Among the myriad types and grades of mesh products we offer, there’s one that stands out due to its distinct magnetic properties: the 430-grade stainless woven wire mesh.

This quick article aims to explain the benefits of selecting this grade for your project.

Let’s get into it….

Before diving into the specifics of the 430 grade, it’s essential to grasp a basic understanding of stainless steel and magnetism. Not all stainless steels are magnetic. Stainless steel is divided into several types, based on its microstructure.

The two primary categories are austenitic and ferritic.

Types of Stainless Steel

Austenitic Stainless Steel: This category is predominant in the world of stainless steel, comprising popular grades like 304 and 316. Austenitic steels are primarily composed of chromium and nickel. They are renowned for their superior corrosion resistance, formability, and weldability. However, when it comes to magnetism, they generally exhibit non-magnetic behavior. This non-magnetism can be attributed to the specific arrangement of their atoms, which disrupts the magnetic domains within the steel. 304 is the industry standard grade of stainless steel used in the wire mesh industry. The vast majority of our specifications are made from this highly useful grade.

Ferritic Stainless Steel: Then we have ferritic steels, like the 430 grade, which are naturally magnetic. These steels have high chromium levels but are devoid of or have minimal nickel content. The difference in composition, particularly the absence of nickel, gives these steels their distinct magnetic properties. Chromium provides decent corrosion resistance, though not as profound as the nickel-containing austenitic grades.

Implications for the Mesh Industry

The magnetic or non-magnetic nature of stainless steel directly influences the applications and utility of meshes made from these materials.

Magnetic Screening: Meshes crafted from magnetic steel, like the 430 grade, can be used in applications where magnetic screening is pivotal. This allows for innovative uses in industries that rely on magnetic properties, such as certain filtration or separation processes. It is a boon for filtration of metals if they can be picked up by the mesh media itself.

Sensor-based Applications: In industries where machinery or equipment uses sensors, the magnetic nature of 430-grade stainless mesh can be advantageous, allowing it to interact with these sensors in ways that non-magnetic mesh cannot.

Weldability and Workability: From a manufacturing standpoint, the choice between austenitic and ferritic meshes also matters. For instance, austenitic meshes, given their excellent weldability, might be preferred for certain designs, while the rigidity of ferritic meshes like the 430 grade could be beneficial for other applications. We have an in house welding department here in our Warrington factory, so if you require any further information on this area then please freely contact us. Our team will always try to help in any way that we can.

These are the main 3 reasons for selecting a 430 grade stainless steel mesh:

Magnetic Properties: As outlines in detail above, the primary factor that distinguishes 430-grade mesh from many other stainless steel mesh grades is its magnetism. This trait can be particularly advantageous in specific applications, such as magnetic screening or where magnetic sensors are employed.

Cost-Effectiveness: Often, 430 stainless wire mesh is more economical than other non-magnetic stainless steel grades. This makes it a preferred choice for projects where magnetism is required without compromising on budget constraints.

Resistance and Durability: While it might not match the corrosion resistance of some higher-nickel stainless steels, 430-grade offers a good balance of resistance to a range of environments, making it suitable for various applications. We are not familiar with an instance where 430 has let down the user in terms of resistance to corrosion.

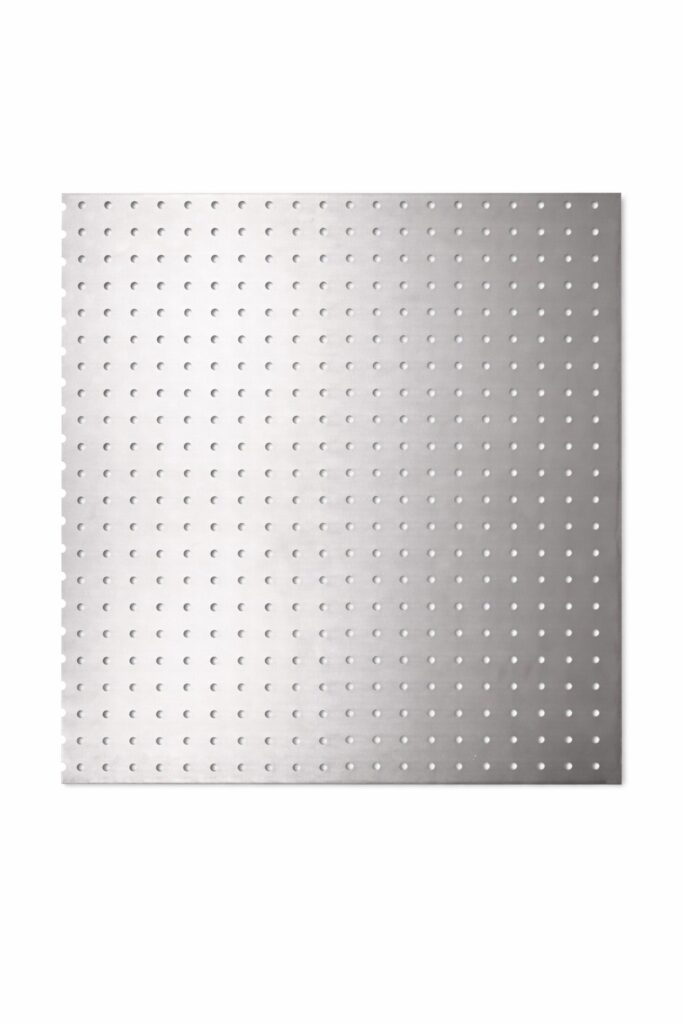

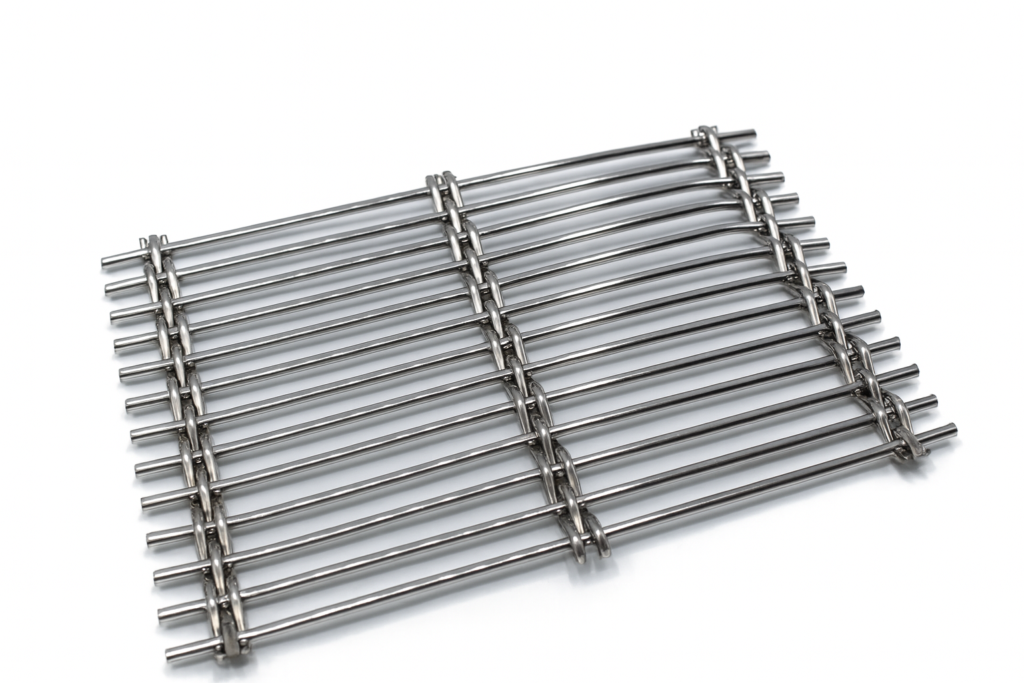

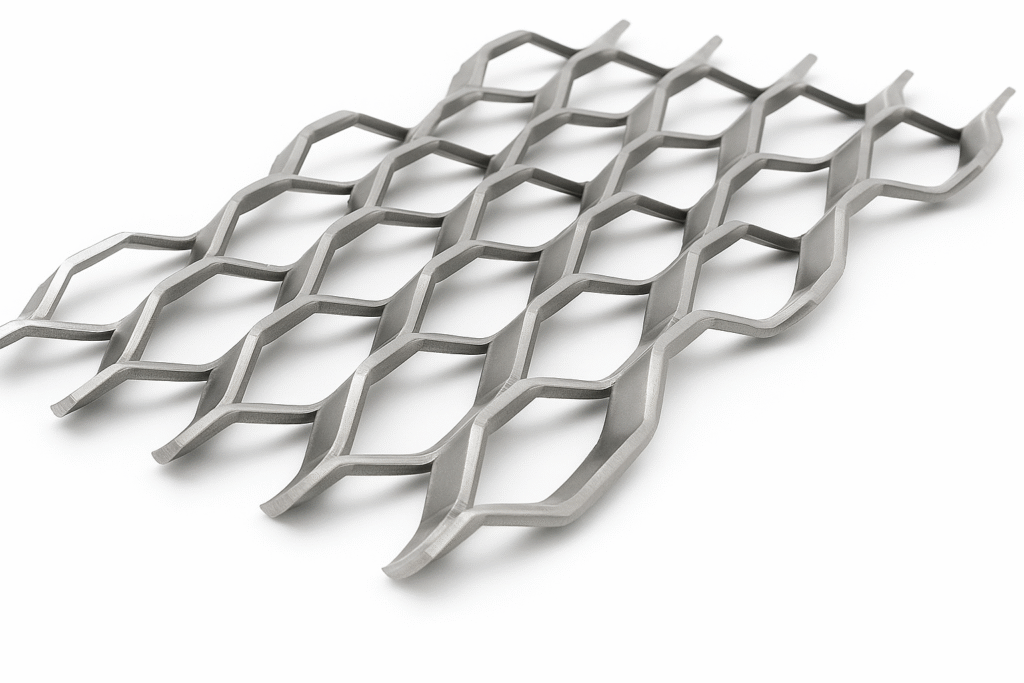

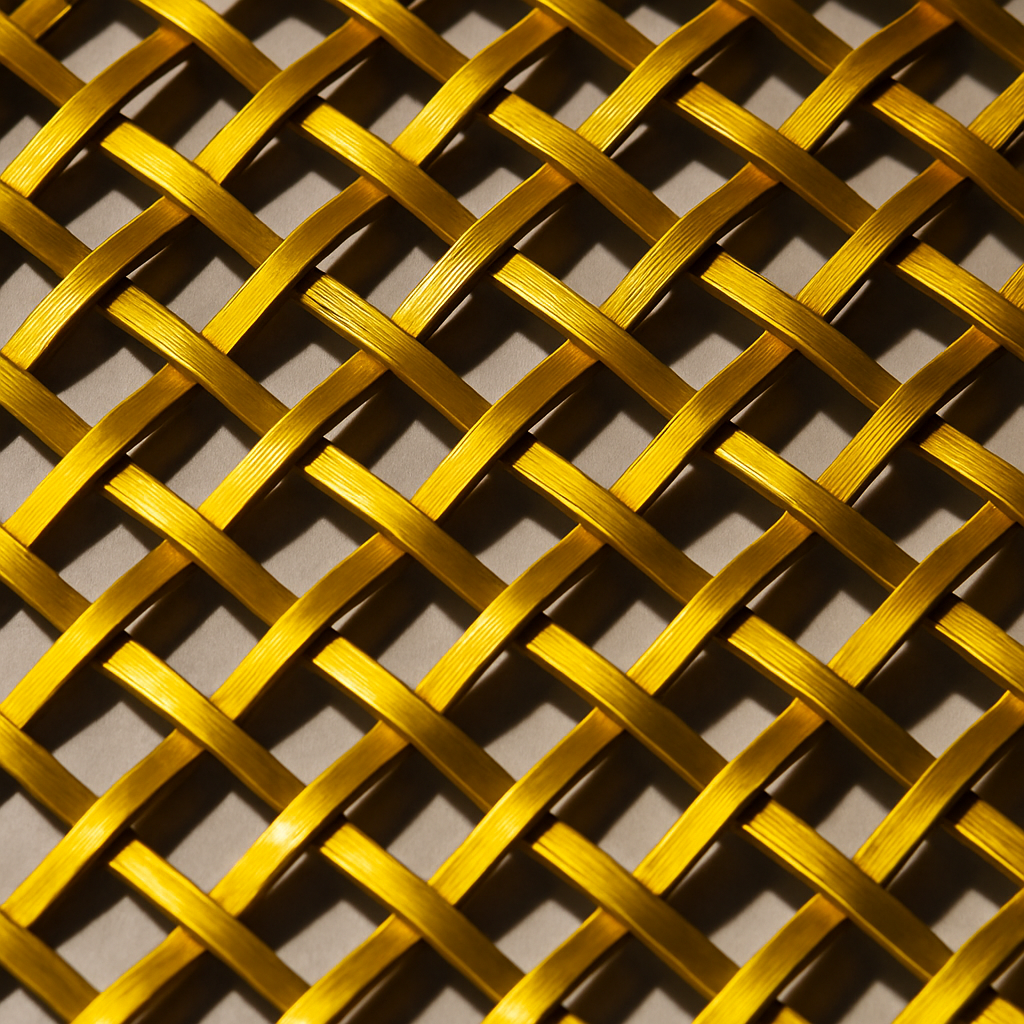

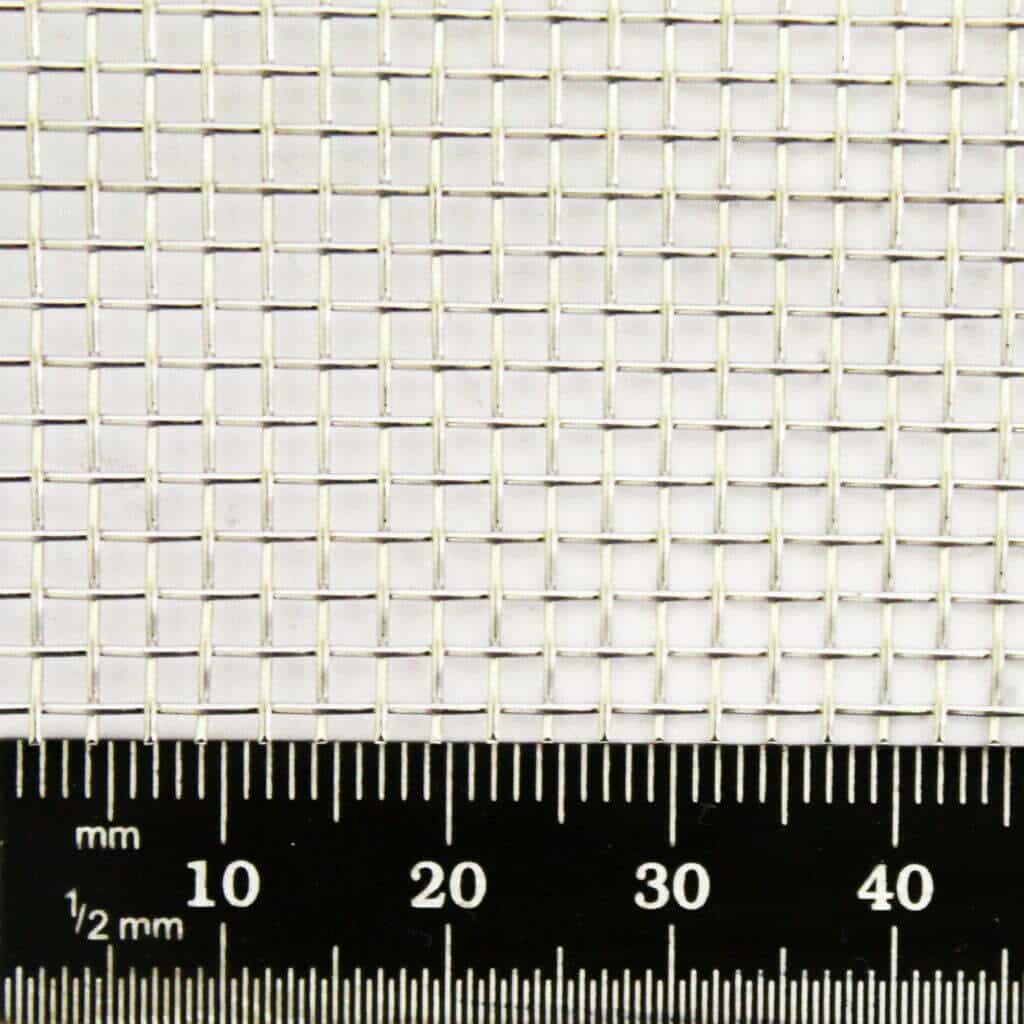

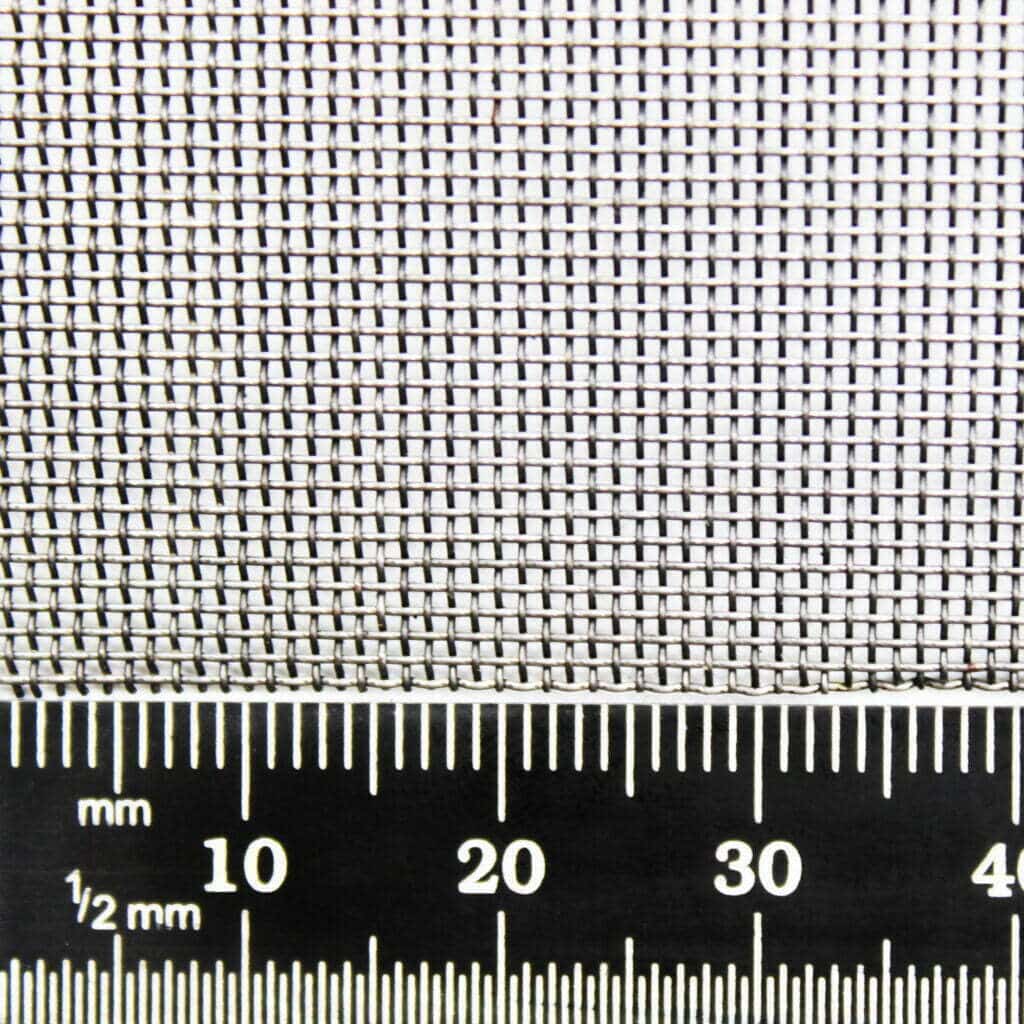

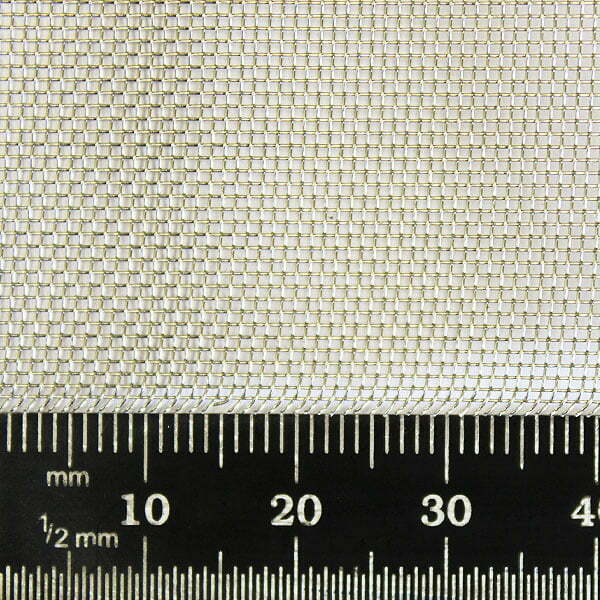

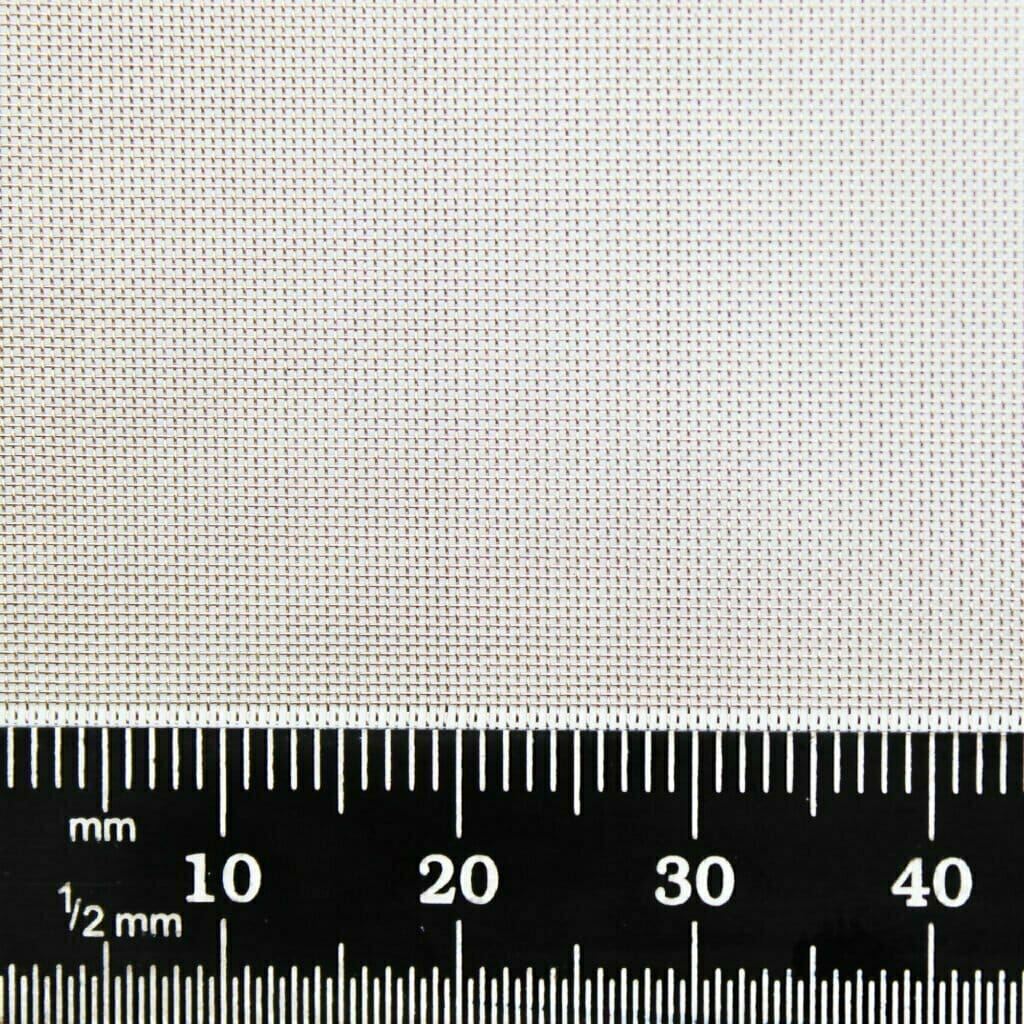

At The Mesh Company, we’re proud to stock a select range of 430-grade woven wire mesh. Our offerings range from larger 2mm holes, ideal for applications that demand more open space, down to finer 0.3mm holes, perfect for intricate filtering and screening needs.

These meshes offer an optimal combination of strength, flexibility, and the unique magnetic quality of 430-grade stainless steel. This versatility ensures that, whether for industrial, architectural, or other purposes, our 430-grade mesh provides a solution that’s both functional and economically viable.

Here are some of our standard magnetic options:

The world of stainless steel mesh is vast, and each grade brings its set of attributes to the table.

The 430-grade woven wire mesh, with its inherent magnetic properties, stands out as a solution for unique challenges, offering both functionality and cost-effectiveness.

We invite you to explore our range of 430-grade stainless woven wire mesh and discover how it can be the ideal choice for your specific needs. Keep an eye on our blog for constant articles on all forms of mesh and metals that may be of interest.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores woven wire mesh sizes in general.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.