Okay. Let’s have a close look at two of our most popular metals.

Choosing the right material that is durable, cost-effective, and corrosion-resistant is often a challenge for engineers and designers.

Due to their unique properties and wide range of uses, stainless steel and aluminium stand out from the many choices available. The purpose of this blog is to provide insight into the corrosion resistance of these two metals, discussing their strengths, weaknesses, and ideal applications.

The process of corrosion is the gradual destruction of materials by chemical and/or electrochemical reactions. Corrosion affects more than just cosmetics; it impacts structural integrity and lifespan. Corrosion can take many forms, including galvanic, pitting, crevice, and intergranular.

Let’s try to find out which metal is better at combating this issue.

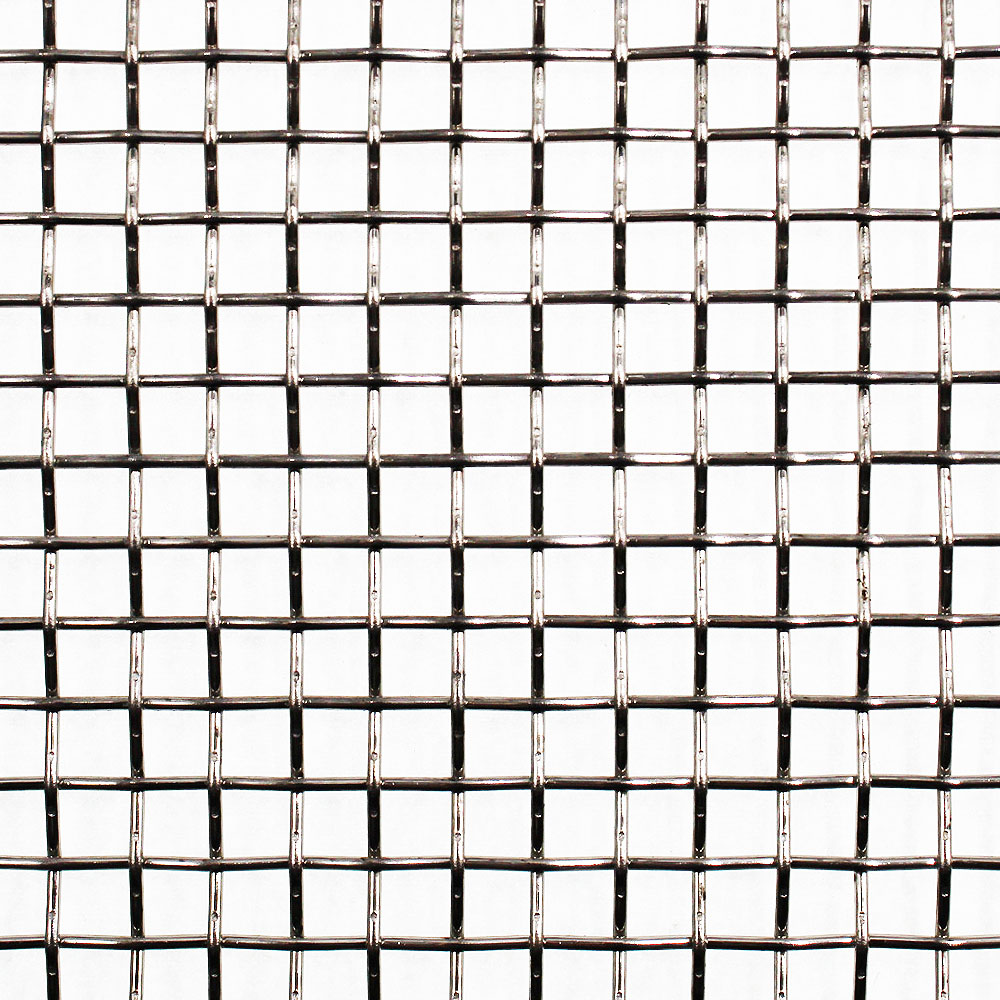

Stainless Steel: Composition and Properties

Chromium, an element found primarily in stainless steel, contributes to its corrosion resistance. When chromium reacts with oxygen, it forms chromium oxide, which protects the underlying metal. Despite scratches, the protective layer quickly reforms due to this self-healing property.

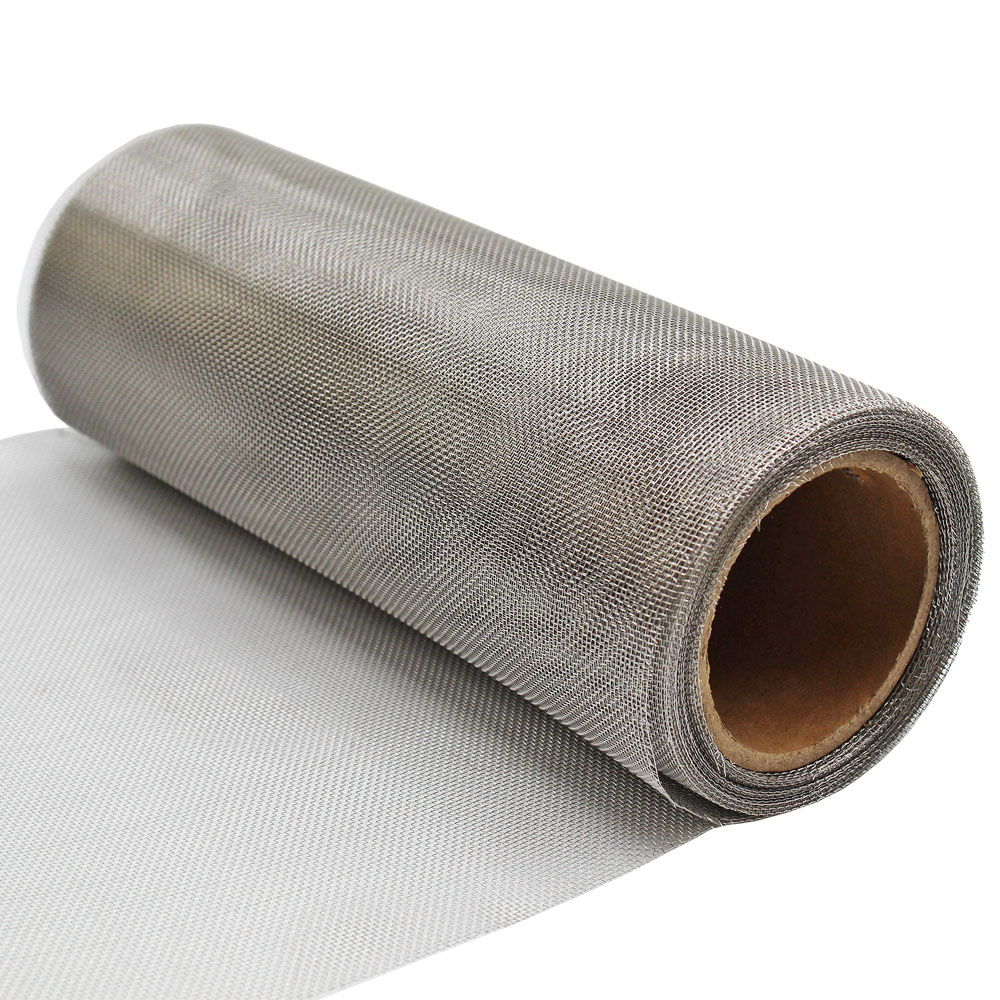

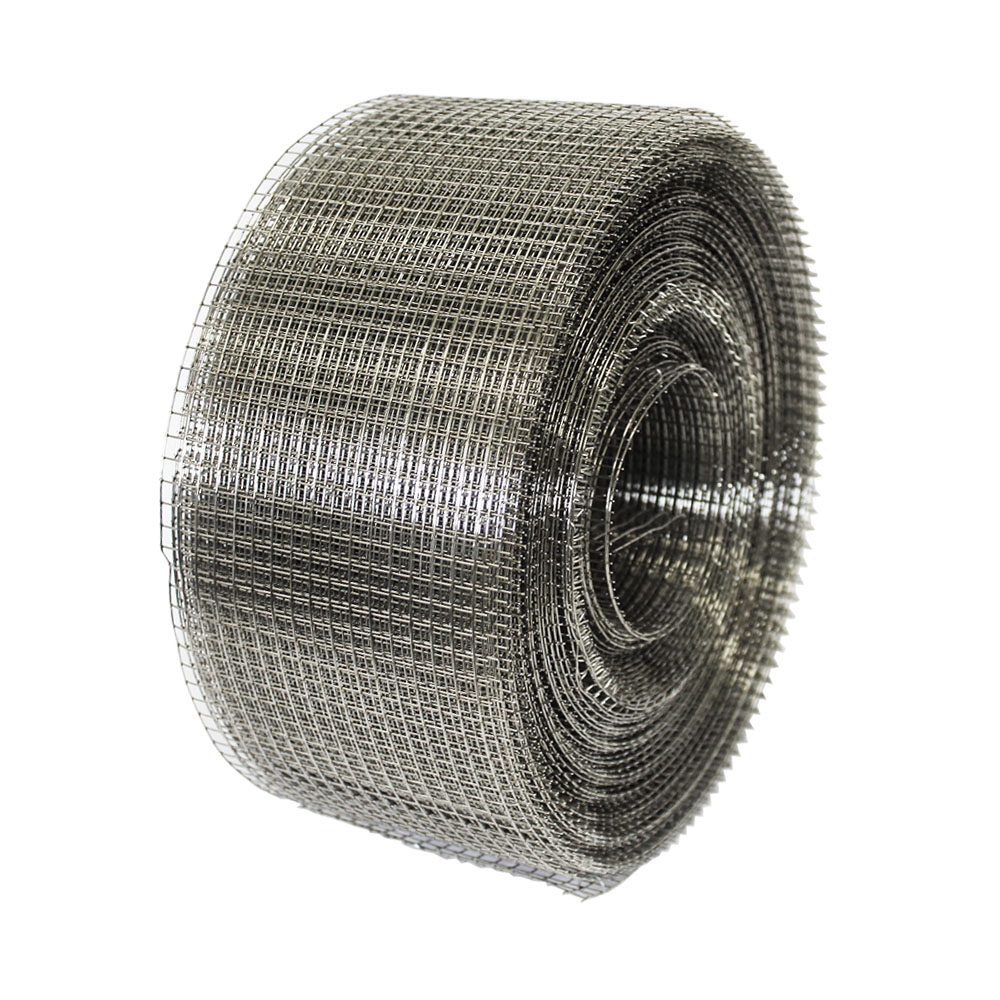

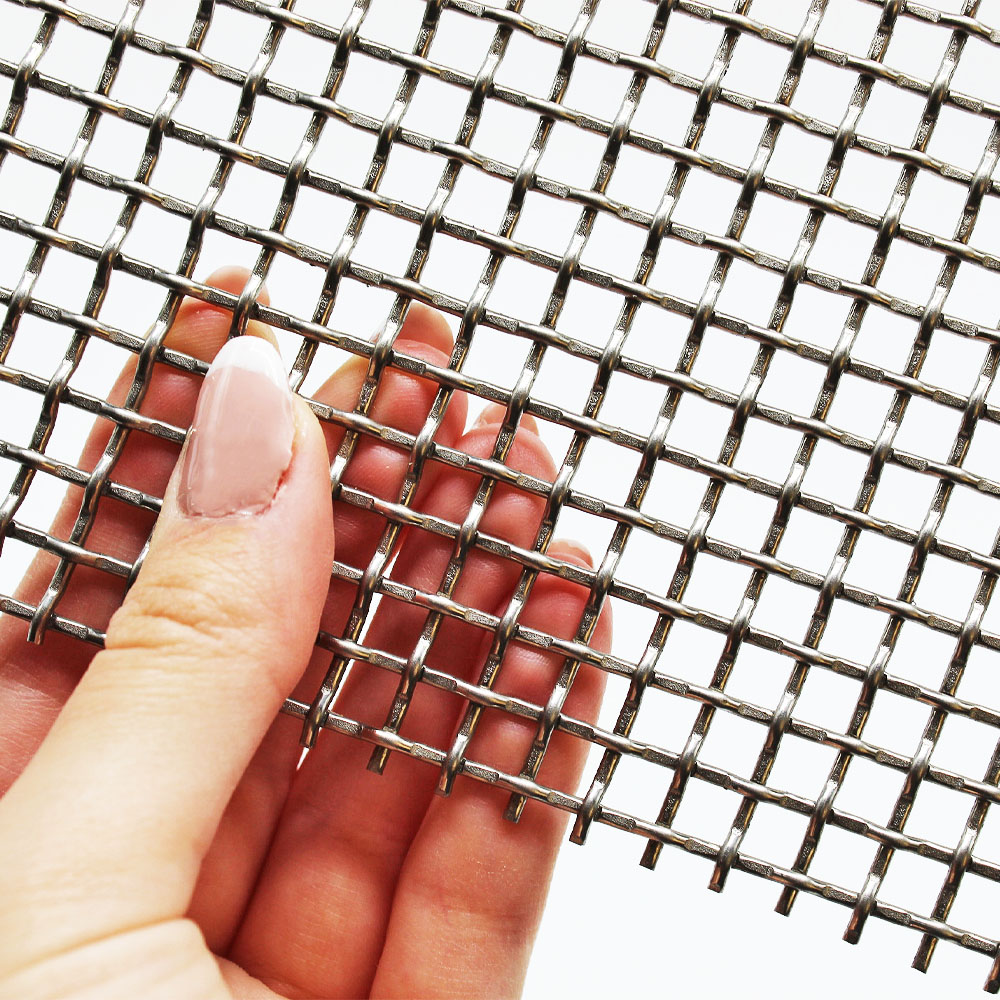

There are many grades of stainless steel available, such as 304 and 316, which offer varying degrees of corrosion resistance and strength.

Our woven mesh is also available in SS430, which is magnetic.

Aluminium: Composition and Properties

Aluminium is a lightweight and corrosion-resistant material that is used across a wide range of industries. As a result of its natural oxide film, further oxidation is prevented. Aluminium’s strength and corrosion resistance can be significantly enhanced when alloyed with copper, magnesium, and zinc. In particular, the 3000 and 5000 series are noted for their good balance of durability and corrosion resistance.

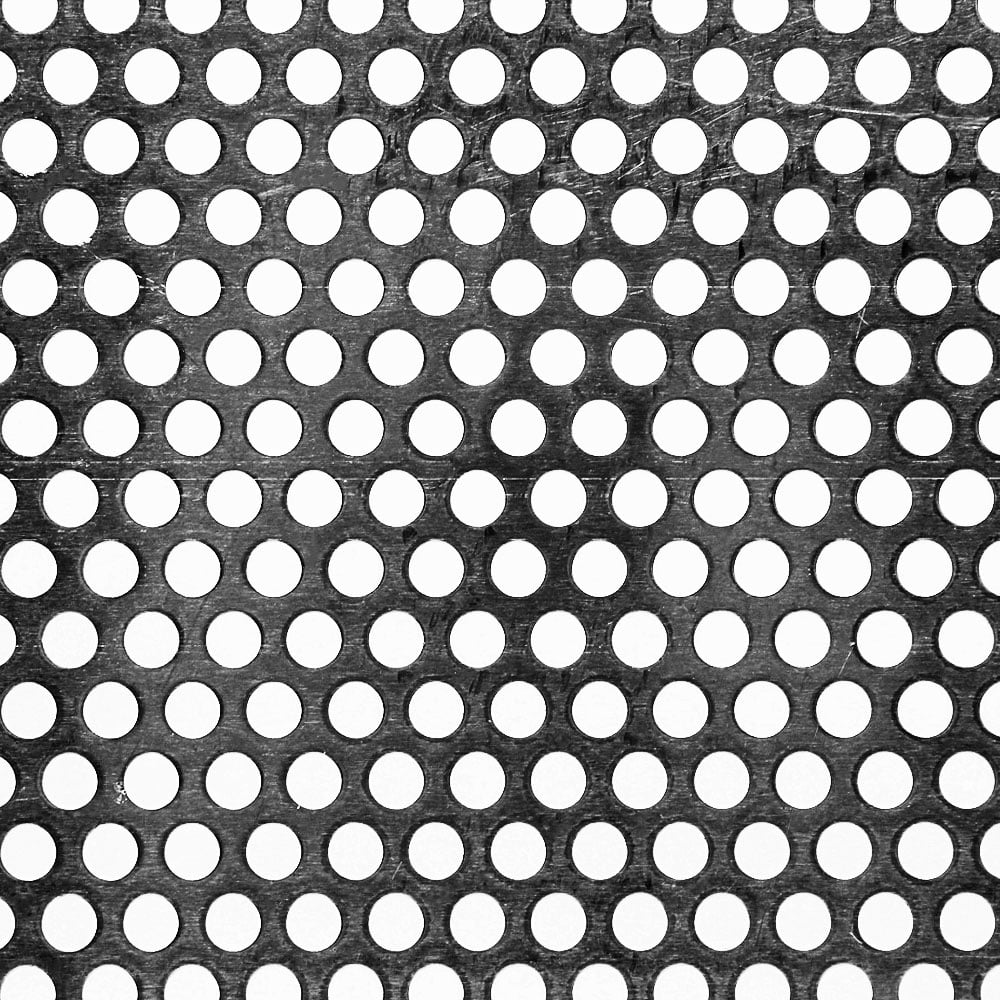

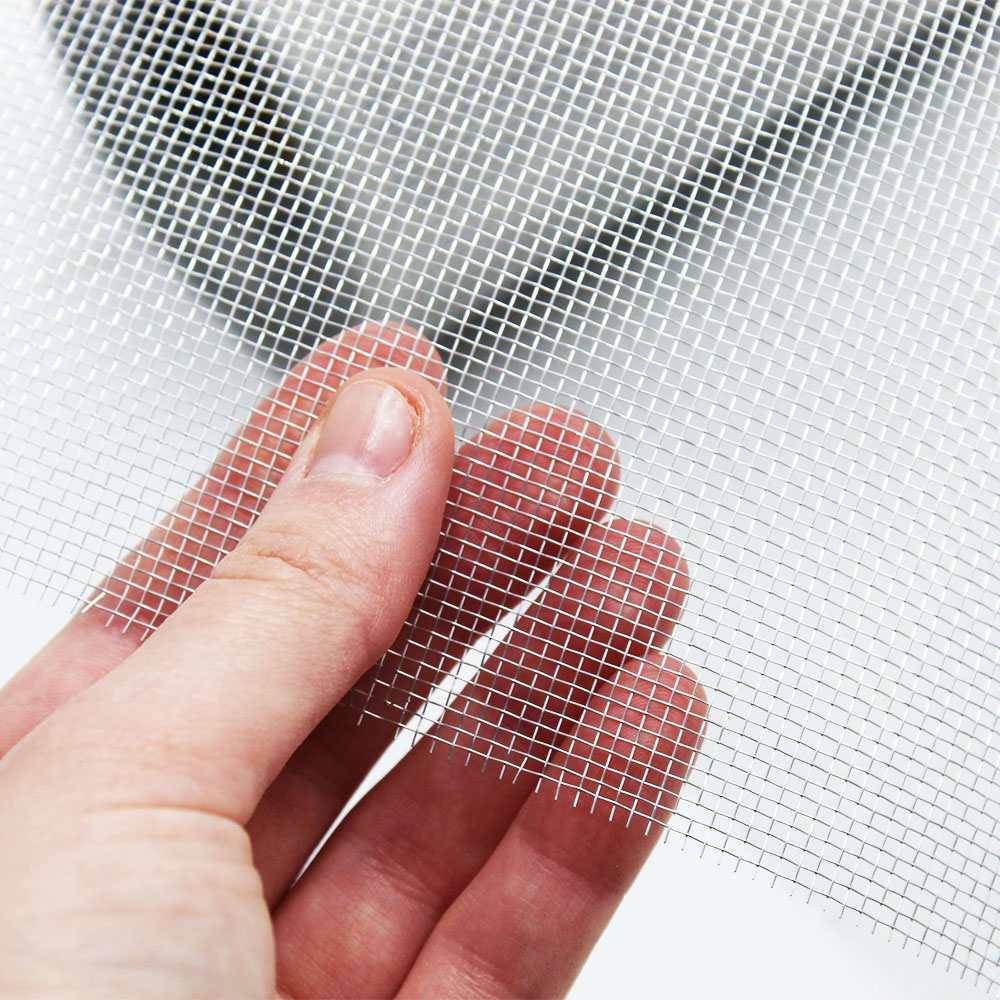

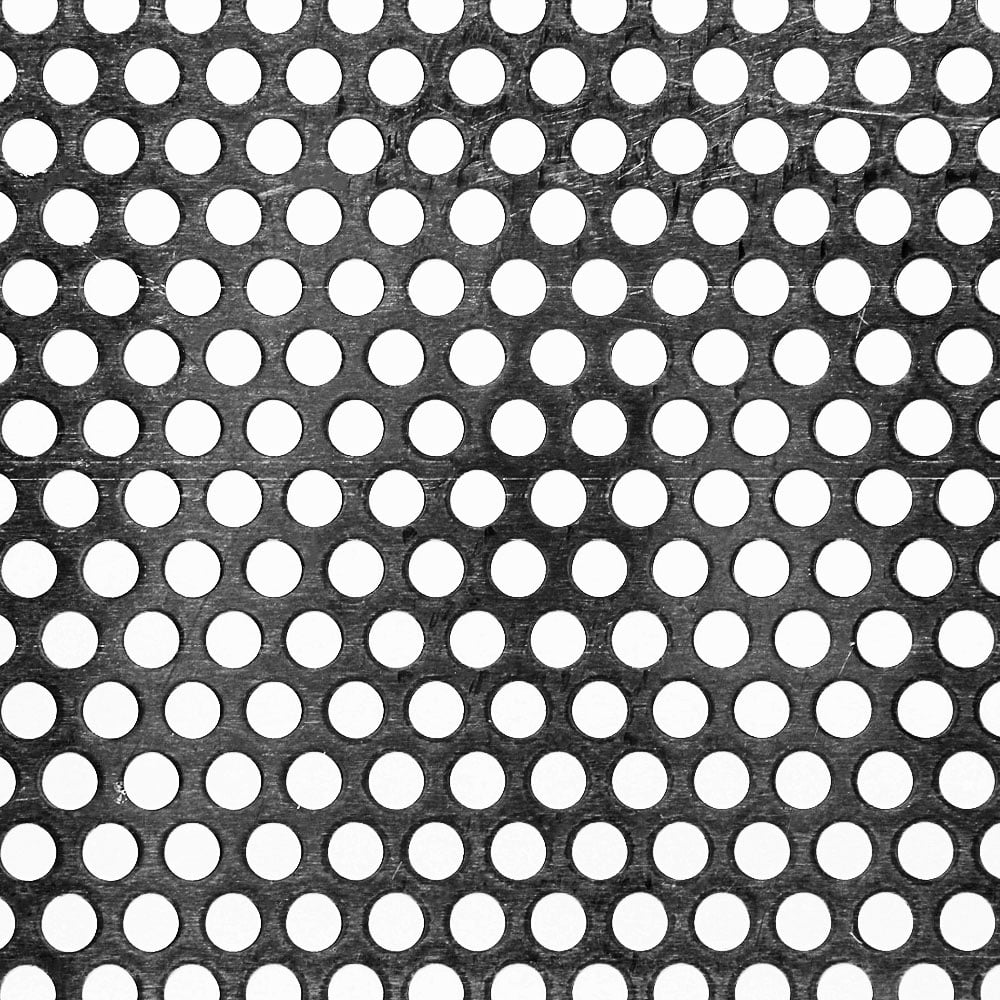

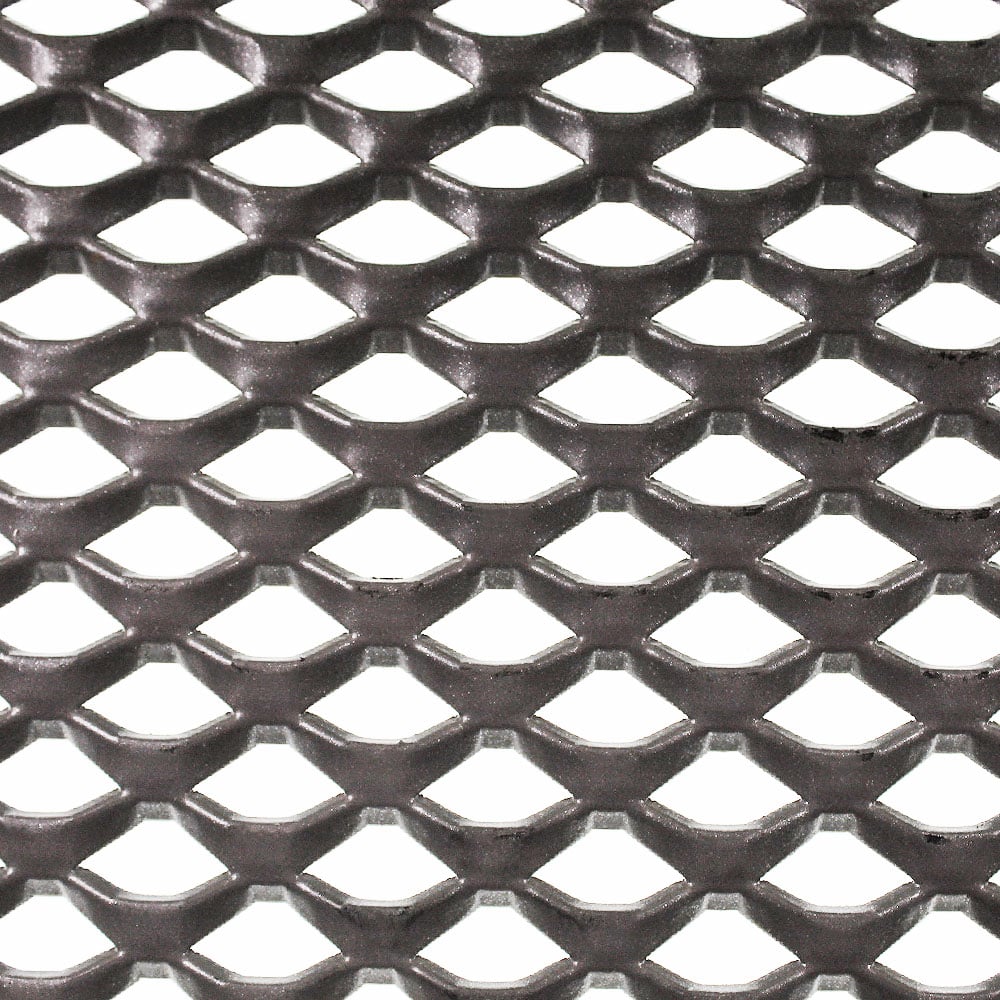

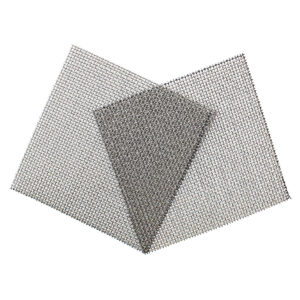

We offer aluminium in woven wire mesh for insect screening and also as perforated metal.

Here’s a table summarising the key points of comparison between stainless steel and aluminium in terms of corrosion resistance:

| Aspect | Stainless Steel | Aluminium |

|---|---|---|

| Corrosion Resistance | High resistance due to chromium oxide layer, making it suitable for harsh environments. | Natural oxide film provides good resistance; however, it’s more susceptible to galvanic corrosion when in contact with dissimilar metals. |

| Ideal Environments | Marine settings, areas with high chloride exposure, and other corrosive environments. | Environments where weight is a critical factor and less corrosive conditions. |

| Applications | Infrastructure, medical devices, kitchenware, and any application requiring durability and high resistance to corrosion. | Aerospace, automotive, packaging industries, and applications requiring lightweight materials with respectable corrosion resistance. |

| Vulnerabilities | Can be costly and heavy, potentially over-engineered for applications not requiring extreme corrosion resistance. | More prone to galvanic corrosion, especially in contact with dissimilar metals, limiting use in certain chemical or marine environments without proper protection. |

| Considerations | Selection often depends on the need for durability and resistance to specific types of corrosion. | The choice may lean towards aluminium when reducing weight is crucial, despite potential concerns over galvanic corrosion. |

There are numerous fields in which stainless steel, enriched with chromium, is essential due to its outstanding corrosion resistance and durability. With its enduring beauty, it enhances landmarks such as New York’s Chrysler Building and St. Louis’s Gateway Arch. In healthcare, it’s vital for sterilisable surgical tools and implants, while the culinary world values its hygiene for utensils and appliances.

Additionally, its ability to withstand extreme conditions makes it indispensable for aerospace and automotive applications. Stainless steel plays a crucial role in applications that require longevity, cleanliness, and aesthetic appeal.

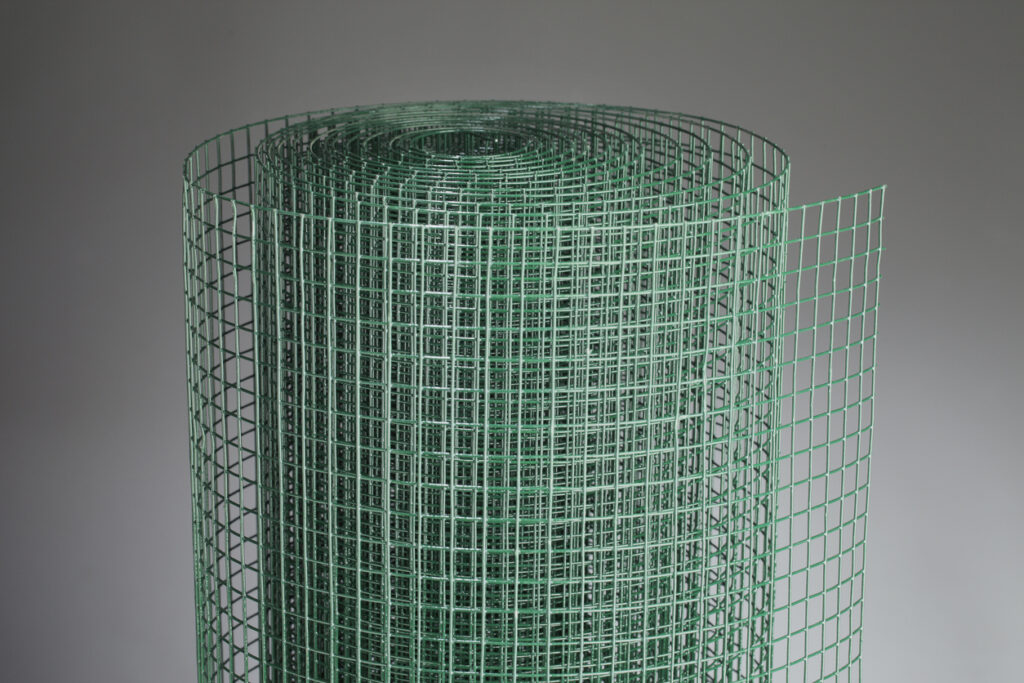

In terms of wire mesh, stainless steel is ideal for rodent control and insect screening outdoors.

Lightweight and corrosion-resistant, aluminium finds its place in sectors that value efficiency and sustainability. In the manufacturing of fuel-efficient vehicles and aircraft, as well as consumer electronics like smartphones, where its thermal properties and sleek aesthetics are crucial, this material plays a crucial role.

Aluminium enhances building designs with energy-efficient facades and window frames, while it offers excellent recyclability and protection in packaging, especially for beverage cans. Aluminium’s diverse applications demonstrate its role in driving innovation and environmental stewardship.

Stainless Steel

Aluminium

It is best practise to clean stainless steel and aluminium regularly to prevent contaminants from breaching the protective oxide layers.

Further, aluminium products can benefit from protective coatings, while stainless steel can benefit from periodic passivation treatments to enhance its chromium oxide layer.

Stainless steel and aluminium both offer distinctive aesthetic appeals that cater to a variety of design preferences and applications. In addition to its sleek, sophisticated appearance, it features a brilliant shine that exudes luxury. High-end appliances, architectural elements, and anywhere a premium look is desired benefit from its ability to be polished to a high gloss.

Aluminium presents a softer, matte finish with a contemporary, industrial vibe, making it an ideal choice for consumer electronics, automotive parts, and modern furniture.

Anodising aluminium adds color and enhances durability, while stainless steel requires frequent maintenance to prevent fingerprints and smudges.

In the end, choosing between stainless steel and aluminium depends on the design’s aesthetic and functional requirements, with each material bringing its own unique characteristics that complement the envisioned space or product.

Stainless steel and aluminium both exhibit significant environmental impacts from production to end-of-life, yet their high recyclability and specific use-phase advantages present a nuanced picture of their sustainability.

Both metals require energy-intensive production processes, with stainless steel requiring the combination of several elements and aluminium requiring electrolysis for extraction from bauxite ore. By reducing the demand for virgin resources, recycled materials help mitigate these impacts.

Stainless steel’s durability and corrosion resistance prolong its lifespan, reducing environmental damage over time, while aluminium’s lightweight nature enhances energy efficiency, especially in transportation, lowering fuel consumption and emissions.

In addition to their exceptional recyclability, both materials can be reused indefinitely without degradation in quality.

In terms of corrosion resistance, aesthetics, and environmental impact, stainless steel and aluminium each have distinct advantages.

Due to its lightweight nature and corrosion resistance, aluminium is ideal for applications where weight reduction is crucial without severely compromising durability. With stainless steel’s sleek, luxurious finish and aluminium’s modern, industrial appearance, both materials offer a variety of design options. Environmentally, their high recyclability offsets the energy-intensive production processes, though aluminium stands out for its contribution to energy efficiency in use-phase applications.

In the end, choosing between stainless steel and aluminium depends on a holistic assessment of their performance across all of the criteria in the article.

We hope that this has been of help for you in the quest for the perfect mesh for your next project.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores using mesh by Understanding Woven Wire Mesh Sizes.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions