If you’re looking for a versatile material that can be used in a variety of applications, then mild steel perforated sheets may be the perfect solution.

These mesh sheets are created by punching holes into a sheet of mild steel, which results in a metal surface that is both strong and functional.

To help you decide if mild steel perforated sheets are right for your needs, we’ve put together a guide on what they are, how they’re made, and why you should choose mild steel. Plus, we’ll dive into the different hole-size options that are available.

Let’s get into it….

Mild steel perforated sheets are made by taking a plain sheet of mild steel and punching a series of holes into it.

The punch press used for perforated metal mesh is typically programmed using a computer-aided design (CAD) software program. The software program allows the manufacturer to create a digital design of the hole pattern and specify the size and spacing of the holes in the metal sheet.

Once the design is created, it is imported into the punch press machine, which is equipped with a computer numerical control (CNC) system. The CNC system reads the digital design and translates it into machine-readable instructions for the punch press.

The CNC system then controls the movement of the punch and die set, as well as the speed and force of the punch press, to create the desired hole pattern in the metal sheet. The operator can also make adjustments to the programming as needed to ensure the holes are aligned properly and meet the desired specifications.

As you will see, holes can be created in a variety of shapes and sizes, depending on your needs. The process of perforating mild steel involves a series of steps, including:

1. Design: The first step in creating a perforated sheet is to create a design that specifies the size, shape, and pattern of the holes. As outlined above.

2. Punching: Once the design is complete, the sheet of mild steel is placed into a machine that punches the holes according to the design.

3. Finishing: Once the holes have been punched, the sheet is finished by cutting it to size and applying any additional treatments, such as powder coating or galvanising.

Mild steel perforated sheets are an excellent choice for a variety of applications for several reasons.

First, mild steel is a durable and strong material, which means that it can withstand a significant amount of wear and tear.

Mild steel is easily weldable and machinable. And, as it is uncoated, it is the best choice if you wish to paint the mesh.

Additionally, mild steel is a cost-effective option, which makes it an excellent choice for projects that have a limited budget.

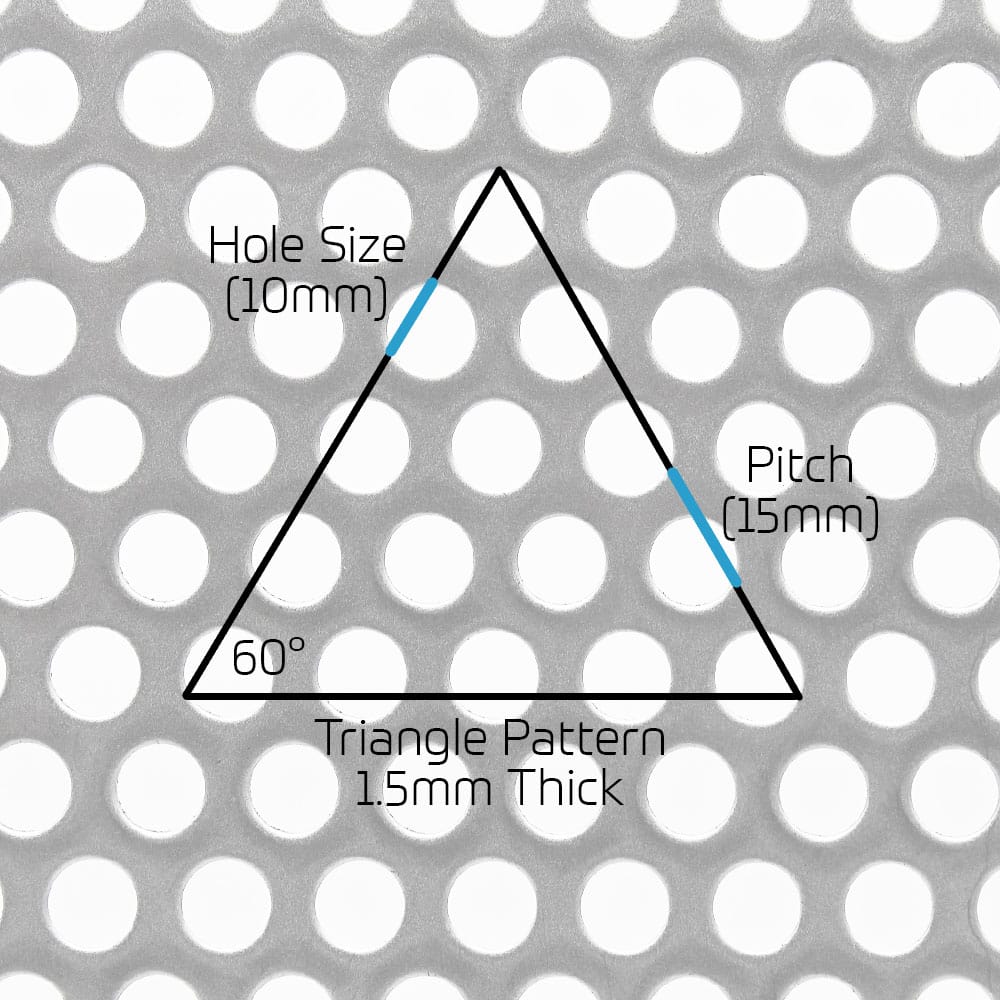

Perforated mild steel sheets come in a wide range of hole sizes, and the size of the holes that you choose will depend on your specific application.

In general, as with wire mesh also, smaller holes are better for applications that require a high level of filtration, while larger holes are better suited for applications that require more airflow. Some of the hole size options that are available include:

1. Micro Perforation: These sheets have very small holes that are less than 1mm in diameter and are generally used for filtration purposes. These holes are very small for perforated metal.

2. Fine Perforation: These sheets have holes that range from 1mm to 3mm in diameter and are used for acoustic and noise control applications.

3. Standard Perforation: These sheets have holes that range from 3mm to 20mm in diameter and are used for a wide range of applications, including machine guards and ventilation systems.

4. Thick Perforation: These sheets have larger holes that range from 20mm to 70mm in diameter and are typically used for industrial and heavy-duty applications. We do not currently offer any from immediate stock in this range.

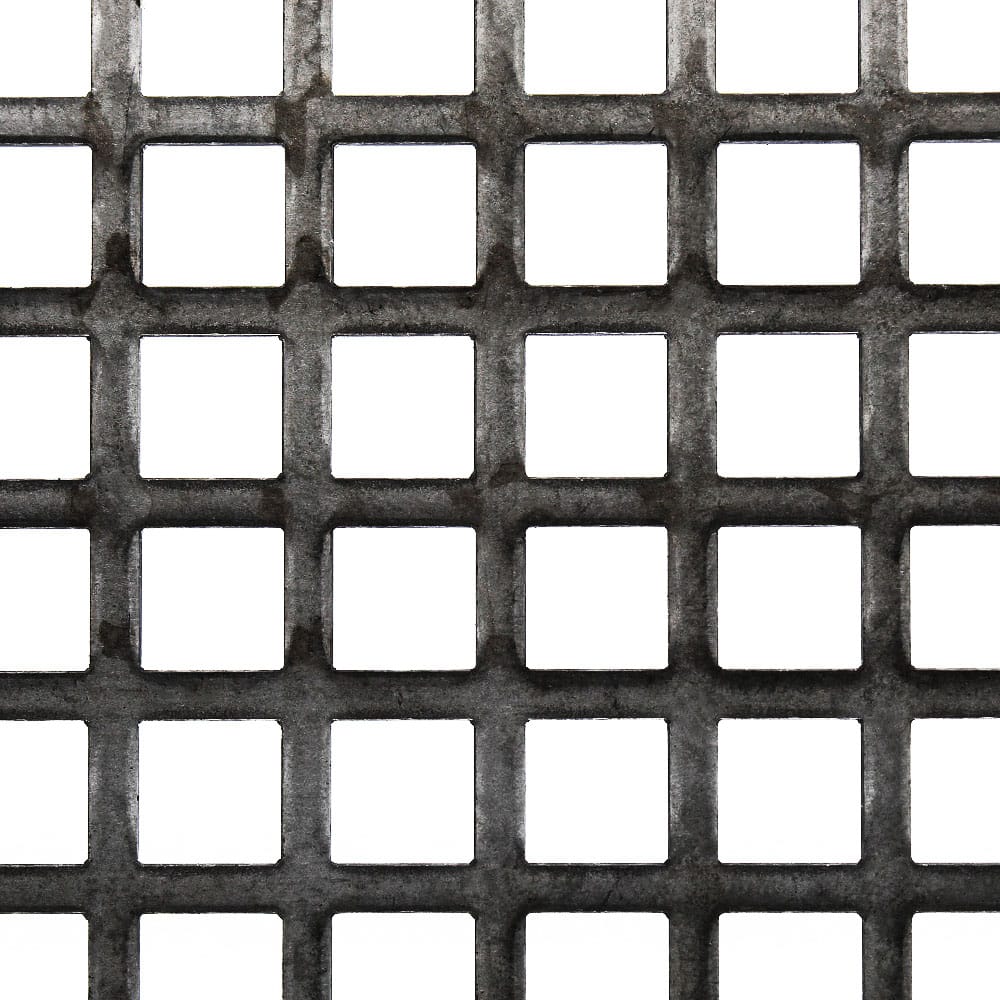

This type of metal is easy to work with and can be adapted to a variety of applications, from decorative panels to industrial machinery.

