Gardening is an art that balances aesthetics and functionality. An integral aspect of this balance is ensuring that our plants are safe from pests and external factors. Enter: garden netting.

The kind of netting material you choose can dramatically affect your garden’s well-being. This article will provide an in-depth comparison of different garden netting materials, highlighting the pros and cons of each, to help you make an informed decision.

Let’s get into it….

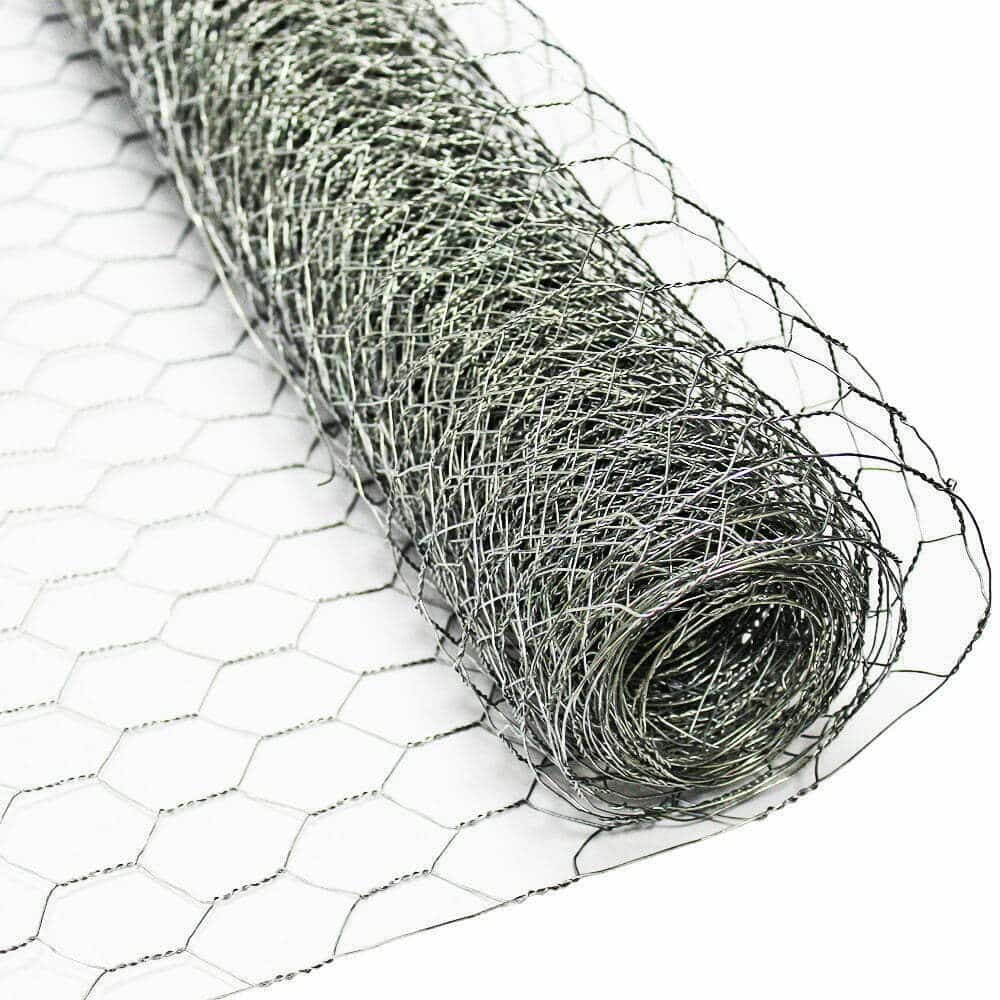

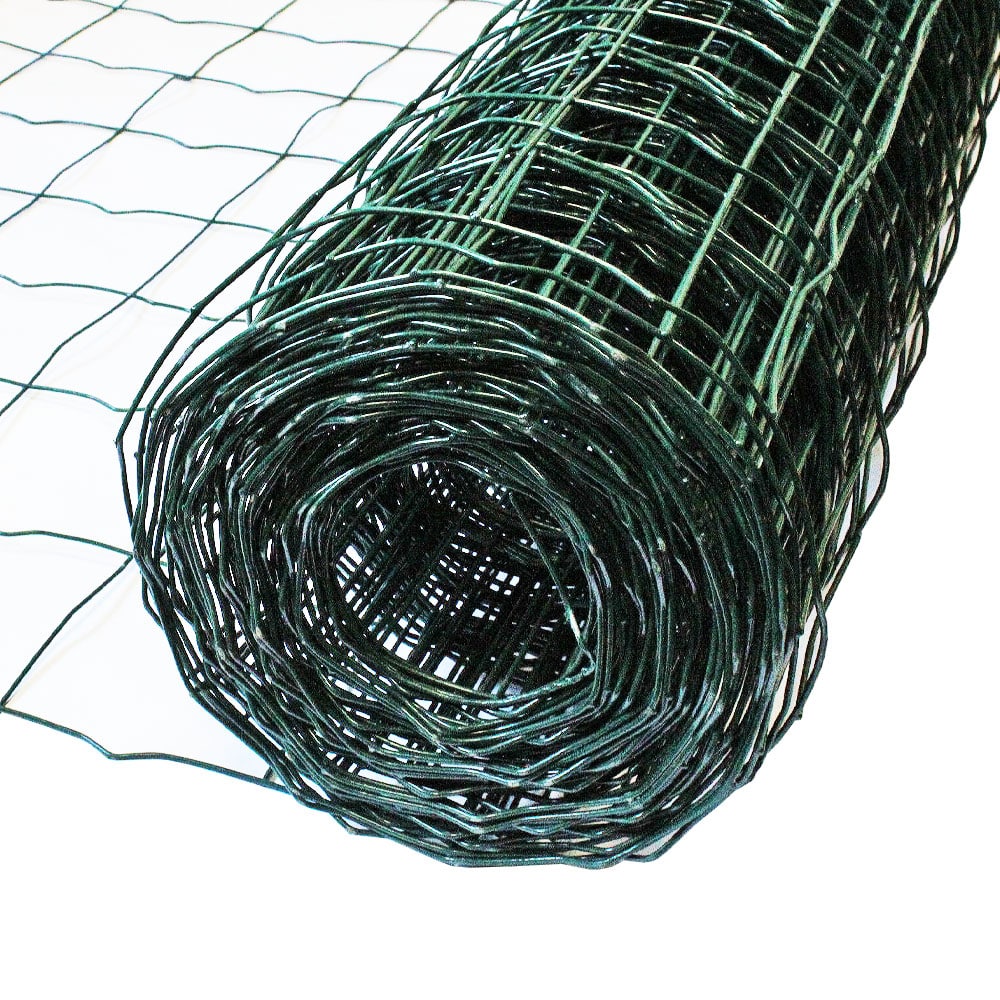

Originally designed to keep hens at bay, chicken wire mesh has now become synonymous with garden protection. Indeed we recently wrote an entire article on using chicken wire in an urban setting.

Advantages:

Versatility: One of the primary advantages of chicken wire is its flexibility. It can be moulded into any shape, making it ideal for uneven gardens or irregular spaces.

Durability: Made of galvanised steel, chicken wire is resistant to rust and corrosion, ensuring a long life in various weather conditions.

Pest Control: The hexagonal openings in chicken wire mesh are perfect for keeping out rabbits, deer, and other garden pests.

Disadvantages:

The chicken wire mesh has a characteristic hexagonal pattern and is made from thin galvanized steel wire. Initially, the wire is fed into a machine that pulls it taut. In parallel, this machine weaves or twists the wire into the familiar hexagonal pattern. The gaps, or “mesh size,” can be adjusted based on the desired specification. Often, the wire is galvanised after weaving, which involves coating it with zinc after it has been woven. As a result, the wire is protected from rusting, thus extending its lifespan. In the case of chicken wire mesh coated with PVC, the wire must be immersed in molten PVC or another coating material to ensure an even protective layer that can also add color.

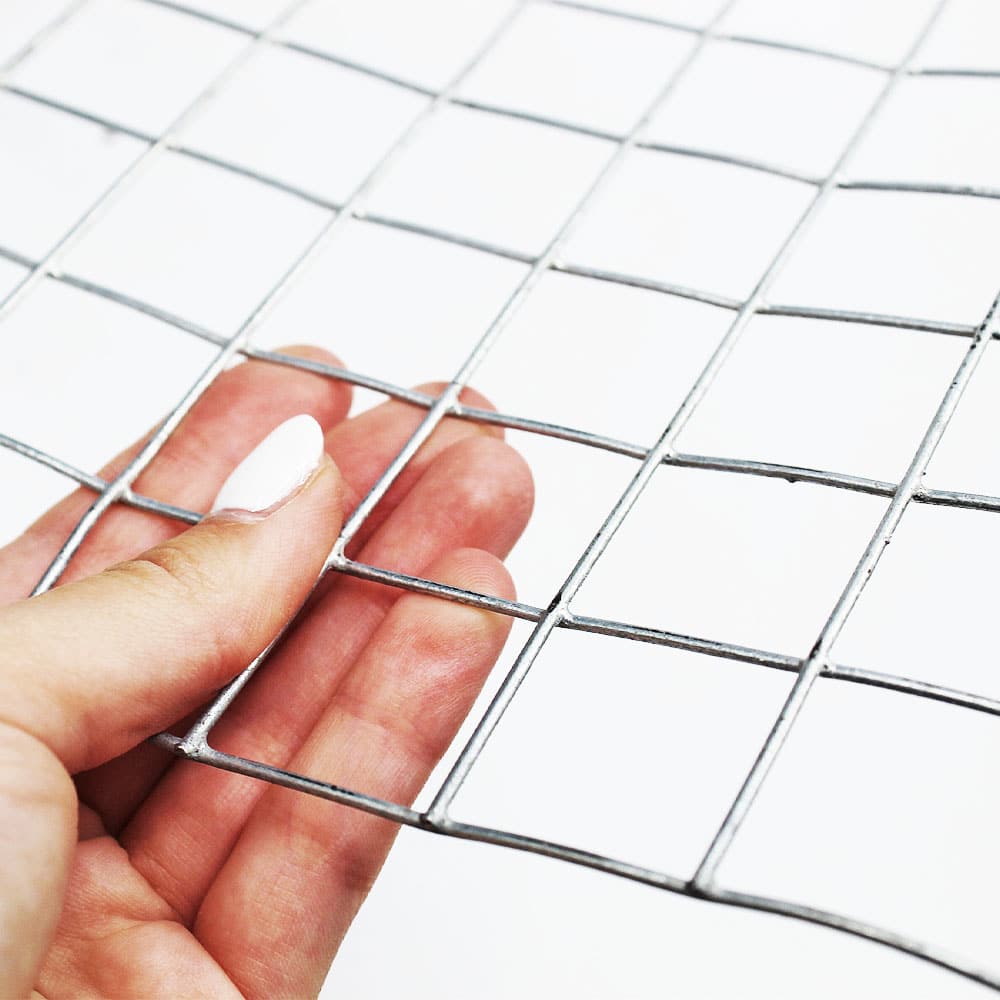

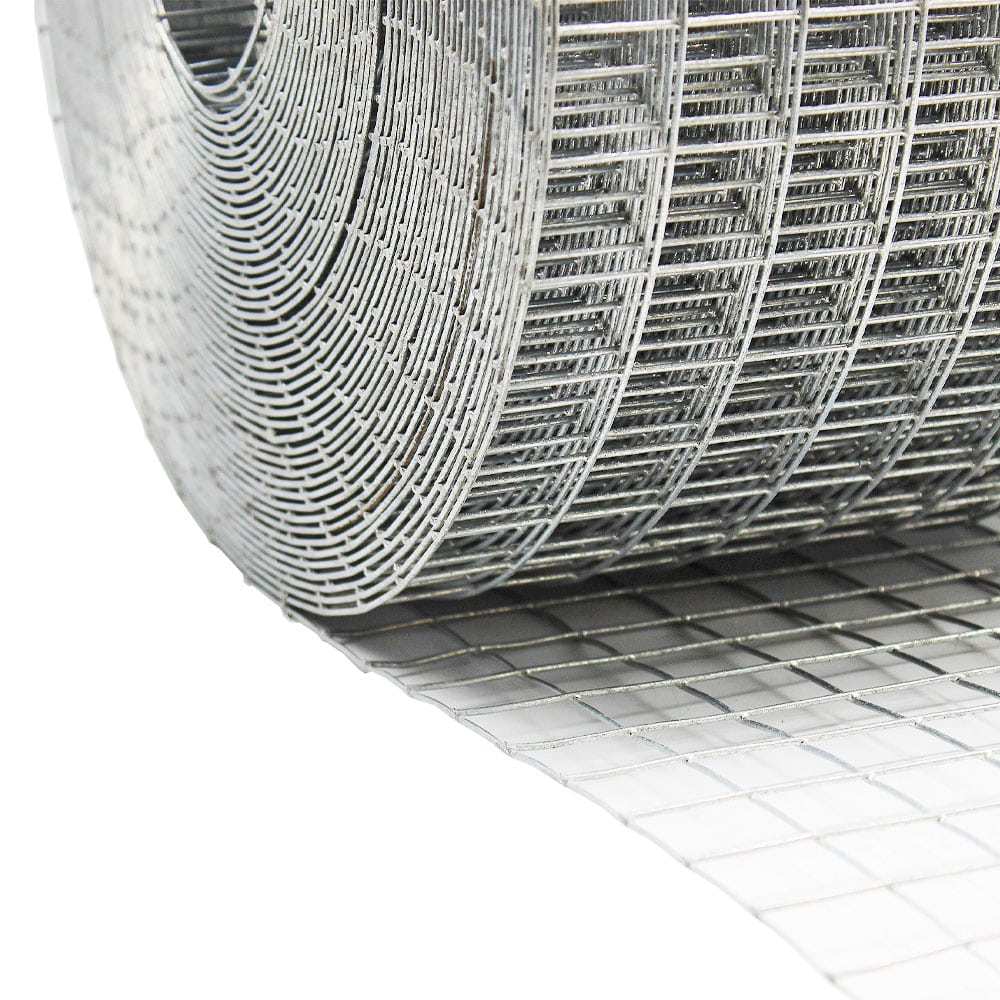

Welded mesh provides a sturdy barrier with its interconnected wires.

Advantages:

Strength: The process of welding the intersections makes this mesh extremely robust, and capable of withstanding pressure from larger animals or even human intruders.

Variability: Comes in various sizes, making it adaptable to different garden needs.

Disadvantages:

The creation of welded mesh involves a slightly different process. To start, longitudinal wires (the line wires) are laid out parallel to one another. Cross wires are then placed perpendicularly over these line wires. Once in position, an electrical current is passed through the contact points, fusing or “welding” the wires together at their intersections. This welding process ensures a strong bond, creating a grid-like pattern. Similar to chicken wire mesh, a galvanisation process often follows the welding, where the mesh is coated in zinc to prevent rust.

For those meshes intended for outdoor use, especially in gardens, an additional PVC or powder coating can be applied for both protection and aesthetics.

Traditionally used for livestock, this fencing has found its place in many gardens today.

Advantages:

Sturdiness: Extremely resilient due to its galvanised finish, it can resist rust and wear for years.

Visually Pleasing: Often used for its aesthetic appeal, blending well with natural garden landscapes.

Disadvantages:

The production of the C8/80/15 stock fence, a specific type of galvanised livestock fencing, follows a distinctive process, tailored to its unique specifications. This alphanumeric code indicates specific attributes: ‘C’ represents the type of knot used, ‘8’ denotes the number of horizontal lines, ’80’ specifies the height in centimeters, and ’15’ gives the spacing in centimeters between the vertical wires.

To start, steel wires, which will form the main structure of the fence, are pre-galvanised. This involves passing them through a molten zinc bath, ensuring a thorough and uniform coating, providing a strong defense against rust and corrosion.

Once galvanised, the wires are set out for shaping. The vertical stay wires are spaced 15 cm apart. Across these, the eight horizontal lines are interwoven, giving the fence its height of 80 cm. The ‘C’ knot is then used to securely join the vertical stay wires and the horizontal line wires. This knotting technique ensures maximum strength and durability, preventing sagging and providing optimal resistance against livestock pressure.

The end result is the C8/80/15 stock fence, a galvanised fence revered for its durability, strength, and specific design catered to livestock containment and land demarcation.

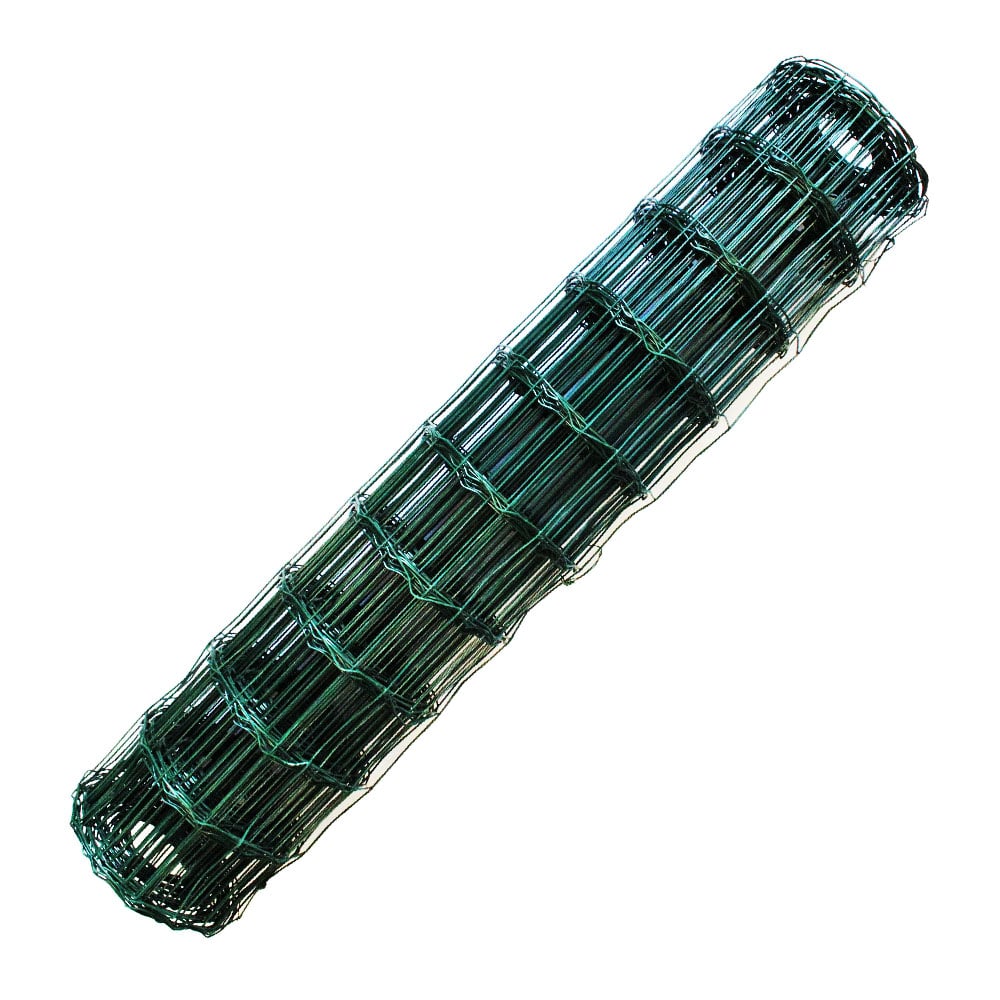

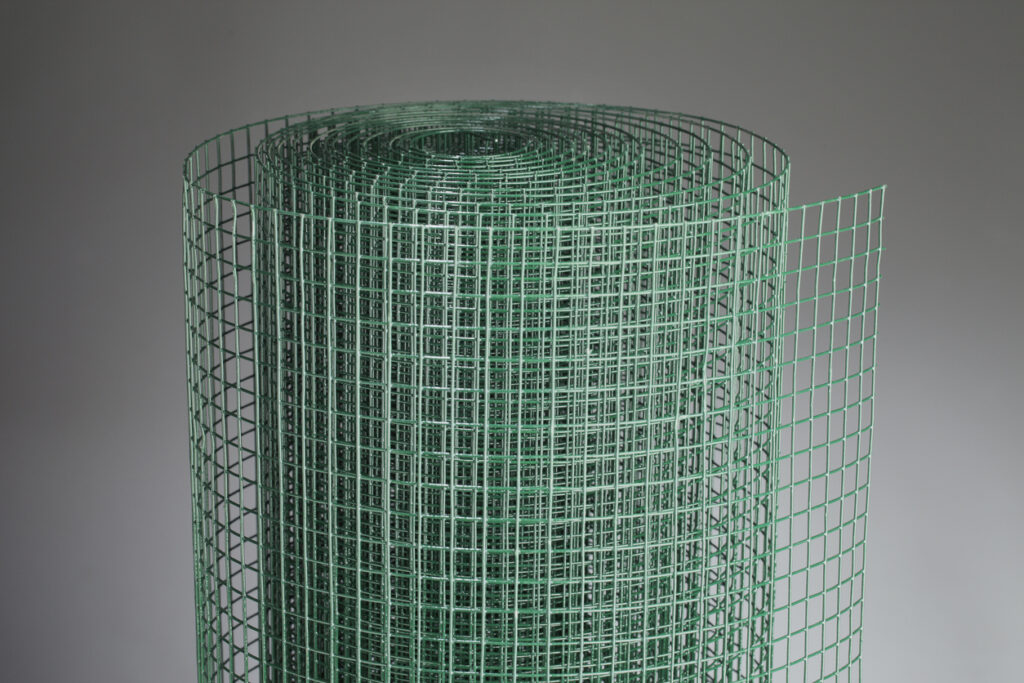

A newer addition, this green fencing mesh provides both functionality and a visual appeal.

Advantages:

Camouflage: The green color allows it to blend seamlessly with garden plants, providing protection without compromising aesthetics.

Durability: Often made with a PVC coating, it offers additional protection against the elements.

Disadvantages:

The manufacture of green wire fencing mesh involves a meticulous two-step process that combines strength and aesthetics. Mesh begins as steel wires. These wires are arranged both longitudinally and perpendicularly, forming a grid pattern. At each intersection, an electric current is introduced, fusing or “welding” the wires together. By welding the mesh, a strong and durable bond is created, allowing it to withstand significant pressure and stress.

After the welding phase, the mesh is coated. The entire welded mesh is submerged in green-colored PVC or a similar coating material. In addition to imparting the mesh with its characteristic green hue, it also serves as an additional barrier against corrosion and rust. The result is a mesh that seamlessly blends into garden settings, offering both robust protection and a pleasing aesthetic.

For Versatility: Chicken Wire Mesh is unbeatable.

For Strength: Consider Welded Mesh.

For Aesthetics with Durability: Galvanised Livestock Fencing is your pick.

For Blending In: Green Wire Fencing Mesh takes the crown.

The garden is a sanctuary. Protecting them requires thought and the right materials. The pros and cons of different netting options can help you make an informed decision based on your garden’s specific needs. The Mesh Company offers top-quality products tailored to the safety and beauty of your garden, and we are always here to help.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions