There are many reasons why mild steel is considered to be a dominant player in the metal industry, and its versatility and affordability make it a top choice for a wide range of uses.

This article delves into the intrinsic properties of mild steel and its significant role in the world of perforated metal, an innovative material used in various sectors, from architectural designs to automotive and agricultural industries.

Perforated metal, characterised by its pattern of holes, slots, or decorative shapes, offers a unique combination of strength, functionality, and aesthetic appeal.

The choice of material is crucial in determining the performance and durability of perforated metal products, and mild steel emerges as a top contender due to its exceptional properties.

This exploration will not only highlight the fundamental characteristics of mild steel but also shed light on why it is an ideal candidate for perforation processes, balancing strength with workability to meet diverse design and functional requirements.

Let’s get into it…

Known for its ductility, weldability, and malleability, mild steel has a low carbon content, typically between 0.05% and 0.25%. Its unique composition allows it to withstand significant stress while allowing for easy shaping and customisation. Its balance makes it ideal for fabrication processes, including cutting, bending, and, most importantly, perforating.

Perforated metal applications benefit from mild steel’s ductility. Material can be stretched and shaped without compromising its structural integrity, which is essential when creating intricate patterns and designs. Further, its weldability allows perforated mild steel components to be easily joined, enhancing design flexibility and allowing complex constructions.

A significant aspect of its effectiveness is its cost-effectiveness. A practical choice for large-scale and cost-sensitive projects, mild steel is more affordable than other metals. Despite its perforations, its natural strength ensures longevity and resistance to wear and tear, both of which are important in both aesthetic and functional applications.

Mild steel plays a crucial role in perforated metal design. To create products that are both structurally sound and visually appealing, its inherent qualities are skillfully exploited. As part of the design process, mild steel thickness and grade are selected based on the intended use and the environmental conditions.

Mild steel’s perforation process is a testament to its strength and workability. Precision and uniform holes, patterns, and designs can be achieved using advanced machinery and techniques, such as CNC punch presses and laser cutting. A key reason for its widespread use is its ability to maintain strength even after perforation. It can withstand considerable weight and stress, making it suitable for applications ranging from architectural facades to heavy-duty industrial screens.

During customisation, mild steel’s workability is crucial. After perforation, it can be easily shaped and bent to accommodate intricate designs. In architectural applications, aesthetics are just as important as functionality.

In mild steel, the balance between strength and workability allows a wide range of hole sizes and patterns to meet aesthetic and functional needs. The versatility of mild steel allows it to be tailored to meet a variety of applications, whether they are small, precise holes for filtration or larger, decorative ones for architectural elements.

In the materials market, mild steel perforated metal stands out for its combination of durability and cost-effectiveness. Its carbon steel composition ensures a high level of resilience and endurance, making it the ideal choice for long-term use. Mild steel remains a highly affordable material, offering a cost-effective solution for both large-scale industrial projects and smaller, custom projects.

Among the many benefits of mild steel in perforated metal is its adaptability to a wide range of industries. Building facades rely on it not just for structural support, but also for aesthetic and environmental considerations, such as light filtration and ventilation. Industrial applications include machinery guards, ventilation grills, and filtration panels, where its durability and strength are vital. Aside from this, it is used in agricultural equipment, such as sorting and screening equipment, due to its ability to withstand harsh conditions.

Its environmental impact is another key advantage. One of the most recycled materials in the world, mild steel reduces the carbon footprint associated with its production and use. Together with its durability, mild steel perforated metal is an economical and environmentally responsible choice.

The use of mild steel in perforated metal offers a wide range of benefits, including durability, cost-effectiveness, versatility across industries, and environmental sustainability. Numerous applications highlight its popularity and indispensability.

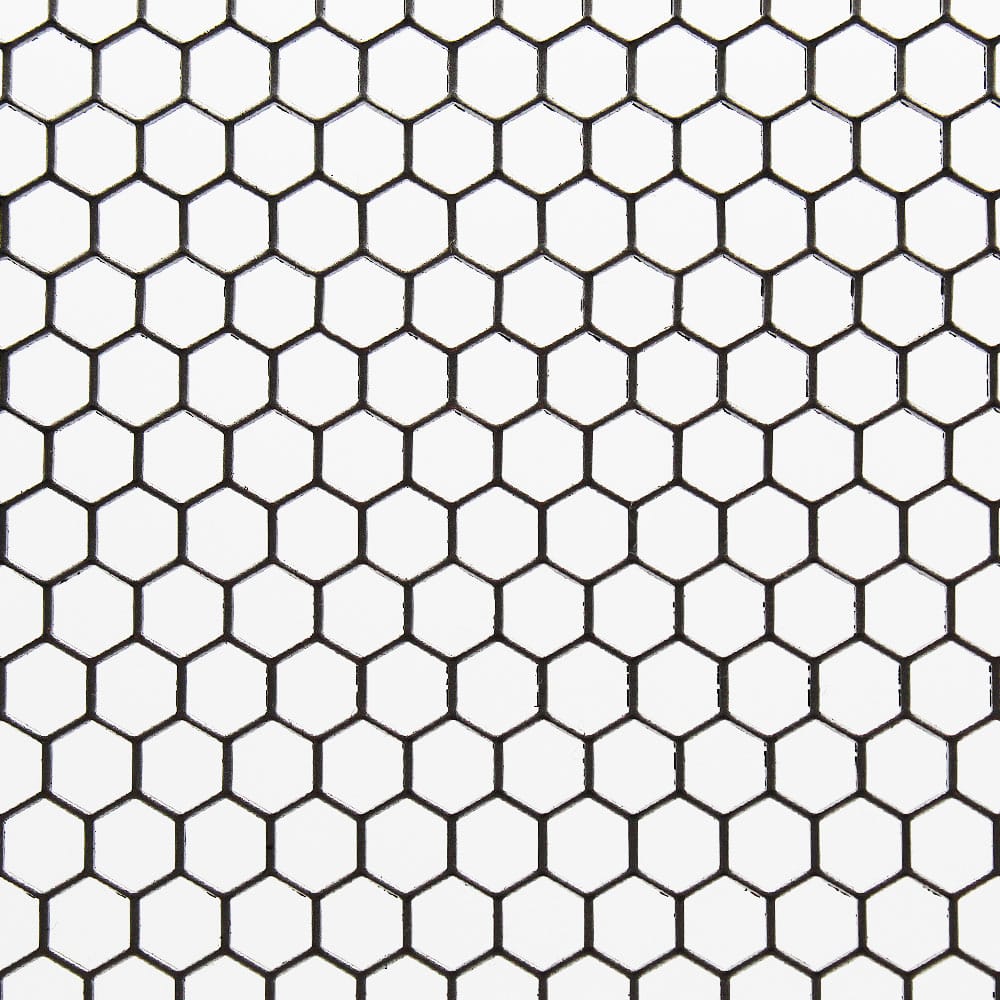

2mm Hexagonal Hole – 2.5mm Pitch – 1mm Thick

In order to create a unique aesthetic, hexagonal perforations provide a unique aesthetic which makes this type of perforation suitable for decorative applications such as lampshades, radiator covers, or for retail displays.

With hexagonal holes 2mm in diameter on a 2.5mm pitch, the steel plate is 1mm thick and offers a blend of visibility and protection.

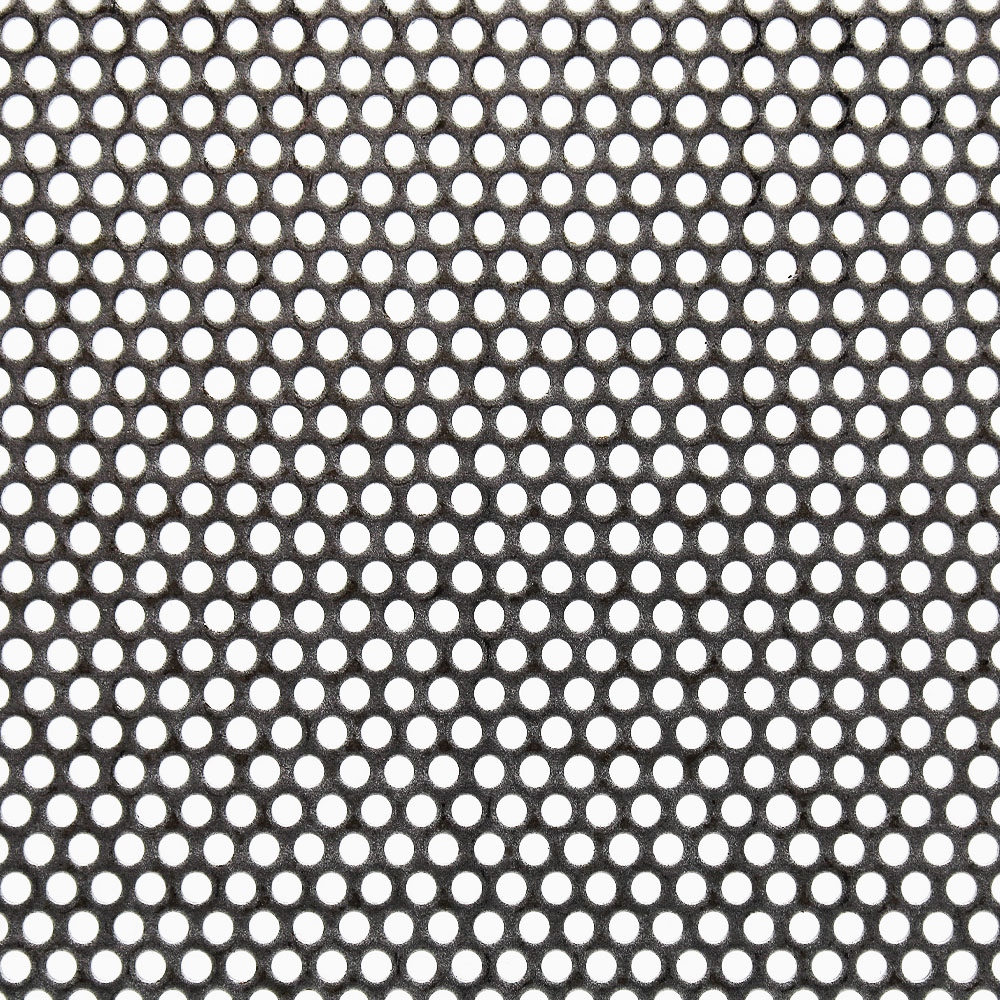

2mm Round Hole – 3mm Pitch – 1mm Thick

Ideally suited for fine filtration and sieving applications, this mesh with 2mm round holes on a 3mm pitch, 1mm thick, is widely used in the food and beverage industry, pharmaceuticals, and chemical processing industries.

In addition to its high open area, the structure maintains adequate strength for processing equipment in spite of its high open area.

3mm Round Hole – 4mm Pitch – 2mm Thick

The 3mm round hole mild steel perforated mesh has a diameter of 4mm, a pitch of 4mm, and a thickness of 2mm. It is ideal for applications requiring moderate airflow and visibility.

Due to its configuration, it is widely used in radiator covers, air conditioning units, and audio equipment cabinets, where it affords efficient heat dissipation and sound transmission while maintaining a protective barrier against the elements.

4.5mm Hexagonal Hole – 5mm Pitch – 1mm Thick

On a 1mm thick sheet, the hexagonal holes measure 4.5mm in diameter and have a 5mm pitch, providing a distinctive aesthetic which is suitable for applications which require a combination of light penetration and privacy.

Because of this, it is the ideal material for outdoor decorative panels, room dividers, and artistic installations.

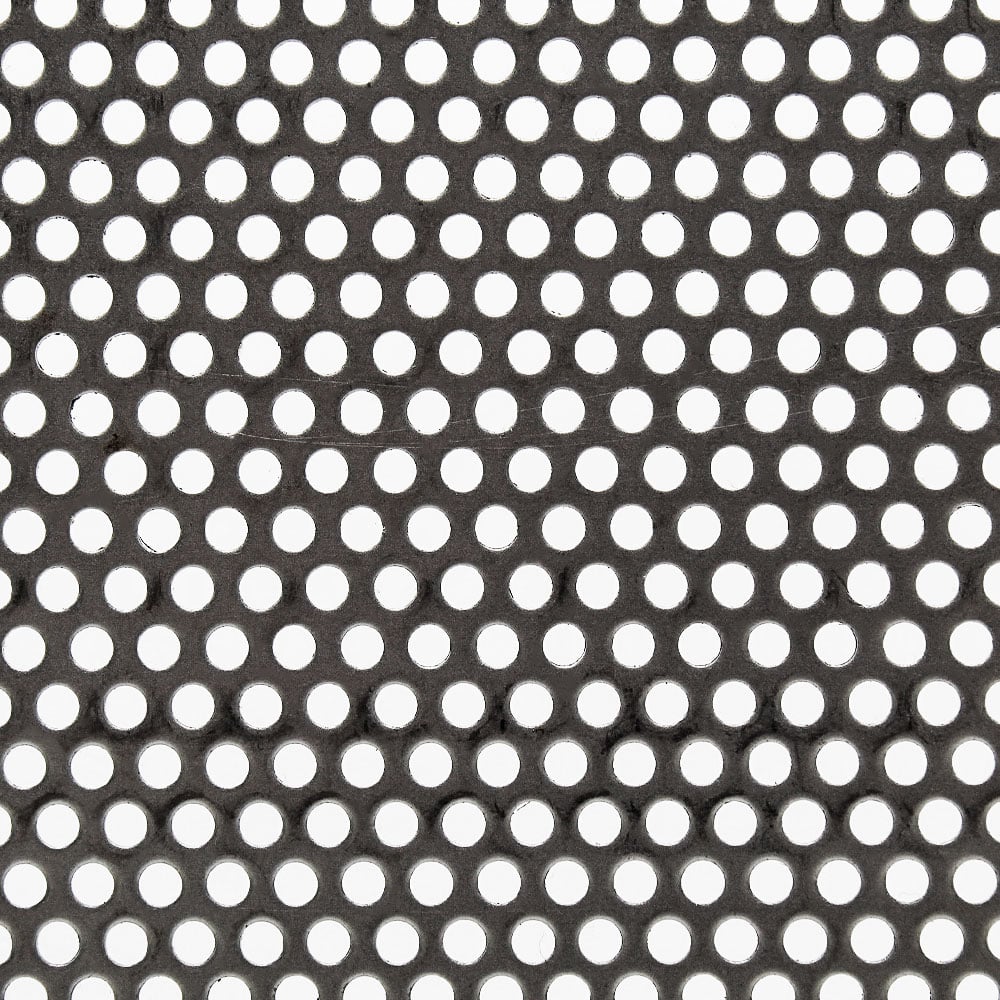

4.5mm Round Hole – 6mm Pitch – 2mm Thick

It consists of 4.5mm round holes with a 6mm pitch and a 2mm thickness, making it a versatile mesh that can be used both in industrial and domestic settings as well.

With a blend of visibility and protection, this material is well-suited for security applications, such as window guards, as well as being an aesthetic component in furniture design.

6mm Hexagonal Hole – 6.7mm Pitch – 1mm Thick

The hexagonal hole pattern on this metal sheet makes it a perfect choice for decorative architectural applications, such as façade elements or privacy screens in homes.

As a result of the 6mm holes positioned on a 6.7mm pitch in a 1mm thick sheet, a unique visual appeal is achieved while maintaining structural integrity.

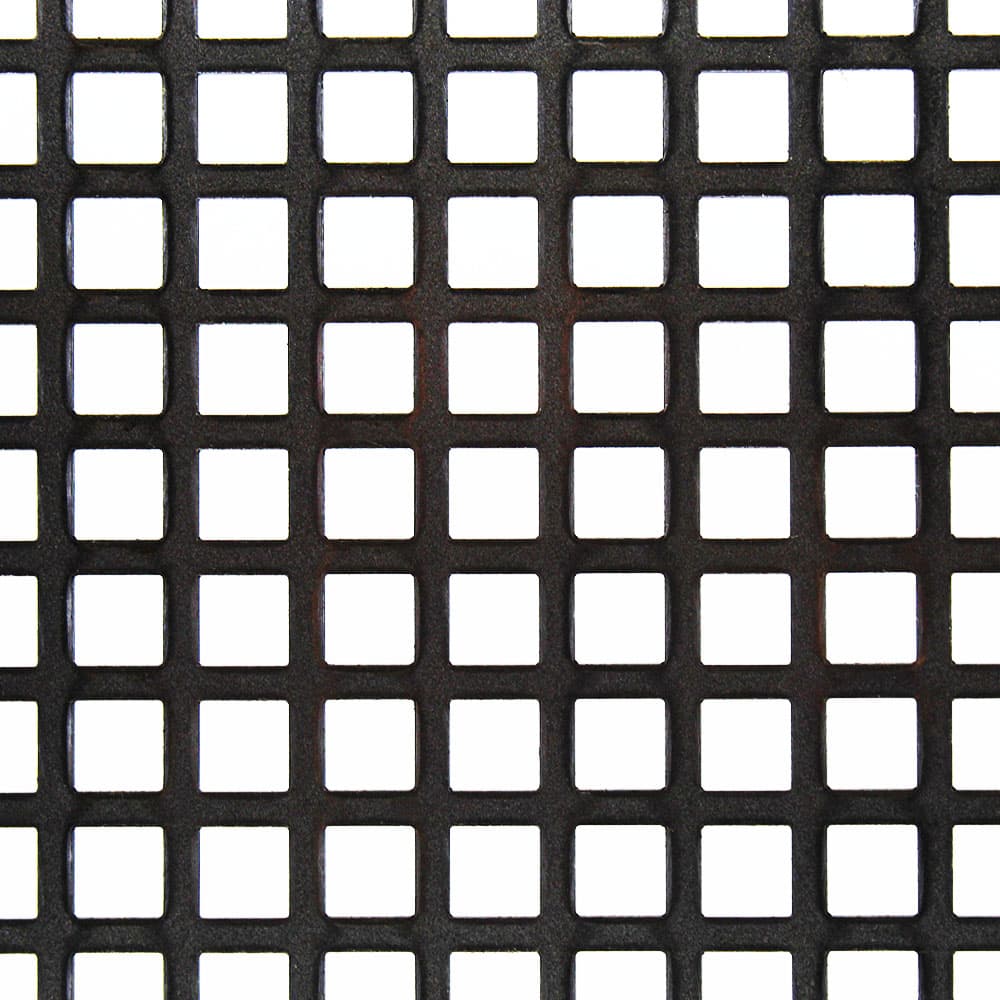

10mm Square Hole – 14mm Pitch – 1.5mm Thick

A 1.5mm thick mild steel sheet with 10mm square holes on a 14mm pitch is an excellent choice for architectural applications, such as building facades and cladding for buildings.

It features square openings that provide a modern aesthetic, and are large enough for decorative lighting effects, while at the same time providing structural strength and protection from the elements.

10mm Round Hole – 15mm Pitch – 3mm Thick

There are 10mm round holes with a 15mm pitch on a sheet that is 3mm thick, making this perforated metal ideal for heavy-duty applications.

This product is commonly used for machine guards, heavy equipment screens, and large-scale ventilation systems in industrial settings, where robustness and durability are of utmost importance.

15mm Square Hole – 20mm Pitch – 2mm Thick

It is a perforated sheet with 15mm square holes, a 20mm pitch, and a 2mm thickness, which is commonly used in larger-scale designs such as outdoor furniture, architectural screens, and garden fencing.

Square designs offer a contemporary look while ensuring durability and stability at the same time.

These mesh sizes and patterns offer unique characteristics, making them suitable for a wide range of applications, from industrial to decorative, demonstrating the versatility of mild steel in perforated metal.

Mild steel is processed and fabricated into perforated metal using a series of sophisticated techniques, each of which plays a crucial role in determining the final product. Among them are punching, laser cutting, and forming. A press is used to punch holes in metal sheets of various sizes and patterns, one of the most common methods. For large-scale production, this method is highly efficient and allows for consistent hole patterns and sizes.

Compared to traditional cutting methods, laser cutting offers a greater degree of precision and flexibility. For intricate patterns and complex designs, it allows for a level of detail that is not possible with traditional punching methods. In addition, this technique minimises material waste, making it both cost-effective and environmentally friendly.

Perforated metal must also be formed into the desired shape during the forming process. Metal can be bent, rolled, or molded to fit specific applications. As a result of mild steel’s malleability, it can be formed into a wide variety of shapes and designs.

The fabrication processes have a significant impact on the material’s properties. In laser cutting, for instance, the heat can affect the metal’s structural integrity at the edges, which is expertly managed to maintain overall strength. The punching process can also harden the surrounding areas of the holes, enhancing the material’s durability.

Mild steel perforated metal offers extensive customisation options, catering to a variety of requirements and design preferences. Metal sheets can be customised by selecting different hole sizes, shapes (round, square, hexagonal, etc.), and patterns, as well as changing the pitch (distance between holes) and size. Designers and architects can tailor the material to specific functional and aesthetic requirements.

Perforated mild steel metal offers a wide range of aesthetic possibilities. It can be finished in various ways, including powder coating, painting, and galvanising, which not only provides protection against corrosion but also adds to the visual appeal. The choice of finishes allows for a spectrum of colors and textures, enabling the metal to blend seamlessly with different design themes and architectural styles.

In architectural applications, mild steel perforated metal creates striking facades, providing a modern and distinctive look as well as practical benefits such as light filtration and privacy. Decorative panels, room dividers, and ceiling tiles use its patterns to create unique lighting effects that enhance the overall ambiance of a room.

Perforated mild steel metal is a preferred choice in many sectors because of its strength, versatility, and aesthetic appeal. Its ability to be customised in size, shape, and finish makes it a versatile material in architecture, industrial design, and beyond. With its adaptability and inherent properties, mild steel perforated metal is a staple in both functional and decorative applications.

Mild steel perforated metal, a material renowned for its strength and durability, requires proper maintenance to ensure its longevity. The perforations should be cleaned regularly with mild, non-abrasive cleaners to remove dirt and debris that can accumulate. In environments with high moisture or salinity, it’s especially important to check for signs of rust periodically. Rust can often be treated with rust inhibitors and protective coatings if it does appear.

The application of protective finishes is another important aspect of maintaining mild steel perforated metal. It is not only aesthetic, but also serves as a barrier against environmental elements such as UV rays, moisture, and pollutants, which can deteriorate the metal over time after galvanising, powder coating, or painting. By reapplying these finishes as needed, the material’s lifespan can be greatly extended.

In addition to environmental conditions, the chemical composition of the material, and the quality of the initial fabrication and finishing processes, mild steel perforated metal’s longevity is influenced by these factors. Especially in corrosive environments, specialised coatings are recommended to prevent degradation. Durability is also determined by the quality of the steel, including its carbon content and any alloying elements.

The properties of mild steel in perforated metal applications are highlighted by several key attributes. From industrial machinery to decorative architectural elements, its inherent strength and malleability make it an ideal material. Whether it’s for large-scale projects or bespoke designs, mild steel presents an attractive proposition due to its cost-effectiveness and durability.

Mild steel is an indispensable material for perforated metal because of its properties. Its combination of strength, flexibility, and aesthetic appeal, as well as its ability to withstand various environments, underscore its utility across a range of industries. With an optimal balance of performance, durability, and design flexibility, mild steel perforated metal is a preferred choice for functional and decorative applications.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog articles that explore everything that you need to know about hexagonal mesh and mild steel perforated metal.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.