Chromatography is an indispensable analytical technique that permeates through numerous scientific disciplines, serving as the backbone for pharmaceutical research, environmental testing, and beyond.

Identifying and quantifying components within a mixture is crucial to science and technology advancement. The preparation of the samples is, however, the foundation of reliable chromatographic analysis. Even minor contaminants or particulate matter can skew results, leading to inaccurate conclusions. As part of the sample preparation process, superfine woven wire mesh plays a crucial role.

By integrating this material into the preparatory stages, researchers can achieve an unmatched level of sample purity, thus ensuring the accuracy and reliability of their chromatographic analyses.

Overview of Chromatography

Chromatography is an analytical method for separating components in a mixture based on their relative affinities towards stationary and mobile phases. Qualitative and quantitative analyses of complex mixtures can be carried out using this technique across a wide range of fields. Whether identifying pollutants in water or determining pharmaceutical ingredient concentrations, chromatography supports critical decisions in research, quality control, and regulatory compliance.

Sample Preparation Challenges

Sample preparation for chromatography presents a number of challenges, chief among them being the need for purity and clarity. The presence of particles or other contaminants in samples can clog chromatographic columns, degrade separation efficiency, or interfere with the detection of target analytes. Impurities of this nature can lead to poor resolution, reduced sensitivity, and ultimately, unreliable data. To prepare a sample for chromatography, these unwanted materials must be meticulously removed without altering the sample’s analytes.

Impact on Analytical Accuracy

Chromatographic results are directly influenced by the quality of the sample. The presence of contaminants and particles can cause significant errors, such as peak tailing, ghost peaks, or complete masking of important analytes. Such inaccuracies can lead to erroneous conclusions in quantitative analysis. As a result, achieving the highest possible sample purity is not simply a matter of procedural rigor but is essential for the integrity of the scientific analysis.

A powerful solution to these challenges is the use of superfine woven wire mesh in sample preparation. Its ability to remove contaminants while preserving sample integrity is a game-changer in chromatography.

Material Specifications

Chromatographic sample preparation technologies utilize superfine woven wire mesh, particularly those made from stainless steel 304 or 316. The exceptional chemical resistance and durability of these materials make them ideal for scientific analysis’ rigorous demands. Due to the addition of molybdenum, 316 stainless steel offers better corrosion resistance from harsh chemicals than 304 stainless steel.

Mesh Properties

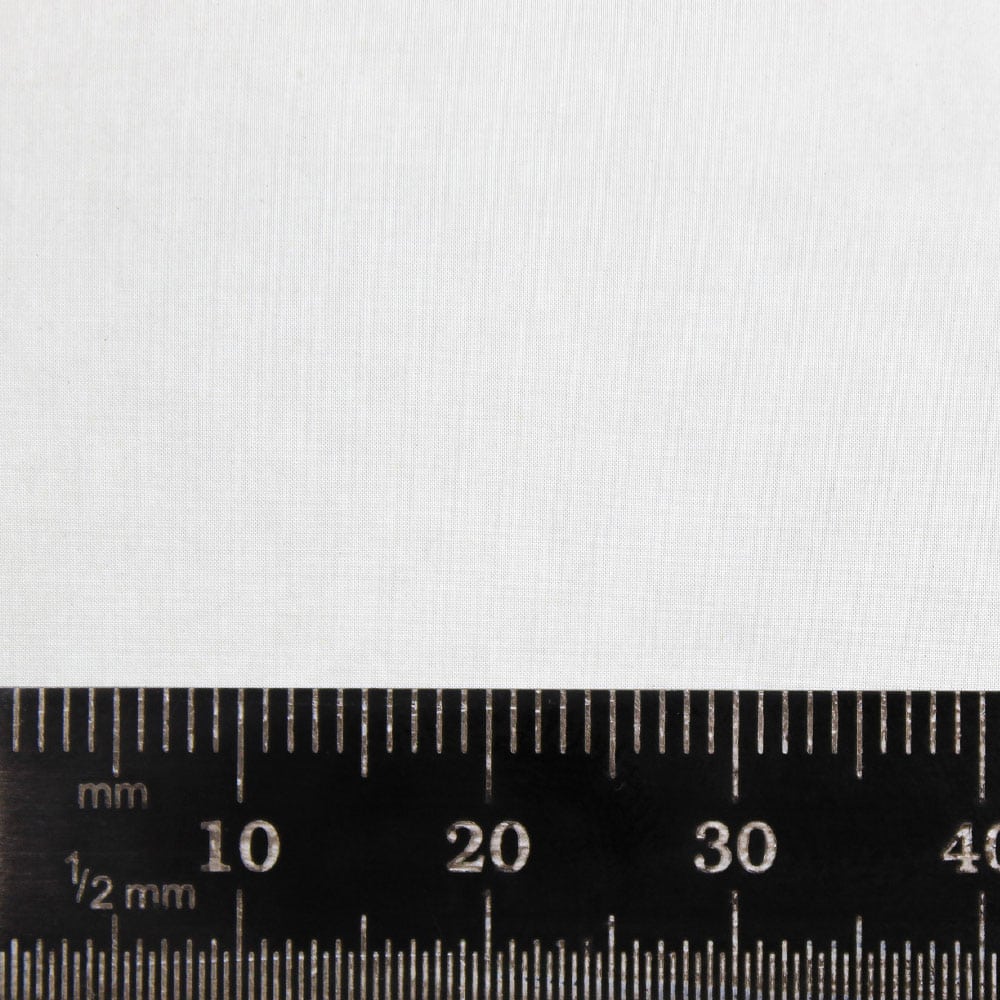

Pore size, wire diameter, and open area are the defining characteristics of superfine mesh. The mesh’s ability to sieve particulate matter from a sample is determined by its porous size, which is often measured in micrometres.

