When selecting the right perforated metal for your project, stainless steel square hole perforated metal mesh offers a unique combination of strength, precision, and aesthetic appeal.

At The Mesh Company, we provide high-quality stainless steel perforated mesh tailored to meet the needs of customers across the UK.

But is this the best option for your requirements?

In this article, we’ll explore why you might choose square hole perforated mesh, how it differs from other metals and shapes, and provide a detailed overview of its uses, benefits, and alternatives.

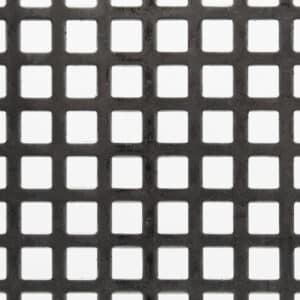

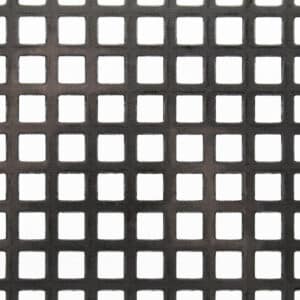

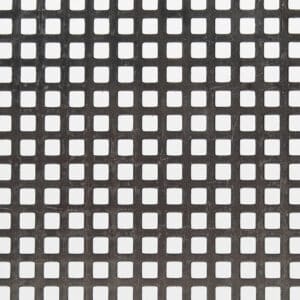

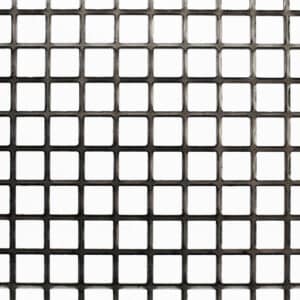

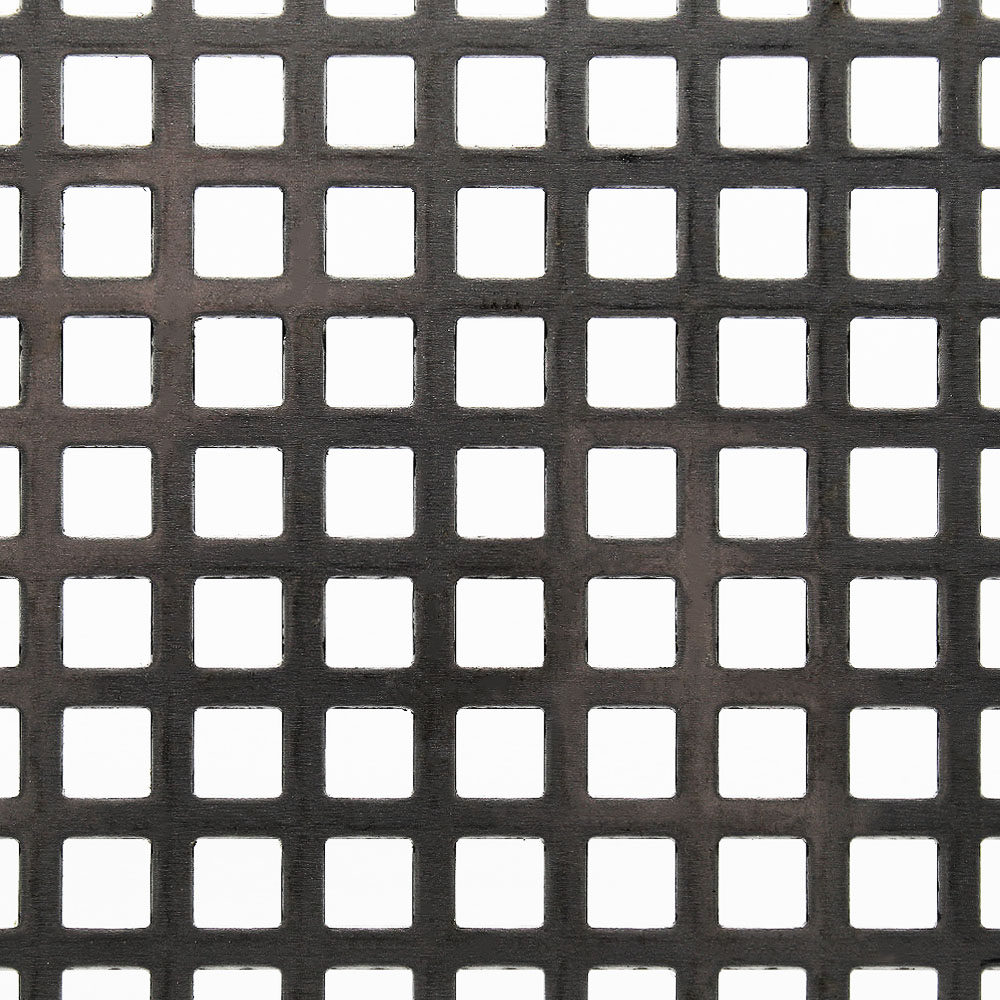

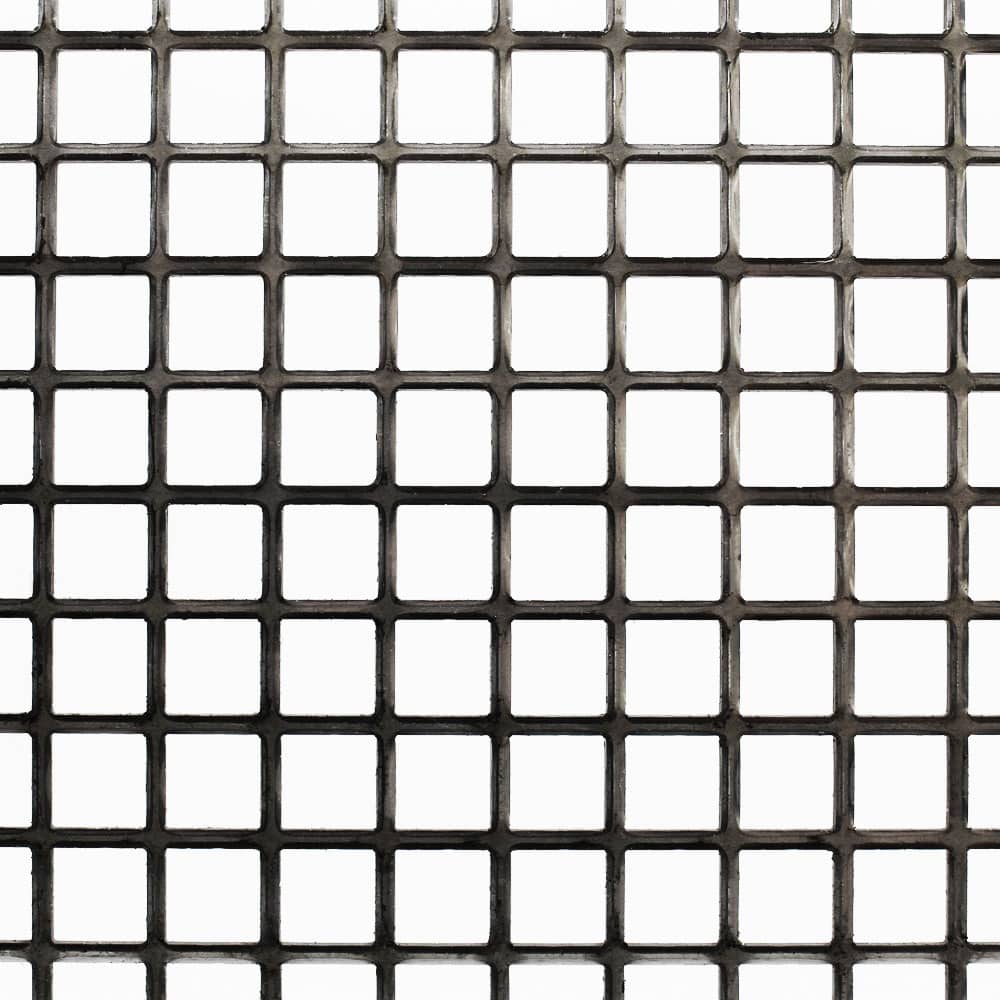

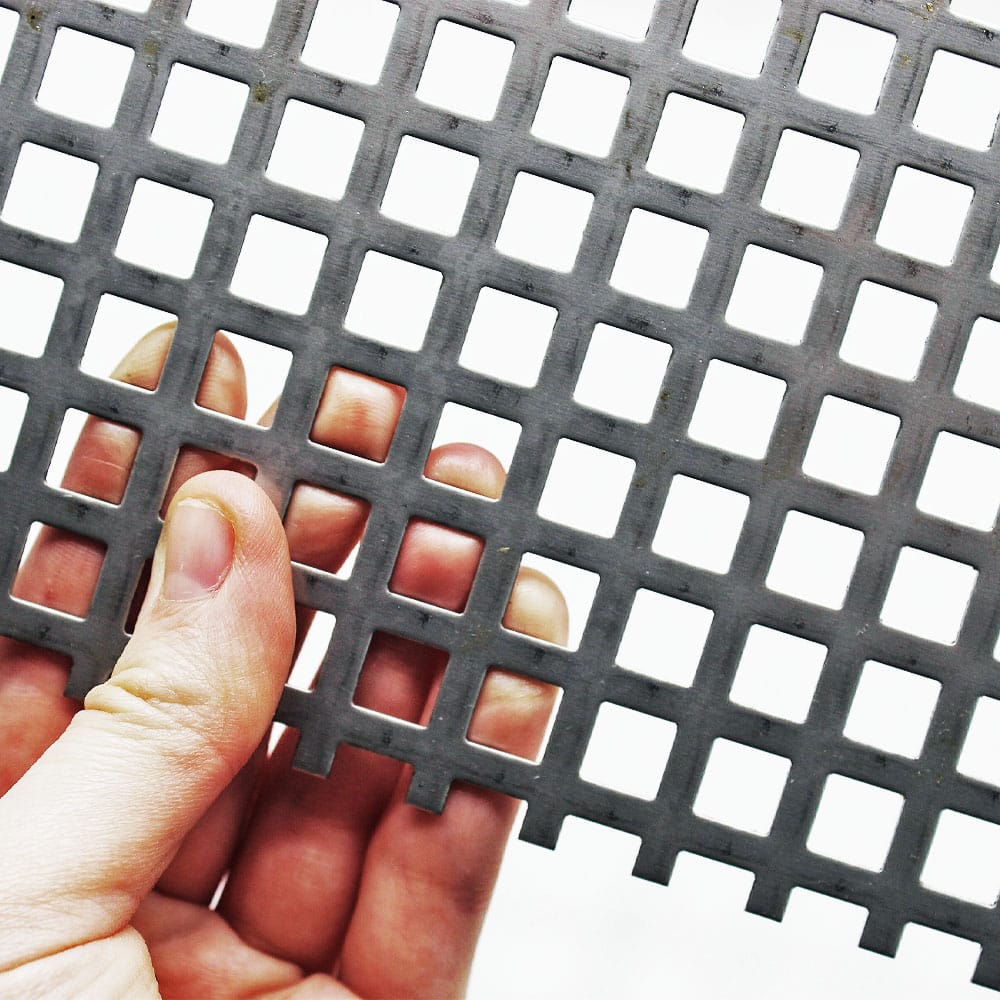

Square hole perforated mesh is made by punching square openings into sheets of stainless steel, creating a precise and uniform pattern. The square design offers excellent strength and rigidity, making it suitable for both functional and decorative applications.

Its stainless steel composition ensures resistance to rust, corrosion, and wear, providing long-lasting performance in a wide range of environments.

Available in various thicknesses and aperture sizes, this mesh offers versatility for projects of all types.

The square hole pattern provides additional strength and stability compared to round holes, especially for load-bearing applications. The uniform structure distributes weight evenly, making it a preferred choice for heavy-duty projects.

Square hole mesh has a clean, geometric appearance, making it a popular choice for architectural and decorative applications. Its crisp lines and polished finish create a contemporary look that stands out in both residential and commercial designs.

Like all stainless steel products, this mesh is highly resistant to rust and corrosion, making it ideal for outdoor and moisture-prone environments. It’s particularly effective in harsh conditions, such as industrial or marine settings.

Square hole perforated mesh is suitable for a variety of uses, from protective grilles to decorative screens, offering both functionality and aesthetic appeal.

While both square and round hole perforated meshes are highly functional, they have distinct differences:

| Pros | Cons |

|---|---|

| Highly Durable and Corrosion-Resistant: Long-lasting in tough environments. | Higher Cost: More expensive than aluminium or galvanised options. |

| Modern and Aesthetic Design: Ideal for architectural and decorative uses. | Rigid Structure: Less flexible than woven or expanded mesh. |

| Greater Open Area: Allows for excellent airflow and visibility. | Specialised Tools Required: Cutting or shaping may need specific equipment. |

| Versatile Applications: Suitable for a wide range of projects. | Overkill for Light Projects: May be unnecessary for low-demand uses. |

| Low Maintenance: Easy to clean and hygienic for sensitive environments. | Reflective Surface: Polished finish may create glare in bright settings. |

If square hole perforated mesh doesn’t meet your specific needs, consider these alternatives:

Each option has unique benefits, and we’re always available to help you find the right material for your project.

If you’re looking for a strong, modern, and versatile material, stainless steel square hole perforated mesh is a great choice. Its superior strength, durability, and clean aesthetic make it ideal for a variety of applications, from industrial flooring to decorative facades.

Explore our range of square hole perforated mesh products on www.themeshcompany.com, and find the perfect solution for your project today.