When it comes to selecting the right material for a project, the decision can often come down to minute details. This is very much the case when it comes to metal mesh.

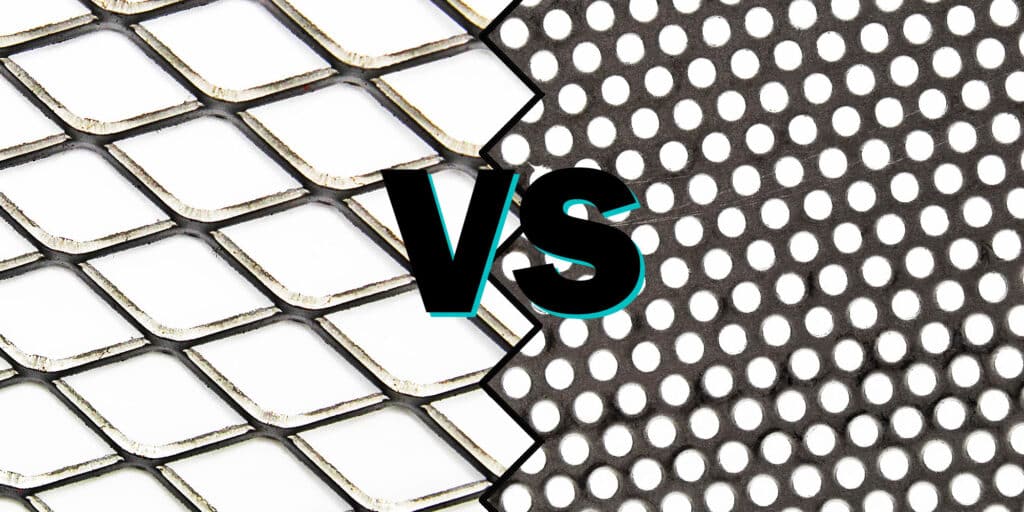

In the realm of mesh sheet, two main contenders often face off – expanded mesh and perforated metal.

Both materials offer a blend of aesthetic and functional properties, but understanding their unique characteristics can help determine the best fit for specific applications.

Let’s get into it….

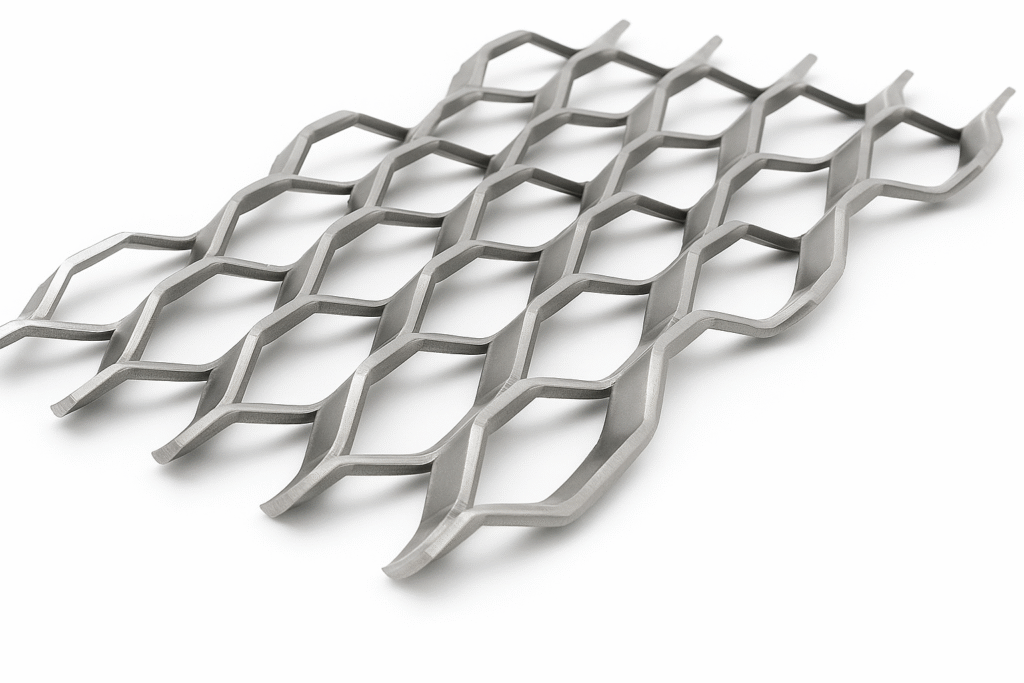

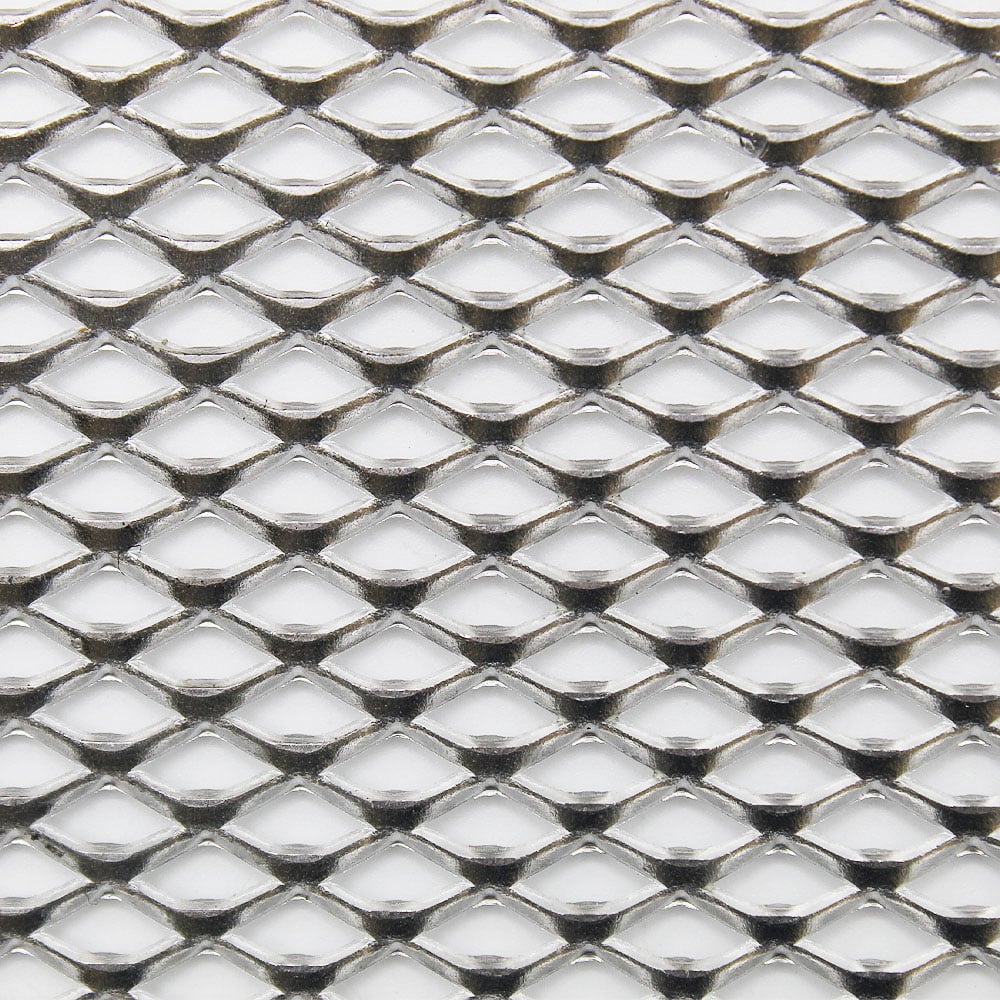

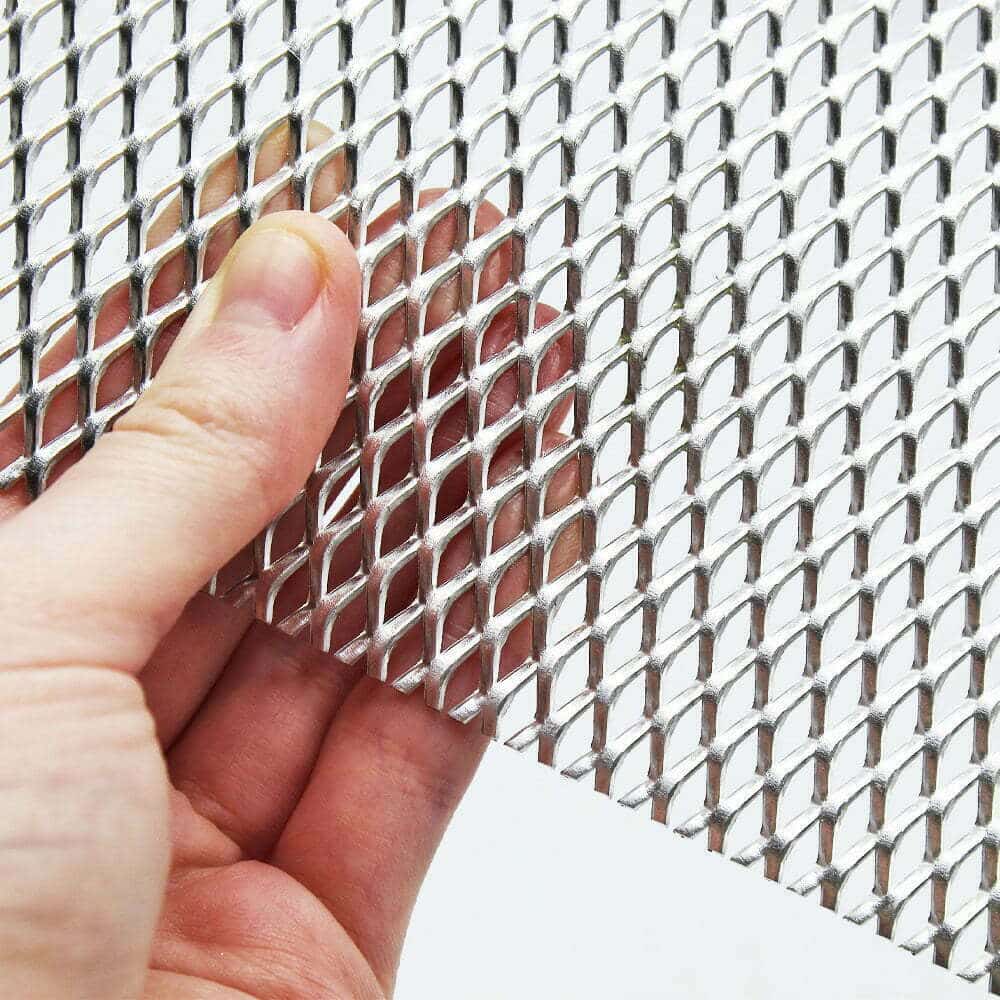

Expanded mesh is made by slicing a solid sheet of metal and stretching it to form a diamond-shaped pattern. This process creates a single, continuous piece of material, ensuring structural integrity. Expanded mesh is known for its versatility, durability, and affordability, making it a popular choice for various applications, including fencing, grating, and architectural features.

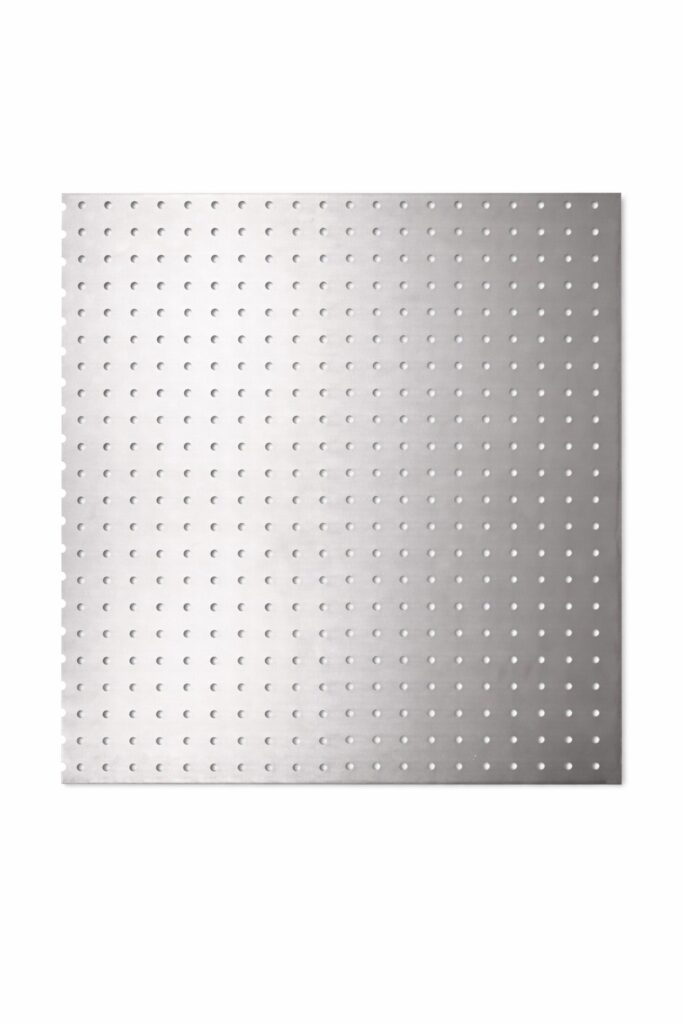

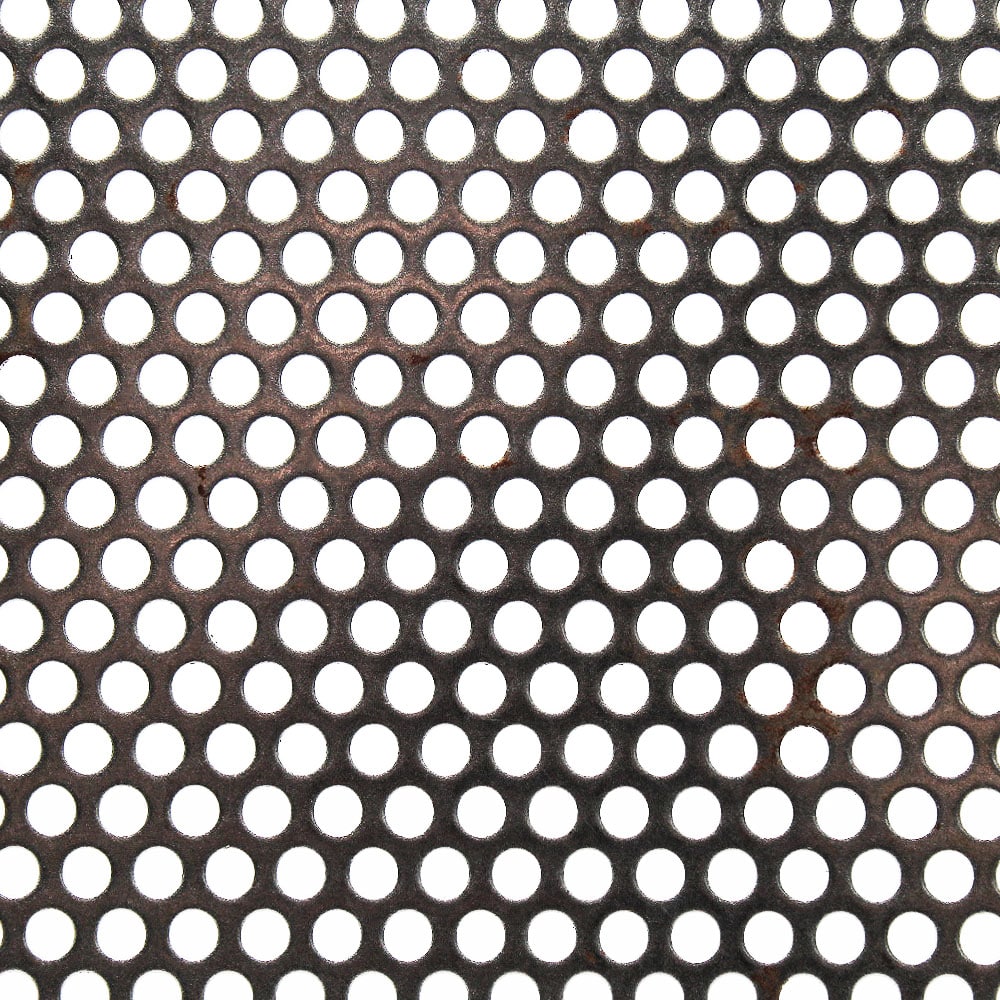

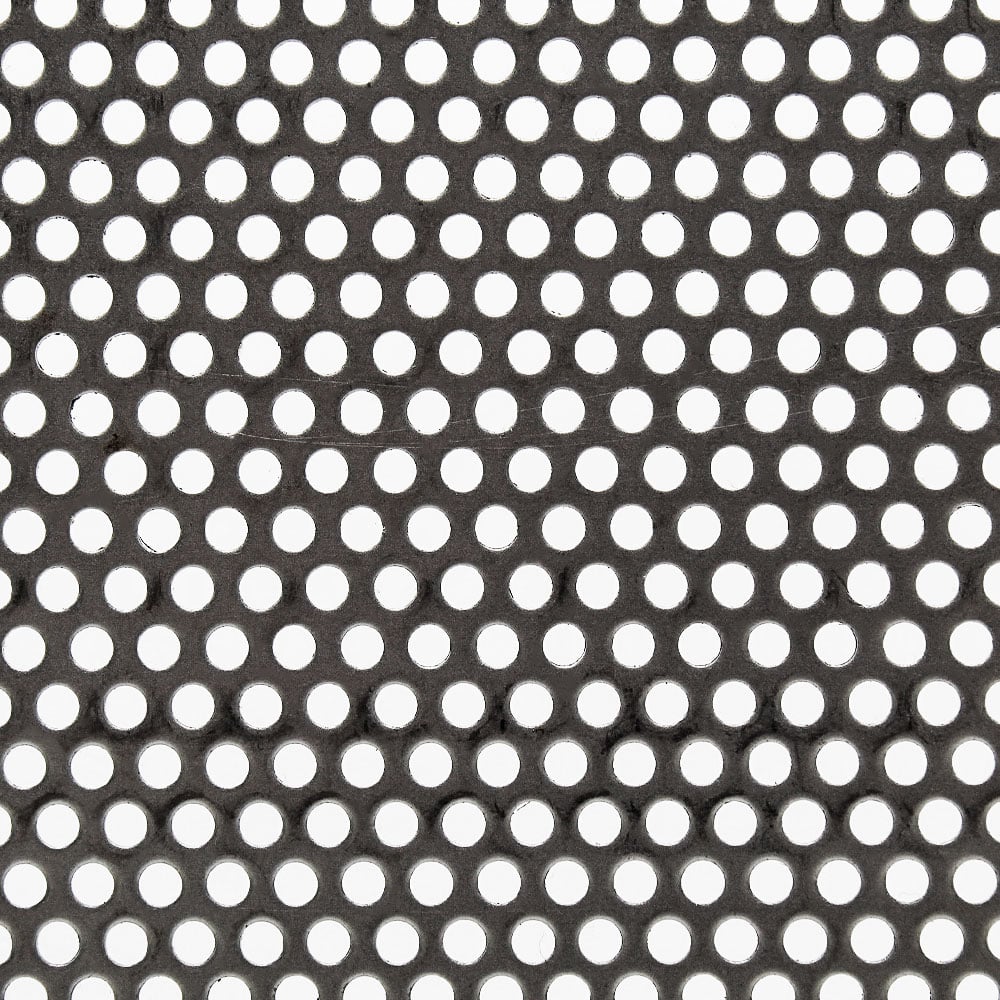

Perforated metal is created by mechanically or manually punching holes into a metal sheet, resulting in a patterned array of holes that can be customised in various shapes, sizes, and arrangements. It is widely used in industrial, architectural, and decorative applications due to its versatility, aesthetic appeal, and the ability to control light and air passage.

The environment where the mesh will be installed plays a significant role in the material selection.

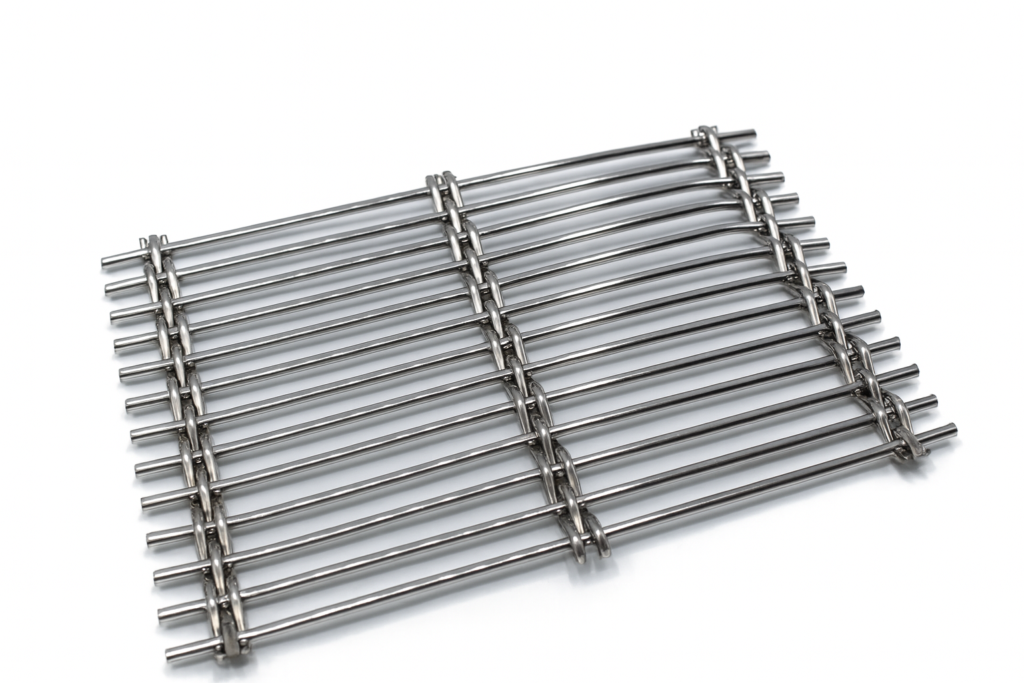

Mesh and metal sheets often need to be integrated or paired with other materials in diverse applications. How they blend and interact can influence the choice.

Perforated metal mesh is characterised by a variety of different features that add to its versatility, one of which is the ability to make holes in a variety of shapes. As each shape has its own set of functional and aesthetic characteristics, it can be tailored to meet the needs of various design preferences as well as the requirements of different projects.

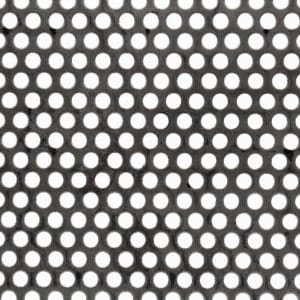

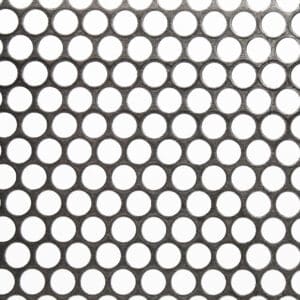

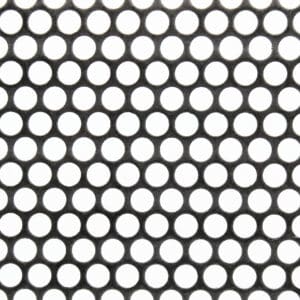

As far as perforations go, round holes are the most common and most popular. The traditional design of this window provides a uniform and symmetrical pattern, allowing for optimal airflow and light passage through the window. Since round holes are designed with a circular shape, they are able to effectively distribute stress, making them suitable for rigorous applications while ensuring a low wear rate due to their circular shape.

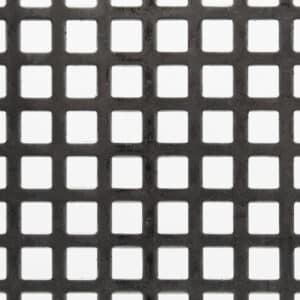

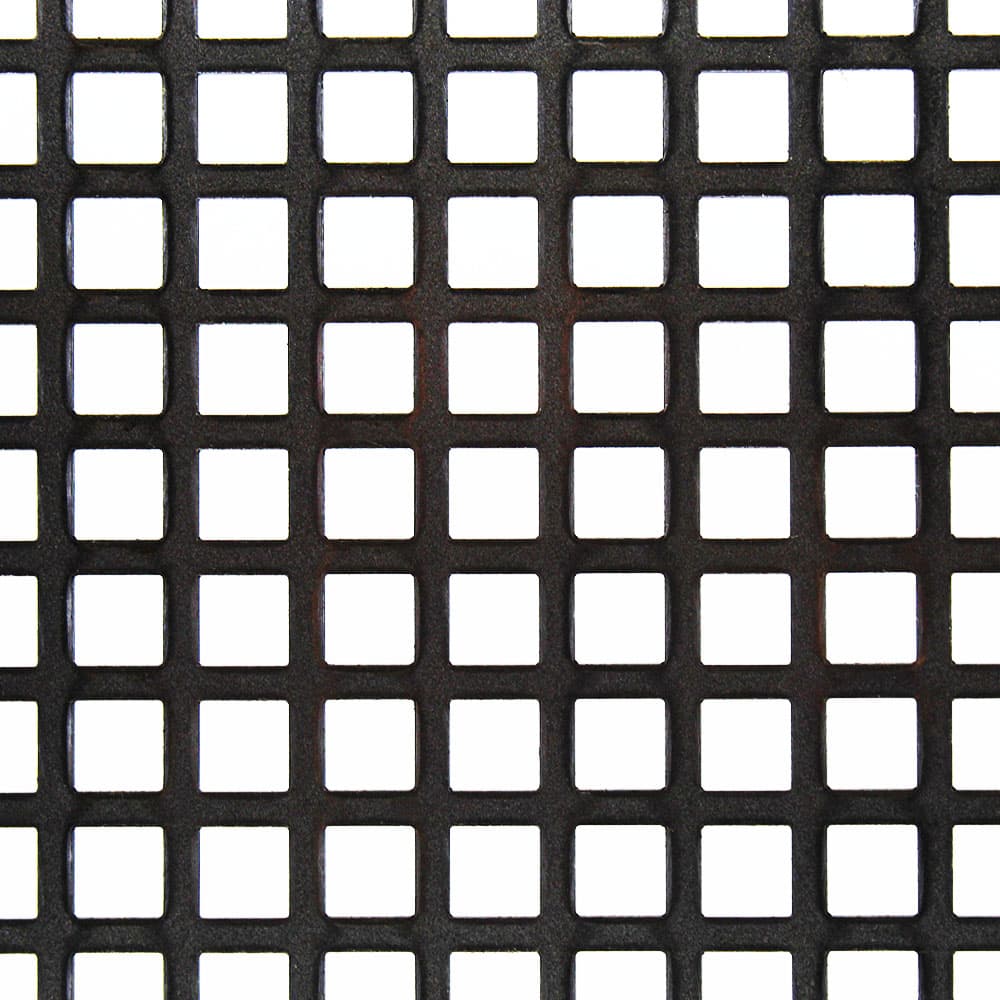

Square hole perforations strike a balance between design elegance and functionality. Often associated with a contemporary flair, they present a modern aesthetic, and provide a consistent open space across the entire floor plan. In addition to their geometric precision, their linear approach to design makes them a favorite in architectural and industrial applications where alignment and uniformity are a key requirement.

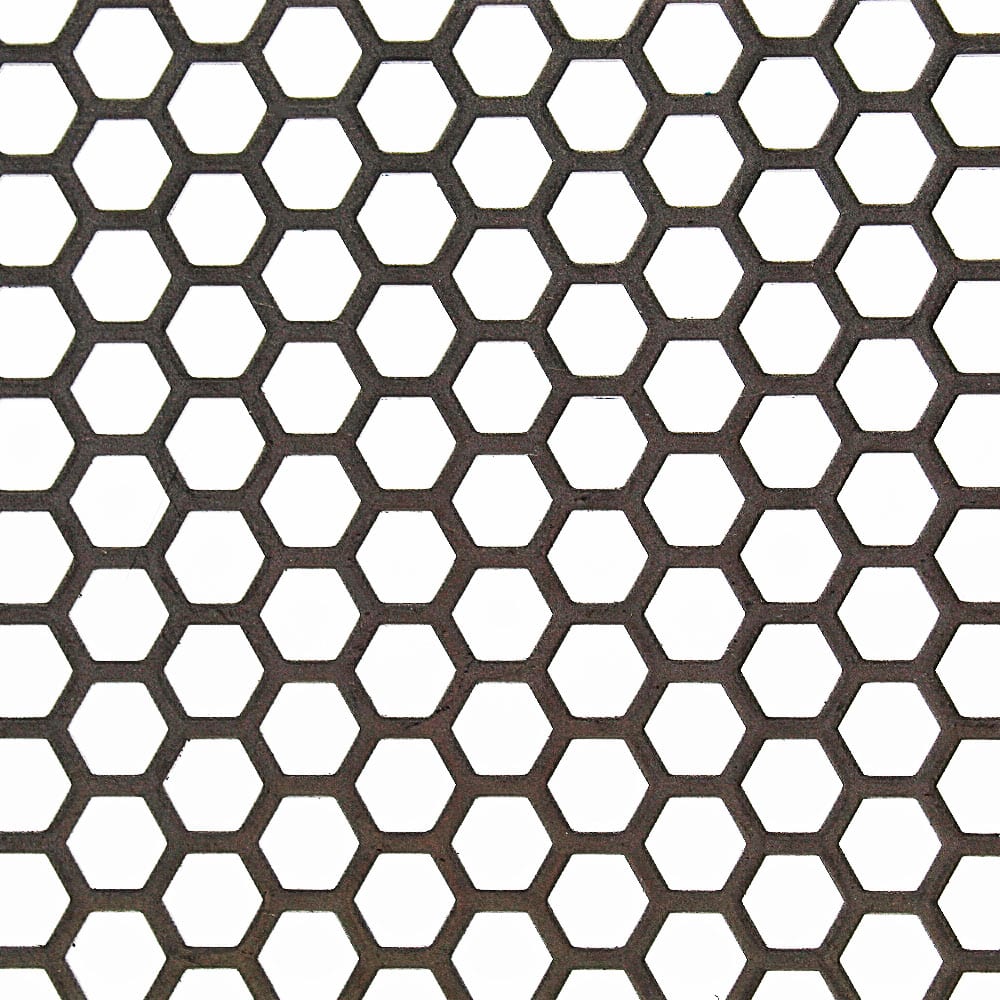

Hexagonal hole perforations, with their six-sided design, are a nod to the beauty of natural patterns, reminiscent of honeycombs. In addition to their aesthetic appeal, hexagonal holes offer a tight interlocking pattern that lends a higher strength-to-weight ratio than other hole shapes. As a result of this shape, it is particularly effective for filtering applications, as it maximises the open area while ensuring that the structure remains intact.

There is no doubt that in the world of perforated metal mesh, the shape of the perforations plays an essential role in influencing both the visual appeal and the performance of the mesh. The choice of hole shape can have a significant impact on the final product’s appearance, feel, and functionality, whether it’s the classic round, the structured square, or the nature-inspired hexagonal.

As we know, when it comes to expanded metal mesh, it isn’t just about the type or thickness of metal that matters; it is about the pattern intricacies that have a significant impact on both the functionality and the aesthetic quality of the final product.

Diamond Pattern: Among the most iconic and widely recognised patterns of expanded metal mesh, the diamond pattern is what most people envision when they think about expanded metal mesh. With its symmetrical, versatile design, it offers an optimal balance between strength, airflow, and visibility. From walkways to fences, its consistent pattern provides a harmonious appearance that makes it a go-to choice for a wide range of applications.

Hexagonal Pattern: A six-sided pattern like honeycomb offers a distinctive aesthetic and structural advantage due to its resemblance to honeycombs. By providing an even distribution of weight and stress, it ensures that the product will last for a long time. In addition to that, its unique appearance gives architectural applications a modern touch that makes them stand out from the crowd.

Square Pattern: There is no better choice than the square pattern if you are looking for a more geometric and contemporary look. A uniform and regular design makes it an ideal option for facades, screens, and decorative partitions, as it provides uniformity and regularity in design. Additionally, the straight lines and angles provide an alternative to the traditional diamond pattern, presenting a clean and orderly appearance as compared to the traditional diamond pattern.

It is important to note that each pattern in expanded metal mesh serves a specific purpose and offers a unique visual dynamic to the user. In order to ensure that the mesh aligns perfectly with the project’s goals, it is vital to consider both the aesthetic preferences and the functional requirements, whether you choose the classic diamond shape, the nature-inspired hexagonal shape, or the modern square shape.

Whether you choose expanded mesh or perforated metal depends on the specific requirements of the project you are working on. Expanded mesh might be a better option for you if structural integrity, durability, and budget are your top priorities. As an alternative, perforated metal could be a better option if aesthetic flexibility, customisation, as well as light/sound control are important to you.

Make sure you consider the environmental conditions, the expected maintenance requirements, and the long-term performance of the equipment when making your choice. Working with a high-quality metalwork professional can also provide you with insights tailored specifically to your specific project requirements, ensuring that the material selected meets not only your aesthetic expectations but also performs optimally in its intended application.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores which to choose between metal and plastic mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.