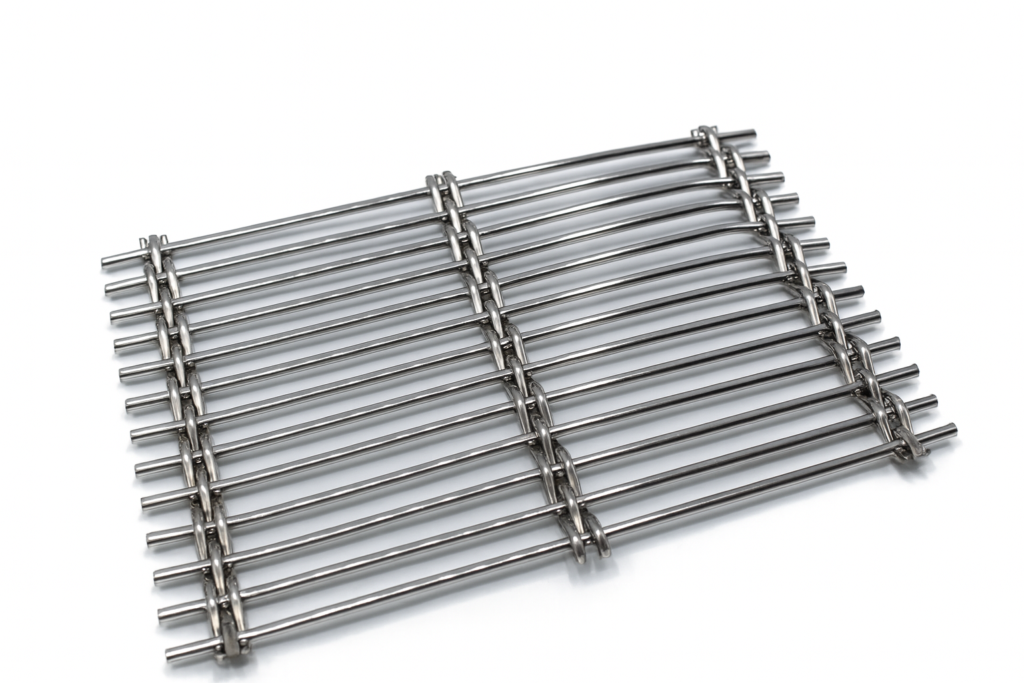

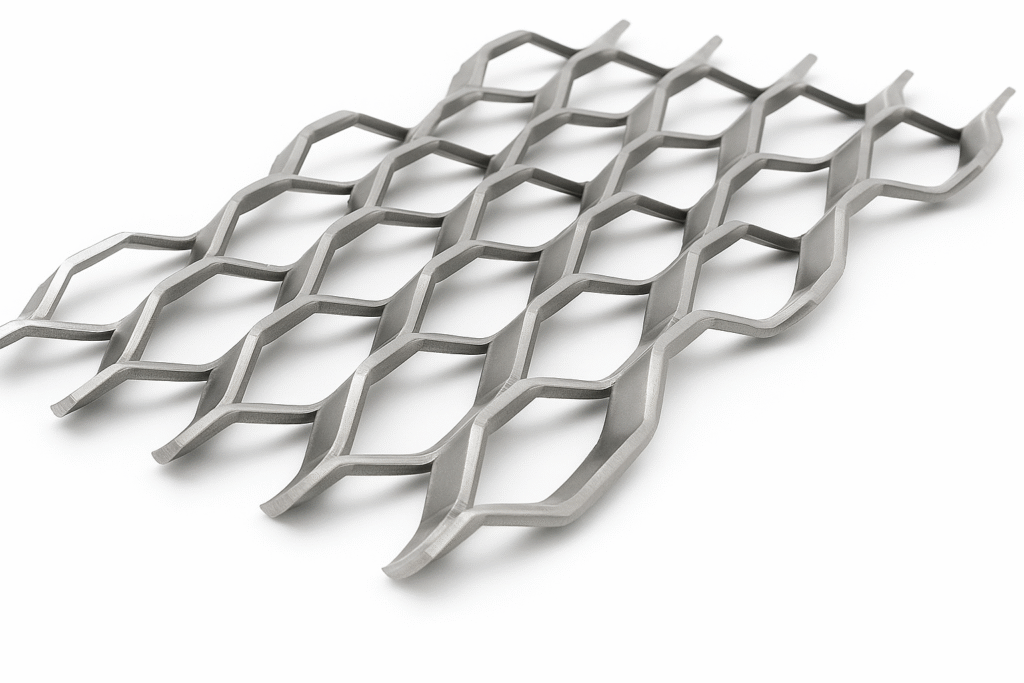

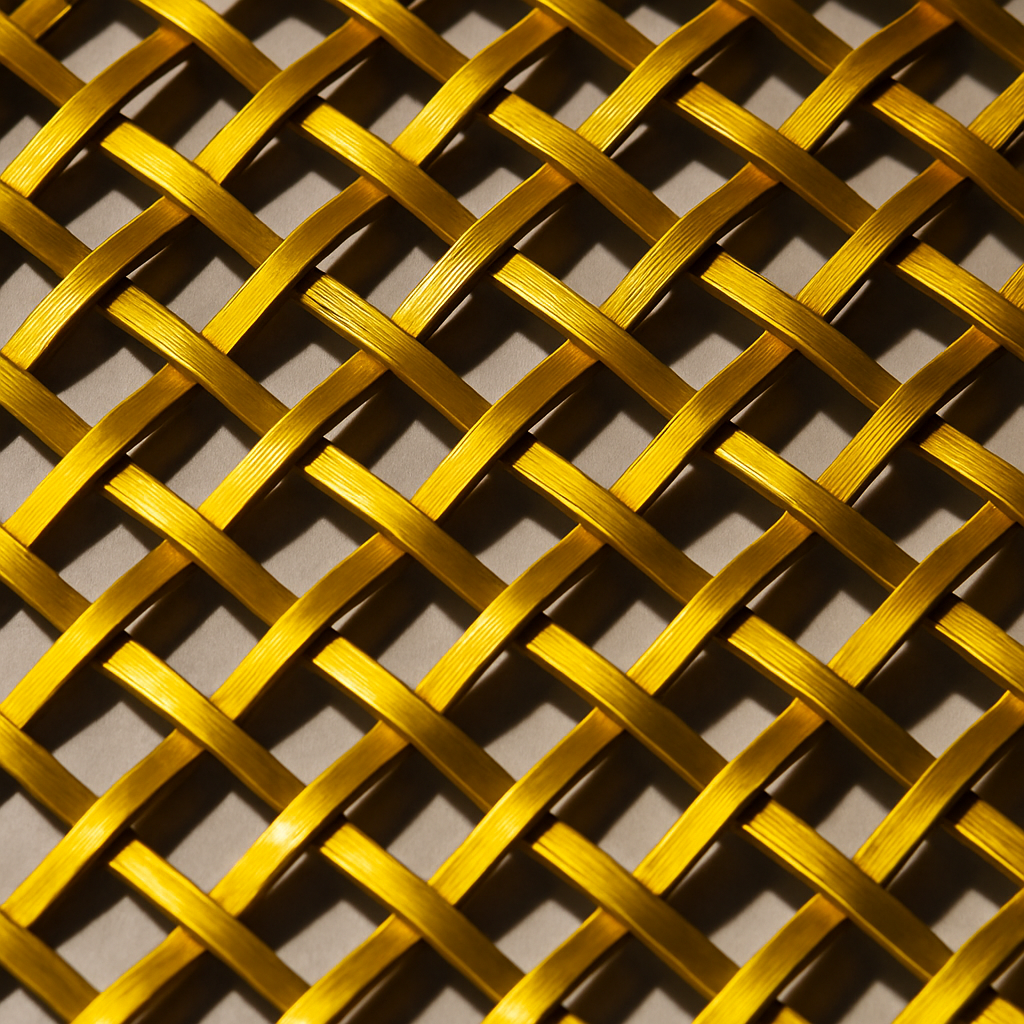

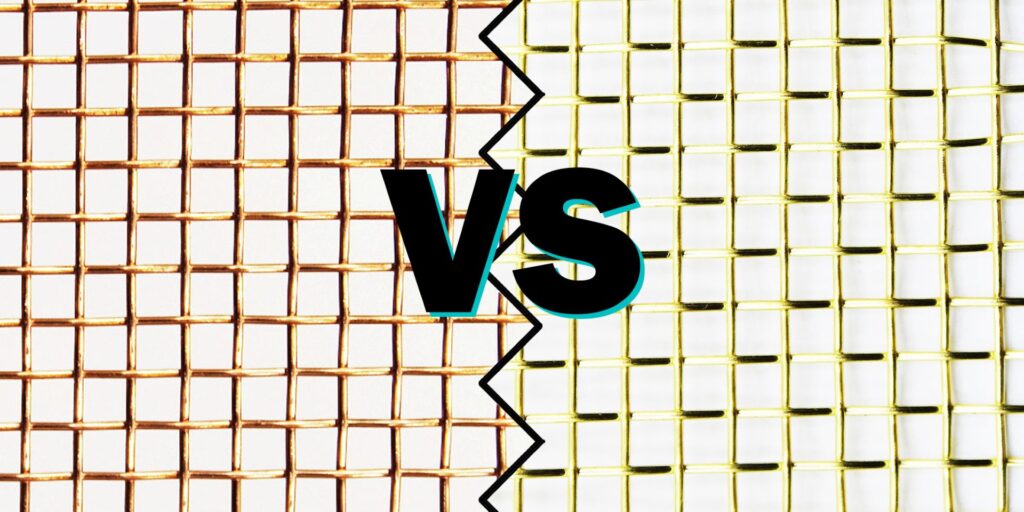

Wire mesh, a mainstay in numerous applications across various industries, is inherently versatile due to the array of materials available for its construction. Two of the most noteworthy contenders in this domain are brass and copper.

Both metals bring unique characteristics to the table, but when it comes to woven wire mesh, which one truly reigns supreme? Let’s dive into an in-depth comparison of these two illustrious materials.

Let’s go….

Brass and copper are known for their distinctive hues, durability, and long history in human civilization. Both metals have demonstrated versatility in decorative arts as well as electrical and construction industries. The advantages of these metals in woven wire mesh go beyond their aesthetic appeal.

Copper: The reddish-brown metal has been used by humans for over 10,000 years. Its role in shaping civilisations is undeniable as one of the first metals mined and crafted into tools.

Copper has been used by humans for thousands of years for a variety of purposes, but it is unclear when it was first woven into mesh. It is thought that metal weaving, particularly with metals like copper, gained popularity during the late medieval period and into the Renaissance as metallurgy advanced and the demand for finer crafted products increased. Structures woven from organic materials, like reeds and fibers, date back millennia.

Brass: Its history is younger than that of pure copper, but no less significant. Brass is an alloy of copper and zinc. Through antiquity, coins, instruments, and decorative items were made from gold because of its golden sheen and resilience.

In the context of industrial advancement, the 18th and 19th centuries saw significant strides in metallurgy and manufacturing techniques, including the capability to produce finer wire products and weaves. This era likely saw an increase in the production of brass mesh for various applications.

