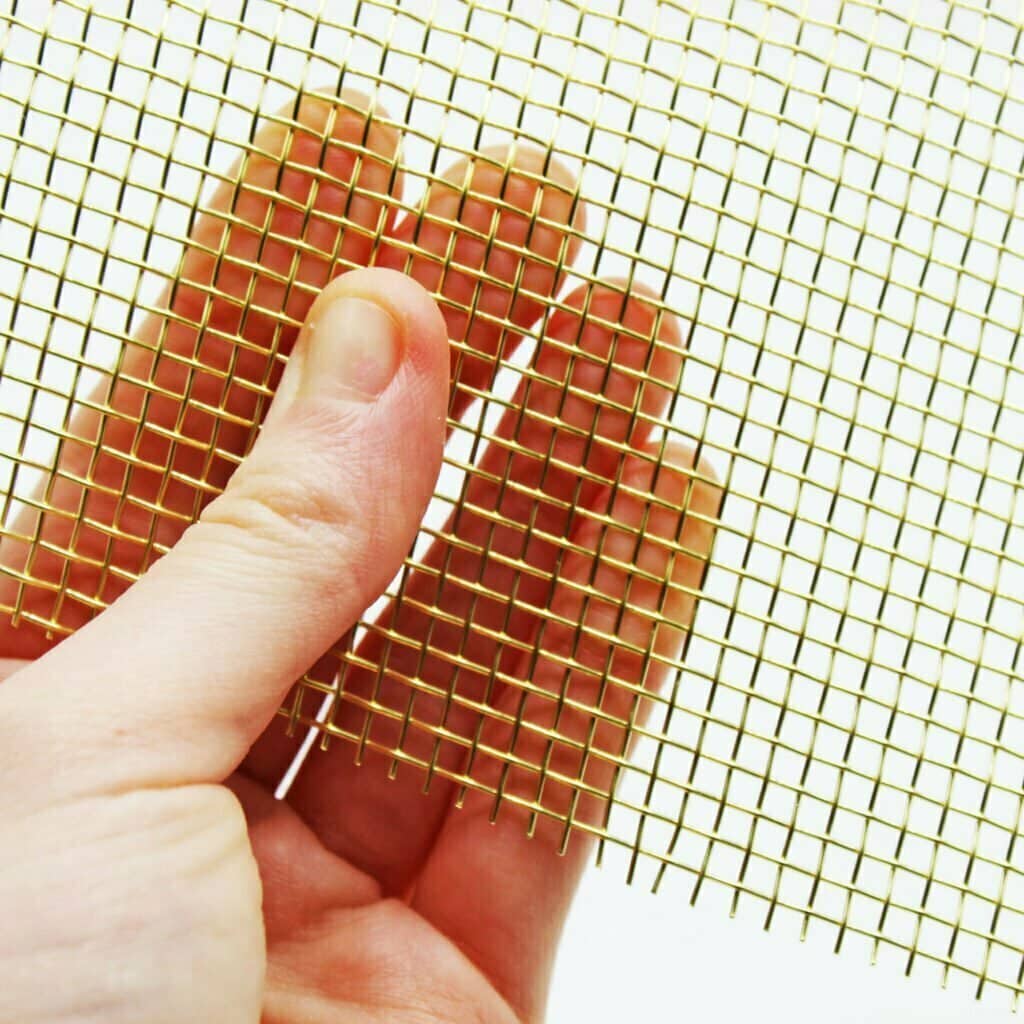

Finally, brass wire mesh is softer to cut and handle than the equivalent stainless steel option.

Verdigris is a green or bluish-green substance that forms on the surface of copper, brass, and bronze when they are exposed to the elements over time. Picture The Statue Of Liberty. Verdigris is often seen on outdoor sculptures, roofs, and other copper or brass fixtures that are exposed to the elements.

This natural patina develops as a result of the metal reacting with air, moisture, and other environmental factors.

Verdigris is typically made up of basic copper salts, including copper carbonate and copper chloride, that form on the surface of the metal.

While verdigris can be an attractive and desirable feature in certain decorative applications, it can also indicate the presence of corrosion or damage to the metal. Please be aware that, over time, verdigris can weaken the metal and cause it to deteriorate. This may necessitate professional restoration or replacement.

Brass wire mesh has many uses both indoors and out.

The Mesh Company have supplied this for all of these standard applications:

Architectural projects: Brass woven wire mesh can be used in architectural applications such as decorative screens, wall panels, and balustrades. It is also great as a radiator screen material.

Filtration: It is often used in filtration applications because of its corrosion resistance, durability, and ability to withstand high temperatures. It can be used to filter gases, liquids, and solids in a variety of industrial settings.

Insect screening: Brass woven wire mesh can be used as insect screening. But we would still recommend stainless steel, aluminium or fibreglass as better options.

Industrial applications: Our group has supplied brass woven wire mesh can be used in a variety of industrial applications, such as conveyor belts, sieves, and strainers. It is often used to protect equipment and machinery from debris and other contaminants.

Artistic applications: Brass woven wire mesh can be used in artistic applications such as sculptures, jewellery, and other decorative items. The malleability of brass allows it to be shaped and moulded into a variety of forms, making it a versatile material for artistic expression. The natural colour is striking too.

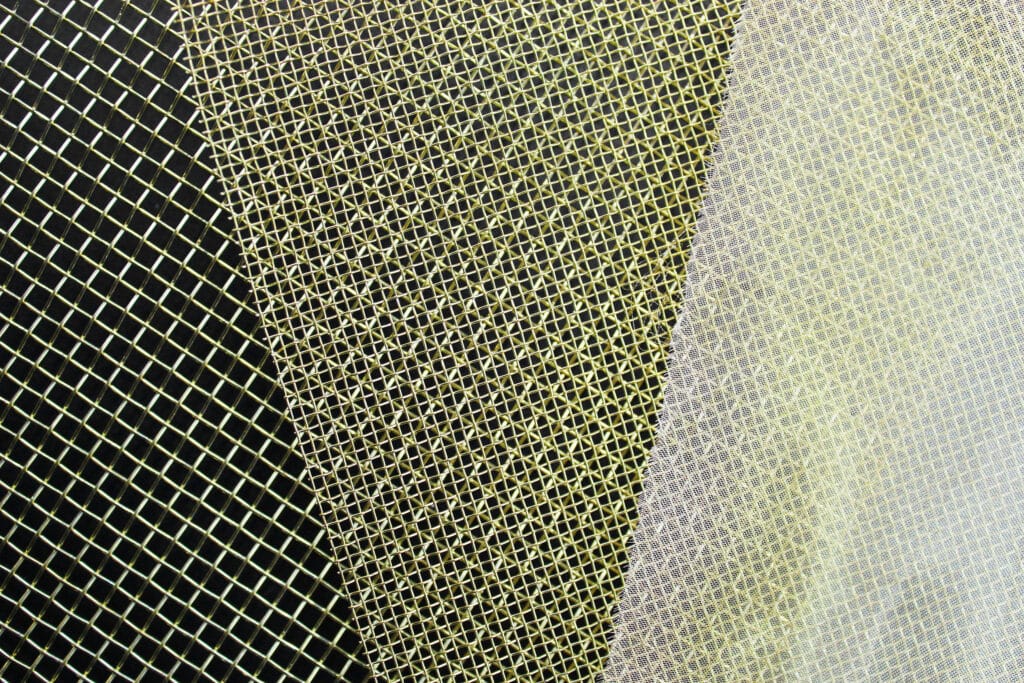

16 Holes Per Inch – 1.2mm Hole

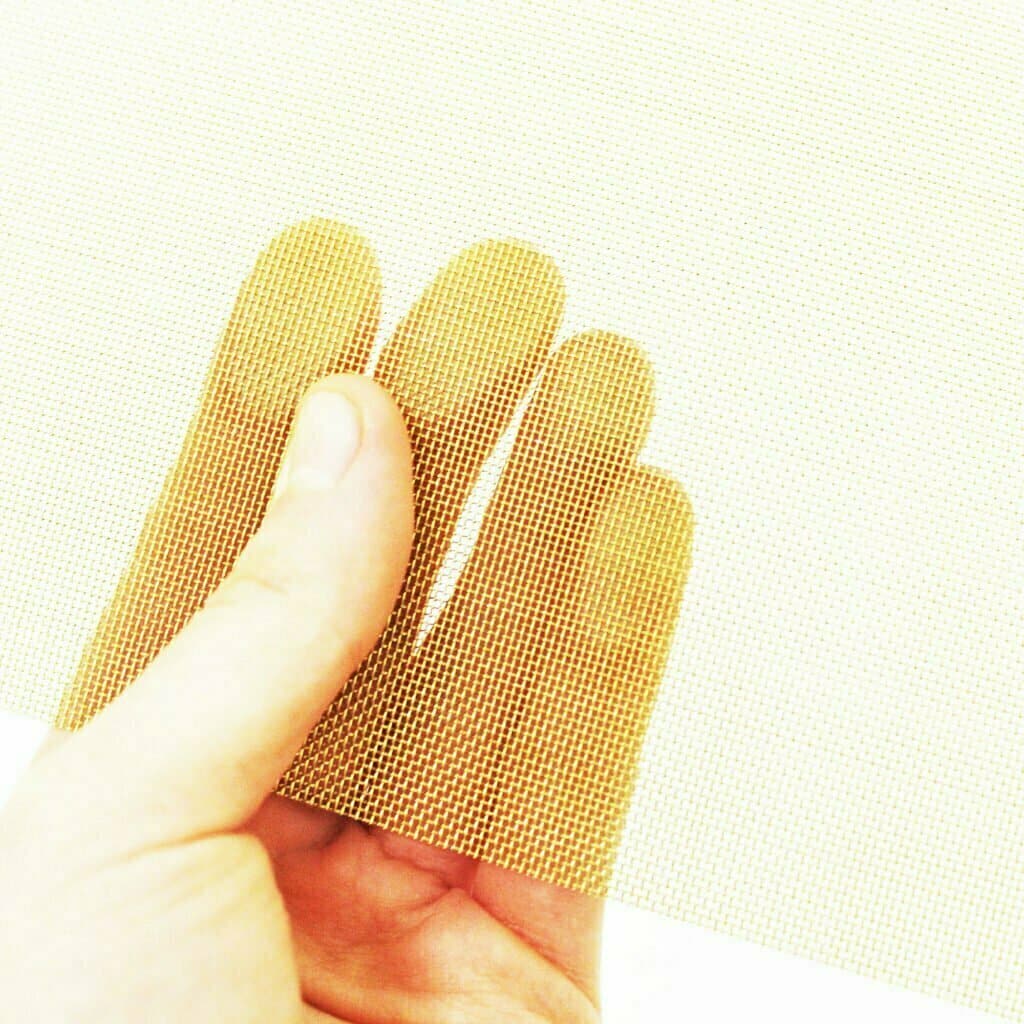

30 Holes Per Inch – 0.57mm Hole

40 Holes Per Inch – 0.42mm Hole

60 Holes Per Inch – 0.26mm Hole

80 Holes Per Inch – 0.18mm Hole

100 Holes Per Inch – 0.14mm Hole

100 Holes Per Inch – 0.2mm Hole

As you can tell, we find that brass woven wire mesh is a great material for myriad reasons.

Mainly thanks to its durability, corrosion resistance, aesthetic appeal, strength, versatility, and ease of use, it has become more and more popular over the years with our customers.

It is a reliable and high-quality material that can be used in a wide range of applications, making it a popular choice for many different types of projects.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new blogs, articles, announcements and guides every week.

Eventually we will have covered everything there is to cover regarding the world of mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions