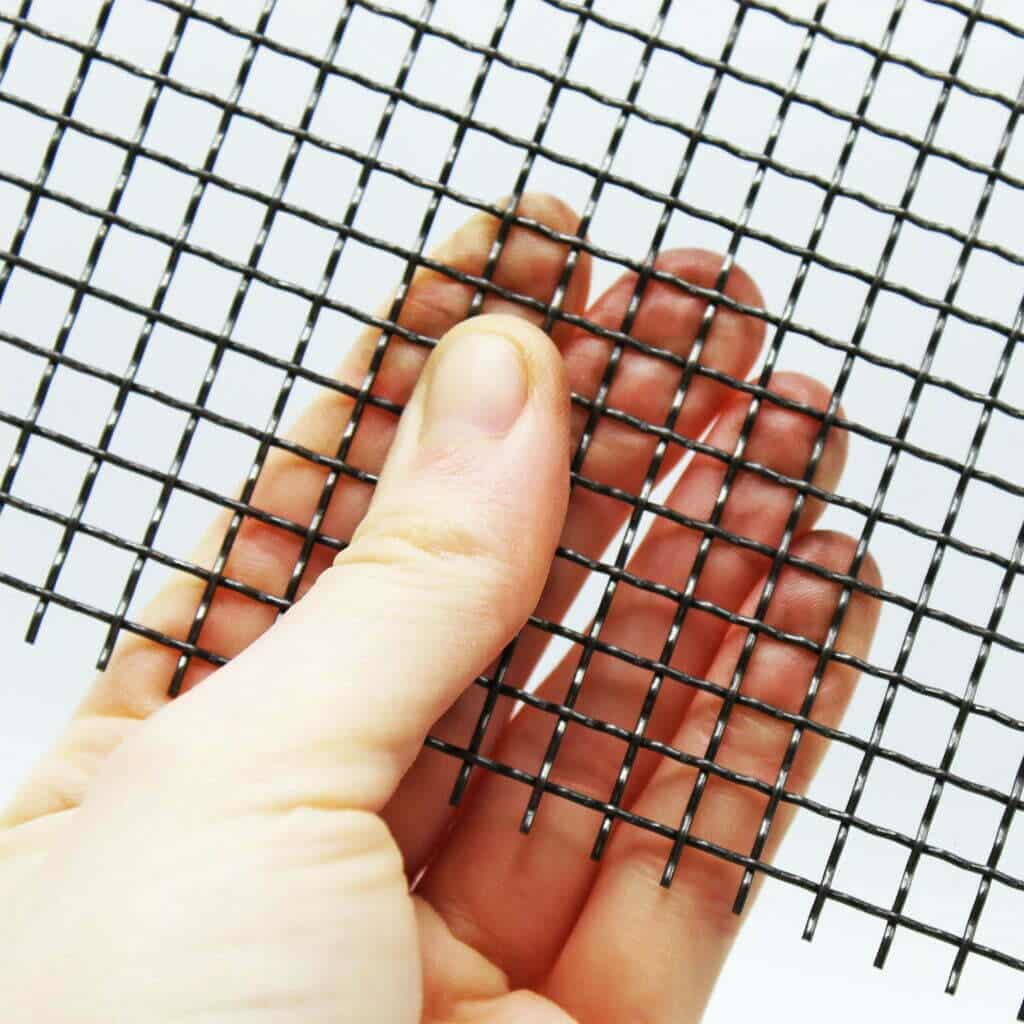

Woven wire mesh is a versatile material used across numerous industries, from construction and agriculture to food production and DIY projects. A critical factor in determining the suitability of woven wire mesh for a particular application is the relationship between wire thickness and hole size.

This blog will explore how these two factors impact the strength and functionality of woven wire mesh. Drawing on examples from The Mesh Company’s comprehensive range, we’ll guide you in choosing the best specifications for your project.

A = π × (d / 2)2

where d is the wire diameter. This value correlates directly with the tensile strength and load-bearing capacity of the wire.

OA = (1 − (wire diameter / pitch)2) × 100

where pitch is the distance between the centres of adjacent wires (essentially, the sum of the wire diameter and the hole size). The thicker the wire, the more durable and resistant the mesh is to deformation. For heavy-duty applications, such as security fencing or industrial sieving, wire thickness is a crucial factor.

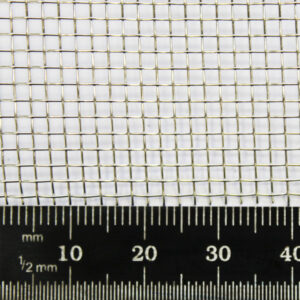

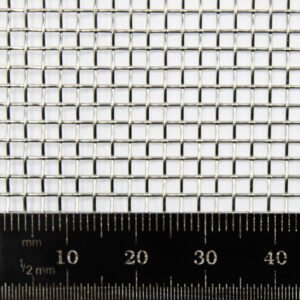

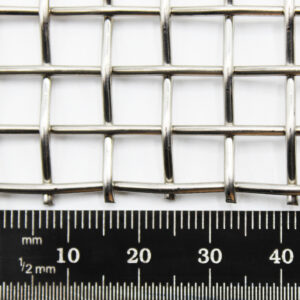

11.1mm Hole, 1.6mm Wire, 2 LPI Stainless Steel Mesh

This ultra-strong mesh is perfect for high-impact applications like industrial sieving or protective barriers.

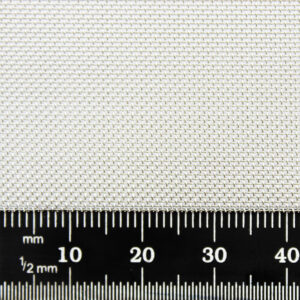

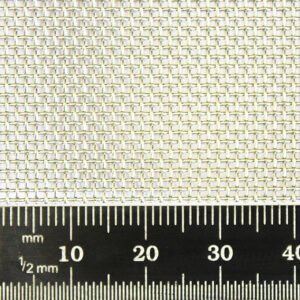

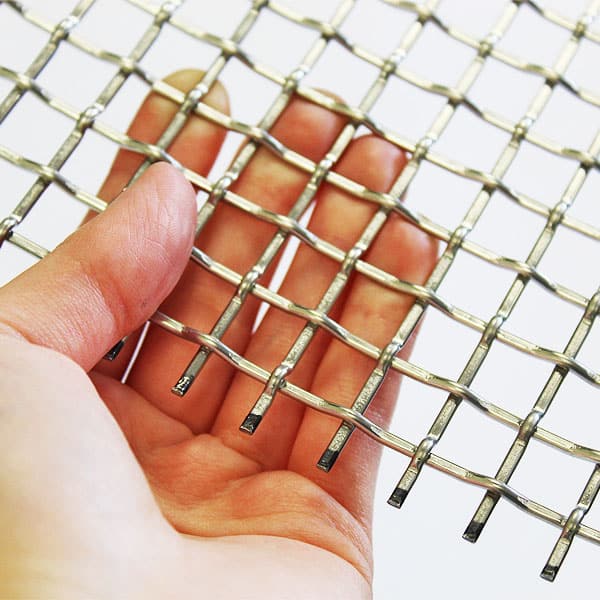

4.75mm Hole, 1.6mm Wire, 4 LPI Stainless Steel Mesh

With its balance of hole size and wire strength, this mesh is ideal for animal enclosures and structural reinforcements.

Hole size determines the type and size of particles the mesh can filter or block. Larger apertures are excellent for airflow and visibility, while smaller apertures provide finer filtration and greater privacy.

Examples from Our Range:

3 Mesh, 6.8mm Aperture, 304 Stainless Steel

The wide aperture makes this mesh perfect for ventilation and architectural applications.

40 Mesh, 0.42mm Aperture, 304 Stainless Steel

A much finer mesh for filtration tasks, such as sieving small particles or protecting against insects.

For most applications, it’s about striking the right balance between wire thickness and hole size. Here’s a breakdown:

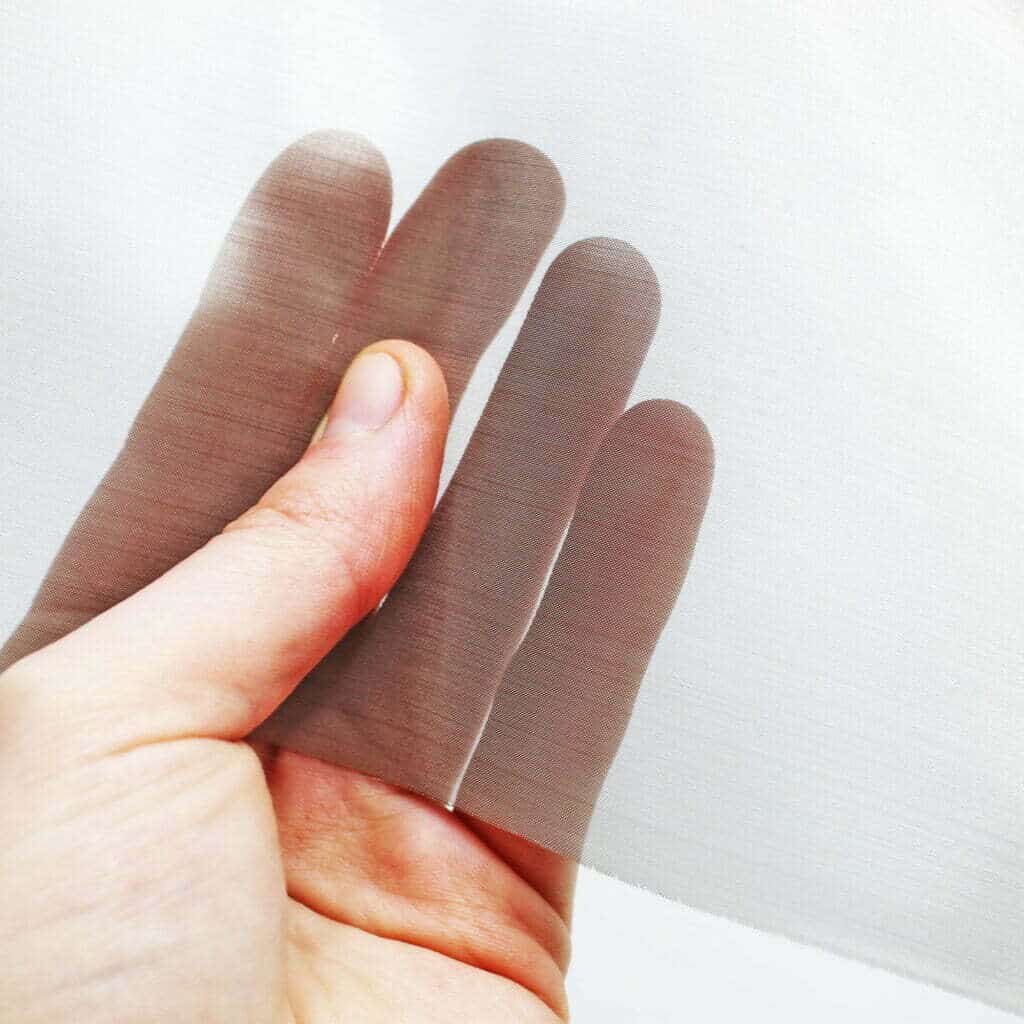

Fine Apertures with Thin Wire

Example: 0.104mm Hole, 0.05mm Wire, 150 LPI Stainless Steel

Perfect for ultra-precise filtration in laboratory or medical settings.

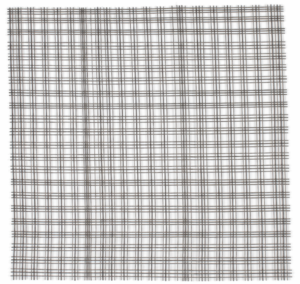

Medium Apertures with Moderate Wire

Example: 1.23mm Hole, 0.355mm Wire, 16 LPI Galvanised Steel

Ideal for rodent control, soffit vents, and general-purpose use.

Large Apertures with Thick Wire

Example: 5.45mm Hole, 0.9mm Wire, 4 LPI Mild Steel

Excellent for heavy-duty projects like fencing and structural support.

Agriculture and Fencing

Industrial and Commercial

DIY and Home Use

At The Mesh Company, we offer an extensive range of woven wire mesh in various specifications, including galvanised steel, stainless steel, brass, and aluminium.

Our products cater to diverse needs, from heavy-duty industrial applications to precise filtration tasks.

Whether you need a robust 4 LPI Stainless Steel Mesh or a delicate 400 LPI Fine Mesh, we have the expertise and stock to meet your requirements.

Wire thickness and hole size are the two most critical factors in determining the strength and functionality of woven wire mesh. By understanding the relationship between these elements, you can select the perfect mesh for your project.

Explore our extensive range at The Mesh Company and discover the ideal balance of strength, flexibility, and performance.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.