Electromagnetic interference (EMI) and radiofrequency interference (RFI) are two critical problems in the technology industry, and even in the home. Both can lead to device malfunction or complete shutdown.

Therefore, it is imperative to employ EMI and RFI shielding techniques to prevent signal distortion and electromagnetic radiation that causes EMI and RFI.

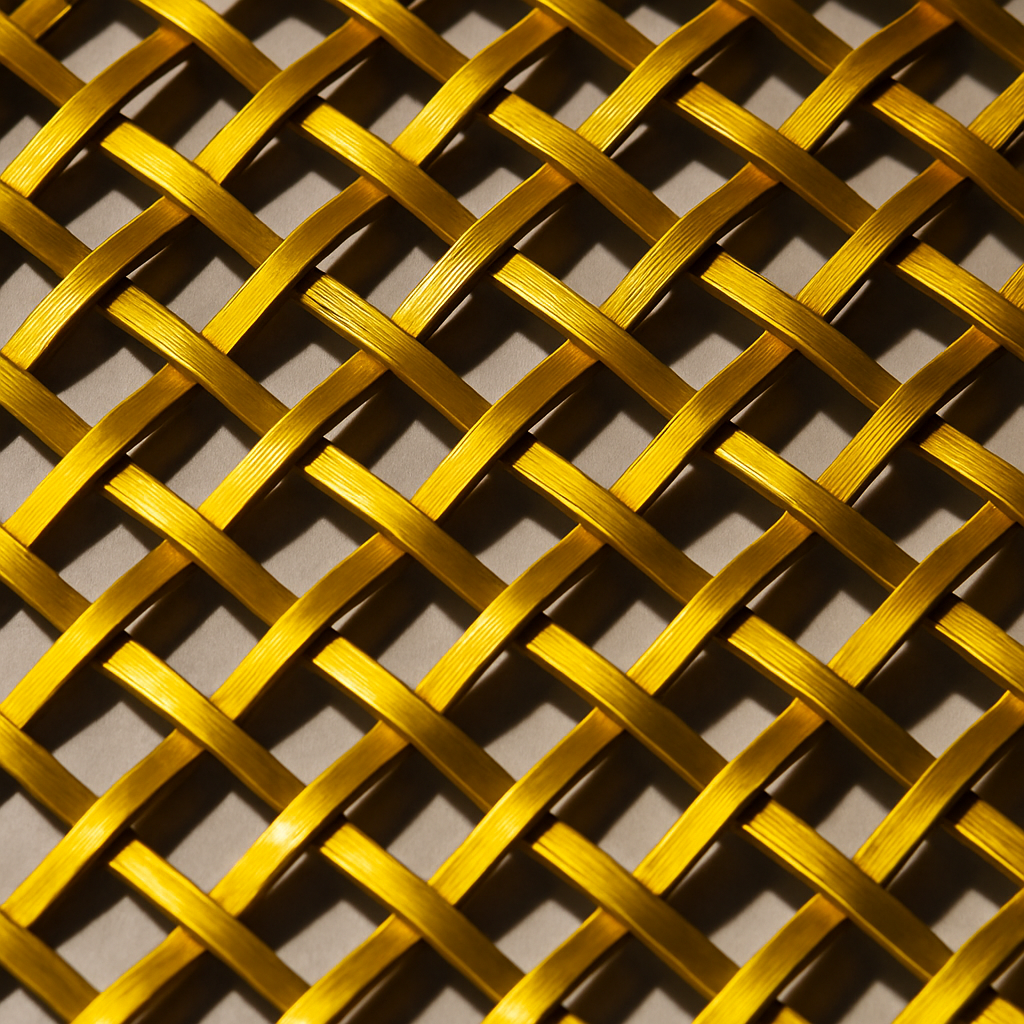

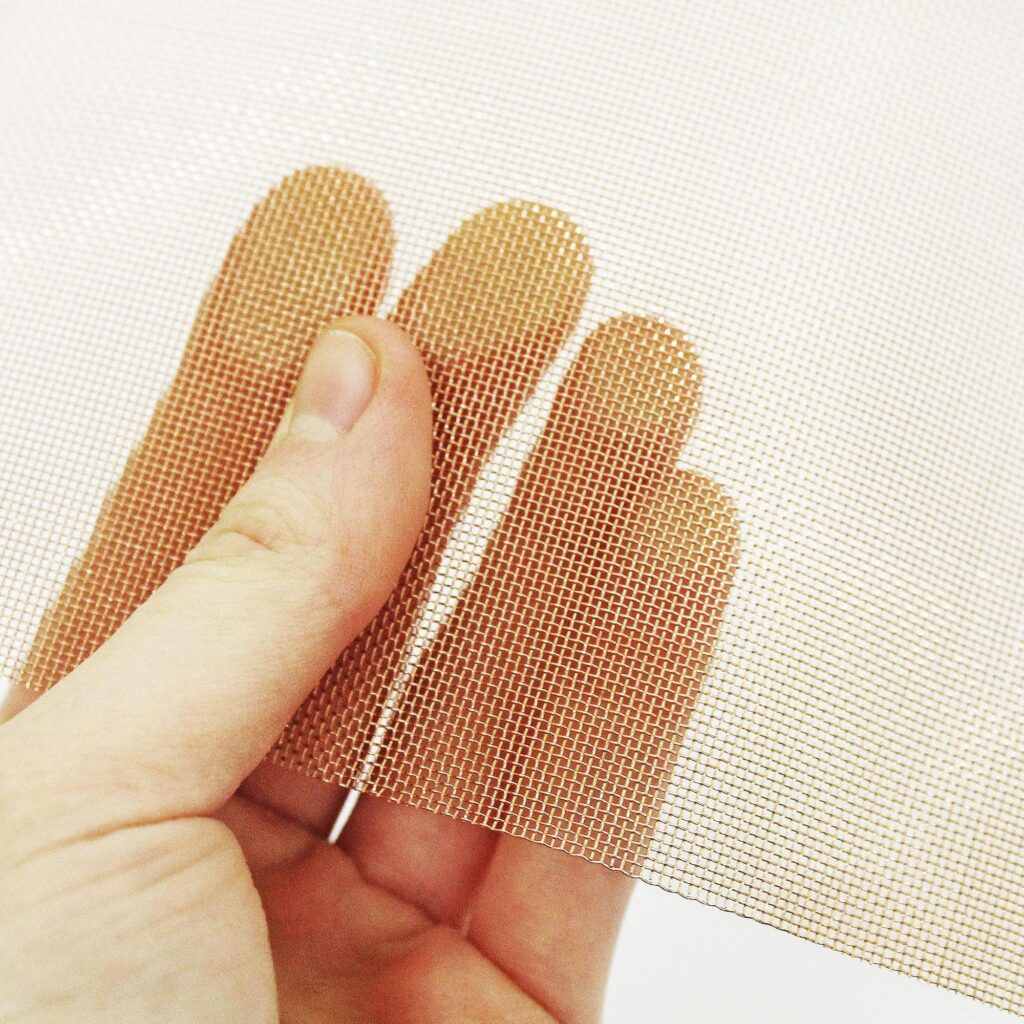

Among various EMI and RFI shielding materials, copper wire mesh is among the most trusted and efficient. The Mesh Company have seen a sharp rise in enquiries for materials for this purpose in recent years.

This article will illustrate the benefits of using copper wire mesh for EMI and RFI shielding.

Let’s get into it……

Our customers find that the main benefits of using wire mesh for RFI & EMI applications are:

Copper has superior electrical conductivity compared to other metals, making it an efficient EMI and RFI shielding material. We have tested many metals for suitability, and copper comes out on top always.

The high electrical conductivity of copper enables the metal to conduct and ground electromagnetic waves effectively, preventing them from passing through electrical devices and causing EMI and RFI.

Moreover, copper wire mesh offers high resistance to thermal and electrical shocks, making it a reliable shielding material.

Copper wire mesh can block RFI (radio frequency interference) by reflecting, absorbing, or attenuating electromagnetic waves.

When electromagnetic waves encounter copper wire mesh, they can be reflected or absorbed by the mesh depending on the frequency of the wave and the size of the openings in the mesh.

At high frequencies, electromagnetic waves tend to be reflected by the copper wire mesh because the wavelength is similar to the size of the openings in the mesh. The copper wire mesh acts as a barrier that reflects the waves back, preventing them from passing through.

Conversely, at lower frequencies, electromagnetic waves can be absorbed by the copper wire mesh. When the wavelength of the wave is larger than the size of the openings in the mesh, the waves can pass through the openings and then interact with the conductive copper wires. This interaction can cause the waves to lose energy, effectively attenuating or reducing their strength.

Simple.

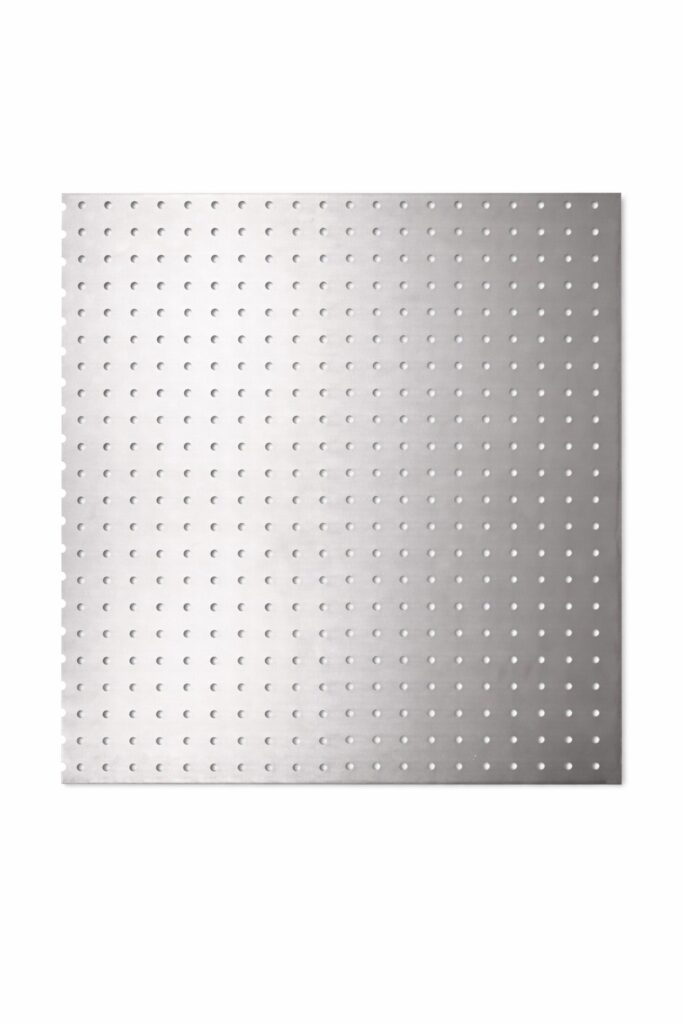

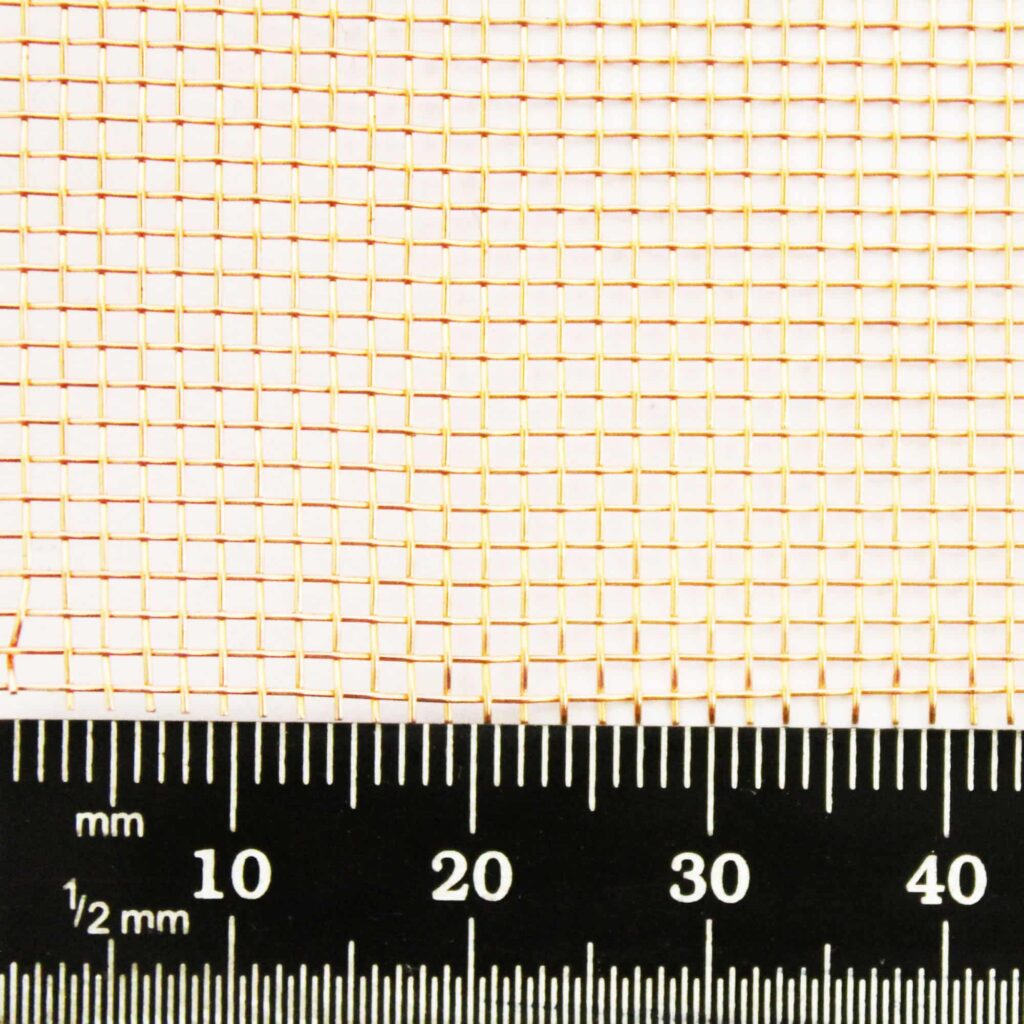

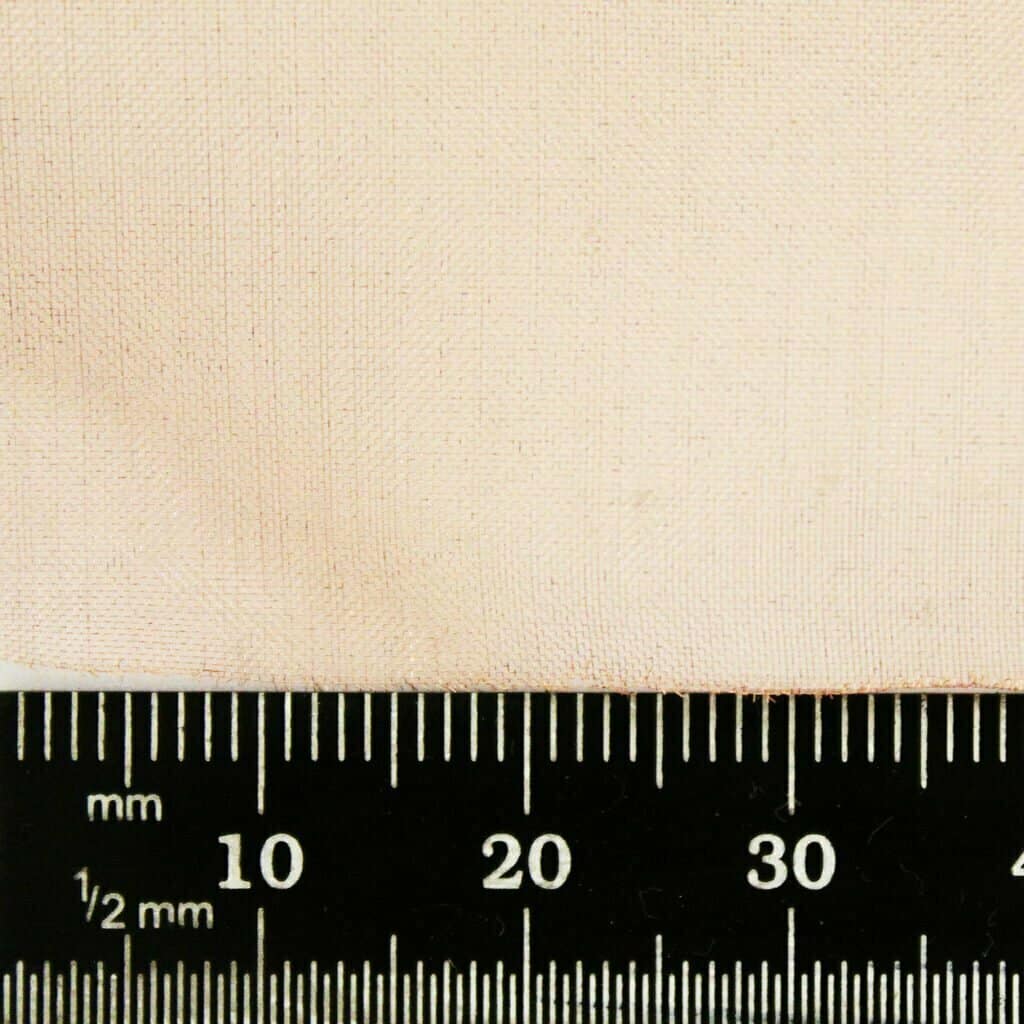

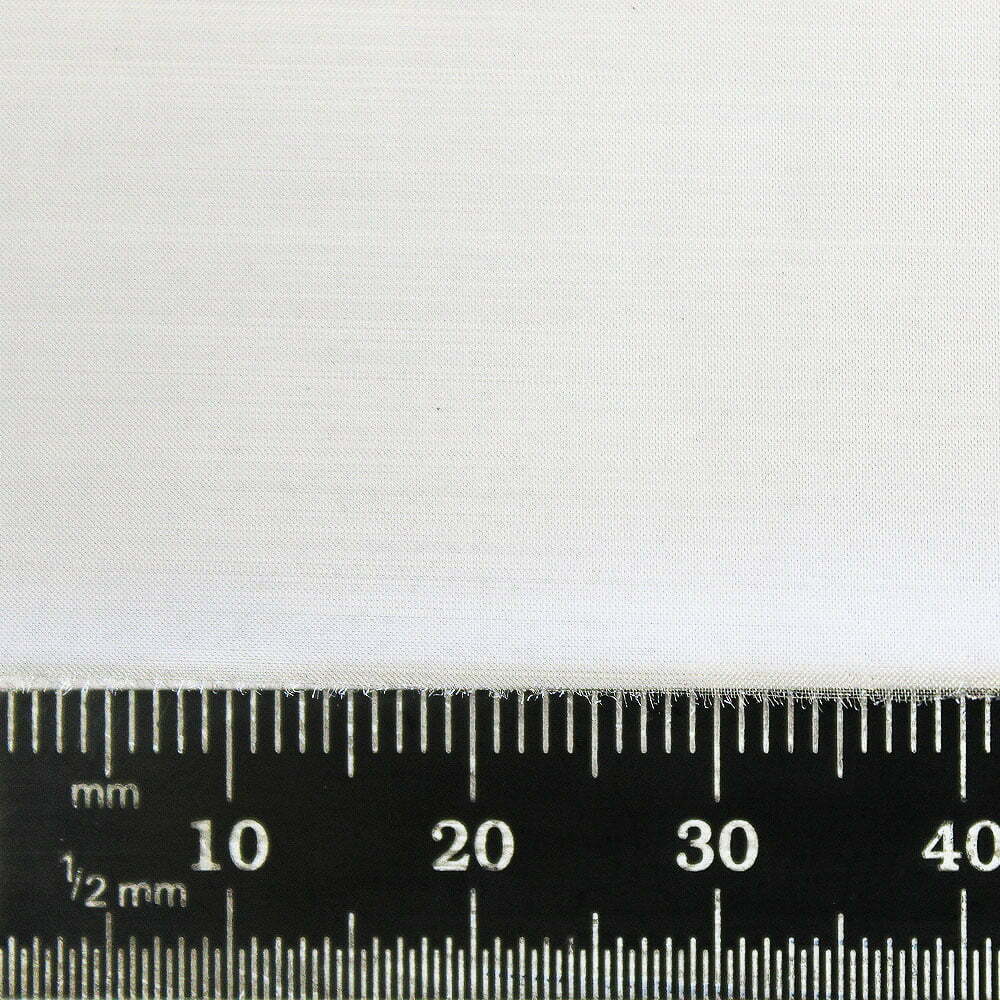

16 Holes Per Inch – 1.23mm Hole

30 Holes Per Inch – 0.57mm Hole

60 Holes Per Inch – 0.26mm Hole

100 Holes Per Inch – 0.2mm Hole

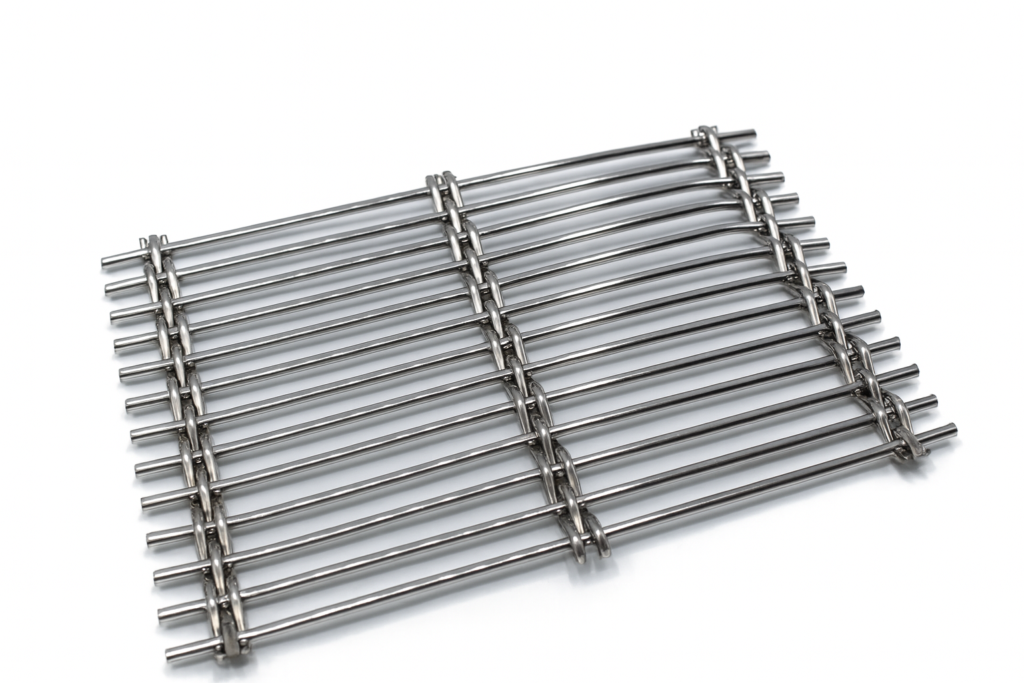

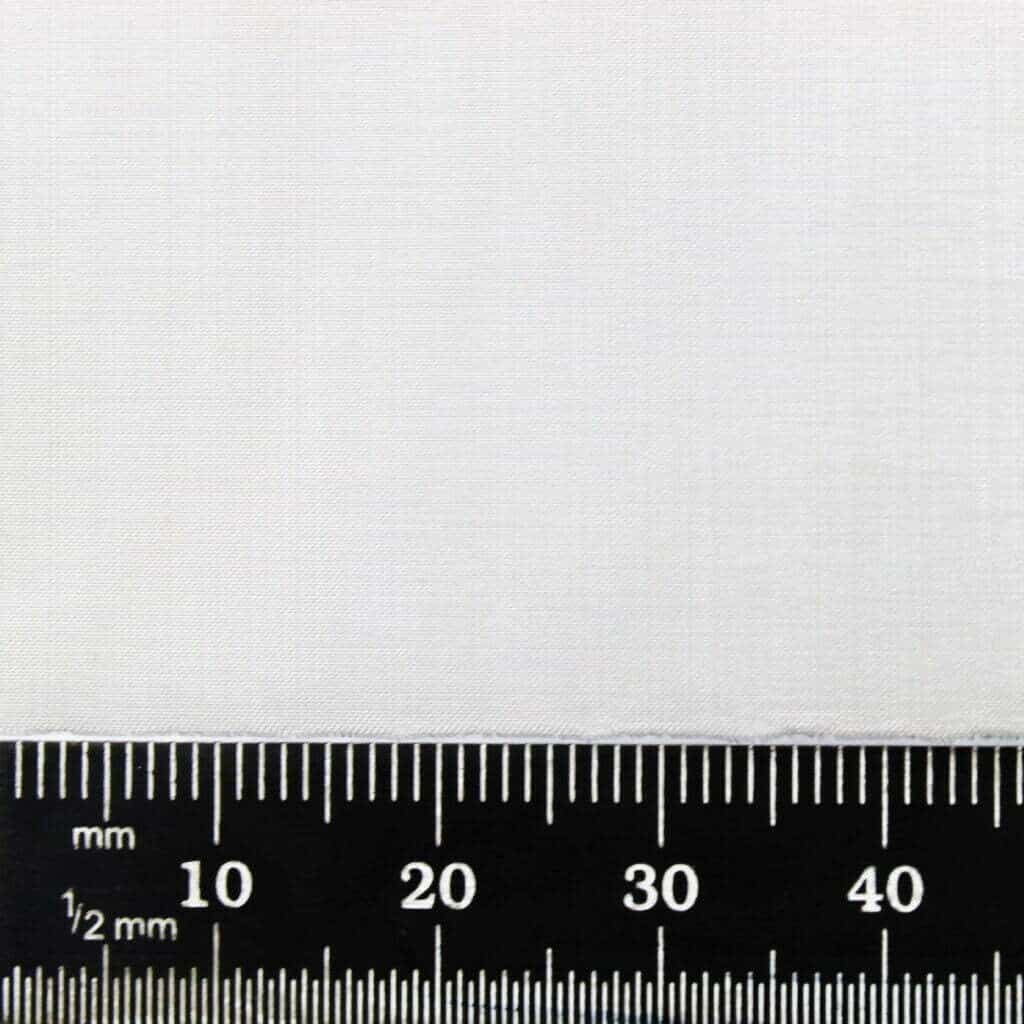

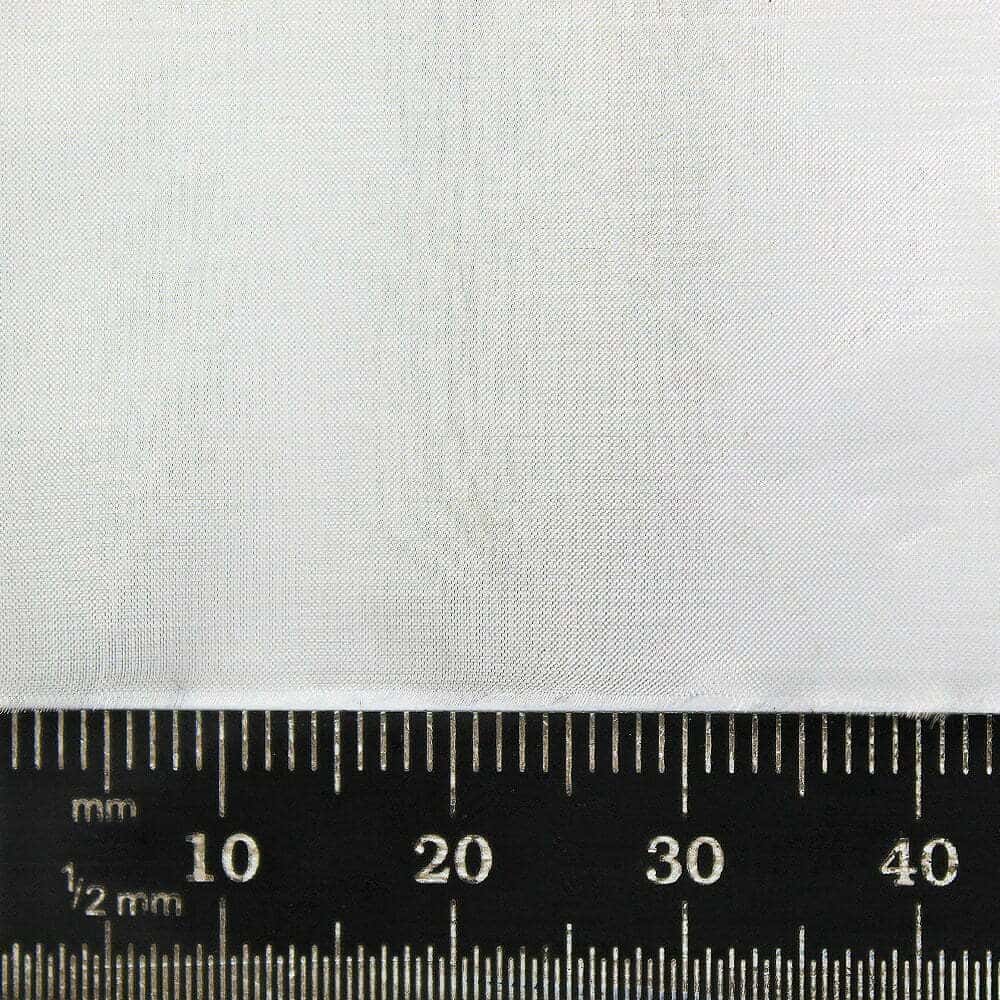

Yes, stainless steel wire mesh can be an effective material for EMI and RFI shielding. Like copper wire mesh, stainless steel wire mesh is highly conductive and can block or absorb electromagnetic radiation.

Moreover, stainless steel wire mesh has a high nickel content, which provides excellent corrosion resistance and durability.

It is also more resistant to oxidation compared to copper, which can make it a more suitable option for harsh or corrosive environments. The options below are 304 grade, but 316 grade would also work and would in fact be preferable in marine environments.

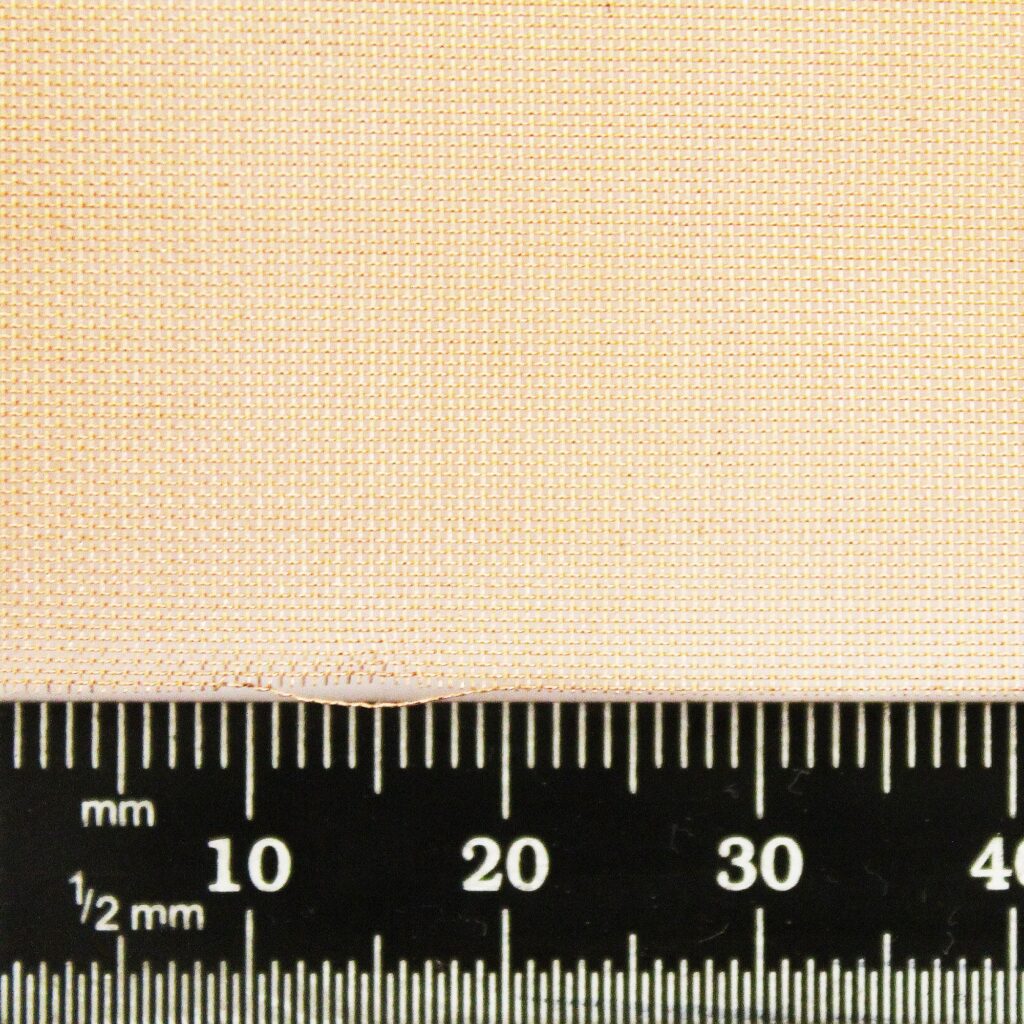

Stainless steel woven wire mesh is best as a fine mesh with small openings that can block or absorb high-frequency electromagnetic waves. The wire mesh can be installed as a shield or barrier around electronic devices, circuits, or other sensitive equipment to prevent interference from external electromagnetic sources.

A full roll of woven mesh is typically 30 metres x 1.2 metres. Any size within that is possible. So we have you covered.

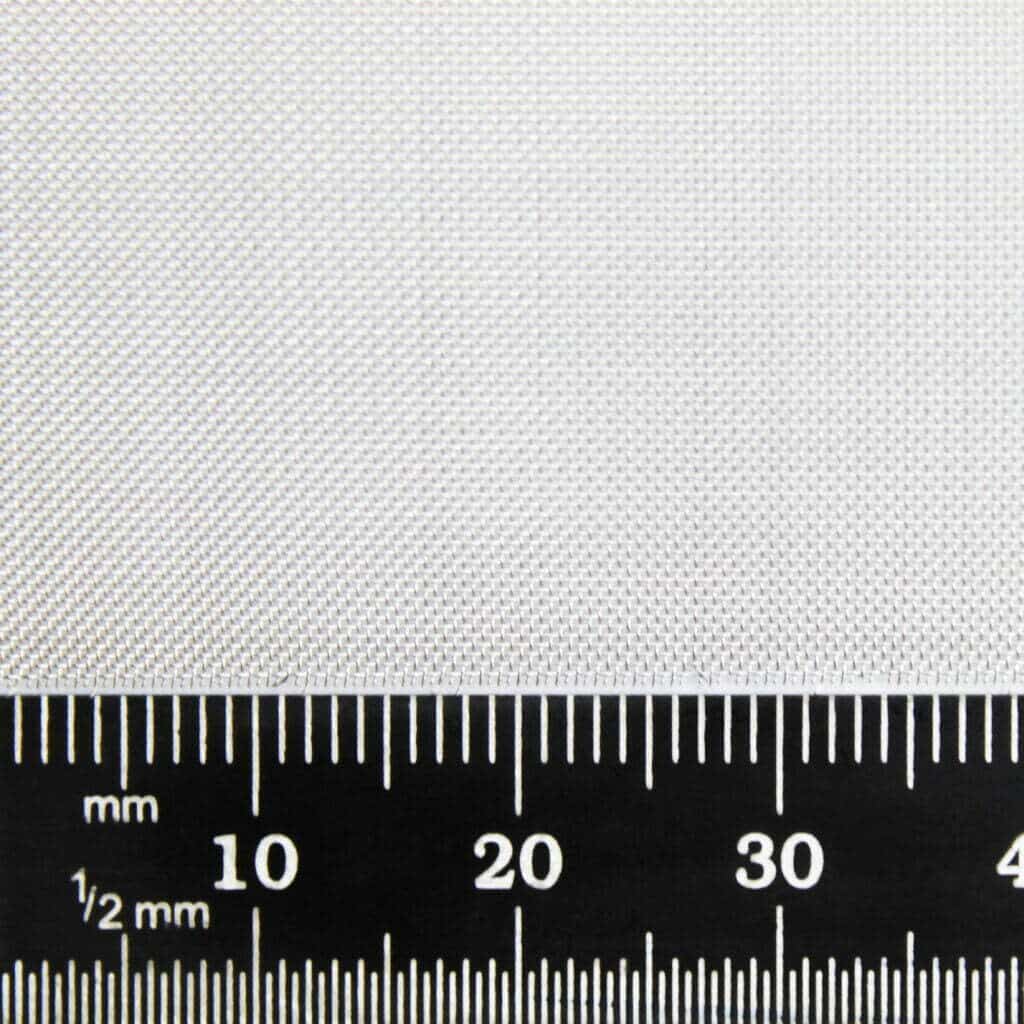

We have around 100 stainless steel options in stock. These are some of the most popular options that we have available that would provide a solution for RFI projects:

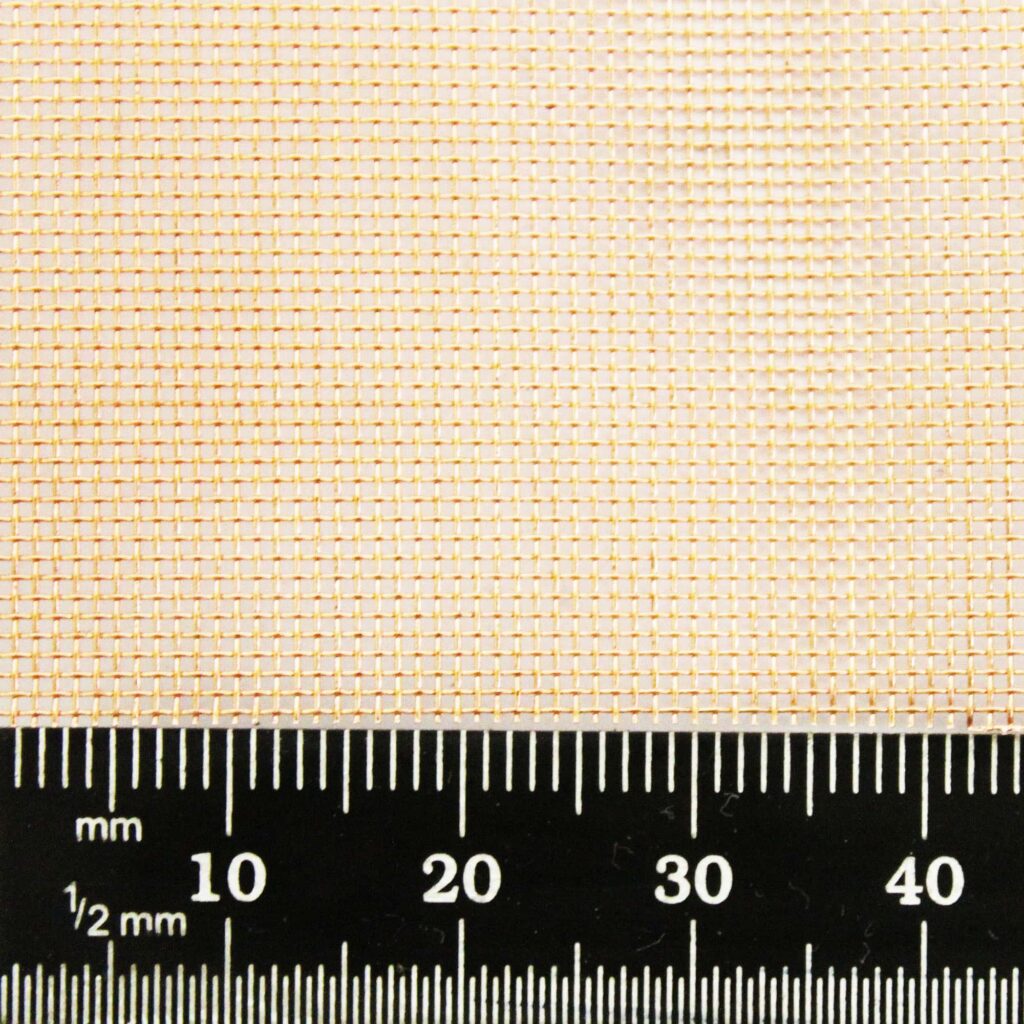

70 Holes Per Inch – 0.22mm Hole

145 Holes Per Inch – 0.12mm Hole

180 Holes Per Inch – 0.09mm Hole

200 Holes Per Inch – 0.077mm Hole

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores myriad benefits of copper wire mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.