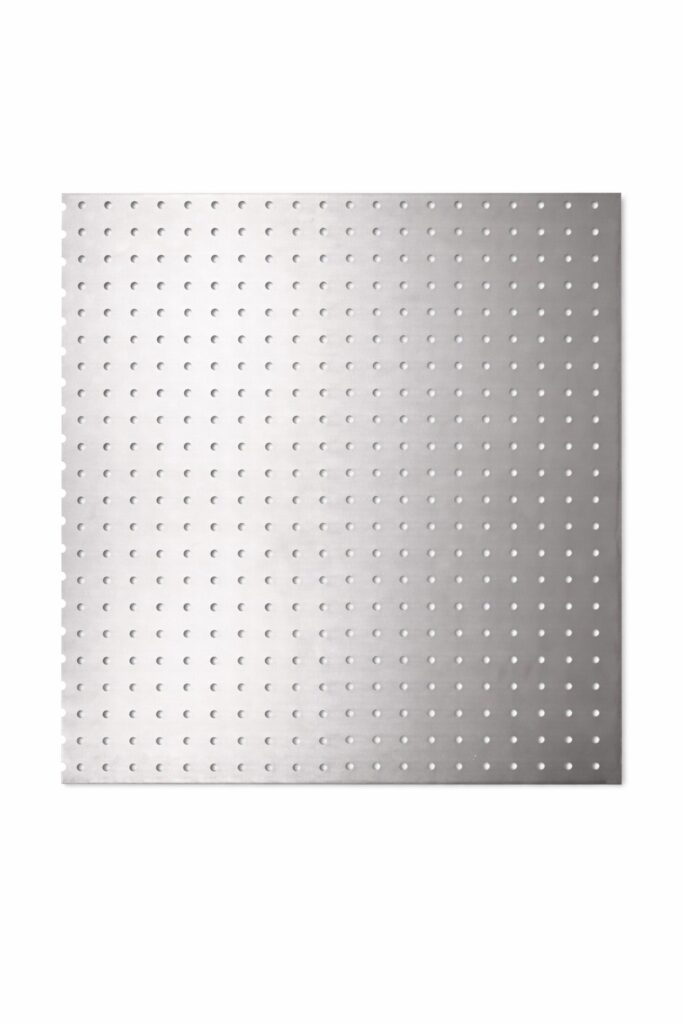

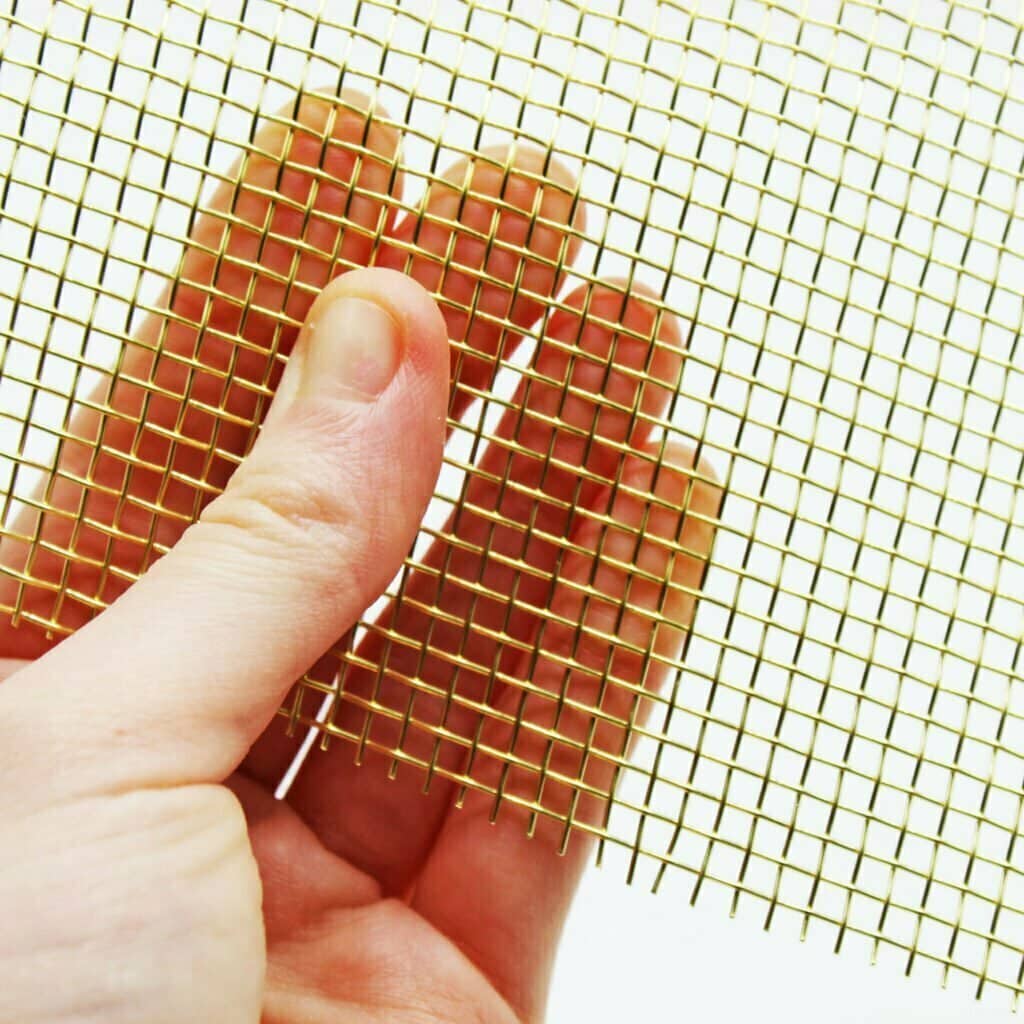

Durability: Both metals are robust, but brass tends to be harder due to its alloyed nature, giving it an edge in applications demanding higher wear resistance.

Conductivity: Copper is one of the best conductors of electricity, making it invaluable for electrical applications. Brass, while conductive, doesn’t match copper’s proficiency in this realm.

Corrosion Resistance: Both materials resist corrosion well, but their reactions differ. While copper can develop a green patina over time, brass tends to maintain its gold-like appearance longer.

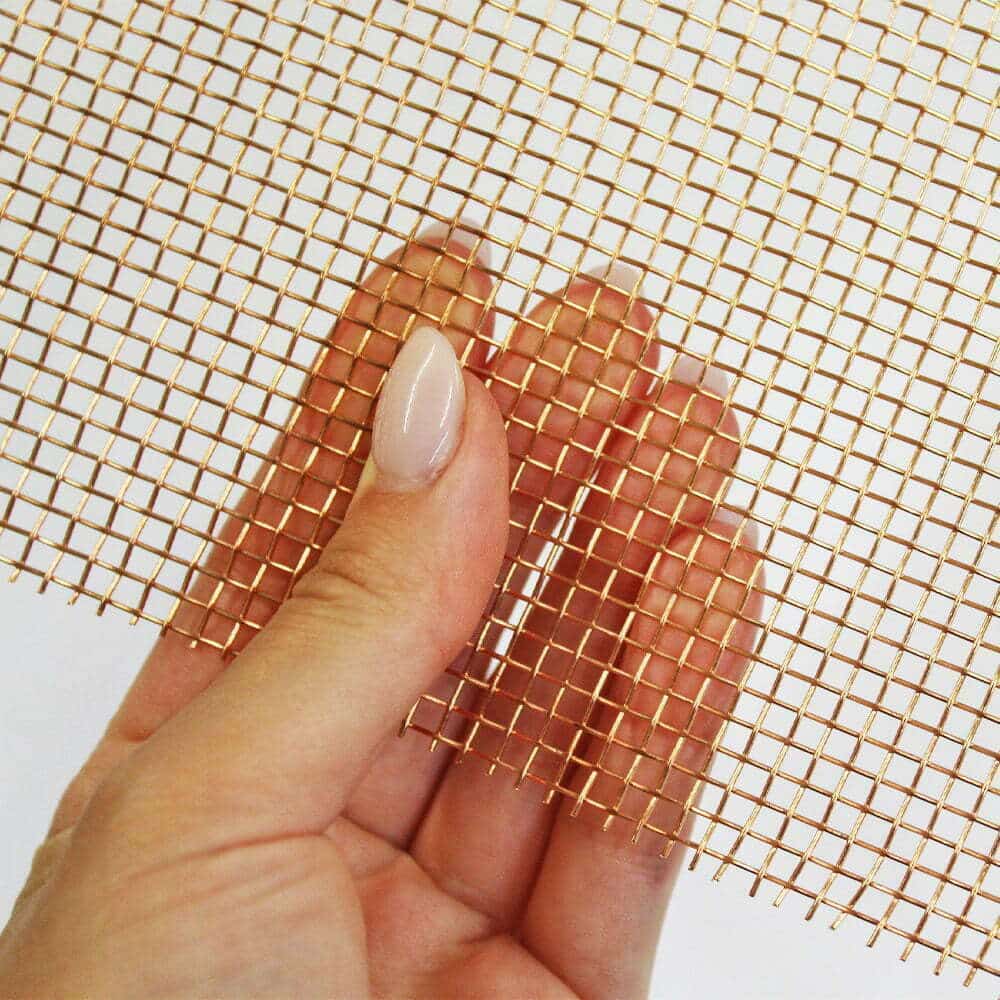

Flexibility: Copper, being softer than brass, is more malleable. This makes it easier to shape and weave, but it might not endure heavy strains as effectively as brass.

Discover the diverse uses of Copper Woven Wire Mesh in our collection.

As important as functionality is, aesthetics cannot be overlooked, especially in visible applications. When exposed to the elements, copper develops a warm, earthy tone. Patina can be a desirable characteristic for those who enjoy an antique or vintage look. With its golden sheen, brass presents a timeless elegance, making it popular in luxury settings or when opulence is desired.

Both materials require relatively little maintenance. Patina on copper can act as a protective layer, while brass’s resistance to tarnishing requires less cleaning. In order to preserve the original lustre of either metal, periodic cleaning with appropriate cleaners is recommended.

Copper and brass both have antimicrobial properties. Hospitals and food preparation areas, for example, can benefit from these materials. In terms of environmental sustainability and eco-friendliness, both metals are recyclable.

Global metal prices, demand, and supply determine the cost. Pure copper, however, tends to be more expensive than brass. This cost difference can be a deciding factor for large-scale projects. When making a decision based solely on price, it’s crucial to consider the long-term benefits and the specific requirements of the project.

What is the best woven wire mesh between brass and copper? Answering this question isn’t easy. Every metal has its distinct advantages, catering to different needs and aesthetics. While copper’s superior conductivity and ever-evolving beauty make it a favorite in certain sectors, brass’s durability and consistent golden appearance make it a favourite in others.

You will make your decision based on the specifics of your project, whether it is the budget, aesthetic preferences, functional requirements, or environmental conditions. Fortunately, both metals offer a blend of functionality and beauty, so you’re bound to find a choice that perfectly fits your vision.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores using copper mesh for EMI and RFI shielding.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.