We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies. Cookie Policy

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site....

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

This cookie stores your consent preferences for cookies on this website.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyse the key performance indexes of the website which helps in delivering a better user experience for the visitors.

This cookie is used by Google Analytics and distinguishes unique visitors on the website.

This cookie is used by Google Analytics to track visitor activities on the website.

This cookie is used by Google Analytics and stores a unique value for each page visited and tracks page views.

This cookie is used by Google Analytics and tracks a visitors session.

Advertisement cookies are used to provide visitors with customised advertisements based on the pages you visited previously and to analyse the effectiveness of the ad campaigns.

This cookie is used by Doubleclick and contains information about a visitor's past visit to other websites that have advertisements from Doubleclick.

This cookie is used by Google AdSense for experimenting with efficiency across websites that use Google Ads.

This cookie is used by DoubleClick to check if a visitor's browser supports cookies.

Copper woven wire mesh welding is a skilled and nuanced task.

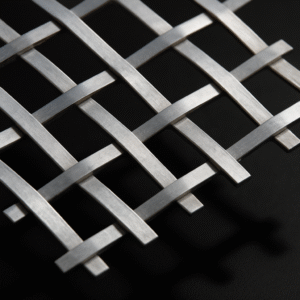

Copper mesh, with its distinct combination of flexibility, durability, and aesthetic appeal, has carved a niche for itself in various industries. From ornate designs in architecture to its crucial role in electronics due to its electromagnetic shielding capabilities, its applications are vast.

Yet, welding this material can be a daunting task for many due to the unique properties of copper. This guide aims to provide a comprehensive overview to help enthusiasts and professionals alike master the art of welding copper woven wire mesh.

Let’s get into it…..

Before even picking up your welding tools, a thorough understanding of copper’s inherent characteristics is essential.

Different projects may necessitate different welding techniques. For copper woven wire mesh, two methods are predominantly used:

For beginners, starting with TIG might be advisable due to its precision, allowing for a better understanding of how copper reacts during the welding process.

The importance of preparation can’t be stressed enough. Given copper’s tendency to oxidize, ensuring a clean surface is paramount for a successful weld.

Welding, while fulfilling, can be dangerous if done carelessly.

Whether you’re using TIG or MIG, setting up your welder correctly is vital.

With everything set up, it’s time to weld.

Like any skill, mastering the welding of copper woven wire mesh takes time. Practice on scrap pieces before moving on to your main project. With patience and consistent effort, the intricacies of welding this unique material will soon become second nature.

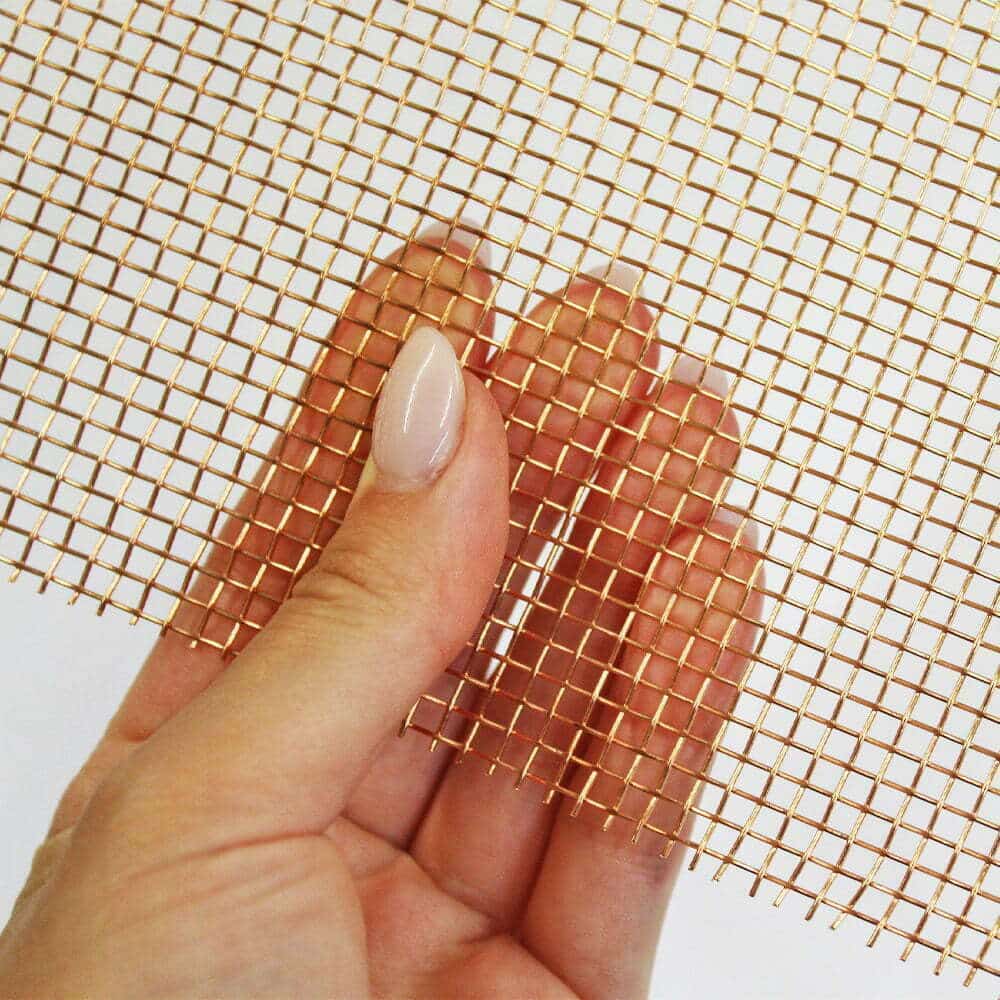

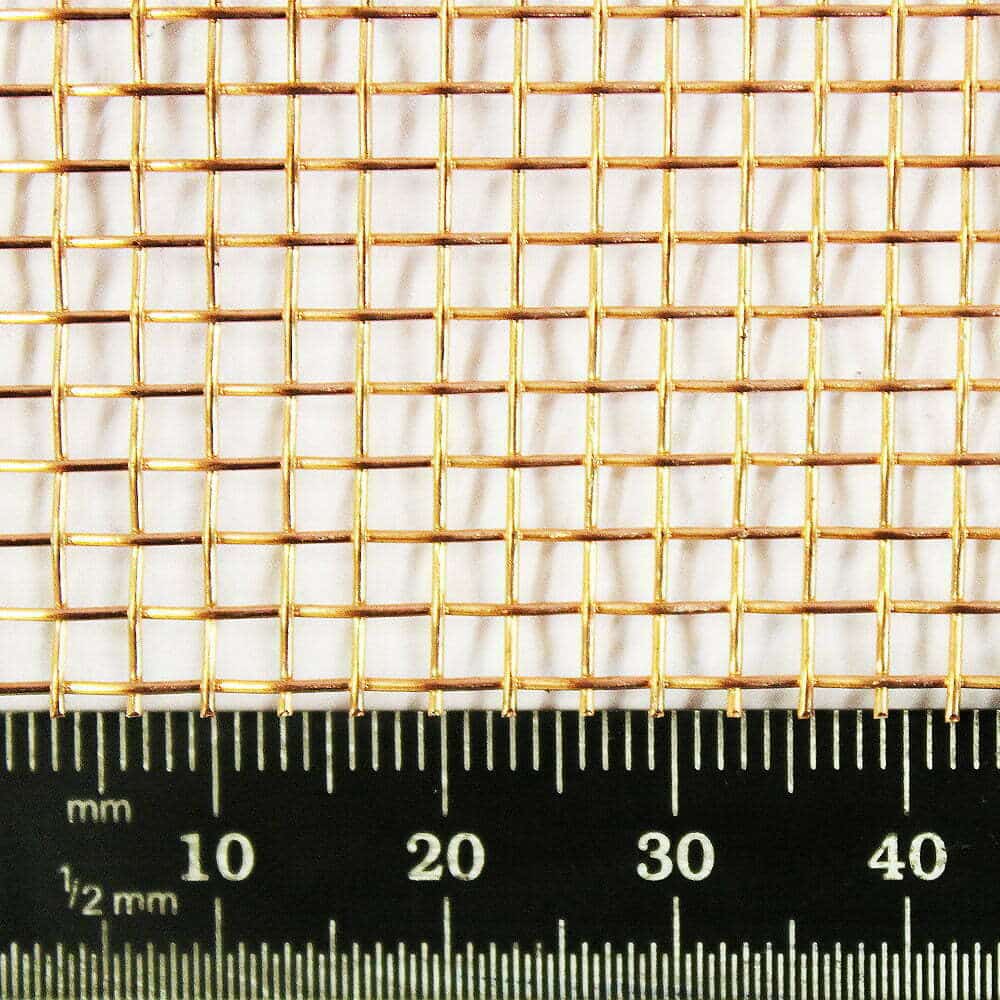

The 8 mesh x 0.63mm copper mesh strikes a balance between durability and finesse, making it an excellent choice for rodent screening. Its tight weave ensures rodents cannot penetrate, while its malleability allows for easy installation around even complex structures. Beyond pest control, this mesh’s conductive properties make it highly effective for RFI (Radio Frequency Interference) shielding, protecting electronic devices from unwanted radio wave disturbances and ensuring smoother device operation.

This mesh would be weldable using the techniques outlined above.

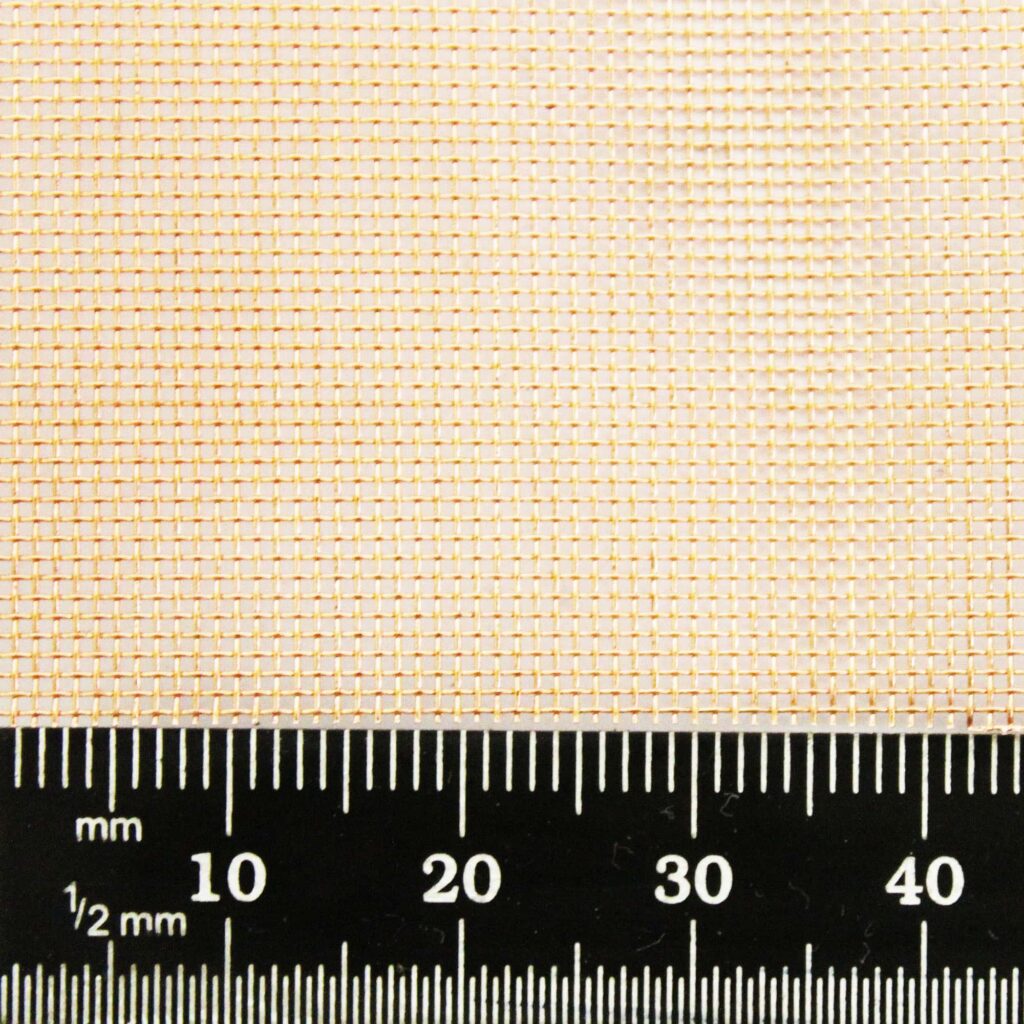

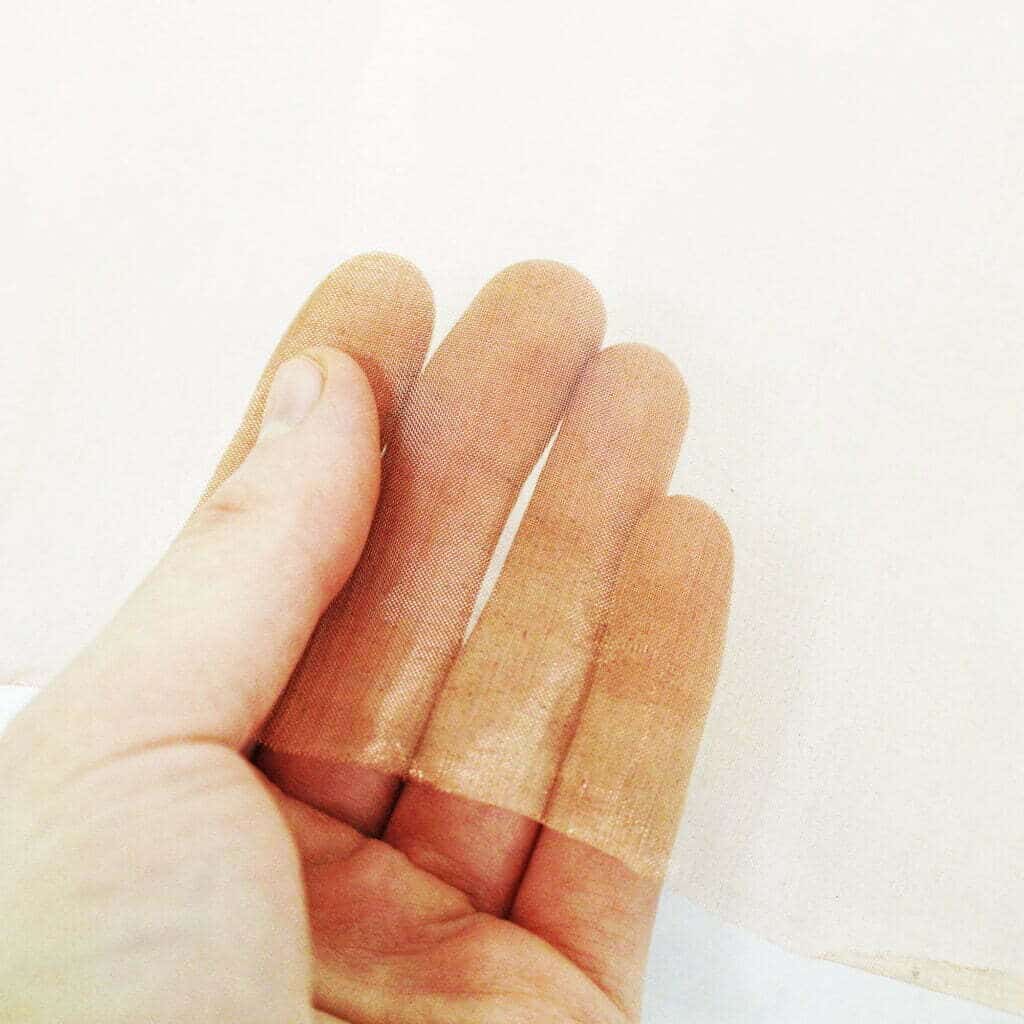

When it comes to copper mesh as fine as cloth, the welding process demands an even more meticulous approach. This mesh type is incredibly delicate, easily comparable to fabric in its flexibility and fineness.

Remember, patience is crucial. Working with ultra-fine copper mesh can be challenging, but with attention to detail and the right technique, you’ll achieve a seamless finish.

Welding copper woven wire mesh, while challenging, is immensely rewarding. By understanding the material, choosing the right welding method, and practicing the correct techniques, you can achieve strong and visually appealing welds every time.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

Please feel free to contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

Reach Out

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions