When it comes to selecting the right type of metal mesh for a project, there’s a multitude of options available, each with its distinct characteristics and applications.

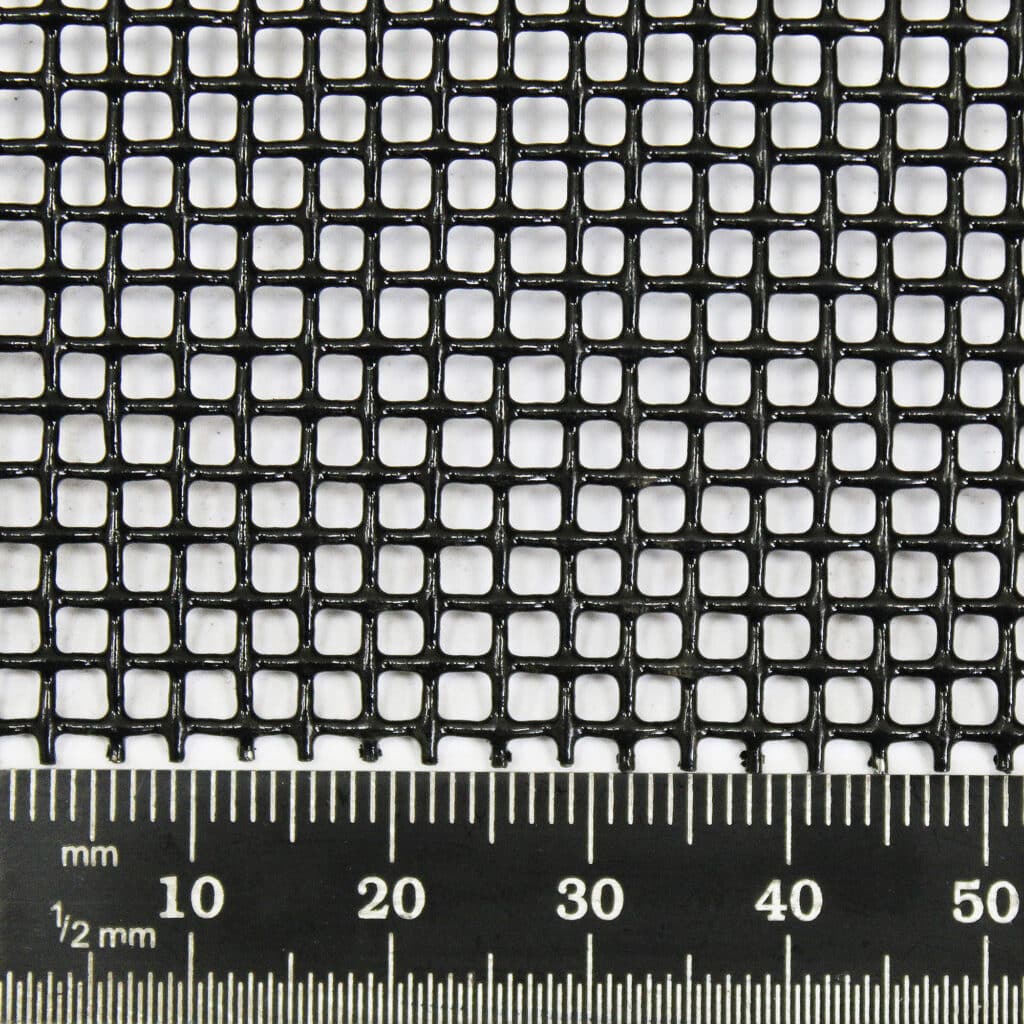

Among these, epoxy coated black metal mesh stands out with our customers for its strength, durability, and aesthetic appeal.

This comprehensive guide dives deep into the process of how black epoxy steel woven wire mesh is made, its primary uses, and why it’s often the preferred choice over other metal meshes.

Let’s get into it….

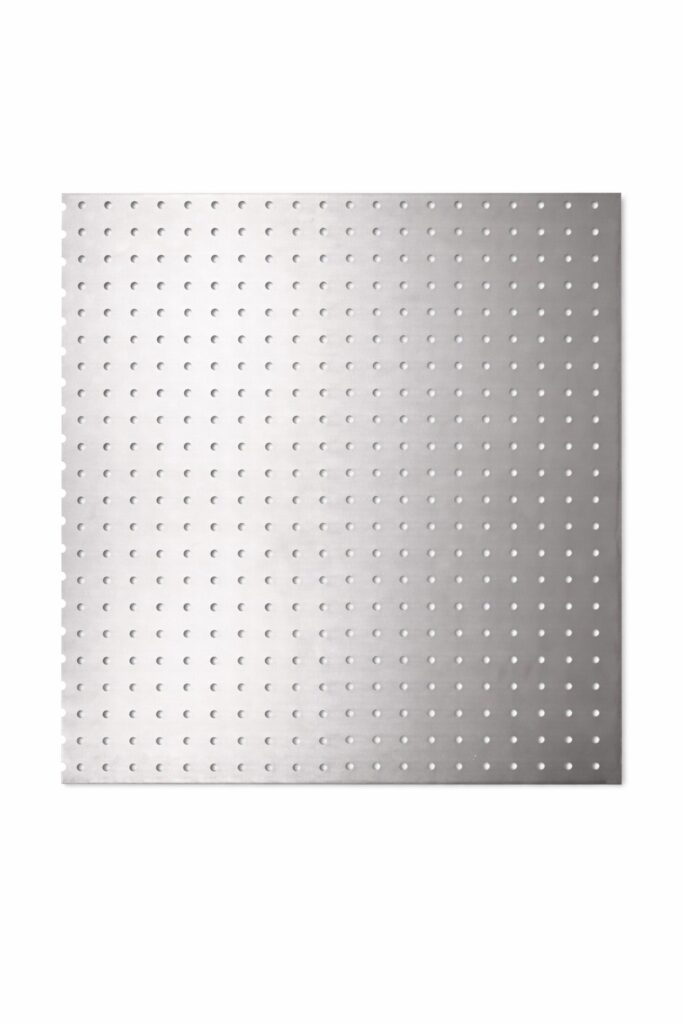

Creating epoxy coated black metal mesh is a process that begins with the base metal, which is usually steel, which is coated with epoxy. In order to form the mesh, steel is used since it is known for its high tensile strength and durability.

Due to the heat involved, it is common for the mesh to bow and deform. This always triggers a rejection of the material.

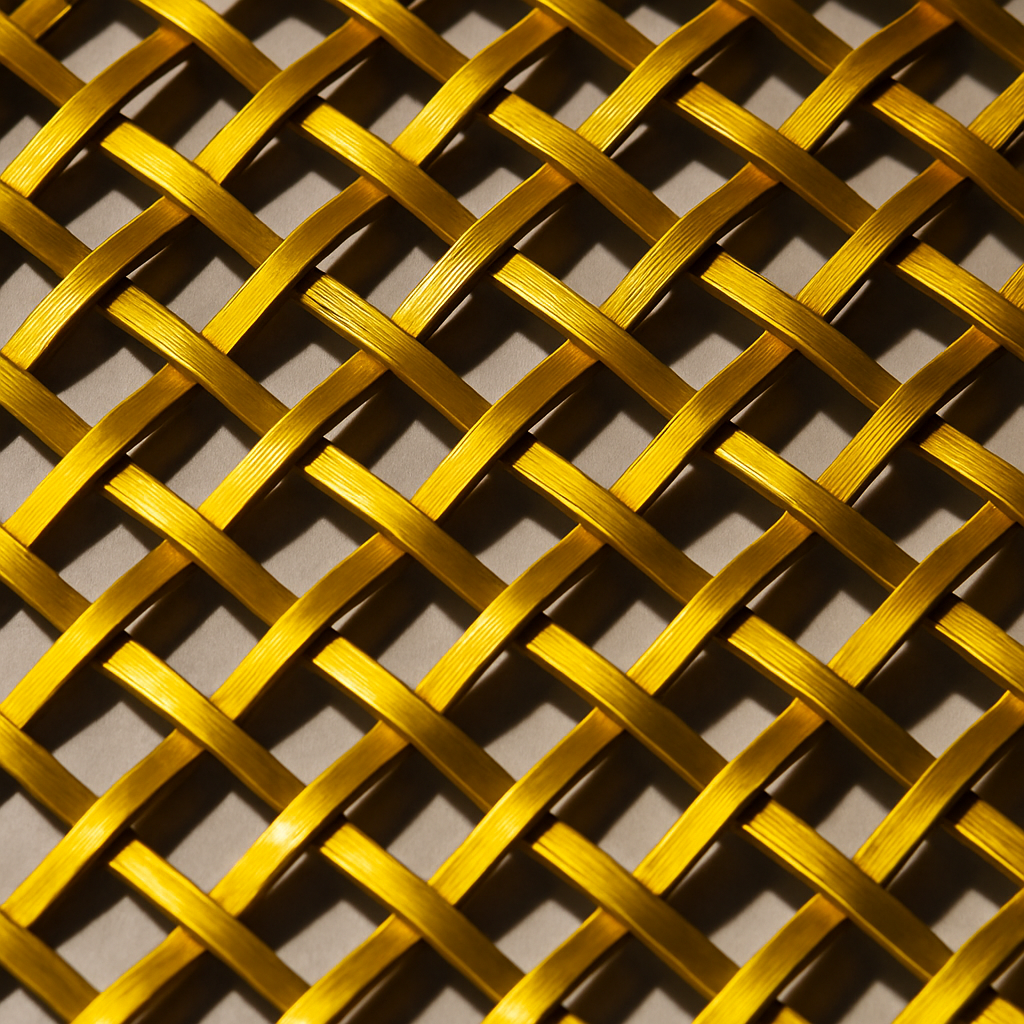

Epoxy coated black metal mesh is renowned for its versatility and effectiveness in various applications. Here are some of the key areas where this mesh excels:

We recently published an article discussing this use for our wire mesh.

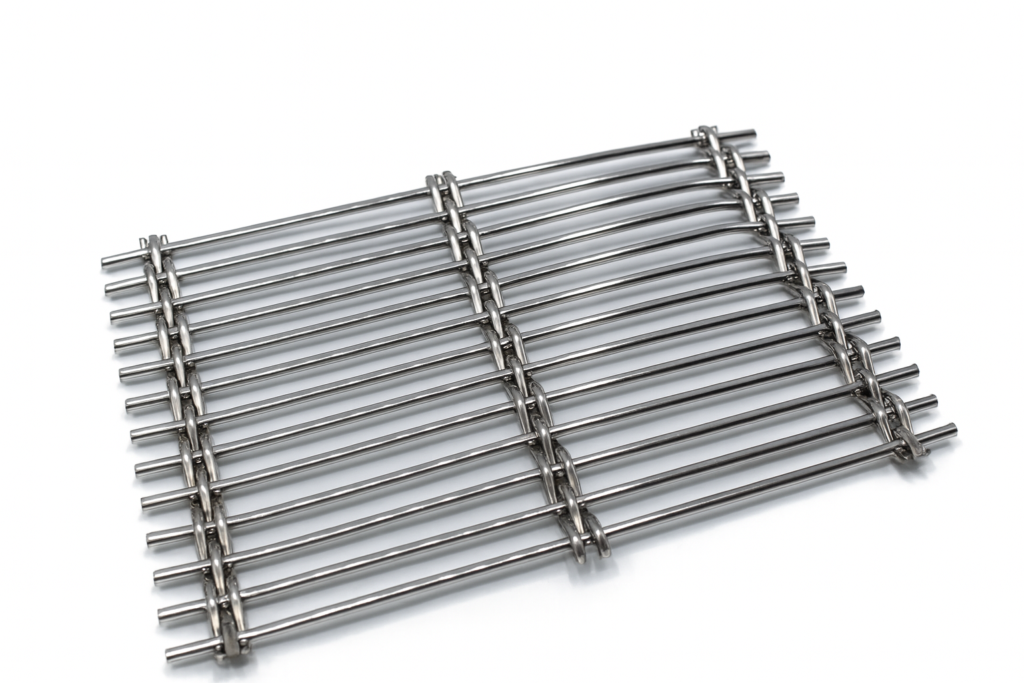

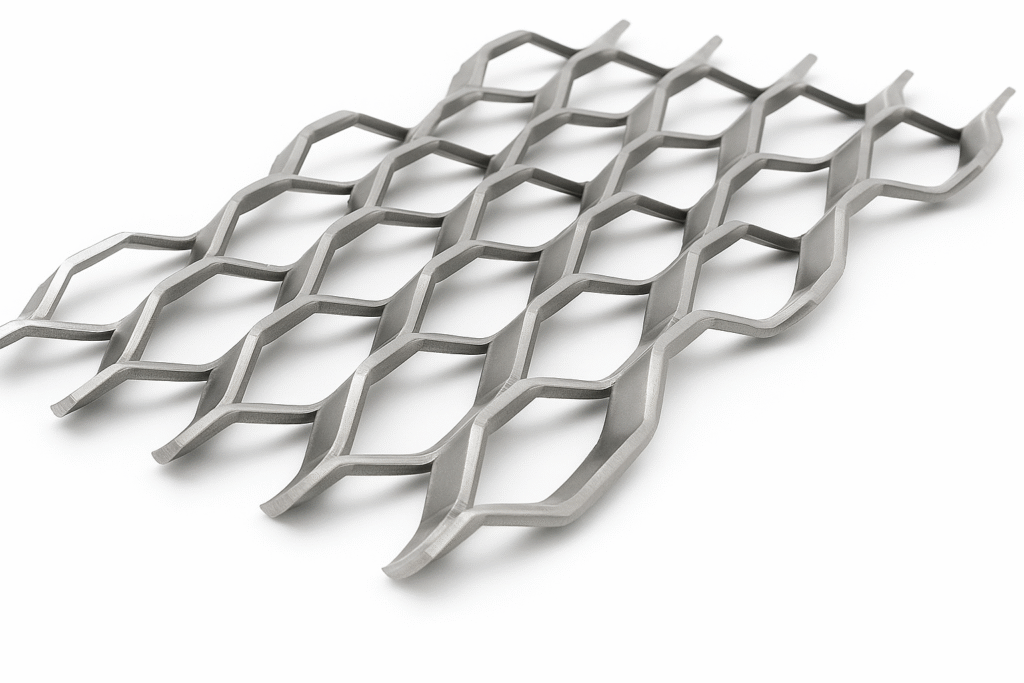

When comparing epoxy coated black metal mesh to other types like stainless steel, galvanised steel, or even non-metallic meshes, several advantages become clear:

With its exceptional durability, aesthetic appeal, and versatility, epoxy coated black metal mesh is a superior choice in a wide range of applications. Whether for industrial use, architectural design, or DIY projects, its unique properties make it an ideal choice for those seeking quality and style in their metal mesh. It’s only when one understands how it’s made and its diverse uses that one can appreciate its craftsmanship and value.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores the benefits of using wire mesh in a beehive.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.