When it comes to building materials, many people think of the usual suspects like concrete, wood, and steel.

However, there’s one building material that’s often overlooked despite its versatility and durability – galvanised steel perforated metal.

This material is widely used in many industries, from construction to automotive to aerospace.

This article will take a closer look at what galvanised steel perforated metal is, its myriad benefits, and how it can be used in various applications.

Let’s get into it….

Firstly, what is it?

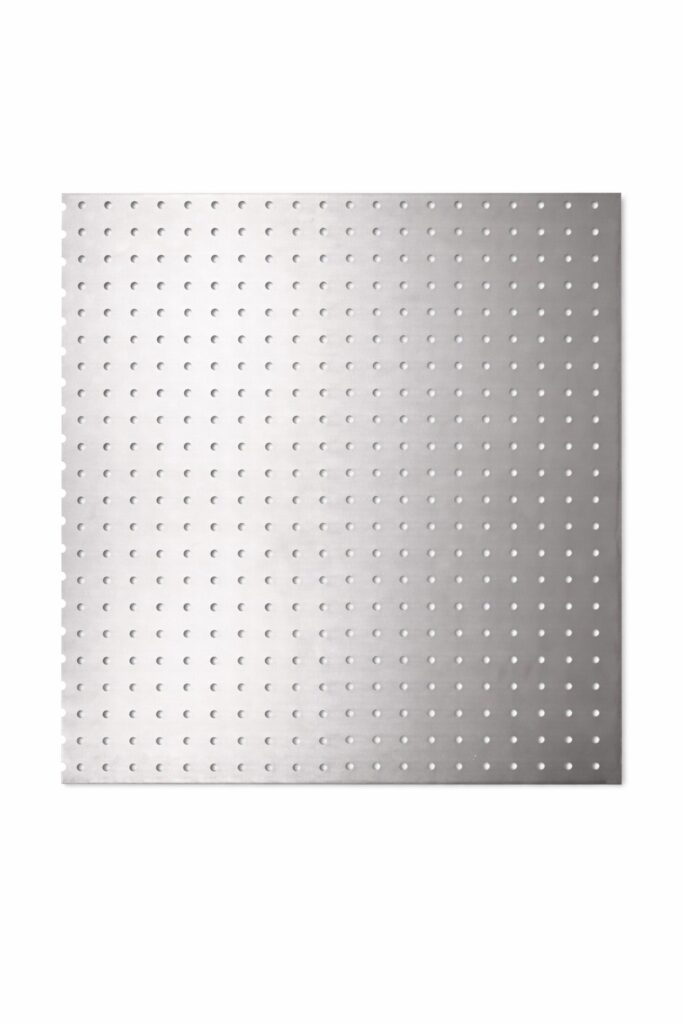

Galvanised steel perforated metal is a type of sheet metal that’s been galvanised through a process that adds a protective layer of zinc on the surface.

The flat sheet metal is then perforated using a machine that creates uniform geometric patterns of holes, slots, or other types of cut-outs.

This makes perforated metal mesh a lightweight and durable material that’s strong, corrosion-resistant, and easy to work with.

One of the biggest advantages of galvanised steel perforated metal is that it’s highly versatile.

It can be used in a variety of applications where strength, durability, and corrosion resistance are essential.

For our customers it’s commonly used as a structural material for building facades, sunshades, and fencing.

It has also been used in automotive and aerospace industries as a material for grilles, filters, and ventilation systems. Additionally, it’s a popular choice for decorative elements like lampshades, signage, and wall art.

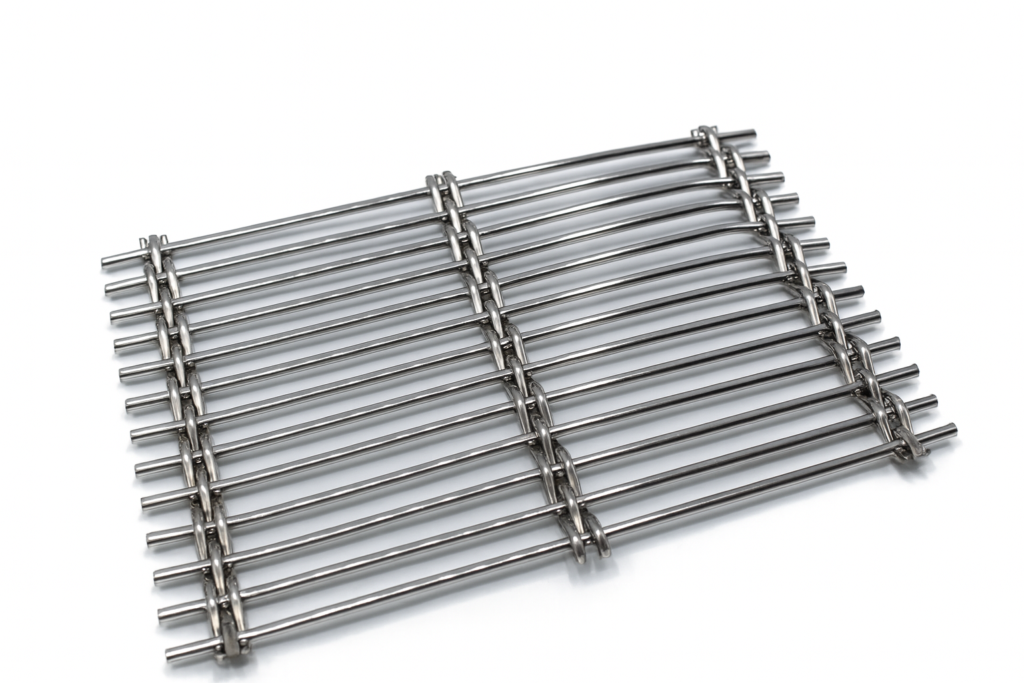

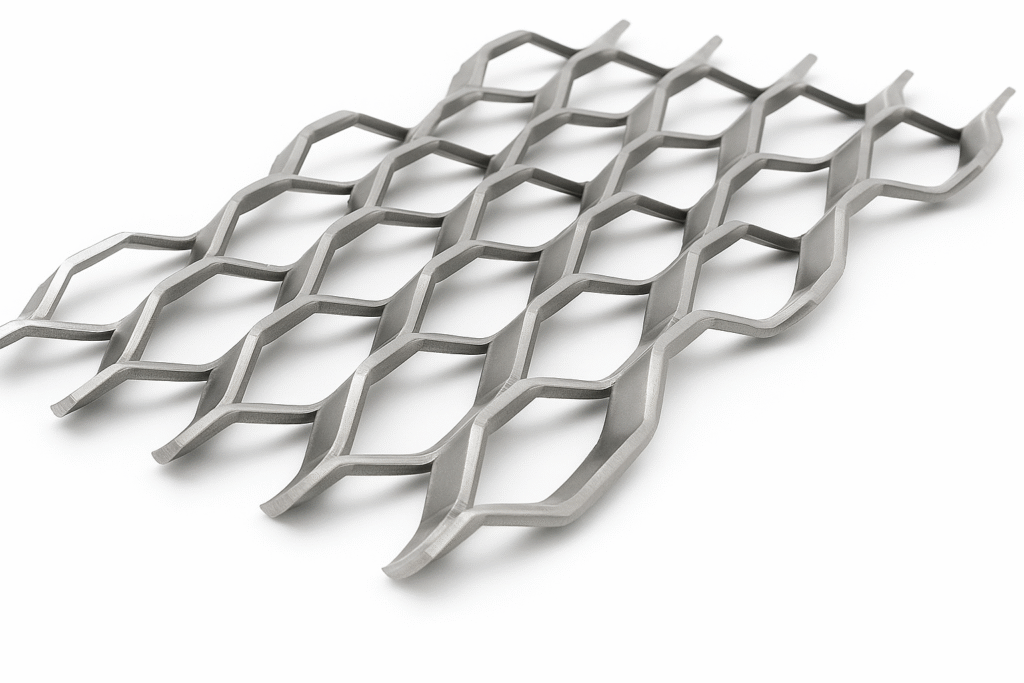

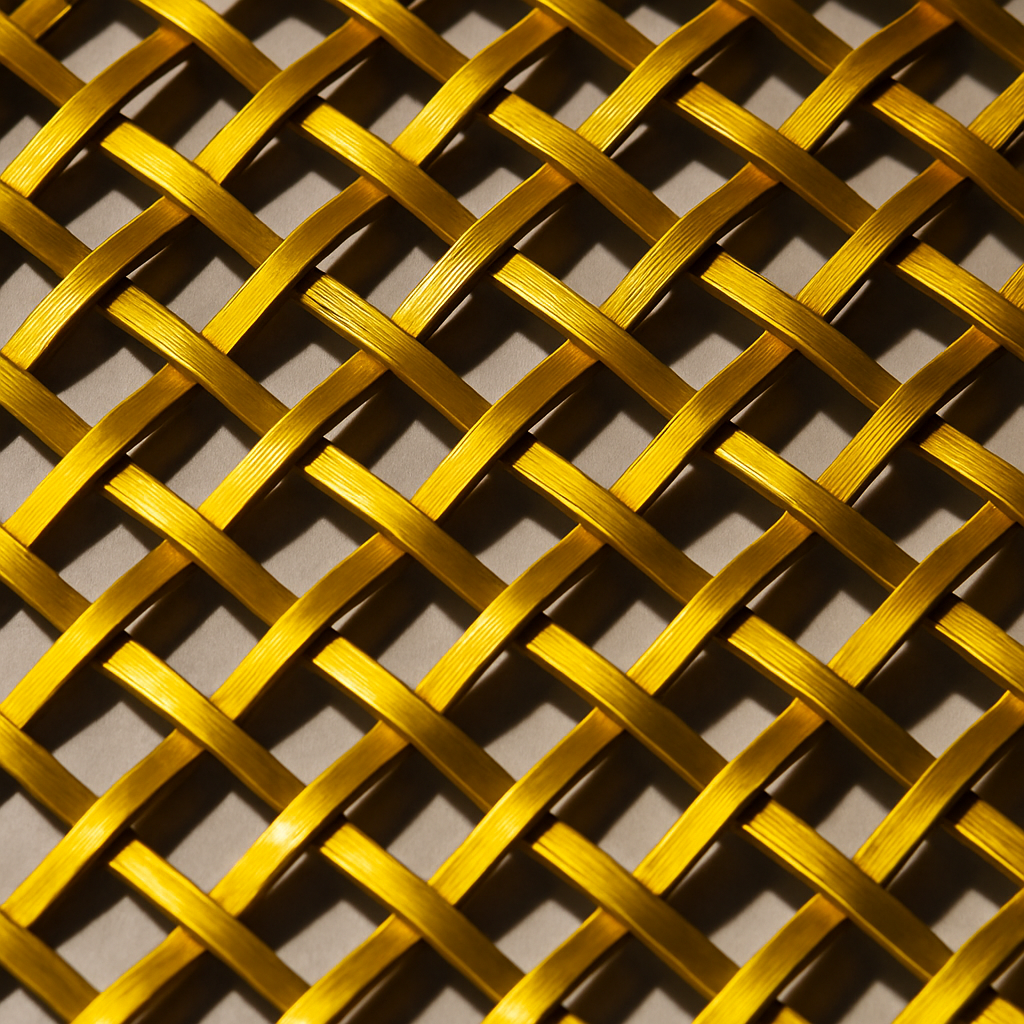

The classic benefit of perforated metal is the fact that there are many hole options. With woven or welded mesh you can either have square, or perhaps a rectangular pattern. With perforated the mesh can be be made in various shapes, sizes, and patterns to suit specific purposes and aesthetics.

Basically it is cheaper, but it is not as resistant to corrosion or long lasting.

Galvanised perforated metal is made from carbon steel that has been coated with a layer of zinc to protect against rust and corrosion. It is a more affordable option and provides good strength and durability.

Stainless steel perforated metal mesh, on the other hand, is made from a corrosion-resistant alloy that contains chromium, nickel, and other elements. It is more expensive than galvanised mesh to produce, but offers superior corrosion resistance, strength, and durability. These characteristics make it a popular choice for high-performance applications where hygiene and cleanliness are important.

In terms of appearance, stainless steel mesh has a silver, shiny finish, while galvanized mesh has a more matte, greyish appearance.

Both options are very popular and used by many of our customers for tough applications.

Here are some examples of applications for this metal mesh:

Working with galvanised steel perforated metal requires some basic techniques and tools.

The material can be cut, bent, and shaped using metal shears, pliers, and hammers. We would advise using a press brake to bend this metal and cutting with an industrial guillotine if possible.

It can also be welded, brazed, or screwed to other materials.

It’s important to wear safety gear like gloves, goggles, and dust masks when handling perforated metal, as the edges can be sharp and the dust can be harmful.

The Mesh Company stock galvanised steel perforated metal in round, square and hexagonal hole options.

Here is a quick breakdown:

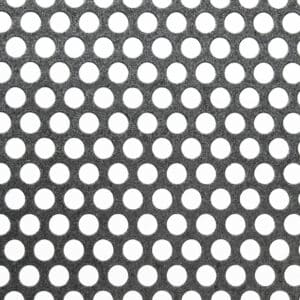

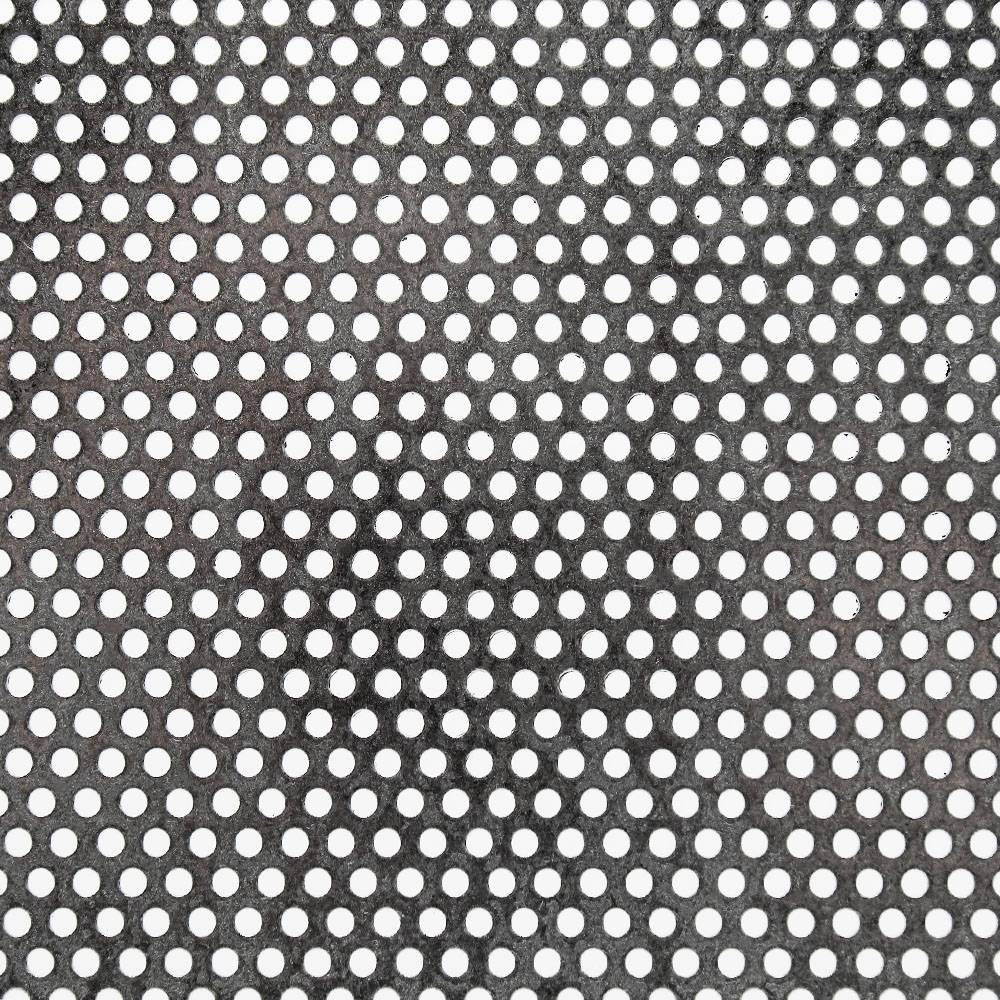

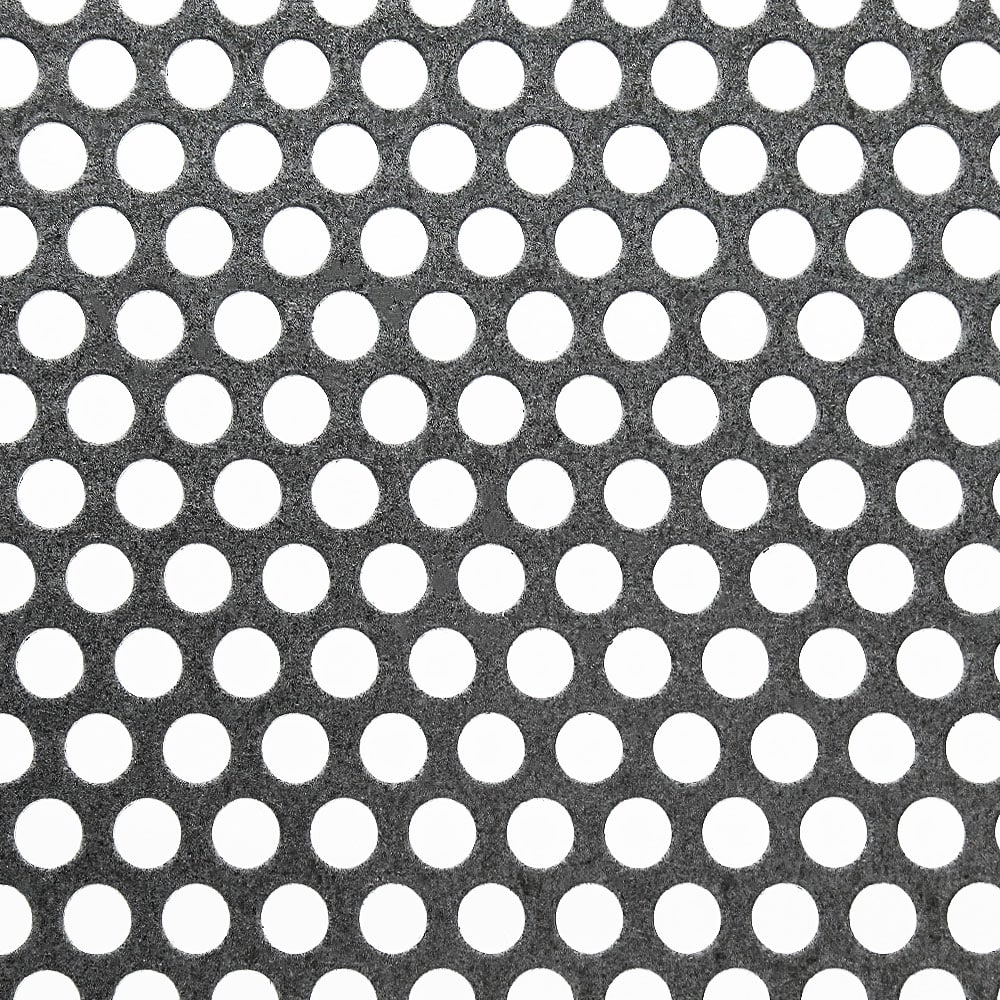

The round hole pattern is one of the most popular perforation styles because it offers a good balance between open area (the amount of open space between the holes) and strength.

Our available range starts at 2mm and goes up to 20mm.

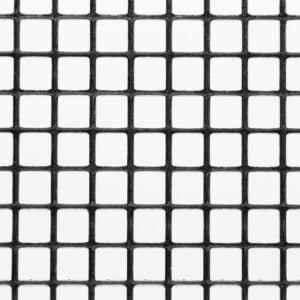

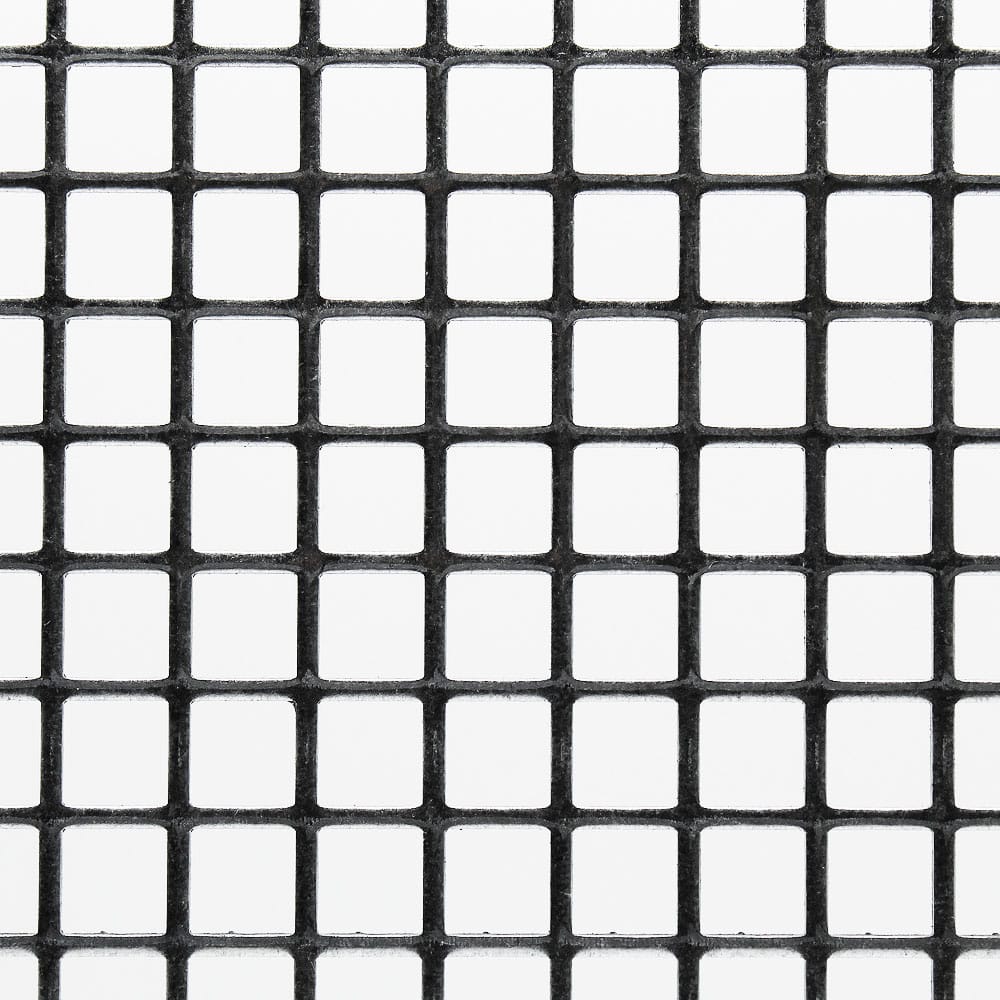

The square hole pattern provides a higher open area than round holes, which allows for better air flow and greater visibility. However, the strength of the sheet may be slightly reduced due to the larger holes.

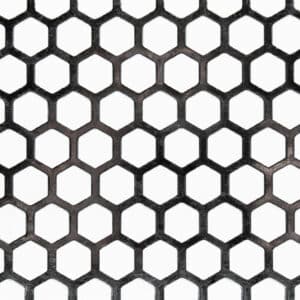

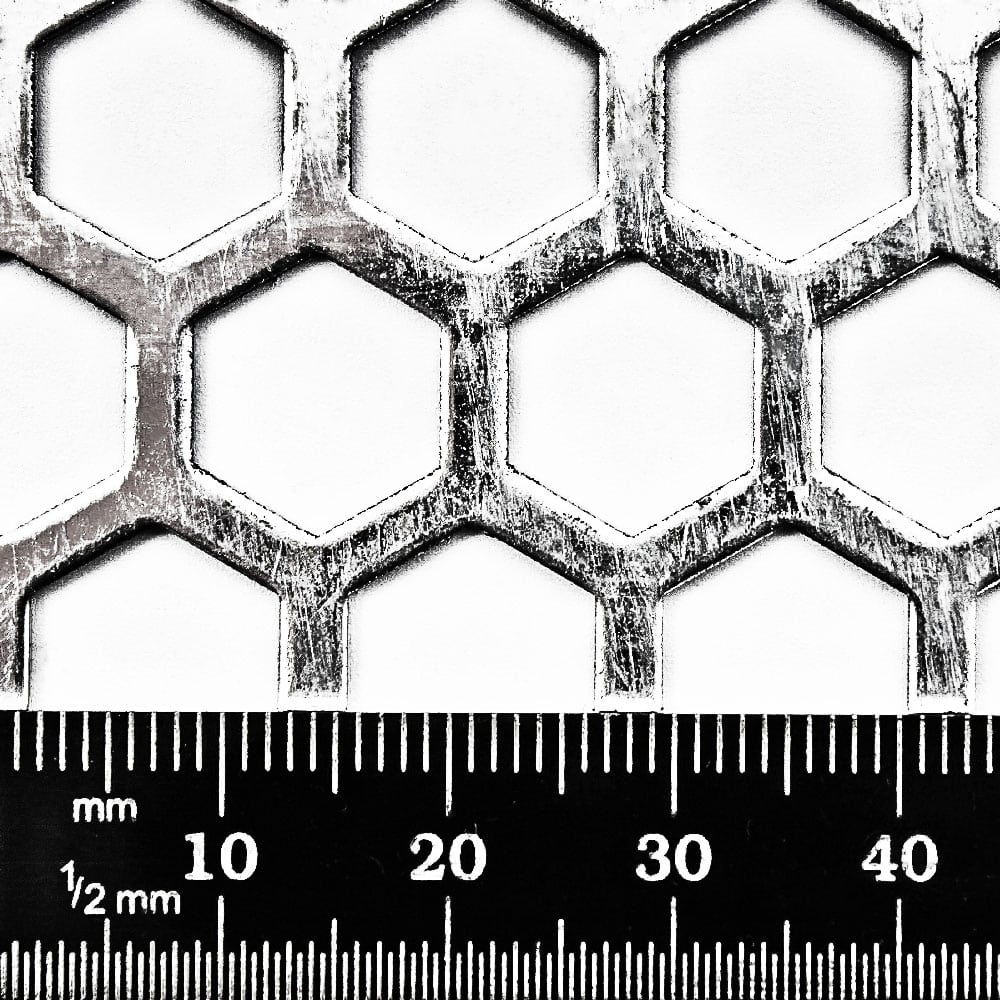

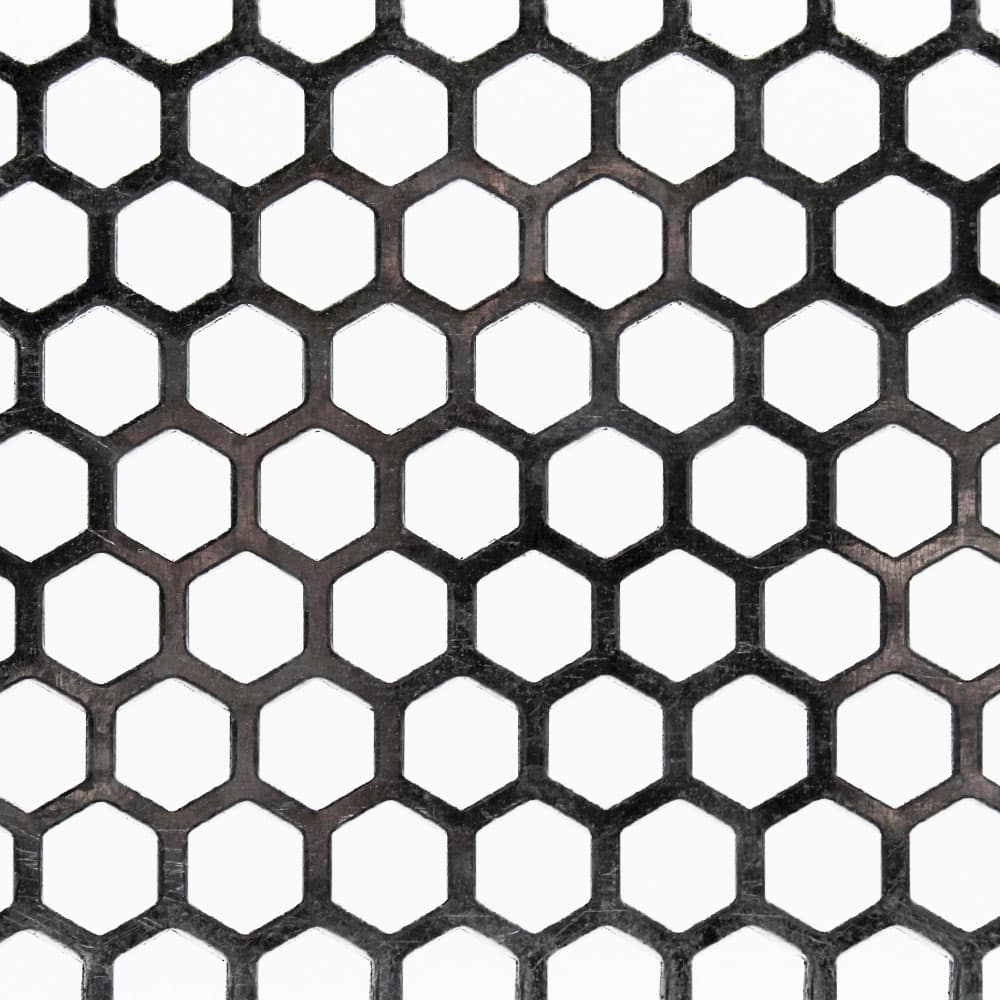

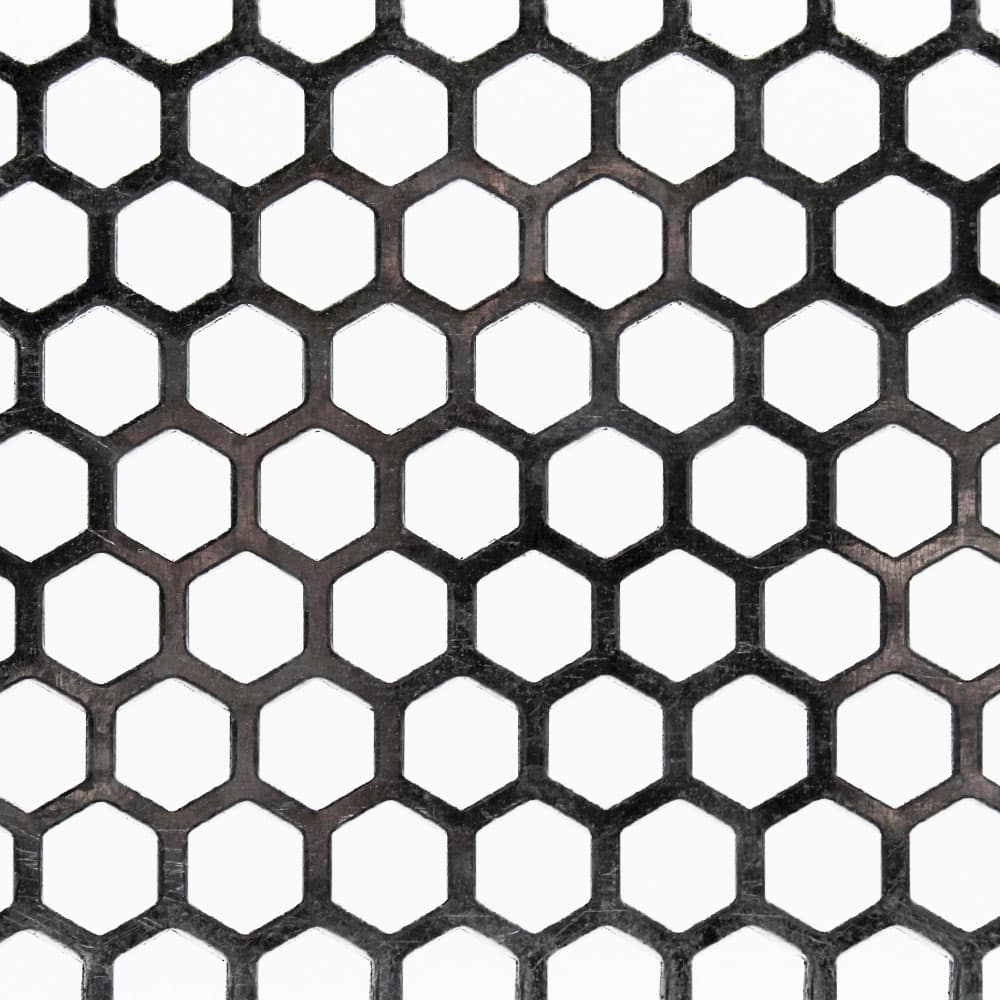

Hexagonal hole perforated metal mesh is often used in architectural and decorative applications due to its unique pattern. It can be used for decorative screens, wall panels, and exterior cladding. The hexagonal pattern can also provide increased airflow and visibility, making it useful in applications such as speaker grills and ventilation systems.

The hexagonal pattern offers a higher open area than square holes but less than round holes, providing a balance between strength and airflow.

Our range starts at 3.5mm and ends at 11mm.

Whether it’s for structural, decorative, or functional purposes, this material offers many benefits that make it a popular choice in many industries.

With its durability, corrosion resistance, and large range of hole options, galvanised steel perforated metal is a reliable building material that won’t disappoint.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.