Architects and designers alike have long favoured brass woven wire mesh for its golden luster and remarkable versatility. From elegant architectural facades to intricate decorative accents, brass mesh is known for its aesthetic appeal and durability.

Beyond its initial shiny allure, brass carries the unique capability to transform, embracing the passage of time through the development of verdigris. Developed as brass is exposed to atmospheric elements, this green patina adds depth and character to the material as it ages.

It is not just a sign of aging; verdigris is a coveted feature that enhances the beauty of brass woven wire mesh and extends its life. In this article, we explore the journey of brass mesh from its pristine beginnings to the distinguished appearance it acquires over time, examining the natural process that gives brass its verdigris patina and the enduring beauty it imparts to architectural and decorative projects.

Let’s get into it…

Different types of brass have different properties due to the proportions of copper and zinc in the alloy. Brass is primarily composed of copper and zinc. The result is a material that is not only visually appealing, but also strong and corrosion-resistant. Brass’ copper reacts with oxygen in the air, forming a protective layer ranging in colour from dark brown to bright green. In addition to altering the material’s appearance, this layer also protects the wire mesh from further environmental wear.

The green patina that covers aged brass is a result of a chemical reaction between copper in the brass and oxygen, carbon dioxide, and moisture. As a result of the surrounding environment, this process called oxidation occurs over time. Verdigris is more likely to form in humid areas or those exposed to saltwater. As a result of the patina, the brass is able to withstand the elements more effectively, as it acts as a protective barrier that halts corrosion. It is crucial to understand this natural aging process for those selecting brass woven wire mesh for their projects, since it signifies the material’s ability to evolve and endure, providing lasting durability and a living finish.

Initial Appearance: There is no denying the allure of brass woven wire mesh in its nascent state. Freshly manufactured brass mesh sparkles with a golden hue, its lustrous appearance evoking a sense of luxury and warmth. Due to its initial brilliance, it is sought after in architectural and decorative designs, where its reflective quality can brighten spaces and add a touch of elegance. New brass mesh serves not only a functional but also an aesthetic purpose, seamlessly integrating into various design schemes, from intricate inlays in furniture to grand facades on buildings.

Aging Process: As brass mesh interacts with its environment, it undergoes an aesthetic transformation. As the mesh ages, its surface reacts with atmospheric oxygen, moisture, and pollutants, changing colour gradually. It can result in a spectrum of patinas, from dark browns to rich greens, each marking a phase in the material’s life. As the transition occurs slowly and gradually, the mesh displays a living history of its exposure and use.

Verdigris Patina: The most distinguished patina is verdigris. A green patina, created by copper reacting with carbon dioxide and water, adds a profound character and depth to brass mesh, transforming its appearance into a work of art. Verdigris does not just symbolise age; it signifies a material that has lived, adding a narrative element to the mesh. Architectural elements, sculptures, and decorative pieces become timeless artifacts when verdigris becomes a coveted aesthetic in settings where history, rustic charm, or a connection to nature are desired.

Protective Qualities: In addition to its visual appeal, verdigris patina also provides functional benefits, shielding underlying brass from corrosion and environmental damage. The natural barrier prevents direct contact between the brass surface and corrosive elements, slowing down the aging process and preserving the mesh’s structural integrity. It is this protective quality that extends the lifespan of brass installations, making verdigris not just an aesthetic choice, but a practical one as well.

Aesthetic Value: Verdigris on brass wire mesh provides unparalleled aesthetic benefits. There is a historical and rustic charm imbued in its architecture and art pieces that is both unique and evocative. Green patinas blend well with natural surroundings, making them ideal for garden sculptures, outdoor furnishings, and architectural accents. Additionally, verdigris lends an air of timelessness and depth to designs that transcend trends by evoking a sense of antiquity. Its contribution to the aesthetic narrative of spaces and objects underscores the transformative power of natural processes in art and design.

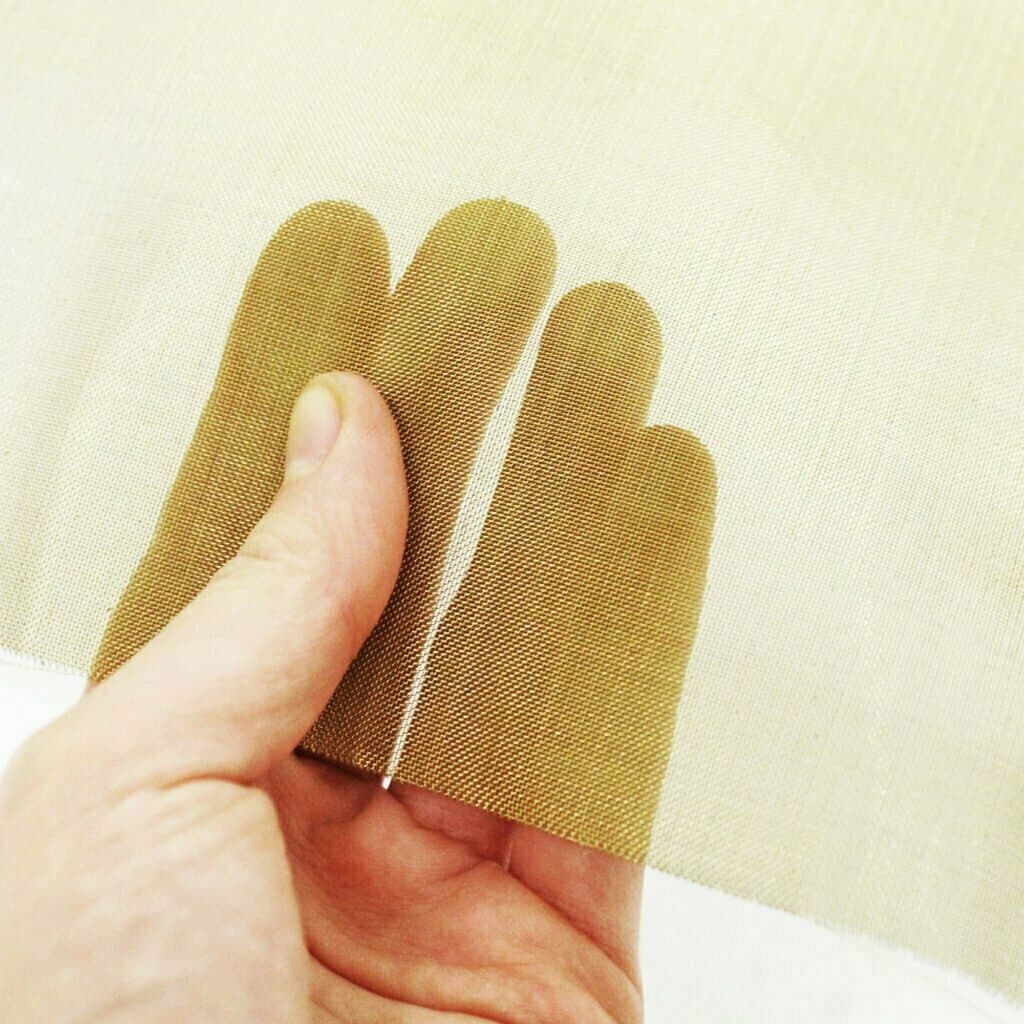

When weaving brass woven wire mesh, it’s not unusual to observe that sometimes a single wire displays a distinct colour from its peers. While intriguing, this phenomenon can be explained by several properties inherent to brass as an alloy as well as the manufacturing process. These factors shed light on the inherent characteristics of brass mesh and its unique aesthetic appeal.

Alloy Composition Variability: Brass is primarily composed of copper and zinc, with the hue of the brass dependent on the ratio of these two metals. Even within the same batch of wire, slight variations in this ratio can result in slight colour variations. Copper wires, for example, may appear redder or more vibrant than those with a higher zinc content.

Oxidation and Patination: Brass, like all copper-based alloys, oxidises when exposed to air. Even before the wires are woven into mesh, this natural process can begin, especially if they are exposed to varying environmental conditions. Patinas range in colour from deep browns to verdigris greens. It is possible for a wire to oxidise at a different rate due to variations in surface conditions, resulting in noticeable differences in colour.

Manufacturing and Handling Processes: Several steps are involved in the production of wire mesh, including drawing, annealing, and sometimes coating. The final appearance of the wire can be affected by slight inconsistencies in these processes. A wire that has been annealed differently may acquire a distinct colour due to changes in its surface structure. The handling and storage conditions can also affect how each wire ages to the point of weaving.

Surface Finishing Variance: Wires may undergo surface treatments aimed at enhancing their aesthetic or functional properties. Colour discrepancies can occur due to variations in how these finishes are applied or adhered to the wire. This is particularly evident in meshes designed for decorative purposes, where the finish plays a significant role in the overall appearance.

To preserve the verdigris patina of aged brass mesh or maintain its original gleam, appropriate maintenance techniques must be understood. In order to preserve verdigris’ distinctive green patina, gentle cleaning methods must be used that do not remove the patina. Dust can be removed using a soft, dry cloth, while stubborn grime can be removed using a slightly damp cloth, being careful not to rub off the patina. It is possible to protect verdigris from wear and environmental factors by applying protective coatings, such as wax or lacquer.

Conversely, maintaining the brass mesh’s original shine requires a more proactive approach. The accumulation of substances that contribute to patina formation can be prevented by regularly cleaning brass with a mild, brass-appropriate cleaner.

The mesh should be thoroughly dried after cleaning to prevent oxidation. In order to keep brass mesh bright and lustrous for a long time, periodic applications of a thin, protective clear coat can inhibit patina development.

Tips to Avoid Verdigris Formation:

Keep It Dry: Moisture is a primary catalyst for verdigris. Ensure that metal objects are kept in dry conditions, and wipe down any moisture immediately.

Regular Cleaning: Clean your brass and copper regularly with a soft cloth and appropriate cleaners to remove any potential oxidising agents.

Apply Protective Coatings: Wax, lacquer, or other protective coatings can create a barrier between the metal and its environment, slowing down the oxidation process.

Use Anti-Tarnish Strips: Placing anti-tarnish strips inside storage areas or with the metal objects can help absorb pollutants that may cause verdigris.

Limit Exposure to Elements: Whenever possible, limit the metal’s exposure to air and humidity. Indoor storage is best for items not meant for outdoor use.

Proper Storage: Store brass and copper items in airtight containers with desiccants to control humidity levels.

Brass woven wire mesh represents a fascinating aspect of design and architecture, from its shiny inception to its distinguished verdigris colour. A natural aging process enhances the mesh’s aesthetic appeal and provides a layer of protection, ensuring its longevity. As a symbol of time and exposure, verdigris patina adds historic and rustic charm to any project when appreciated as a symbol of time and exposure.

Understanding the care required is crucial when preserving verdigris for its protective and aesthetic qualities, as well as preserving brass’s original radiance. Architects and designers can incorporate the unique properties of aged brass mesh into their projects to achieve outcomes that are both functional and enchanting. Readers are encouraged to explore the possibilities of brass woven wire mesh in their work, using the insights provided to select and care for this material appropriately.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually, we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores using brass as a filter.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.