One of the main benefits of square-hole perforated metal is its ability to allow for improved ventilation and airflow, making it ideal for use in HVAC systems.

Additionally, the square holes provide a unique design element that can add visual interest to any project.

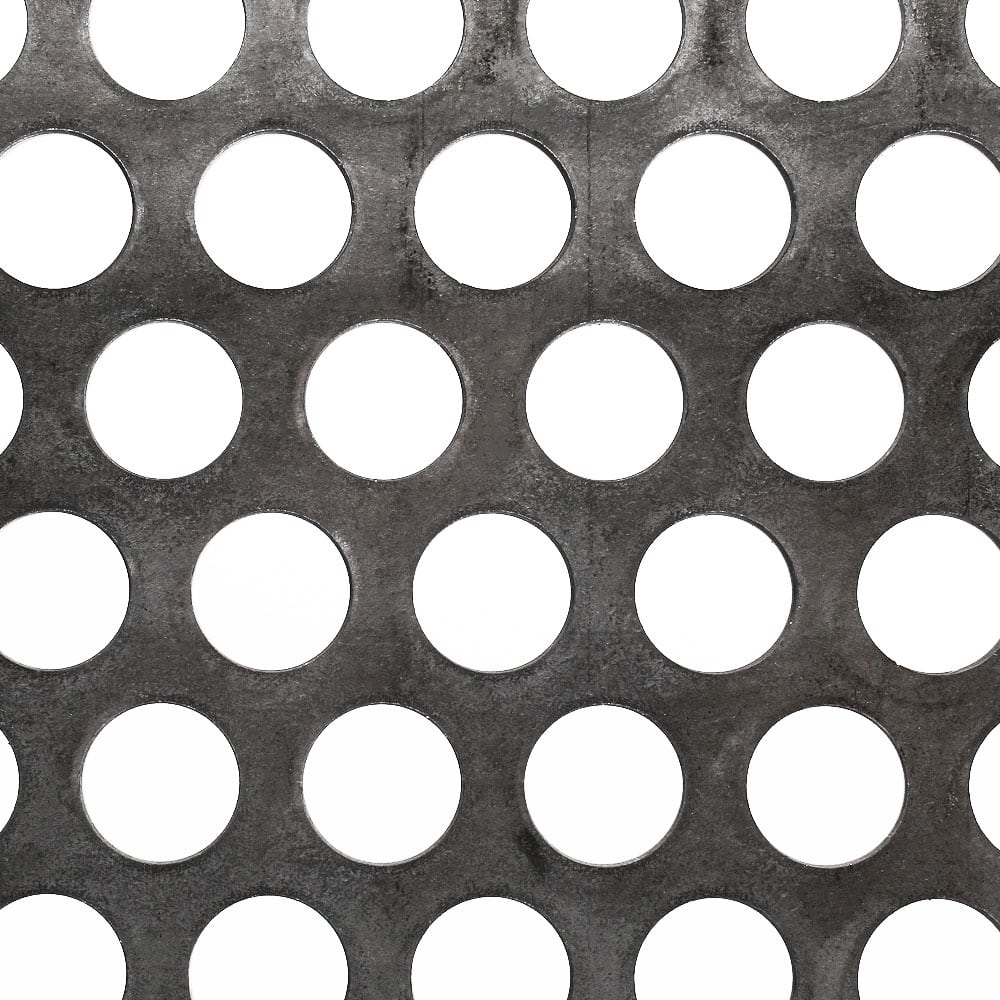

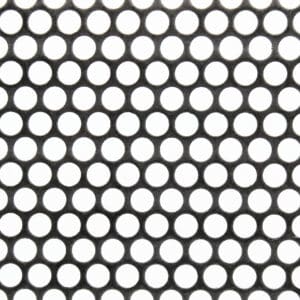

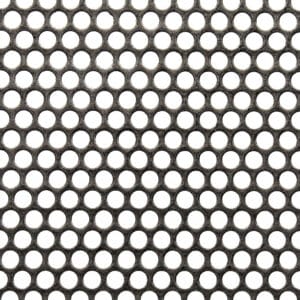

Round perforated metal made of mild steel comes with several benefits. The holes in the metal allow for increased airflow and greater visibility, making it an ideal option for decorative, architectural, and industrial purposes.

The round holes also provide a unique aesthetic appeal to any project, adding a touch of style and sophistication. Some common applications of round perforated metal include ventilation screens, speaker grilles, and filtration systems.

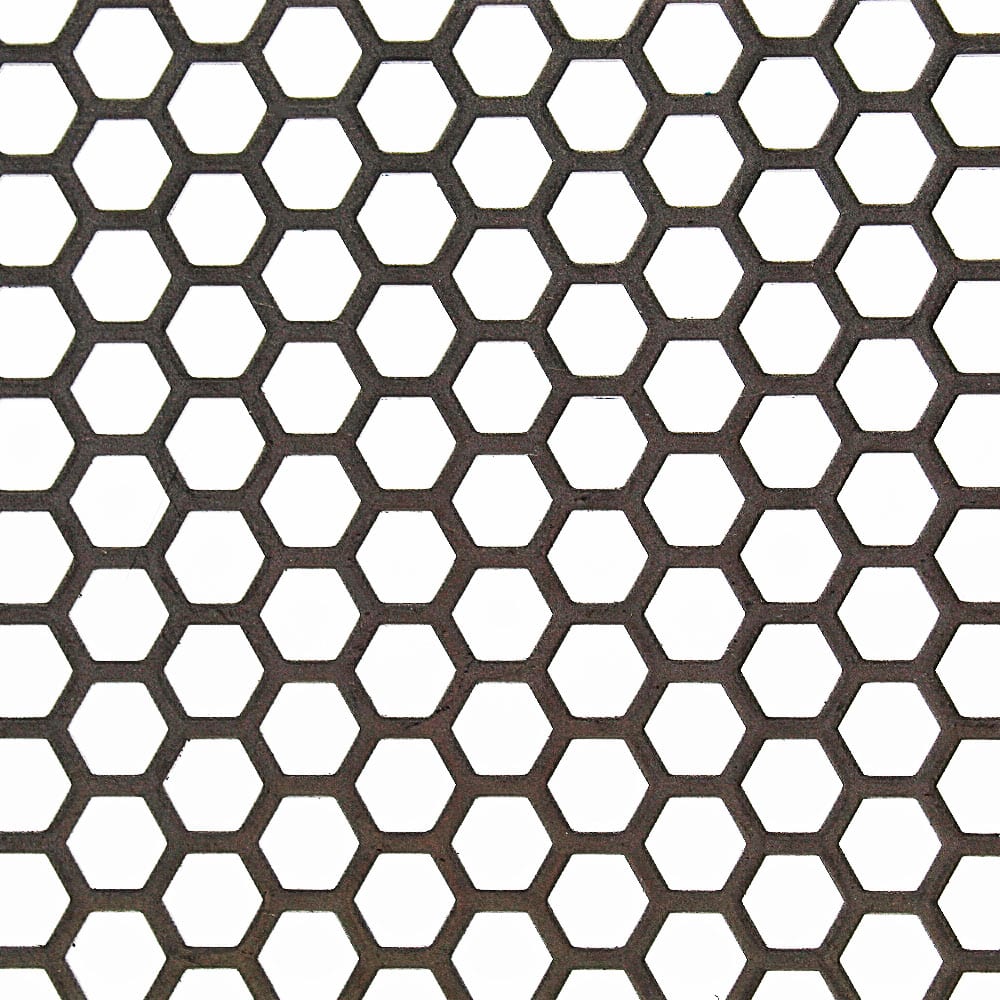

Hexagonal perforated metal is a type of mild steel sheet with hexagonal-shaped holes that are uniformly spaced throughout the surface.

The hexagonal hole pattern offers a number of benefits, including superior ventilation, filtration, and drainage capabilities. Because the holes have an open design, hexagonal perforated metal allows air and light to circulate through, making it an ideal material for use in architectural and decorative applications.

Additionally, the unique design of the hexagonal hole pattern lends itself well to industrial applications, such as grating and screening applications. From construction to automotive manufacturing, hexagonal perforated metal is a versatile material that is well-suited for a wide range of applications.

Mild steel perforated sheets are an excellent choice for a wide range of applications, thanks to their durability, strength, and versatility.

Whether you’re looking for a way to filter air or noise, or you need a sturdy material for machine guards, perforated mild steel sheets can provide a solution that meets your needs.

The Mesh Company offer more than 50 standard perforated mesh options. With so many to choose from, you can find the perfect perforated sheet for your project.

So why not consider mild steel perforated sheets for your next project?

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions