£8.99 – £399.99 inc VAT

This website is secured:

✔ The UK’s Largest Range Of Mesh Products

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Sizes & Larger Sheets Available

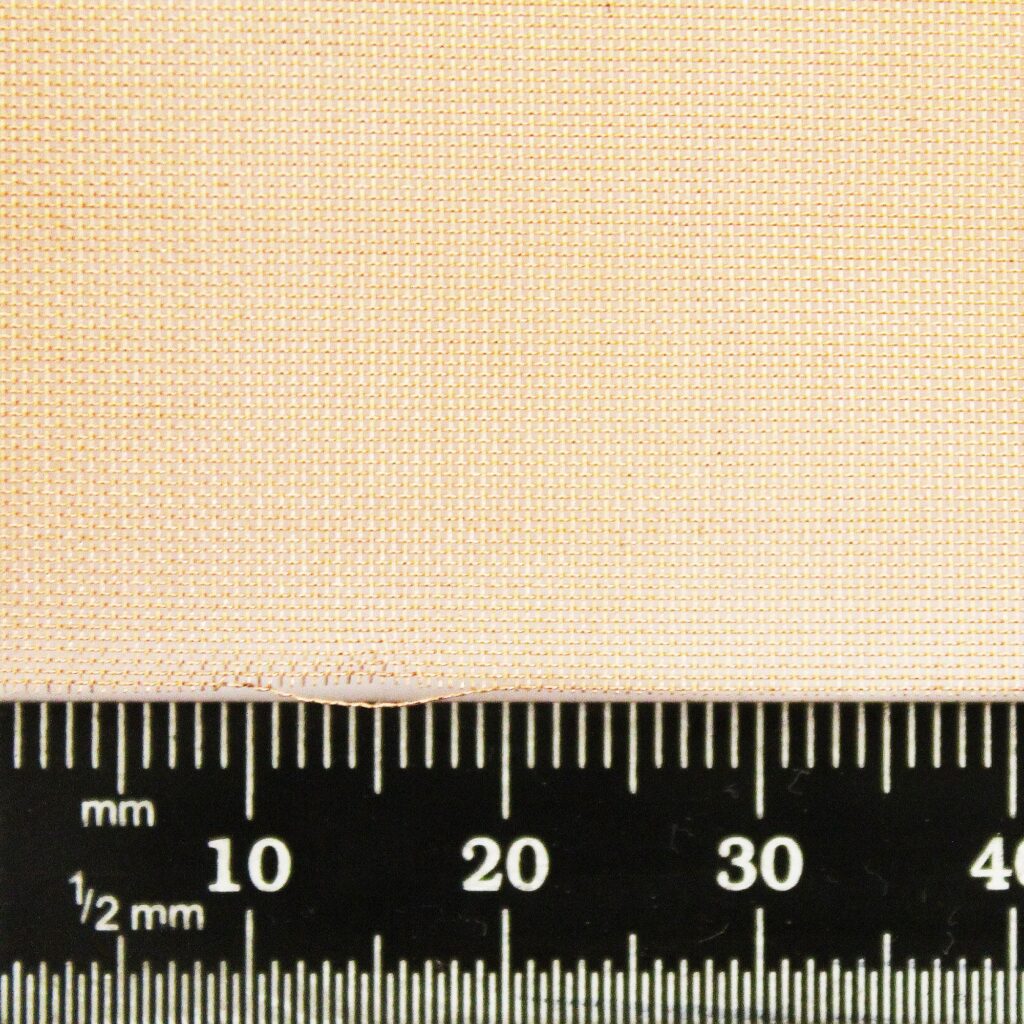

The Mesh Company offers a premium 0.263mm hole fine copper mesh woven from solid copper wire. Known for its softness and ease of use compared to stainless steel, this pure copper mesh efficiently screens out RFI interference while maintaining airflow and light transmission. With 60 holes per linear inch and specifications like 0.16mm wire thickness, it’s the optimal choice for RFI screening needs. Easily tailored with scissors, this fine copper mesh provides both functionality and convenience.

We weave this 0.263mm hole fine copper mesh from solid copper wire. We love working with copper mesh. It is so soft to cut and use compared to the stainless equivalent.

Looking for the perfect solution to your RFI screening needs? Look no further than pure copper fine mesh woven wire by The Mesh Company. With a 0.26mm hole and 0.16mm wire, this fine copper mesh can effectively screen out unwanted interference while allowing for air and light to pass through. With a remarkable 60 holes per linear inch, this copper mesh offers unparalleled screening capabilities that are sure to meet and exceed your expectations. Whether you’re looking to build a robust RFI screening system or simply need to enhance the performance of your current setup, The Mesh Company’s pure copper fine mesh has got you covered.

The specifications of this woven wire mesh are as below:

Wait!! Before you order your mesh please first check out our clearance listing which is where we put all of our over-run bargain rolls at reduced prices. You never know, you might find just the roll that you need for your purposes.

The Mesh Company has an enormous range of wire mesh products. We truly are an industry leader among suppliers of weld mesh and woven wire materials. With the capabilities we have in-house, we can provide virtually anything you require. Chicken wire, insect meshing and rodent mesh materials are also available in large stock quantities at bargain prices.

Our group have been in the mesh industry for over 150 years. We are one of the UK’s most trusted mesh suppliers because:

The Mesh Company has an enormous range of woven wire mesh products. We truly are an industry leader among suppliers of weld mesh and woven wire materials. With the capabilities we have in-house, we can provide virtually anything you require.

Brass, stainless, black, and galvanised steel wire mesh materials are also available in large stock quantities at bargain prices. See our blog for specific information on all of our various

Yes, copper with 60 holes per linear inch can be used for EMI (electromagnetic interference) screening purposes. Material density is determined by the number of holes per linear inch, also known as mesh count or mesh size.

Copper is an excellent conductor of electricity and has good electromagnetic shielding properties.

A mesh count of 60 holes per linear inch indicates a relatively fine woven pattern, offering higher density and smaller openings compared to lower mesh counts. This fine mesh size helps to prevent the passage of electromagnetic waves at certain frequencies while allowing airflow and visibility.

Copper mesh sheets can be used in various applications, including electronic enclosures, computer cabinets, equipment racks, shielding for sensitive electronic components, and communication devices. By preventing external interference and minimizing unwanted electromagnetic emissions, it helps contain electromagnetic radiation within the enclosure.

It is important to ensure proper installation and grounding when using copper mesh sheets for EMI screening. To conduct electromagnetic currents, the sheets must be securely attached to the desired surfaces and connected to a suitable grounding system.

It is worth noting that the specific application and the desired level of EMI shielding effectiveness may require different mesh sizes or additional measures such as gaskets, conductive coatings, or specialized shielding materials. You can determine the most appropriate solution for your specific requirements by consulting with an EMI shielding specialist or engineer.

Easily. We would use standard kitchen scissors or even fingertips alone.

Fine copper woven wire mesh can be welded, but it requires careful consideration and specialized techniques due to the properties of copper.

Copper has a high thermal conductivity, which means it conducts heat very effectively. This characteristic can make welding copper challenging because it dissipates heat quickly, making it more difficult to achieve a strong and consistent weld.

When welding fine copper woven wire mesh, it is essential to use a welding method suitable for copper and take certain precautions:

Check out our blog ‘the myriad benefits of pure copper wire mesh’ for more information on this product. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

We have also provided a detailed article on using copper mesh for RFI and RMI shielding.

Also, we have an ever expanding YouTube channel. We created this channel to help showcase our products, inform our customers on the wire mesh market, and use our position as a trusted authority in our industry to help all to understand exactly what metal mesh can offer.

We also offer similar products through our highly popular eBay store, check us out there too.

| Sheet Size | 150 x 150mm x 2 Pack, 210 x 300mm x 4 Pack (A4 x 4 Pack), 300 x 300mm, 420 x 594mm (A2), 500mm x 500mm, 594 x 840mm (A1), 1000 x 500mm, 1000 x 1000mm, 5m x 1000mm (1 metre), 10m x 1000mm (1 metre) |

|---|

In 2008 Locker Wire Weavers launched The Mesh Company to bring our enormous range of wire mesh products to the general public for the first time. Previously wire mesh was only available for trade customers.

We continue to extend our range, and now proudly offer many forms of mesh and metal products for the best possible prices. We specialise in woven wire mesh. As a group we work closely with architects and designers to develop ground-breaking new applications for our multifunctional range of materials. We also offer state of the art fabrication and engineering for projects of all sizes.

Strong ties with the Warrington community continue to be at the very core of our business. We are proud to invest in the training and developing our staff of all levels in line with the traditions set by Thomas Locker, who founded our group 150 years ago when he invented the electronic loom. We continue to bring ingenuity and strong ethics to our day to day business.

The Mesh Company continues Warrington’s historic role in the wire industry. For more than 140 years, our group has been a leader in the supply and manufacture of woven wire mesh and wire cloth. Having been founded in Warrington, UK in 1878, Locker mesh products still retain the quality craftsmanship and spirit of innovation that were so characteristic then.

Available Options

You will find full rolls of this insect netting here. Please be advised that the majority of woven mesh is usually available in a maximum roll size of 30 metres by 1200mm. Please email us if you wish to discuss purchasing this mesh in any size – sales@themeshcompany.com.

Feel free to call us if you wish to discuss any of our products – (+ 44) 01925 406 602. We are always happy to help in any way that we are able to.

We also offer this product through our highly popular eBay store, check us out there too.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions

Nigel –