The wire diameter affects the mesh’s strength and filtration capabilities, while the open area percentage affects its throughput and resistance to clogging. By effectively separating desired analytes from particles and other impurities, these features ensure clear, uncontaminated samples in chromatography, which requires precision.

Enhanced Filtration Efficiency

Filtration is enhanced by the tight weave of superfine mesh. With this precision, even the smallest particulates are removed from samples, ensuring the purity required for accurate chromatographic analysis. Stainless steel mesh ensures complete sample recovery, preventing any loss of analytes and preserving the integrity of the analysis, unlike other filtration materials.

Resistance to Chemicals

The inherent resistance of stainless steel mesh to a wide range of chemicals is one of its most significant advantages. Chromatography, where samples often come into contact with solvents and reactive agents, requires this property. Due to stainless steel’s resistance, the mesh does not react with these substances or leach contaminants into the sample, maintaining the sample’s purity.

Reusability and Sustainability

Stainless steel mesh offers an eco-friendly alternative to disposable filters due to its durability. Due to the mesh’s ability to withstand repeated use without degradation, the same piece can be used across many sample preparations, resulting in a significant reduction in waste. A further benefit of superfine woven wire mesh is its reusability, along with its ability to be cleaned and sterilized without compromising its filtration capabilities.

The preparation of liquid samples is a crucial step in liquid chromatography that directly influences the accuracy and reliability of results. In this preparatory phase, fine woven wire mesh acts as an effective pre-filter for removing particulate matter from liquid samples. The tight weave and precise pore size ensure that only liquid passes through, while suspended solids are effectively trapped. In order to prevent chromatographic columns from clogging, this filtration step is crucial. Inconsistent flow rates, poor resolution, and ultimately unreliable chromatography results can result from clogged columns. Labs can enhance the efficiency of liquid chromatography procedures by incorporating superfine mesh into sample preparation workflows, protecting analytical columns and ensuring high-quality separations.

Gas Chromatography

The purity of gas samples is paramount in gas chromatography. The presence of contaminants and particulates in gas samples can adversely affect the performance of analytical equipment, resulting in damage to sensitive detectors and column blockages. Before introducing gas samples into the chromatograph, superfine woven wire mesh serves as an effective filtration solution. Gas chromatography applications, where samples often undergo vaporization, require meshes that can withstand high temperatures and resist chemical reactions. By removing particulates at this critical juncture, the mesh helps in preserving the operational integrity of the gas chromatographic system, ensuring accurate and consistent analytical outcomes.

Innovative Uses

As a result of its adaptability, superfine woven wire mesh has been used in innovative chromatographic techniques, enhancing sample preparation and analytical results significantly. The use of superfine mesh in conjunction with solid-phase extraction (SPE) is one notable case study. The mesh was utilized as a support structure for SPE media, enabling efficient extraction of analytes from complex biological matrixes. As a result of this innovative approach, not only did the recovery rates of target compounds improve, but also the sample preparation process was streamlined, reducing the amount of time and solvent consumed in the preparation process.

In the field of environmental testing, superfine mesh was used to collect and analyze airborne particulates, another innovative application. Using the mesh as a filter in air sampling equipment, environmental samples were precisely collected and then analyzed using chromatography to identify contaminants and monitor pollution levels. It demonstrates the mesh’s versatility and its contribution to environmental science, enhancing analytical accuracy and environmental health monitoring.

In addition to improving sample clarity, protecting analytical equipment, and driving innovation in analytical methodologies, these practical applications demonstrate the transformative impact of superfine woven wire mesh on chromatography sample preparation.

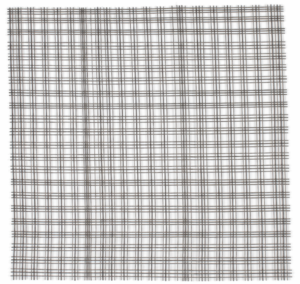

325 LPI Stainless Steel Mesh (0.043mm Hole)

400 LPI Stainless Steel Mesh (0.039mm Hole)

500 LPI Stainless Steel Mesh (0.025mm Hole)

Incorporating superfine woven wire mesh into laboratory workflows requires careful attention to handling, cutting, and cleaning to maintain its integrity and effectiveness. When introducing this mesh into your lab, consider the following guidelines:

Troubleshooting Common Issues

The superfine woven wire mesh offers laboratories unprecedented levels of sample purity and clarity in chromatography sample preparation. In addition to its exceptional filtration capabilities, stainless steel is durable and chemically resistant, making it an invaluable asset for chromatographic analysis.

Researchers and laboratories should explore the possibilities of superfine woven wire mesh. With this advanced material, you not only streamline your analytical processes, but also pave the way for significant advancements in analytical science. Through the use of superfine woven wire mesh, chromatography can be pushed to new levels of precision, reliability, and insight.

We would be happy to assist you with your project whenever you need us, so please contact us and we will help you in any way that we can.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores the filtration capabilities of 325 mesh in general.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.