It is crucial to select the right woven wire mesh for sieving applications if you wish to achieve efficient and accurate particle separation.

It is very important to understand the key factors to consider when choosing mesh sizes, materials, and weave patterns since there are many options available. In this comprehensive guide, we will walk you through everything you need to know to make an informed decision and achieve optimal results in your sieving process.

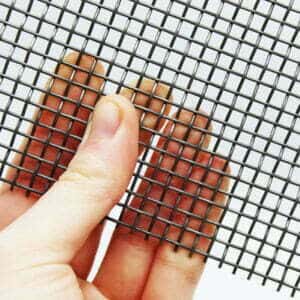

Determining the particle size range: Consider the size of the particles you need to separate and the mesh opening size based on the size of the particles.

Define the required throughput: Assess the volume of material that needs to be processed within a given time frame.

Consider the desired level of accuracy: It is important to determine the level of precision that your application requires.

Conduct preliminary tests with small quantities of material to gauge the actual sieving rate achievable with the chosen mesh and equipment. Adjust the desired throughput accordingly based on the results obtained during the trials.

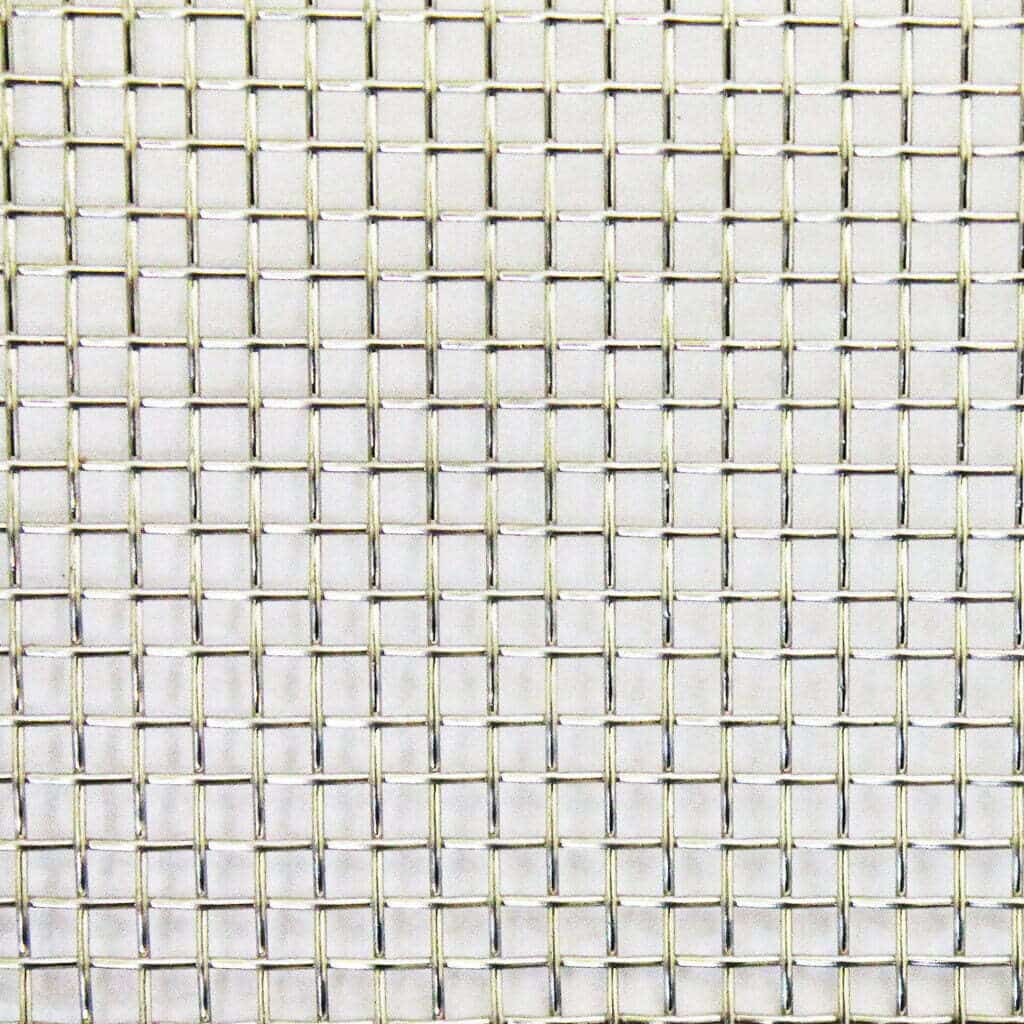

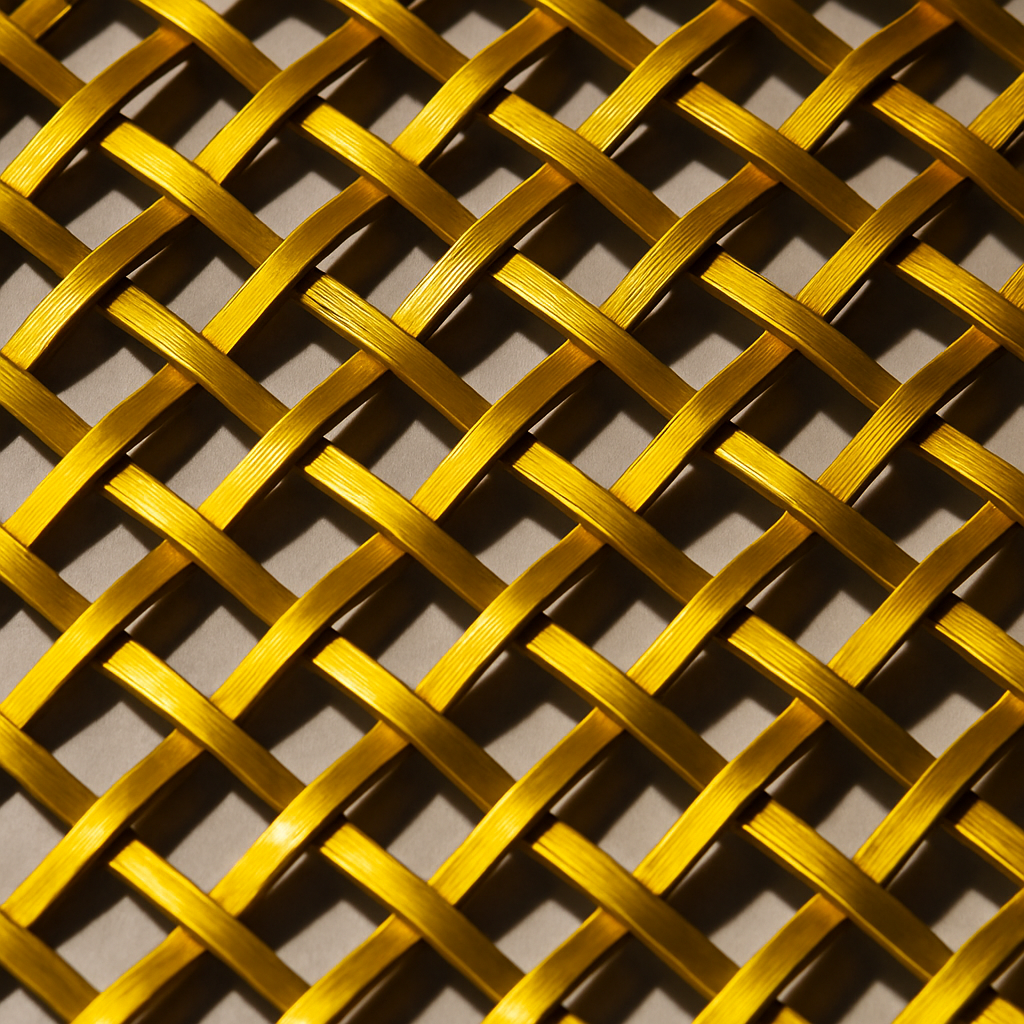

The Mesh Company specialises in many forms and metals of woven wire mesh. The main being:

There are many other options. Depending on specific requirements, materials like bronze, aluminum, or nylon can be considered.

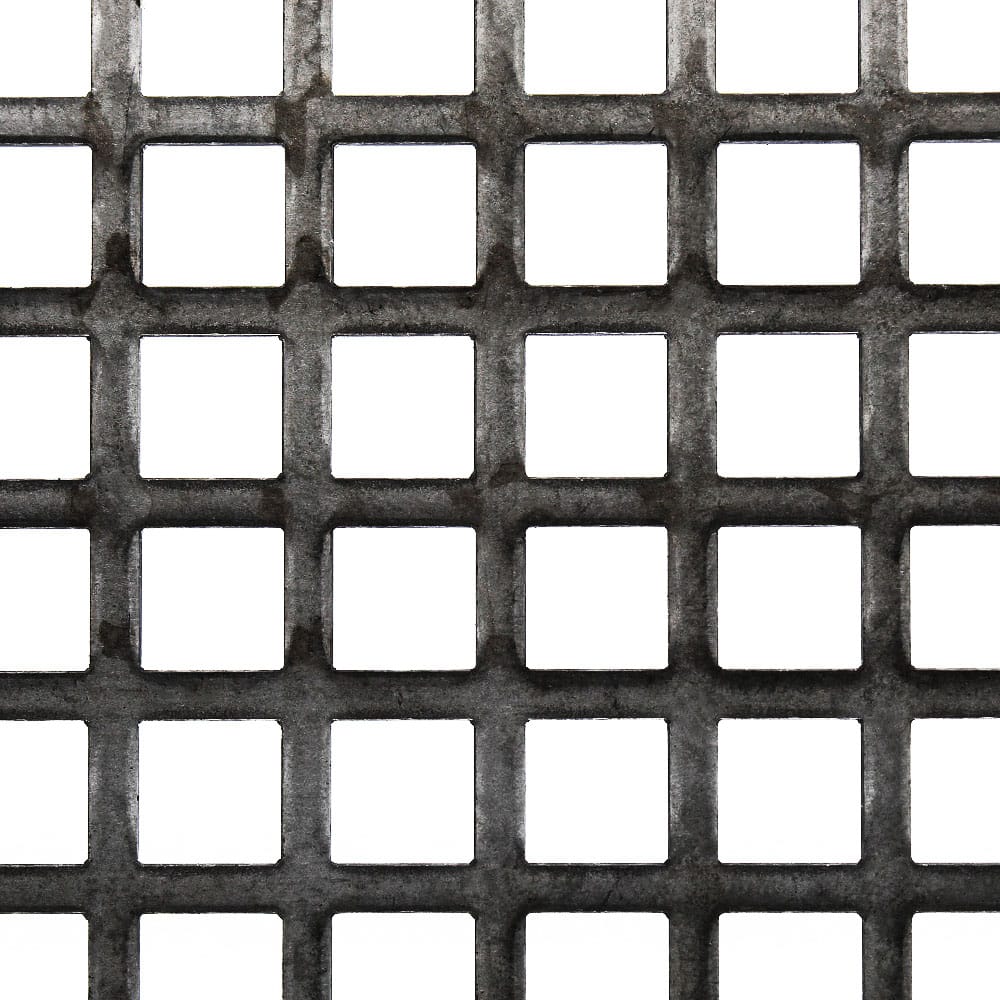

We also offer a massive range of perforated metal mesh options. This includes many hole sizes and metal options.

Additionally, the open area percentage of perforated metal mesh can be tailored to specific sieving requirements. By adjusting the size, shape, and spacing of the holes, the open area can be optimised to achieve the desired sieving efficiency. This flexibility makes perforated metal mesh suitable for a wide range of applications, from coarse sieving to fine particle separation.

It is important to consider environmental factors such as temperature, humidity, and the amount of corrosive substances in the environment when selecting a wire mesh. As a result of these factors, the mesh material that is most suitable for the particular operating conditions will be determined. In addition, it is crucial to consider industry-specific requirements since different industries have their own set of standards and regulations that must be adhered to. Ensuring compliance with these standards and regulations is essential when choosing the appropriate wire mesh for your application.

In the world of sieving applications, choosing the right wire mesh is crucial for optimal performance. One important aspect to consider is the cleaning requirements of the mesh. Evaluate whether the mesh needs to be removed for thorough cleaning or if it can be cleaned in place. Understanding the cleaning process will ensure proper maintenance and longevity of the wire mesh.

Additionally, it is essential to follow recommended cleaning procedures to avoid damaging the wire mesh. Different meshes may have specific cleaning instructions to maintain their integrity and effectiveness. By adhering to these procedures, you can ensure that the wire mesh remains in optimal condition for accurate sieving results.

Taking into account the cleaning requirements and following proper cleaning procedures are essential steps in selecting and maintaining woven wire mesh for sieving applications. These practices will contribute to the longevity and efficiency of the mesh, allowing for reliable and accurate sieving in various industrial settings.

In selecting the right woven wire mesh to use for sieving applications, there are a number of factors to consider, including particle size, mesh material, weave pattern, as well as application-specific requirements. As long as you understand these key elements, you will be able to make an informed decision and optimise your sieving process so that it is efficient and accurate. To ensure reliable and consistent results in your sieving applications, it is imperative that you choose reputable suppliers and prioritise high-quality mesh.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions