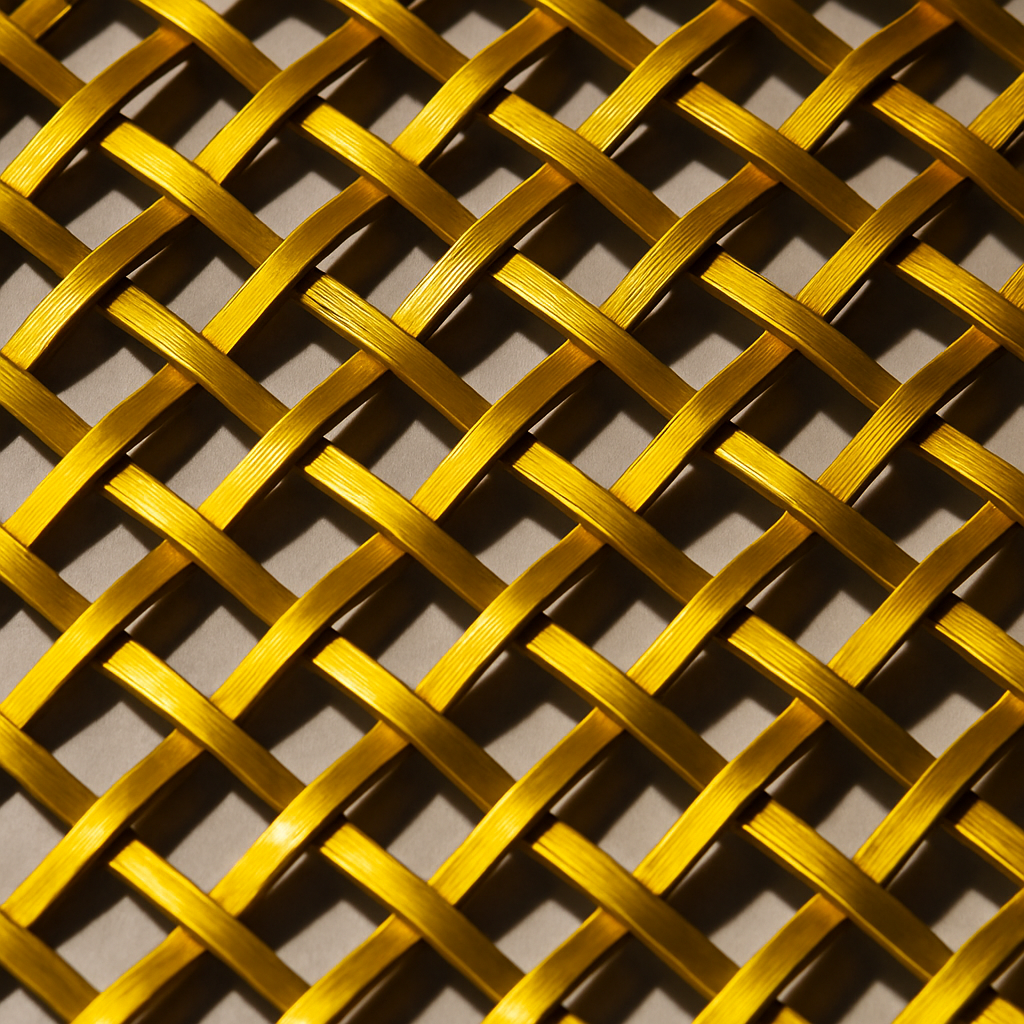

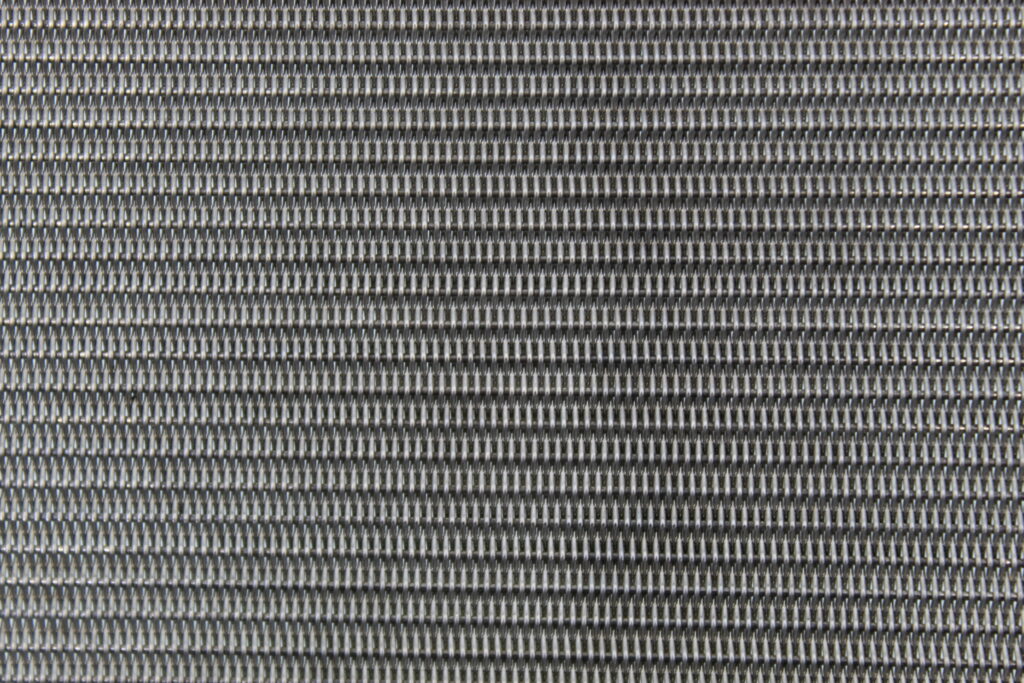

Hollander mesh, also known as Dutch weave mesh, is renowned for its fine filtration capabilities, making it a popular choice in various industrial, environmental, and creative applications.

Keeping this specialised mesh clean is crucial not only for ensuring optimal performance but also for prolonging its lifespan.

Here, we dive into essential tips and best practices for cleaning Hollander mesh effectively.

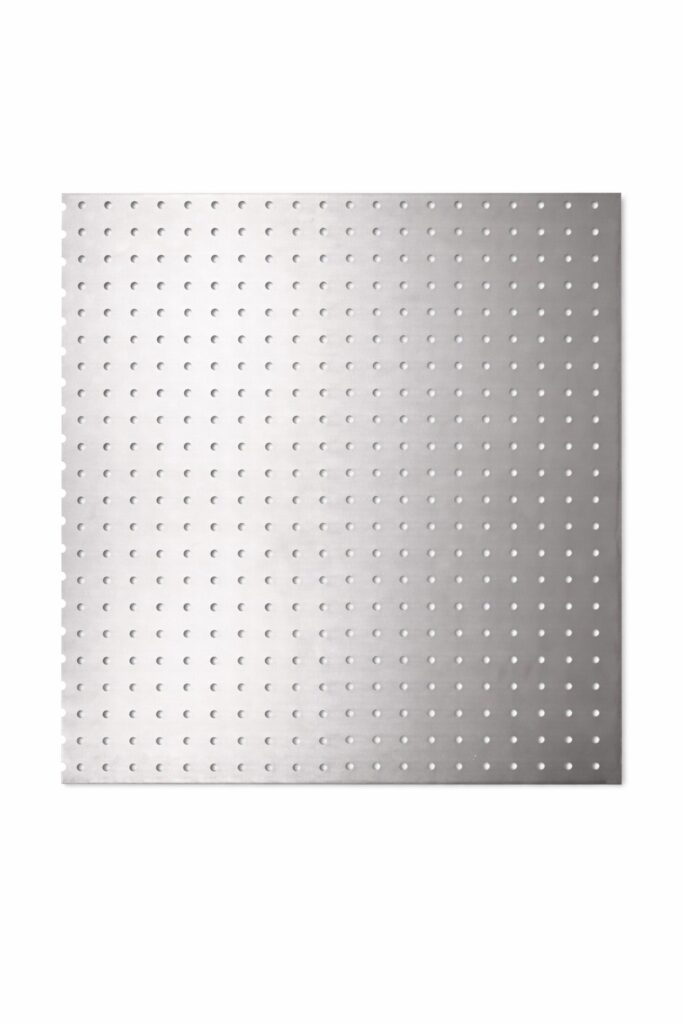

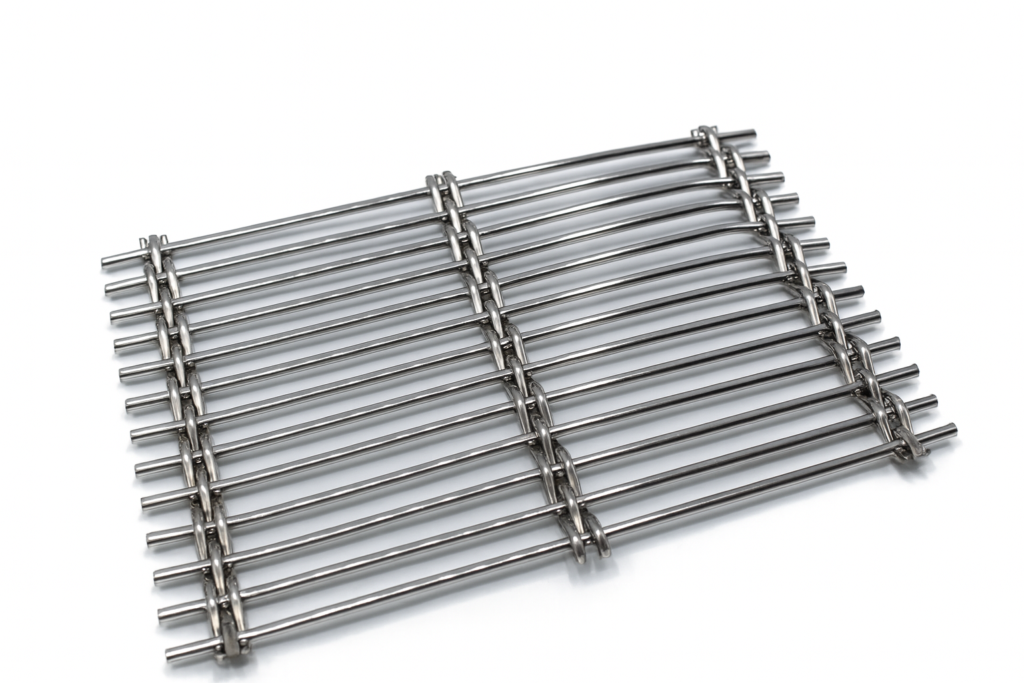

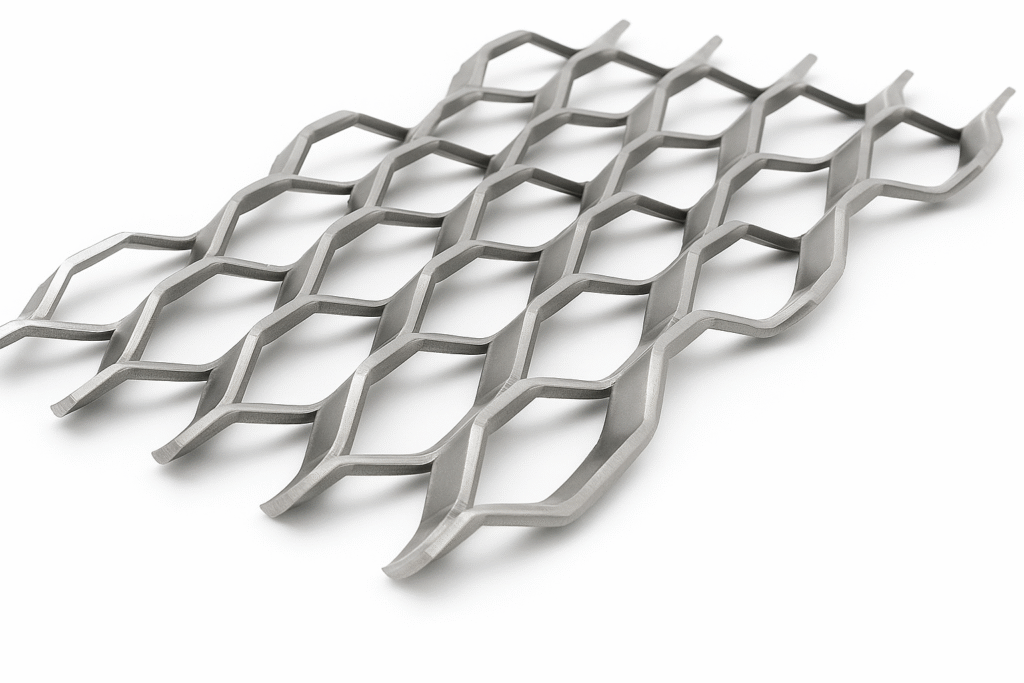

Before diving into the cleaning process, it’s important to understand the specific type of Hollander mesh you are dealing with.

This mesh comes in different materials such as stainless steel, bronze, copper, and synthetic fibers, each requiring slightly different care methods.

In order to maintain the integrity of Hollander mesh, regular inspections are essential. Check to see if there are any signs of wear, tear, or clogging in the system.

The early detection of potential problems can prevent more severe problems down the line and keep your mesh in top shape for a long time.

Rinse with Water: The first step in cleaning Hollander mesh is to rinse it with water to remove any loose particles. If the mesh is used in applications involving oils or sticky substances, warm water is recommended for more effective removal of residues.

Use Appropriate Cleaning Agents: For more thorough cleaning, especially if the mesh has accumulated oils or other stubborn residues, use a mild detergent or a cleaning agent that is compatible with the material of your mesh. For stainless steel meshes, solutions that are non-abrasive and free from chlorine are best, as chlorine can corrode the material.

Soft Brushing: If particles are stuck in the mesh, gently use a soft-bristled brush to dislodge them. It’s important to brush parallel to the wires to avoid damaging them.

Avoid Harsh Chemicals: Harsh chemicals can damage Hollander mesh, especially if it’s made of finer, more delicate materials. Always check the compatibility of cleaning chemicals with the specific material of your mesh.

Rinse Thoroughly: After cleaning, it’s crucial to rinse the mesh thoroughly with clean water to remove any soap or chemical residue, which could affect its performance or cause damage over time.

Dry Properly: Ensure the mesh is completely dry before reinstalling or storing it. Moisture can lead to rust formation, particularly in metal meshes. If possible, dry the mesh in a well-ventilated area or use a gentle air blower.

Here’s a table outlining the pros and cons of cleaning Hollander mesh:

| Pros | Cons |

|---|---|

| Enhances Performance | Time-Consuming |

| Regular cleaning removes debris and buildup, ensuring optimal filtration efficiency and airflow. | Depending on the level of debris, cleaning can be a meticulous process that requires significant time investment. |

| Prolongs Lifespan | Risk of Damage |

| Proper maintenance prevents premature wear and tear, extending the life of the mesh. | Improper handling during cleaning (e.g., using harsh chemicals or scrubbing too vigorously) can damage the delicate structure of the mesh. |

| Cost-Effective | Requires Specific Care |

| Maintaining the mesh through regular cleaning reduces the need for frequent replacements, saving money in the long run. | Different types of Hollander mesh (e.g., stainless steel, copper) may require specific cleaning agents and techniques, complicating the maintenance process. |

| Prevents Contamination | Drying Challenges |

| Regular cleaning helps avoid contamination of processed materials, crucial in industries like food processing and pharmaceuticals. | Ensuring the mesh is completely dry to prevent rust or other moisture-related damages can be challenging, especially in less ideal environments. |

1. Food and Beverage Industry

2. Pharmaceuticals

3. Chemical Processing

4. Water Treatment

5. Automotive Industry

6. Aerospace

7. Mining and Metallurgy

8. Textiles

The process of cleaning Hollander mesh is a straightforward one, yet it must be done with great care.

As long as you follow these simple tips, you will be able to maintain the excellent condition of your mesh for many years to come, providing reliable performance for many years to come.

As regular maintenance enhances efficiency, it also contributes to the cost savings of the company by extending the mesh’s lifespan and thus reducing the need for replacements.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores metal mesh vs plastic mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.