£14.99 – £46.99 inc VAT

This website is secured:

✔ The UK’s Largest Range Of Mesh Products

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

@ ☏ Bespoke Sizes & Larger Sheets Available

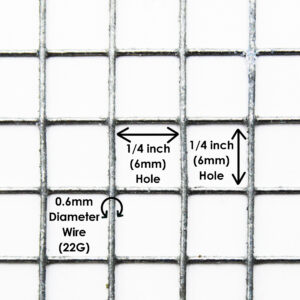

3mm round hole galvanised steel perforated metal is a versatile and durable solution designed for various applications. With a 3mm round hole aperture and 5mm pitch, this product is ideal for filtration, ventilation, and screening purposes. Made from 1mm thick galvanised steel, it resists rust and corrosion, making it suitable for both indoor and outdoor use.

3mm round hole galvanised steel perforated metal is produced by punching flat galvanised plate with a specific pattern. The customer’s requirement for metal for cosmetic or application purposes drives this decision.

This premium product is crafted from 1mm thick flat sheet galvanised steel, a material treated with a zinc coating to resist rust and corrosion. The perforated metal comes with 3mm aperture round holes and a 5mm pitch, which is the distance from the start of one hole to the next, or the sum of the hole size and the gap between holes. This design ensures versatility, durability, and suitability for a wide array of applications, from filtration and ventilation to screening. The galvanised steel construction guarantees strength, durability, and resistance to wear and tear, making it apt for both indoor and outdoor applications. Moreover, our product is eco-friendly; galvanised steel is recyclable, and the galvanisation process prolongs the steel’s lifespan, minimizing the need for frequent replacements and contributing to a more sustainable environment.

Sheets with perforations are commonly used to allow air to pass through. Ventilation and filtration are the main uses for this mesh type. Rodent proofing is another use for perforated sheeting.

Our group have been in the mesh industry for over 150 years. We are one of the UK’s most trusted metallic mesh suppliers because:

We also offer a massive range of hexagonal hole galvanised metal sheet options from immediate stock.

In order to produce galvanised steel hexagonal perforated metal mesh sheet, flat sheet metal is punched with a hexagonal hole. Perforated sheets are commonly often used in applications where the passing of air is required. Because the holes are punched, it is possible to have a far stronger finished metal product than it would be for the equivalent thickness in woven or welded mesh.

Yes, perforated metal mesh can be painted or coated. In the event that you want to apply any kind of paint or coating to the surface, it is imperative to properly prepare it. It is very important for the metal mesh to be clean, dry, and free of any dirt, grease, or oil on the surface of the mesh. If there is any rust or corrosion on the surface, it should be removed, and the surface may need to be primed to ensure a proper adhesion between the paint or coating and the surface. A paint or coating must also be selected that is suitable for the type of metal that is going to be used as well as the intended use of the metal. For example, galvanised steel perforated metal mesh may require a special primer and paint that are formulated for use on galvanised surfaces. In addition, some coatings may offer additional benefits, such as increased corrosion resistance or UV protection.

In order to make perforated metal mesh, a machine called a perforating press or a punch press machine is used that punches holes into a sheet of metal after it has been heated. The process begins with a roll or sheet of metal, which is fed into the perforating press. The press is equipped with a die and a series of pins or punches that are aligned in a specific pattern, corresponding to the desired hole size and spacing. As the metal passes through the press, the punches are forced through the metal, creating a series of holes. It is then necessary to cut the perforated metal mesh to the desired size, and, if necessary, to apply a coating in order to increase its durability or aesthetic appeal. As a result of this process, a wide variety of hole sizes, patterns, and configurations can be created, making perforated metal mesh a versatile and customizable material.

Check out our blog about galvanised steel perforated metal mesh for more information on that large range of materials.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

We also offer similar products through our highly popular eBay store, check us out there too.

| Perforated Mesh Sheet Size | 150 x 150mm x 2 Pack, A4 x 4 Pack (210 x 300mm x 4 Sheets), 300 x 300 (30 x 30cm) Sheet, 250 x 500 (25 x 50cm) Sheet, 500 x 500 (50 x 50cm) Sheet, 100 x 1000 (10 x 100cm) Sheet, 250 x 1000 (25 x 100cm) Sheet, 500 x 1000 (50 x 100cm) Sheet |

|---|

In 2008 Locker Wire Weavers launched The Mesh Company to bring our enormous range of wire mesh products to the general public for the first time. Previously wire mesh was only available for trade customers.

We continue to extend our range, and now proudly offer many forms of mesh and metal products for the best possible prices. We specialise in woven wire mesh. As a group we work closely with architects and designers to develop ground-breaking new applications for our multifunctional range of materials. We also offer state of the art fabrication and engineering for projects of all sizes.

Strong ties with the Warrington community continue to be at the very core of our business. We are proud to invest in the training and developing our staff of all levels in line with the traditions set by Thomas Locker, who founded our group 150 years ago when he invented the electronic loom. We continue to bring ingenuity and strong ethics to our day to day business.

The Mesh Company continues Warrington’s historic role in the wire industry. For more than 140 years, our group has been a leader in the supply and manufacture of woven wire mesh and wire cloth. Having been founded in Warrington, UK in 1878, Locker mesh products still retain the quality craftsmanship and spirit of innovation that were so characteristic then.

Available Options

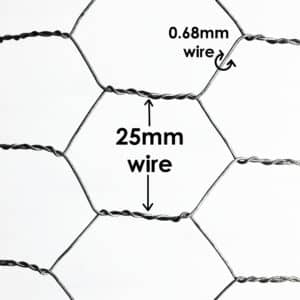

You will find full rolls of this insect netting here. Please be advised that the majority of woven mesh is usually available in a maximum roll size of 30 metres by 1200mm. Please email us if you wish to discuss purchasing this mesh in any size – sales@themeshcompany.com.

Feel free to call us if you wish to discuss any of our products – (+ 44) 01925 406 602. We are always happy to help in any way that we are able to.

We also offer this product through our highly popular eBay store, check us out there too.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions

Reviews

There are no reviews yet.