Mesh materials come in various forms, each offering unique properties and benefits suited to specific applications. Understanding the differences and advantages of each type is crucial in making an informed decision that aligns with the project’s requirements and goals. The most common question that we get from our customers is usually “Which Mesh Can I Use For My Project?”.

It is clear that The Mesh Company specialises in providing a diverse range of mesh materials, catering to a wide spectrum of industrial and architectural needs.

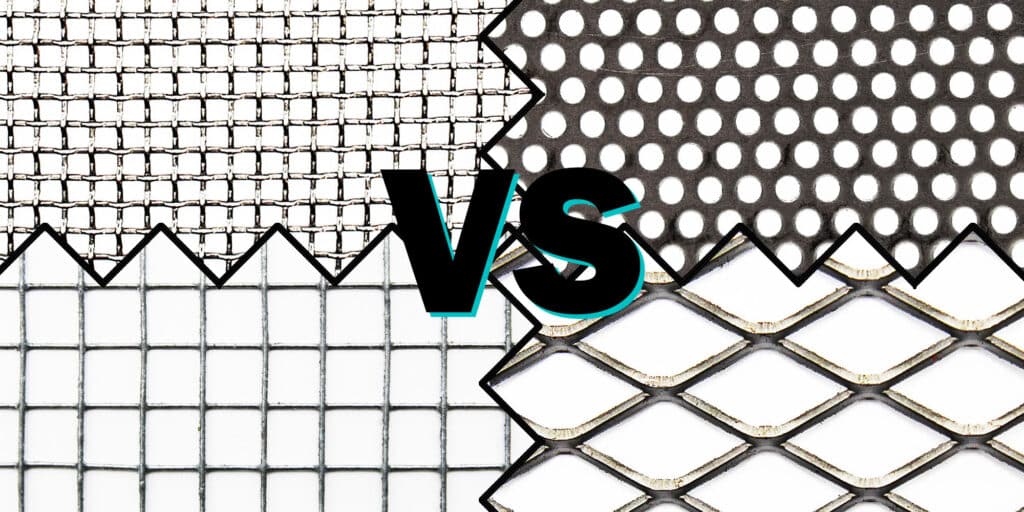

This guide focuses on four primary types of mesh:

Each type presents distinct characteristics and applications, making them suitable for various tasks, from reinforcing concrete in construction to enhancing aesthetic appeal in architectural designs.

If you have the time then hopefully this detailed article will provide the answers that you need in terms of which mesh material to select for your project…

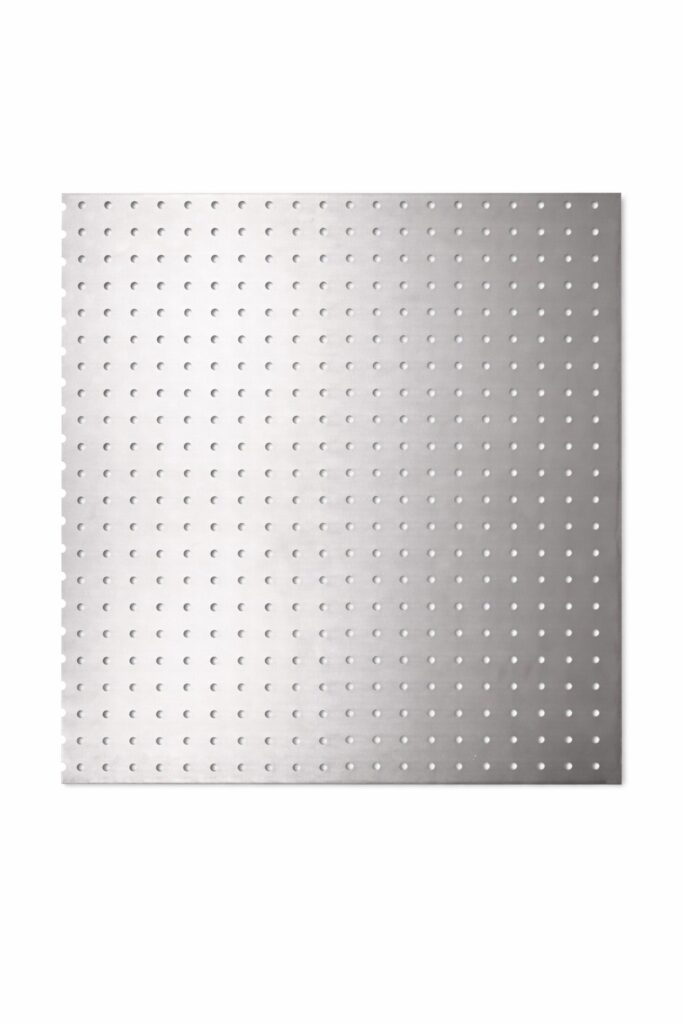

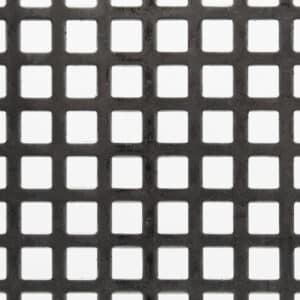

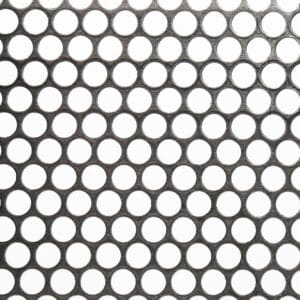

Perforated metal mesh, a highly versatile and commonly used material, is characterised by its array of precise holes or perforations. There are various shapes, sizes, and patterns of perforations that are available with this mesh type, which make it particularly adaptable to a wide variety of different applications due to its level of customisation.

It is created by punching sheet metal panel. This gives a strong product with a lot of potential hole shapes and sizes.

The Mesh Company offers an extensive selection of perforated metal mesh options, including but not limited to:

Each variety caters to different requirements, ranging from structural applications to aesthetic enhancements. Specifications such as hole size, pitch (distance between holes), and thickness determine a mesh’s suitability.

There are numerous advantages to using perforated metal mesh. With excellent ventilation capabilities, it is ideal for air flow systems, and its sound absorption qualities make it ideal for acoustic panels. As a result of its filtration properties, perforated mesh is a preferred choice for a variety of industrial processes. The aesthetic appeal of perforated metal mesh cannot be overstated, as its use in architectural designs provides both functional and decorative benefits.

Common applications of perforated metal mesh extend to various sectors. This material is used in architecture for façade cladding, decorative panels, and privacy screens, providing a blend of visual appeal and practicality. Perforated mesh panels are widely used in auditoriums, conference rooms, and other spaces where sound control is essential. Using this mesh in air ventilation systems ensures efficient air flow while filtering out unwanted particles. In both industrial and architectural settings, perforated metal mesh is versatile and useful.

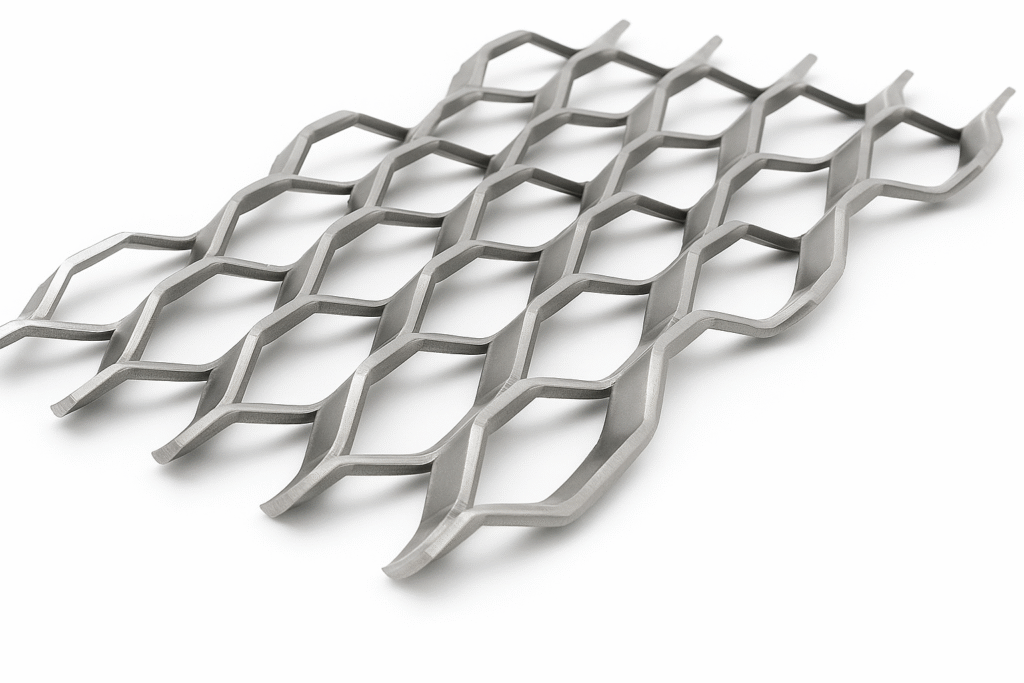

Expanded metal mesh is a distinctive and highly functional material widely used in various industrial, architectural, and security applications. It is often likened to perforated metal as it has similar characteristics for the end use.

As a result of its unique manufacturing process, this mesh stands out from other types of mesh. As a result of this process, the solid metal sheet is slit and stretched, resulting in a one-piece construction that does not unravel or fray as a result of the process. In this way, a mesh with diamond-shaped openings is created, resulting in a pattern that is both strong and lightweight thanks to its diamond-shaped openings. As a result of this production method, the material retains its structural integrity, which results in a high strength-to-weight ratio and a long service life.

The Mesh Company offers a broad spectrum of expanded metal mesh, catering to diverse needs and specifications. Some of the offerings include:

These variations differ not only in material composition – aluminium versus mild steel – but also in dimensions and thickness, allowing customisation in accordance with specific project requirements.

Corrosion-resistant and lightweight, aluminium expanded mesh is ideal for outdoor and architectural applications. In contrast, mild steel expanded mesh is prized for its strength and durability, making it suitable for more demanding structural applications.

Expanded metal mesh has a wide range of applications and advantages. Durability is one of its key strengths. Because it is made from a single piece of metal, it is extremely durable and long-lasting. The security aspect of expanded metal mesh is also important. Providing a secure environment without compromising visibility or air flow, its robustness makes it an excellent choice for protective barriers and fencing.

It also allows air, light, and visibility to pass through. In HVAC systems, machinery guards, and architectural facades, this feature is particularly useful when ventilation is required while security and visibility are not compromised. Openings in the mesh allow adequate airflow and light penetration while preventing unwanted access.

Give Me Some Examples Of Its Uses Please

In terms of use cases, expanded metal mesh finds its place in various settings:

Expanded metal mesh, due to its unique manufacturing process and versatile properties, offers a durable, secure, and functional solution. With its adaptability to a variety of applications, from industrial safety to architectural aesthetics, it satisfies the diverse needs of modern construction and design.

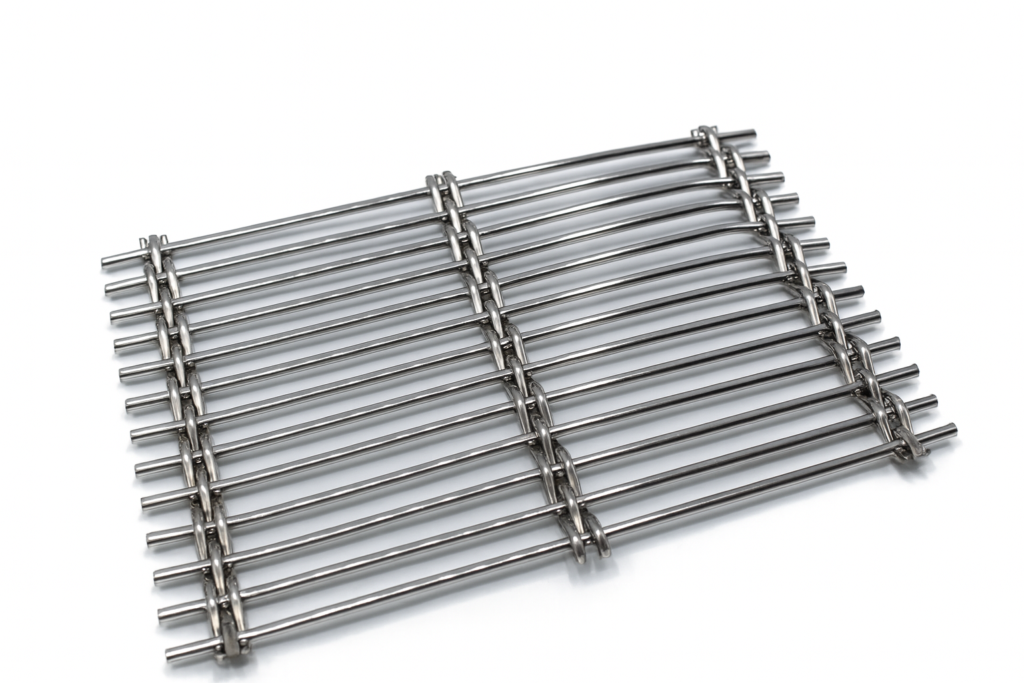

Welded wire mesh is a robust and versatile material widely used across various industries due to its exceptional strength and adaptability. Steel wires are precisely welded at their intersections to form a grid-like structure. Parallel longitudinal wires are laid out, then intersected with transverse wires. A solid bond is formed at each junction by welding the wires together, usually by electric fusion. The mesh produced by this method is exceptionally strong and rigid, with uniform openings.

The Mesh Company offers a diverse range of welded wire mesh products, catering to a wide array of applications and requirements. These products vary in several key aspects, such as:

For example, their offerings include:

These variations allow for a range of applications, from light-duty tasks to heavy-duty industrial uses.

One of the most significant properties of welded wire mesh is its strength and durability. At each intersection, welding creates a strong bond that maintains the mesh’s shape and integrity, even under stress or when cut. Due to its strength, it is an ideal choice for applications requiring robust structural support.

Material selection plays a crucial role in corrosion resistance. For example, galvanized steel offers excellent corrosion and rust resistance, making it suitable for outdoor or humid environments. Stainless steel mesh can also be used in environments with higher corrosion resistance, such as marine or acidic environments. The PVC coating further enhances the durability and lifespan of welded wire mesh.

What Would I Use Welded Mesh For?

Welded wire mesh has a wide range of applications, some of which include:

With its strength, versatility, and durability, welded wire mesh is an indispensable material. With its ability to provide structural support and aesthetic enhancement, it stands as a testament to modern materials’ innovation and adaptability.

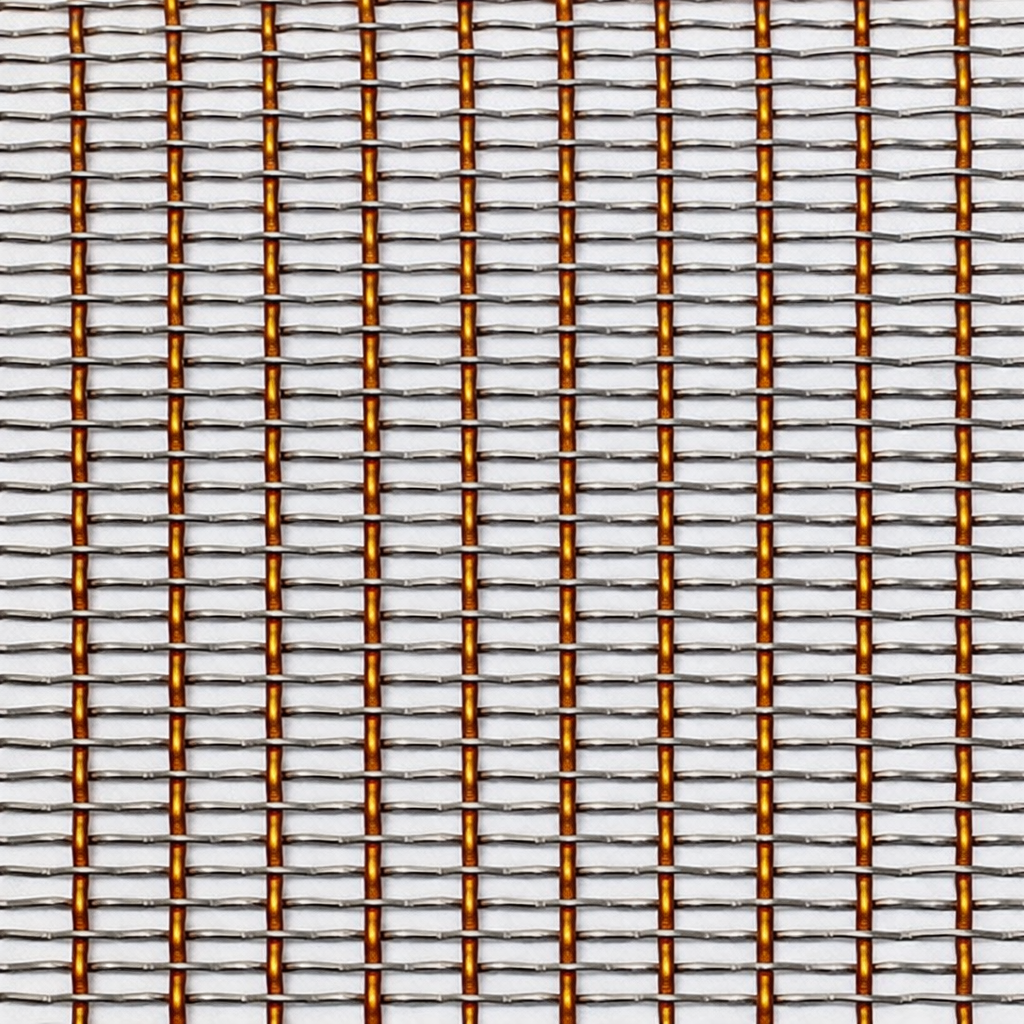

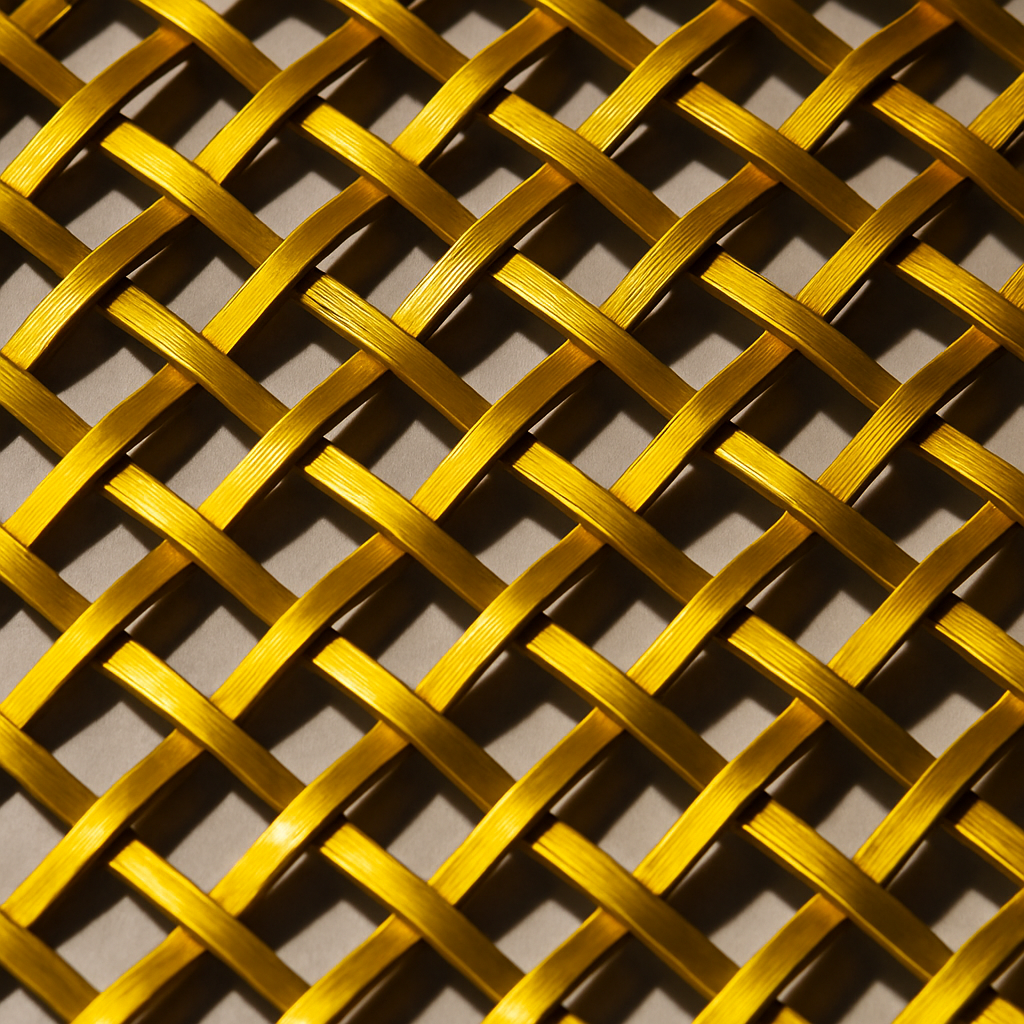

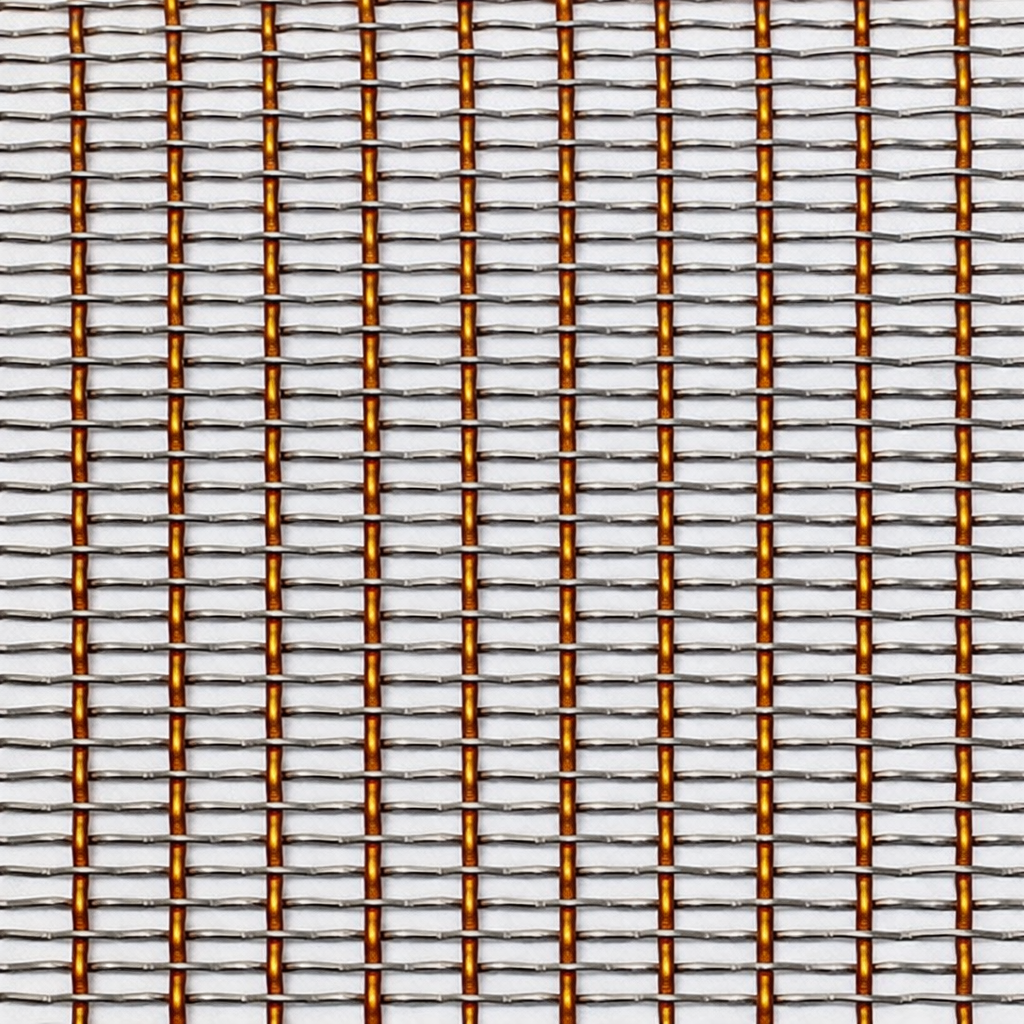

Known for its precision weaving process and wide range of applications, woven wire mesh is a highly intricate and versatile material. Weaving metal wires together in a similar manner to weaving cloth results in a mesh with uniform openings and a flat surface. A stable and consistent pattern is formed by interlacing longitudinal (warp) and transverse (weft) wires at right angles. This process allows for a variety of weave patterns, including plain weave, twill weave, and Dutch weave, each offering distinct characteristics.

Mesh Company offers a wide selection of woven wire mesh in a variety of materials, wire diameters, and weave patterns. From micron-sized meshes to coarser varieties, they cater to a wide range of needs. Their range includes the following examples:

Depending on wire diameter, hole size, and number of lines per inch, these varieties can be customised to suit specific project needs. Due to their strength, flexibility, and corrosion resistance, stainless steel is commonly used for woven wire mesh.

One of the most valuable characteristics of woven wire mesh is its precision and versatility. Due to its tight tolerances and specific mesh counts, it is ideal for applications that require precise filtration and separation. With its variety of weave patterns, it can also be tailored for specific strength, permeability, and aesthetic needs.

What Can I Use Woven Mesh For?

The applications of woven wire mesh are diverse and span across various industries:

In summary, woven wire mesh stands out for its precision and versatility.

Its ability to be tailored to specific requirements makes it an invaluable material for industrial processes and architectural designs alike. Despite its practical and creative applications, woven wire mesh remains a preferred choice due to its combination of functional and aesthetic qualities.

Choosing the Right Mesh Material: Summary and Guidance

Selecting the right mesh material is a crucial decision that can significantly impact the outcome of various projects. Every mesh material offered by The Mesh Company has its own unique characteristics, advantages, and applications. Making an informed decision will be easier if you understand these key points.

Summary of Key Points and Characteristics:

Perforated Metal Mesh:

Expanded Metal Mesh:

Welded Wire Mesh:

Woven Wire Mesh:

Guidance for Choosing the Right Mesh Material:

The selection of the appropriate mesh material is a key factor in the success of any project. In addition to meeting immediate functional requirements, the material must also meet long-term durability and maintenance requirements.

By carefully considering the unique properties and advantages of each mesh type, one can ensure that the chosen material not only meets the current needs but also stands the test of time, contributing positively to the overall success and sustainability of the project.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.