Ensuring workplace safety is paramount in industries where machinery and heavy equipment are in operation. Machine guards and safety screens serve as protective barriers that prevent injuries, reduce hazards, and improve workplace efficiency. Among the various materials available, wire mesh stands out as an ideal choice due to its strength, visibility, and ventilation properties.

At The Mesh Company, we provide high-quality wire mesh solutions that meet the demands of industrial safety regulations. This article explores why wire mesh is a superior material for machine guarding, its benefits, different types available, and how to choose the right option for your needs.

Industrial environments often involve high-speed machinery, rotating parts, and hazardous processes. Without adequate protection, workers face risks such as accidental contact, flying debris, and entanglement hazards. To prevent these dangers, machine guards act as physical barriers that comply with safety standards set by organisations such as the HSE (Health and Safety Executive) in the UK.

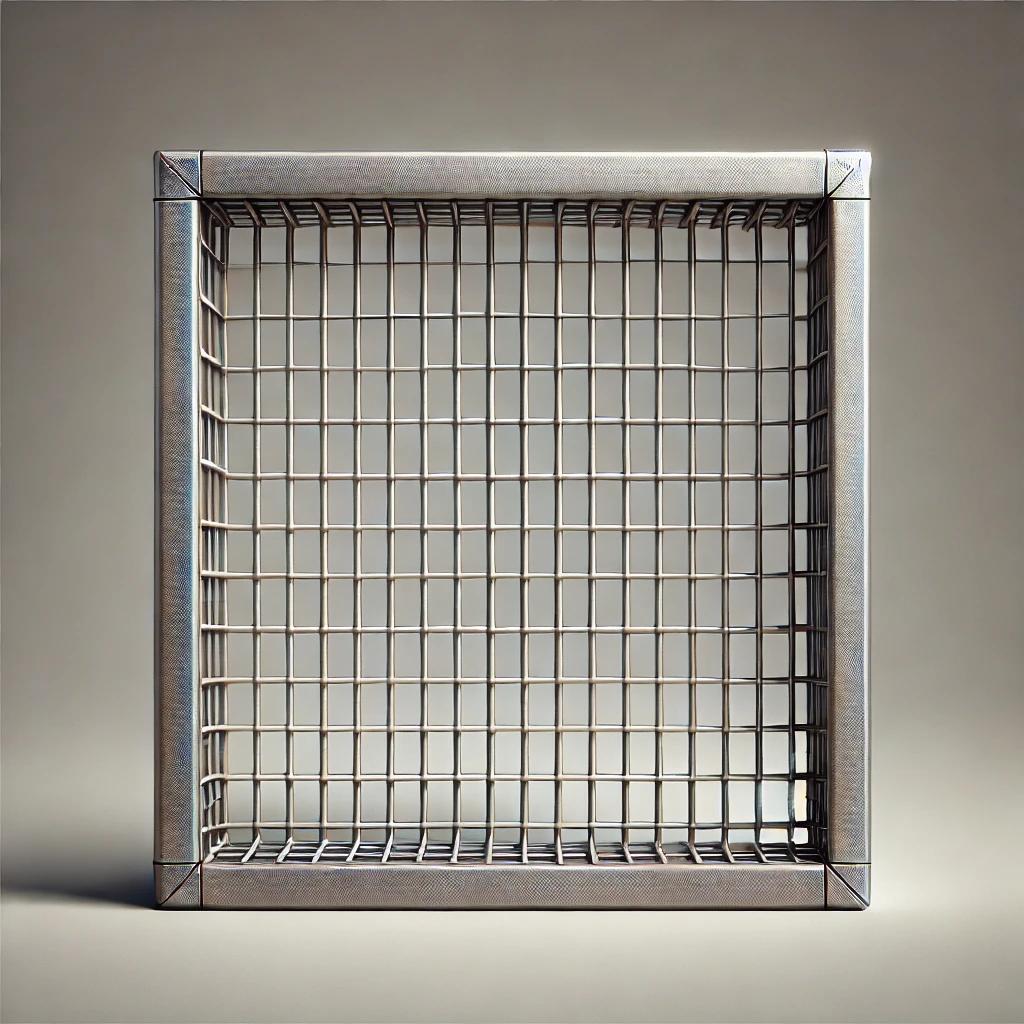

Wire mesh offers a solution that is both protective and practical. Unlike solid panels, mesh allows visibility, air circulation, and quick maintenance access, making it a preferred choice in manufacturing plants, warehouses, and workshops.

✅ Example from The Mesh Company:

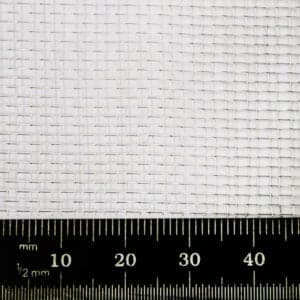

One of the primary reasons wire mesh is used for machine guards is its high tensile strength. Depending on the material, it can withstand high impact and prolonged use without deteriorating. Stainless steel and galvanised steel meshes offer excellent resistance to corrosion, heat, and wear, ensuring long-term protection in industrial settings.

✅ Recommended product:

Unlike solid metal barriers, mesh allows clear visibility of machinery while maintaining protection. This feature is crucial for operators who need to monitor equipment function and detect potential faults quickly. Clear sightlines improve workplace efficiency, as maintenance teams can assess problems without dismantling entire sections of the guard.

In industries where machines generate heat, proper ventilation is essential to prevent overheating and maintain operational efficiency. Wire mesh facilitates air circulation, reducing the risk of machinery malfunction caused by trapped heat. Additionally, it helps in environments where dust and fumes need to be controlled.

✅ Recommended product:

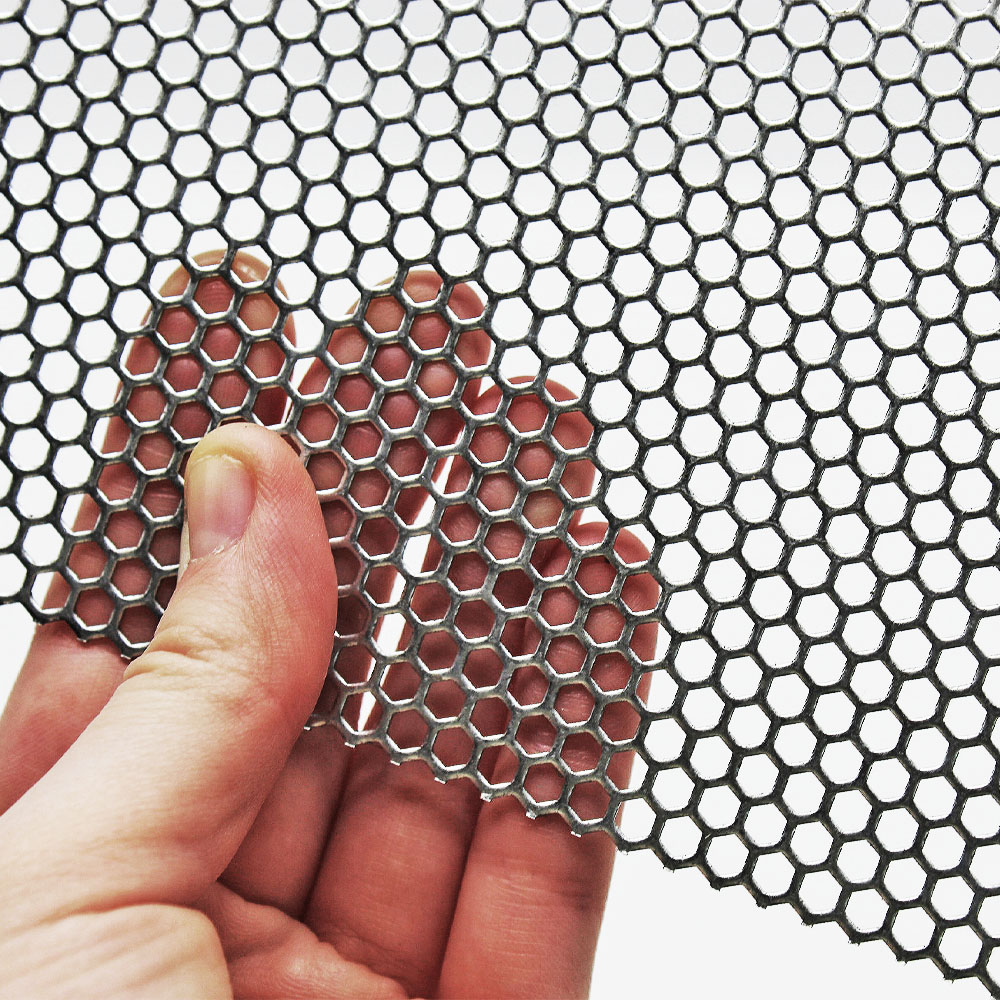

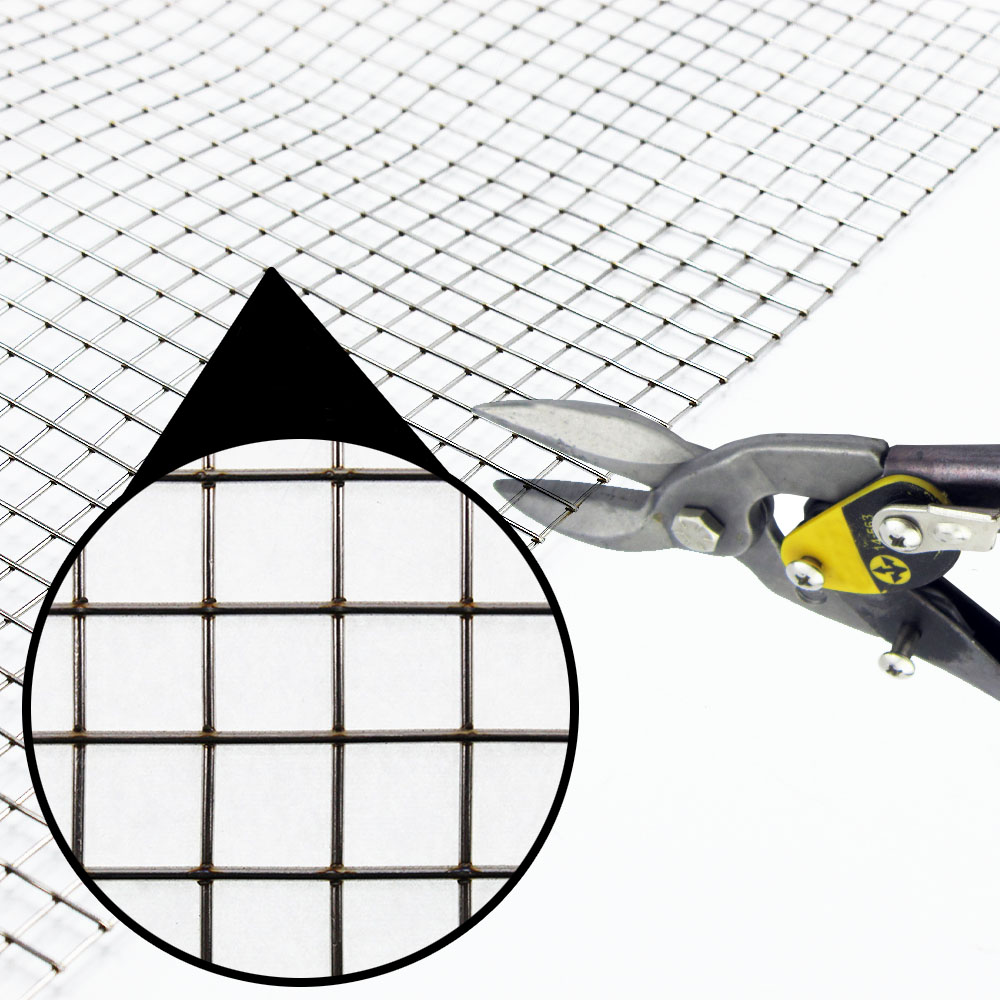

Not all machine guarding requirements are the same. Some applications require fine mesh for high-precision protection, while others need heavier gauge mesh for structural integrity. Wire mesh is available in various sizes, thicknesses, and coatings, making it highly customisable for specific needs.

✅ Recommended product:

Wire mesh is lightweight compared to solid steel panels, making installation and adjustments easier. It can be secured using bolts, welded frames, or quick-release fasteners, ensuring a firm yet modifiable setup. Additionally, maintenance teams can clean or replace sections without dismantling the entire guard, reducing downtime and improving efficiency.

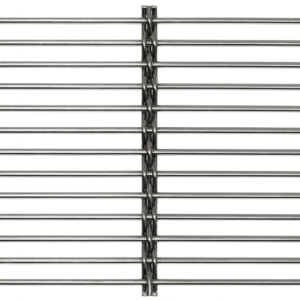

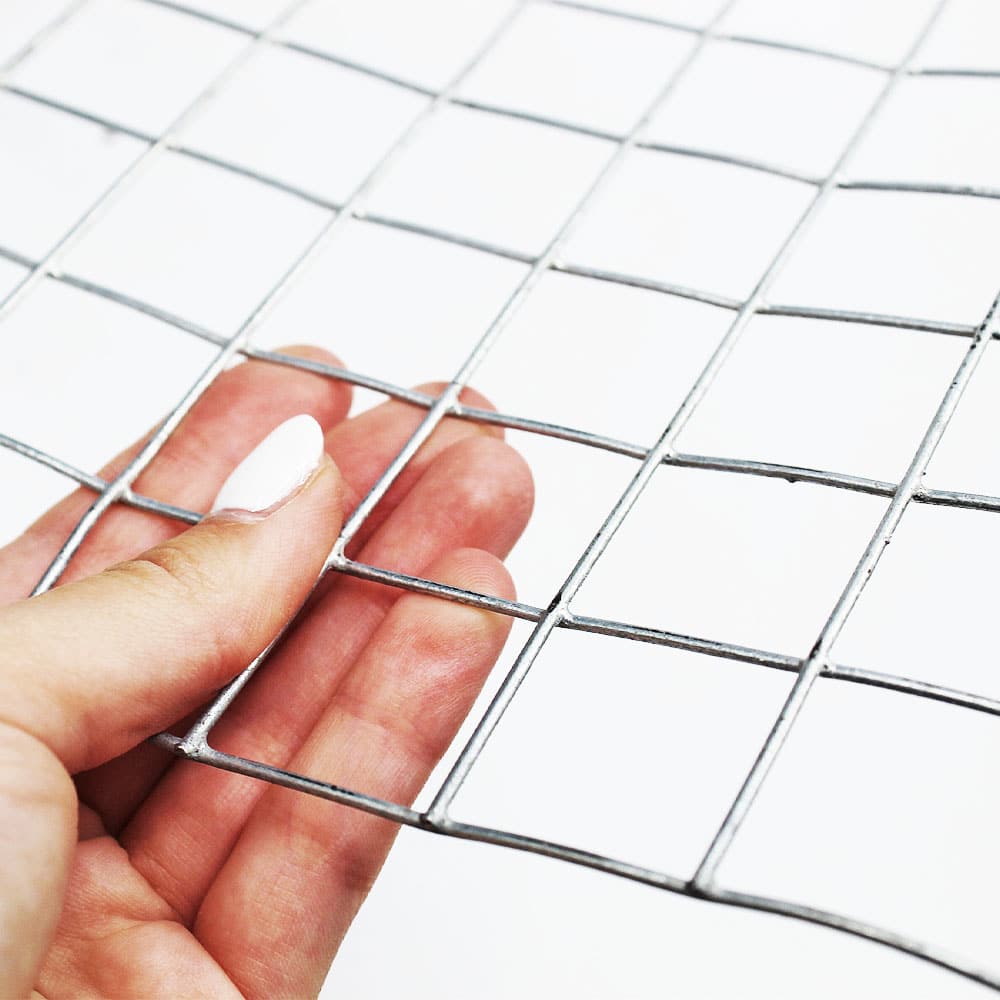

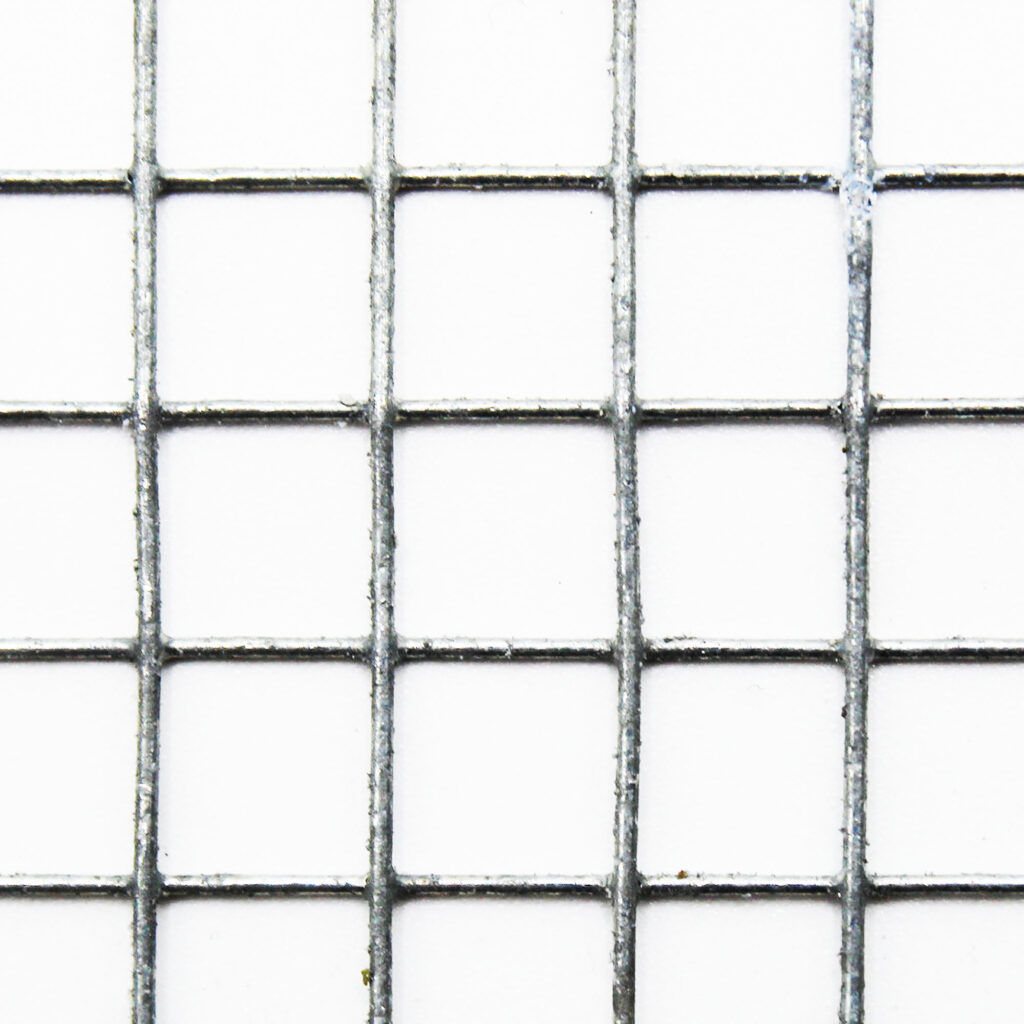

✔ Strong and rigid due to welded joints at each intersection

✔ Available in stainless steel, galvanised steel, and mild steel

✔ Suitable for permanent machine enclosures and security barriers

✅ Recommended product:

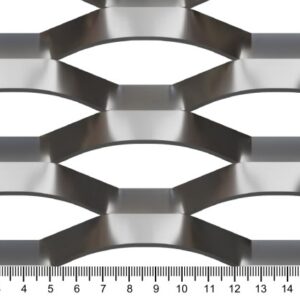

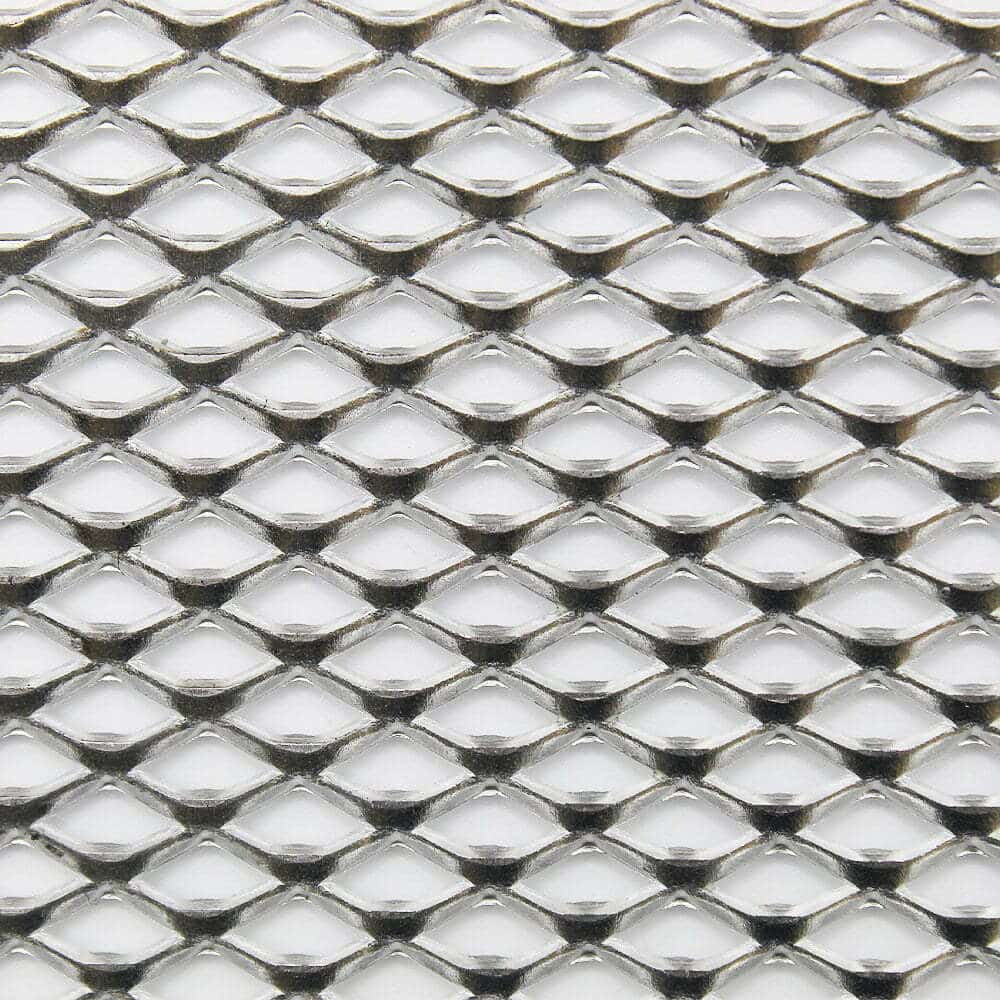

✔ Provides high strength while remaining lightweight

✔ Ideal for high-impact areas requiring additional durability

✔ Allows good airflow while preventing debris penetration

✅ Recommended product:

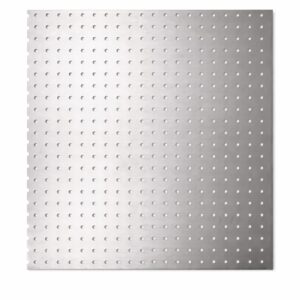

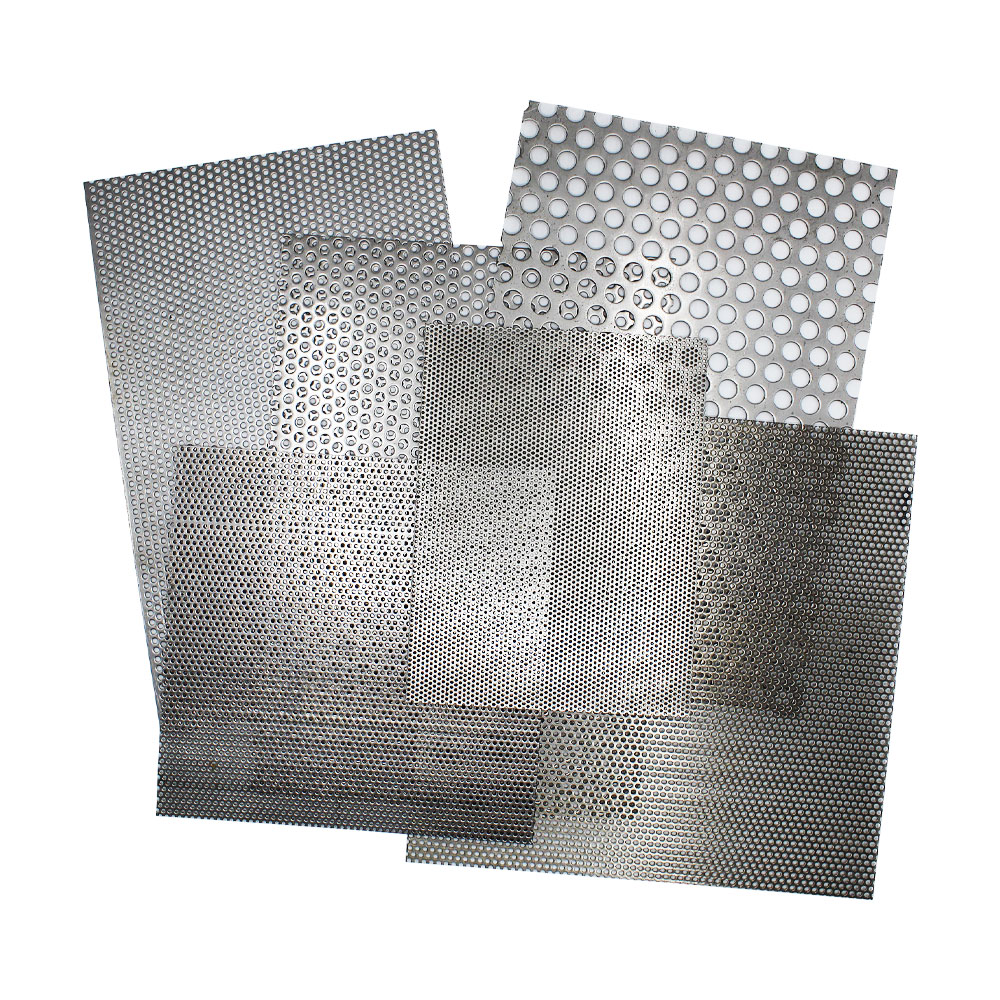

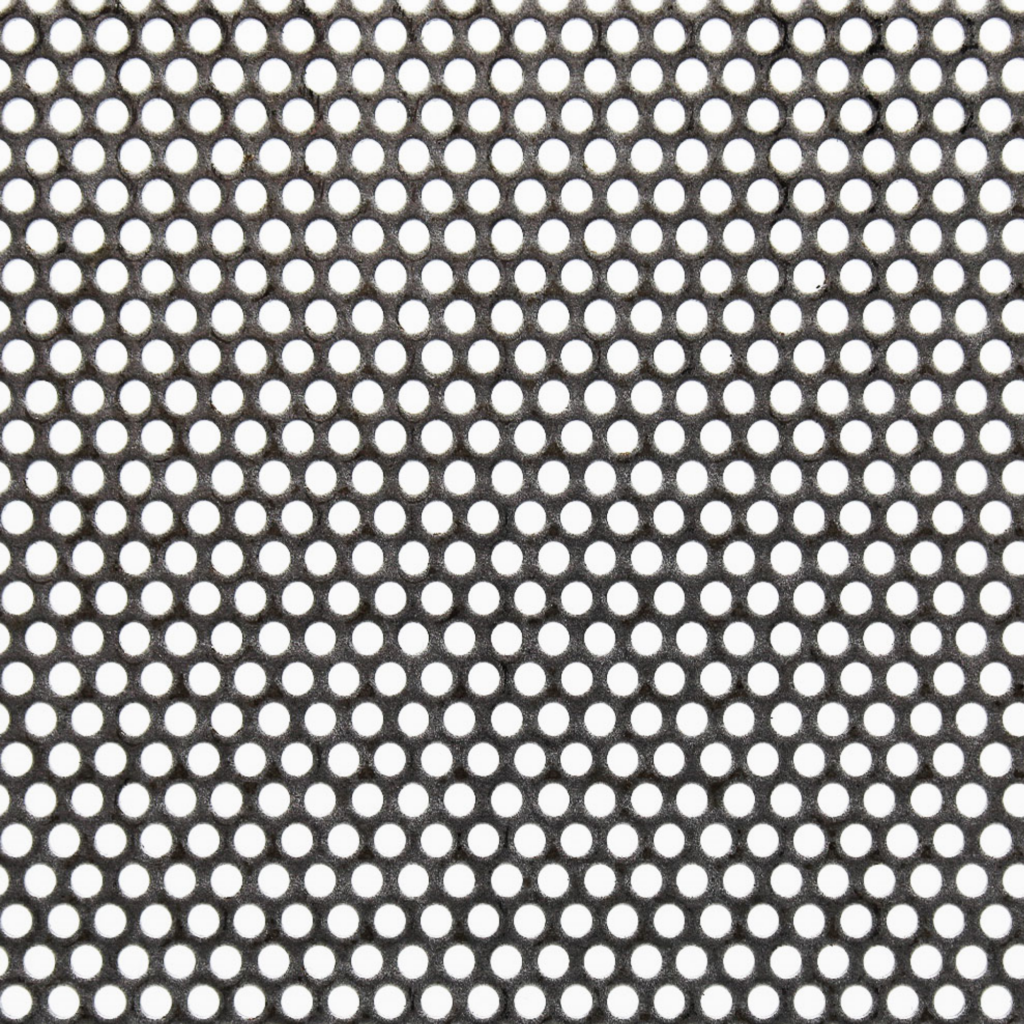

✔ Offers precise control over airflow and visibility

✔ Available in different hole sizes and patterns

✔ Used in areas where partial shielding is needed

✅ Recommended product:

✅ Example from The Mesh Company:

To maximise the effectiveness of machine guards, proper installation and maintenance are essential.

Wire mesh offers an unmatched combination of strength, visibility, and airflow, making it the perfect choice for machine guards and safety screens. Whether you need a high-strength barrier, a corrosion-resistant enclosure, or a lightweight ventilation screen, the right wire mesh can significantly enhance workplace safety and operational efficiency.

At The Mesh Company, we provide a wide range of high-quality wire mesh solutions for machine guarding applications. Our team can help you choose the perfect product based on your specific requirements.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.