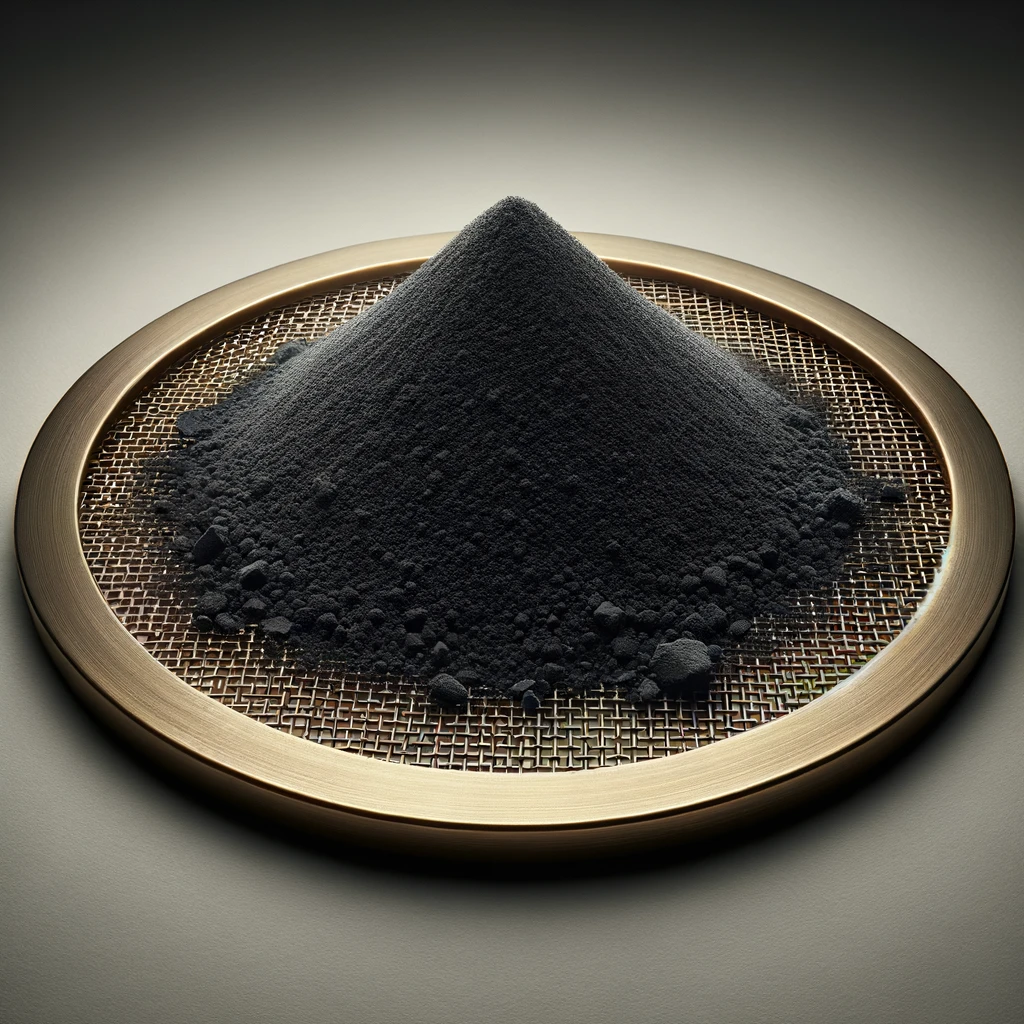

When it comes to filtration, the choice of material is just as important as the technology used. The phosphor bronze alloy has a remarkable combination of durability, corrosion resistance, and elasticity, making it ideal for wire mesh applications, especially fine powder filtration. This alloy, primarily composed of copper with tin and phosphorus additives, offers a balance between strength and malleability, making it ideal for crafting wire mesh with precise filtration properties.

Various industries utilise phosphor bronze wire mesh, from pharmaceuticals and food processing to chemical manufacturing and environmental science. With the wide range of mesh sizes available, from 1.29mm holes to ultra-fine 0.062mm holes, phosphor bronze mesh can meet diverse filtration requirements.

By exploring the suitability of each mesh size for fine powder filtration, this article provides insight into how phosphor bronze wire mesh can enhance filtration processes in a variety of applications.

Let’s go…

The inherent material properties of phosphor bronze make it valuable for filtration applications. Due to its durability, it offers a robust solution for filtration systems that require longevity and durability. In applications involving vibration or continuous flow, fatigue resistance ensures the mesh can withstand repeated cycles of stress without compromising its structural integrity.

Another important property of phosphor bronze is its corrosion resistance, which makes it ideal for environments prone to chemical exposure or moisture. Having this characteristic is particularly useful in industries where the mesh may come into contact with corrosive substances or may have to perform under varying pH levels without deteriorating.

The elasticity of phosphor bronze is often overlooked. The mesh maintains its shape and aperture size under stress, ensuring consistent filtration. When fitted into frames or fixtures, the mesh’s elasticity facilitates installation and handling, as it can slightly deform without breaking.

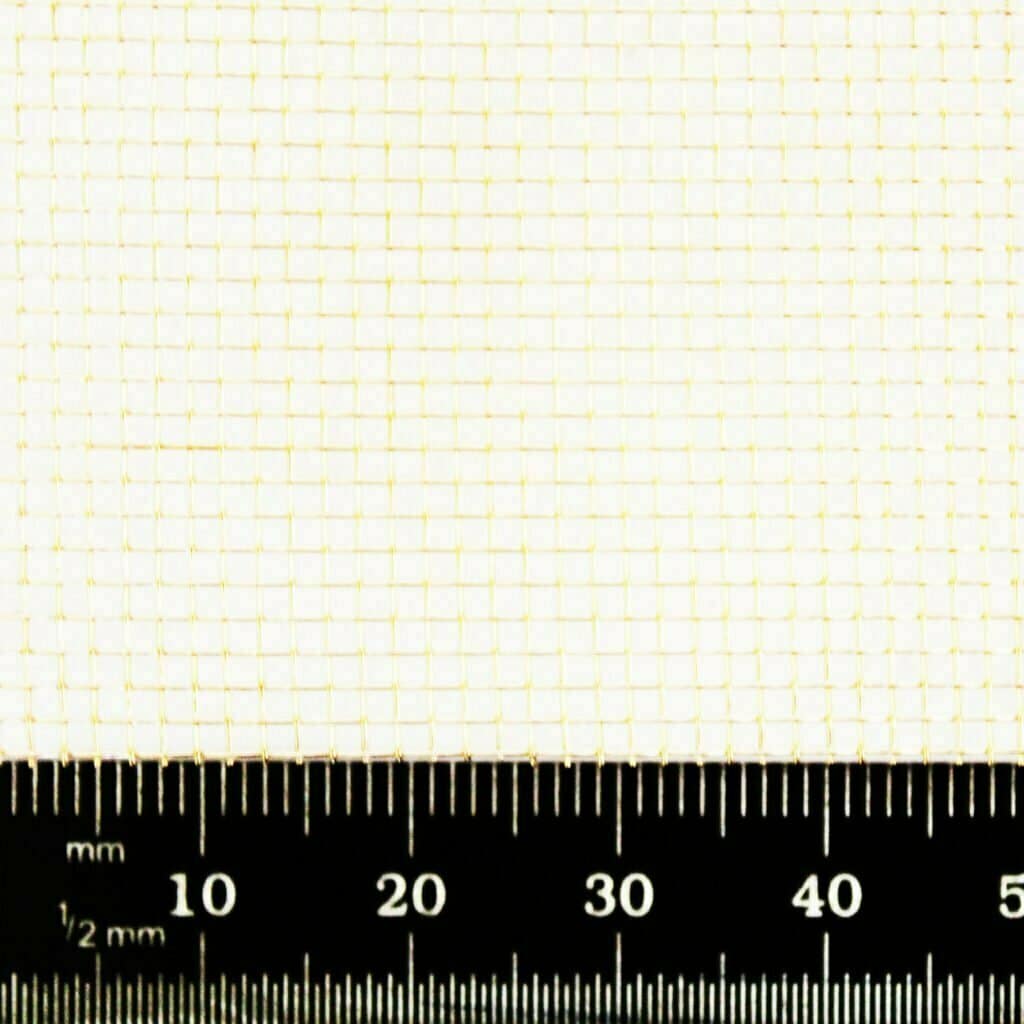

A mesh’s filtration efficiency is determined by its weave density and wire diameter. With a finer wire diameter, a higher density weave can capture smaller particles, making it suitable for ultra-fine filtration. On the other hand, a looser weave with a thicker wire diameter may be used for coarser filtration, which requires greater particle retention and higher flow rates. Phosphor bronze mesh is produced by selecting the weave density and wire diameter based on the filtration requirements of the application, balancing particle retention with flow restriction requirements.

Due to its durability, resistance to fatigue, corrosion resistance, elasticity, and precise control over mesh specifications, phosphor bronze wire mesh is an excellent choice for fine powder filtration. Phosphor bronze wire mesh has the reliability and performance that few other materials can match, whether it is used to retain ultrafine particulate matter or to process materials efficiently in harsh chemical environments.

1.29mm Hole – 0.3mm Wire – 16 LPI

It is designed for coarser filtration processes where the primary objective is to separate larger particulates. Due to its relatively large aperture size, it is ideal for applications in agriculture, food, and beverage, and even construction and landscaping for soil sifting. While larger particles are efficiently retained, the 1.29mm hole size ensures that there is minimal flow resistance, making it suitable for processes that require moderate filtration and high throughput.

0.144mm Hole – 0.11mm Wire – 100 LPI

This mesh size is used in industries where precision is a must. In pharmaceutical manufacturing, it is used for filtration of excipients and active pharmaceutical ingredients, ensuring purity and consistency. In food processing, it removes fine impurities from liquids and powders, such as when milling flour or producing high-quality beverages, where safety and clarity are paramount.

0.106mm Hole – 0.063mm Wire – 150 LPI

This mesh size lends itself to a wide range of applications, from industrial filtration to environmental testing where precision and reliability are essential. The fact that it can withstand harsh conditions while providing fine filtration makes it a popular choice for water treatment processes, air quality monitoring, and even in the aerospace industry for various filtration applications.

0.077mm Hole – 0.05mm Wire – 200 LPI

This mesh size provides a balance between filtration efficiency and airflow, making it ideal for applications requiring both fine filtration and ventilation. In HVAC systems for industrial facilities where air quality control is crucial, or in automotive systems for filtering air to engines and cabins, its versatility is evident. Despite providing an effective barrier against fine particulates, the mesh allows for free airflow.

0.062mm Hole – 0.04mm Wire – 250 LPI

A mesh size of this size is ideal for ultra-fine filtration, such as in chemical processing or specialised laboratory research. Its ability to filter out minute particles makes it indispensable for processes involving fine chemicals, where contamination control is crucial. Additionally, this mesh can be used in laboratory settings for particle size analysis and other precision-dependent tasks, ensuring that experiments are meticulously controlled.

Phosphor bronze wire mesh size selection is a nuanced process that requires careful consideration of several factors. It is the particle size of the powders to be filtered that determines whether a coarser or finer mesh is required. Additionally, mesh sizes that offer finer filtration may reduce throughput, depending on the desired flow rate. For filtration to be successful, the mesh must be strong enough to withstand the pressures and conditions of the process.

In order to determine the best mesh size for a particular application, testing and evaluation are essential steps. In order to balance filtration efficiency, flow rate, and durability, pilot-scale tests can provide insight into the performance of different mesh sizes under actual operating conditions. The selection process can be further refined by consulting with experts in filtration and material science, who can ensure that the chosen phosphor bronze wire mesh size is optimal for the task at hand.

This detailed examination of each standard mesh size further underscores the importance of precise selection to meet specific filtration challenges, making sure that each application gets optimal performance as well as longevity and durability from phosphor bronze.

With its durability, corrosion resistance, and suitability for fine powder filtration, phosphor bronze is an invaluable resource in processes where purity, precision, and reliability are crucial. For coarser separations in agriculture, fine particle removal in pharmaceutical manufacturing, or ultra-fine filtration in chemical processing, phosphor bronze wire mesh offers tailored solutions.

In conclusion, the journey through phosphor bronze wire mesh highlights a path to achieving unparalleled filtration results. Experts can offer personalised recommendations and insights, ensuring that phosphor bronze wire mesh is successfully integrated into your system.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores woven filter mesh in general or using fine brass mesh as an oil filter.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.