£8.99 – £299.99 inc VAT

This website is secured:

✔ The UK’s Largest Range Of Mesh Products

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Sizes & Larger Sheets Available

The stainless steel fine wire mesh, made of 304-grade material, is known for its high durability and precision with 145 holes per linear inch and 21,025 per square inch. With a wire thickness of 0.052mm and an aperture of 0.123mm, it offers a 49% open area, ensuring optimal airflow and fine filtration. Remarkably user-friendly, this mesh can be easily tailored using standard kitchen scissors or even fingertips, making it ideal for various applications, from professional uses to DIY projects.

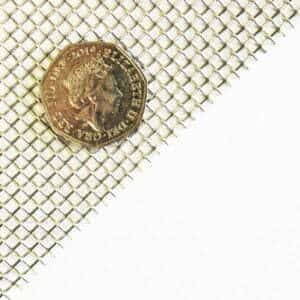

0.123mm hole stainless steel fine wire mesh in top quality 304 grade made from 0.052mm wire. As you can see from the image, this is a fine mesh specification. The holes are very small and not especially visible by naked eye. It is of interest to anyone who needs a fine mesh for any application. You would be able to bend and fold this mesh by hand very easily.

The stainless steel fine wire mesh is a meticulously crafted product of 304-grade quality, known for its resilience and durability. With holes amounting to 145 per linear inch, and a staggering 21,025 per square inch, it stands as a testament to precision engineering. This mesh boasts a wire thickness of 0.052mm and an aperture size of 0.123mm, making it both sturdy and refined in its design.

One of the outstanding features of this mesh is its open area percentage of 49%. This ensures optimal airflow and fluidity, making it suitable for a range of applications requiring such fine filtrations or separations.

The specifications of this woven wire mesh are as below:

Wait!! Before you order your mesh please first check out our clearance listing which is where we put all of our over-run bargain rolls at reduced prices. You never know, you might find just the roll that you need for your purposes.

We also offer a massive range of 304 stainless steel perforated metal sheet options from immediate stock. In order to produce stainless steel perforated metal sheet, flat sheet metal is punched with round or square holes. Perforated sheets are commonly often used in applications where the passing of air is required. Because the holes are punched, it is possible to have a far stronger finished metal product than it would be for the equivalent thickness in woven or welded mesh.

Our group have been in the mesh industry for over 150 years. We are one of the UK’s most trusted mesh suppliers because:

The Mesh Company has an enormous range of woven wire mesh products. We truly are an industry leader among suppliers of weld mesh and woven wire materials. With the capabilities we have in-house, we can provide virtually anything you require.

Copper, brass, black, and galvanised steel wire mesh materials are also available in large stock quantities at bargain prices. See our blog for specific information on all of our various woven wire mesh materials.

Yes, the stainless steel fine wire mesh is eminently suitable for filtration purposes. Its precision, defined by 145 holes per linear inch and 21,025 holes per square inch, guarantees meticulous filtration. Due to its 0.123mm aperture size, it effectively filters out very small particles, making it ideal for applications that require fine and consistent filtration. 304-grade stainless steel, combined with the durability and chemical resistance of this mesh, makes it an ideal choice for a broad range of filtration applications.

304-grade stainless steel fine wire mesh exhibits good heat resistance. 304-grade stainless steel can withstand continuous temperatures up to 870°C (1598°F) and intermittent temperatures up to 925°C (1697°F). However, its strength tends to decrease at elevated temperatures.

Furthermore, stainless steel is non-combustible and does not ignite or burn. Fire or high temperatures can cause it to get hot, but it won’t catch fire. When exposed to prolonged high heat, stainless steel can also discolor or tarnish. Discoloration, often in a bluish hue, does not affect the material’s structural integrity, but it can affect its appearance.

Yes, the thinness of the wire can affect its heat resistance and overall behavior under elevated temperatures. Here’s how:

Check out our blog ‘everything that you need to know about woven filter mesh’ for more information on this product. Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

You may also be interested in our blog about hardware cloth. This article explains the term in great detail.

We also offer similar products through our highly popular eBay store, check us out there too.

| Woven Mesh Sheet Size | 150 x 150mm x 2 Pack, A4 x 4 Pack (210 x 300mm x 4 Pack), 300 x 300mm (30 x 30cm) Sheet, A3 x 3 Pack (300 x 420mm x 3 Pack), 500 x 500mm (50 x 50cm) Sheet, A2 420 x 594mm (42 x 59.4cm) Sheet, A1 594 x 841mm (59.4 x 84.1cm) Sheet, 1000 x 500mm (100 x 50cm) Sheet, 1000 x 1000mm (100 x 100cm) Sheet, 5 Metre x 1000mm (1 Metre) Roll, 10 Metre x 1000mm (1 Metre) Roll |

|---|

In 2008 Locker Wire Weavers launched The Mesh Company to bring our enormous range of wire mesh products to the general public for the first time. Previously wire mesh was only available for trade customers.

We continue to extend our range, and now proudly offer many forms of mesh and metal products for the best possible prices. We specialise in woven wire mesh. As a group we work closely with architects and designers to develop ground-breaking new applications for our multifunctional range of materials. We also offer state of the art fabrication and engineering for projects of all sizes.

Strong ties with the Warrington community continue to be at the very core of our business. We are proud to invest in the training and developing our staff of all levels in line with the traditions set by Thomas Locker, who founded our group 150 years ago when he invented the electronic loom. We continue to bring ingenuity and strong ethics to our day to day business.

The Mesh Company continues Warrington’s historic role in the wire industry. For more than 140 years, our group has been a leader in the supply and manufacture of woven wire mesh and wire cloth. Having been founded in Warrington, UK in 1878, Locker mesh products still retain the quality craftsmanship and spirit of innovation that were so characteristic then.

Available Options

You will find full rolls of this insect netting here. Please be advised that the majority of woven mesh is usually available in a maximum roll size of 30 metres by 1200mm. Please email us if you wish to discuss purchasing this mesh in any size – sales@themeshcompany.com.

Feel free to call us if you wish to discuss any of our products – (+ 44) 01925 406 602. We are always happy to help in any way that we are able to.

We also offer this product through our highly popular eBay store, check us out there too.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions

Reviews

There are no reviews yet.