In the realm of industrial engineering, the pivotal role of fine mesh filtration cannot be overstated.

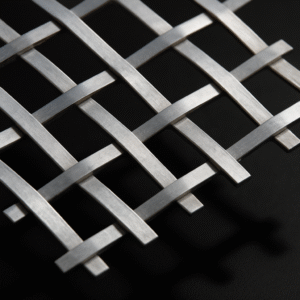

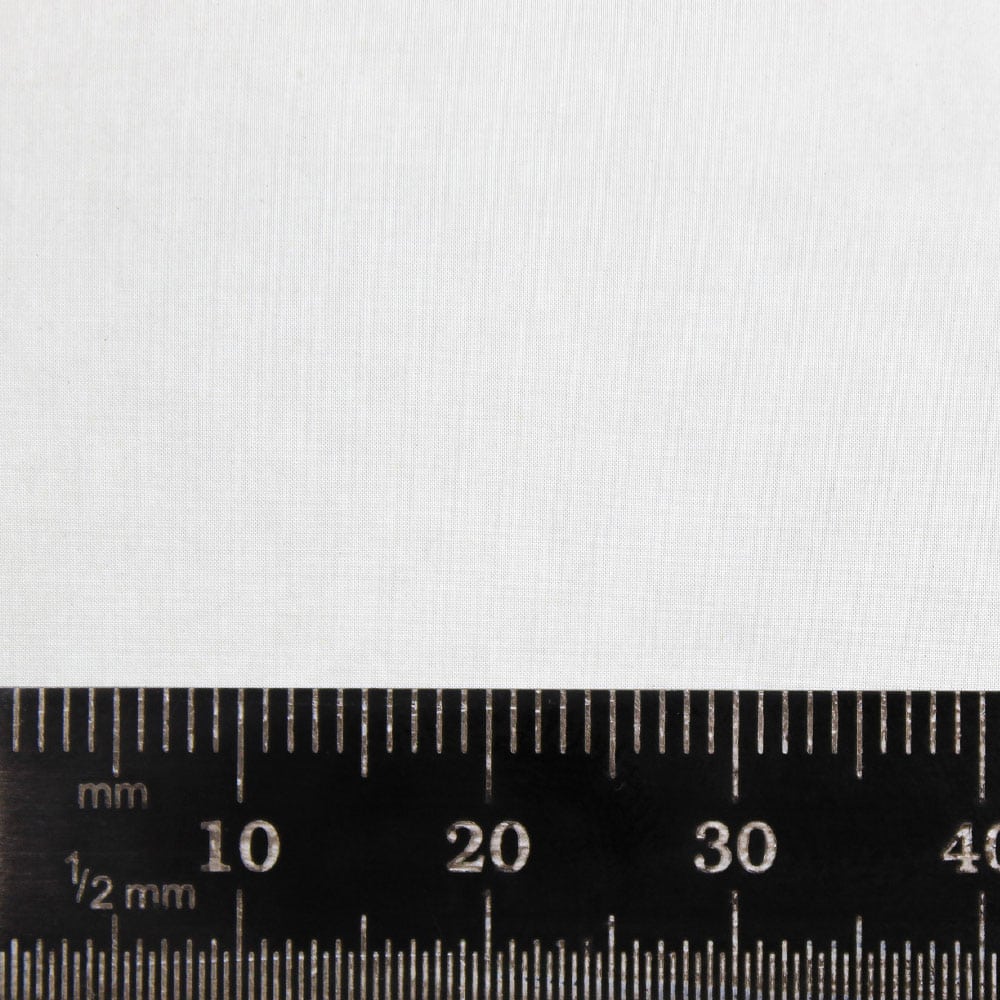

Our stainless steel mesh with 0.043mm holes and 325 lines per inch (LPI) stands out for its exceptional precision and versatility.

This mesh combines superior filtration efficiency and unparalleled durability, making it an indispensable tool in a wide range of applications. 304 stainless steel is a material renowned for its resistance to corrosion and oxidation, ensuring that the mesh stays intact even under the most extreme conditions.

Our article explores the multifaceted nature of this fine stainless steel mesh, shedding light on its technical advantages, innovative uses, and the science behind it. As with all of our articles, we hope that this is relevant and of great use to your search. Please contact us for any information that you may require.

In fine mesh filtration, particulate matter is separated and removed from fluids or gases through a barrier whose openings are precisely controlled in size. This process is highly dependent on the size and tightness of the holes, which 325 LPI stainless steel mesh excels at. Featuring holes as small as 0.043mm, it captures extremely fine particles without compromising flow rates, offering unsurpassed filtration detail.

This mesh has been meticulously engineered to optimize performance by balancing pore size, wire diameter, and open area percentage. In addition to providing an effective filtration medium, 304 stainless steel is durable and resistant to a wide range of chemicals, further enhancing this balance. In sensitive applications, this resistance is crucial to maintaining purity and preventing contamination. In addition, the ease of maintenance associated with 304 stainless steel ensures that the mesh can be cleaned and reused, supporting sustainable operations.

To put into context how fine this mesh is, human hair measures from 0.04mm to 0.1mm on average. So this is as fine as an especially fine human hair.

Applications for the 325 LPI stainless steel mesh are as diverse as they are critical. Chemical processing industries use it to remove impurities and protect sensitive equipment in filtration systems. As a result of its precision, it has proven invaluable in pharmaceutical manufacturing, where product purity is crucial, and even the smallest contamination can have a significant impact. In the food and beverage sector, it contributes to achieving clarity and quality in products, including beverages and edible oils.

In specific filtration systems, this fine mesh has yielded significant benefits, including increased efficiency and reduced downtime. A case study in a pharmaceutical plant demonstrated how the 325 LPI mesh significantly reduced product contamination, enhancing safety and productivity. Similar to a brewery, the introduction of this mesh into the filtration process enhanced the clarity and stability of beer, directly improving consumer satisfaction and product quality.

The importance of fine stainless steel mesh in meeting and exceeding regulatory standards cannot be overstated. Reliability, efficiency, and adaptability make it a cornerstone in the pursuit of excellence across various industries, proving that the right materials and technologies can drive not only compliance but innovation and quality improvement as well.

The 325 LPI stainless steel mesh transcends its conventional applications, proving invaluable in laboratory settings, scientific research, and development. Its ultra-fine filtration capability makes it an ideal candidate for sophisticated experimental setups, sample preparation, and analytical procedures where precision is paramount. In addition to ensuring durability, 304 stainless steel prevents contamination of sensitive experiments.

Controlling and removing particulate matter is crucial for the accuracy and reliability of experimental results in laboratory environments. With its 0.043mm holes, the 325 LPI mesh provides an unmatched level of precision filtration, capable of capturing sub-micron particles. In applications such as chromatography, spectrometry, and microscopy, where samples’ clarity and purity directly affect the outcome and validity, this level of filtration is particularly beneficial.

Mesh is also used in biological sample preparation, water purification processes, and even in the development of medical devices that require sterility and particle retention. In addition to its versatility and utility in research settings, its resistance to a variety of chemicals and high temperatures make it suitable for a wide range of experimental conditions.

In research and development projects, 325 LPI stainless steel mesh has had a tremendous impact. It ensures that experiments are not compromised by external contaminants by maintaining stringent research standards. By using it, scientists are able to obtain accurate, reliable data, thus advancing scientific knowledge and innovation. The mesh facilitates discovery of new insights and technology development across a variety of fields by providing a clear, uncontaminated pathway for analyses.

Researchers and scientists will benefit greatly from incorporating this fine mesh into their work.

Here is a quick list of just some of the uses that we are aware of:

As we deep-dive into the 0.043mm hole, 325 LPI stainless steel mesh, we’ve highlighted its outstanding filtration capabilities, remarkable versatility, and robust strength.

Crafted from high-quality 304 stainless steel, this fine mesh stands as a testament to engineering excellence, suitable for a myriad applications that stretch across the spectrum from critical industrial processes to the realm of creative home DIY projects.

Due to its exceptional performance in the most demanding environments, this mesh plays a vital role in increasing efficiency, ensuring quality, and fostering sustainability in all kinds of operations, whether it’s pharmaceutical manufacturing, food and beverage production, or laboratory experiments.

If you need a super fine filter then we believe that this would be an excellent choice. Please contact us if you have a specific requirement for any filtration task and we will point you in the right direction.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores using fine mesh to filter pollen.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions