Mild steel perforated metal mesh represents a harmonious blend of strength, versatility, and aesthetic appeal, finding its use in myriad applications across various industries.

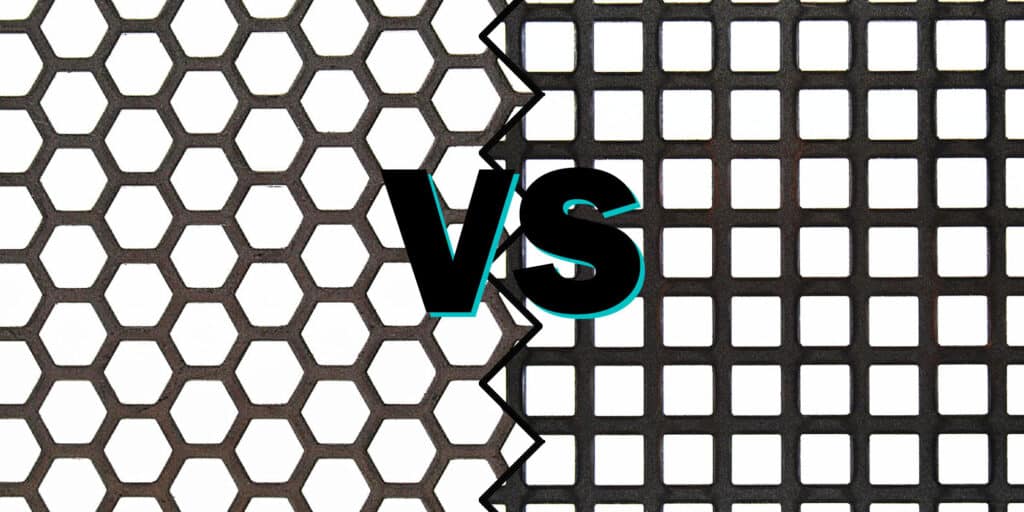

Its functionality rests on the distinctive pattern of holes perforated into the steel, each offering unique properties and advantages. Hexagonal and square hole patterns are among the most popular and widely used. We will examine the characteristics, applications, and factors that influence the selection of these two patterns in this comprehensive guide.

In this study, we will evaluate the suitability of hexagonal and square hole patterns in mild steel perforated metal mesh for different applications and environments. There is a selection of sizes and thicknesses to choose from which we will discuss in greater detail later in this article.

In addition to their aesthetic appeal, each pattern has its own functional characteristics, making the choice between them more than just a matter of taste.

During our exploration of hexagonal versus square holes, we’ll examine airflow, strength, visual impact, and practical applications. The purpose of this guide is to help you understand the differences between these hole patterns and to help you select the right one for your specific needs, whether they are for architectural designs, industrial applications, or custom work.

If you can’t decide between these patterns then hopefully this guide will help.

Let’s get into it..

Mild steel, an alloy of iron and carbon with a relatively low carbon content, is known for its fundamental properties that make it a prime candidate for perforation. Mild steel’s malleability makes it especially suitable for creating hexagonal and square holes, allowing for precise and clean perforations without compromising the material’s integrity. As a result of its malleability and inherent strength, mild steel is a versatile material.

The durability of mild steel is another of its key attributes. Due to its durability, it is ideally suited for both indoor and outdoor applications. It can withstand significant wear and tear. Various applications benefit from the material’s ability to withstand environmental factors, especially when treated or coated. Please note that uncoated steel will rust when it comes into contact with moisture. We recommend stainless steel for rust resistance.

A standout feature of mild steel is its cost-effectiveness. Compared to other metals, it is more affordable while still maintaining high quality and durability. The balance between affordability and performance makes it an attractive choice for large-scale projects and applications.

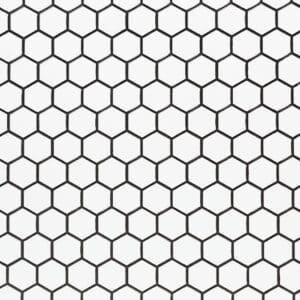

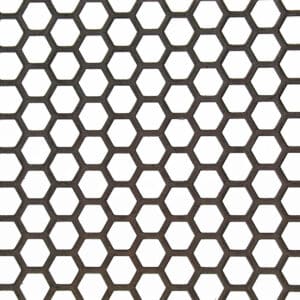

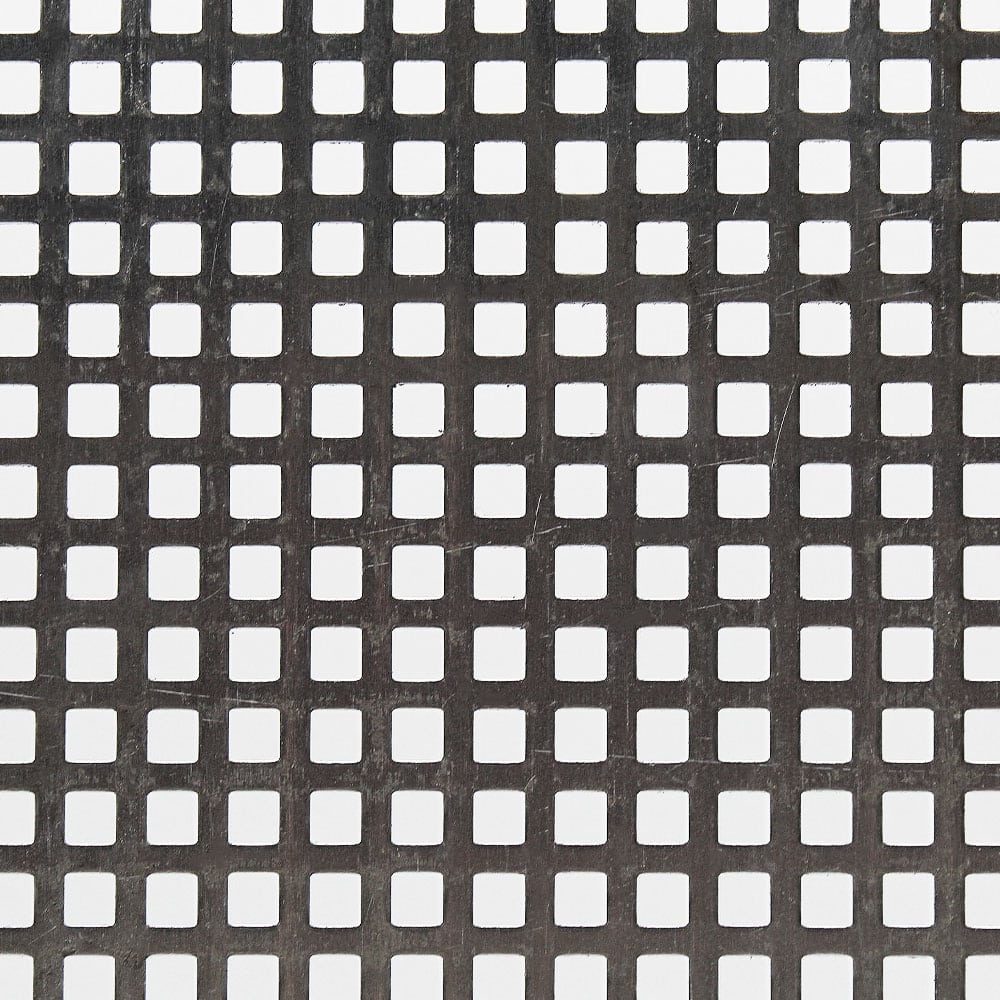

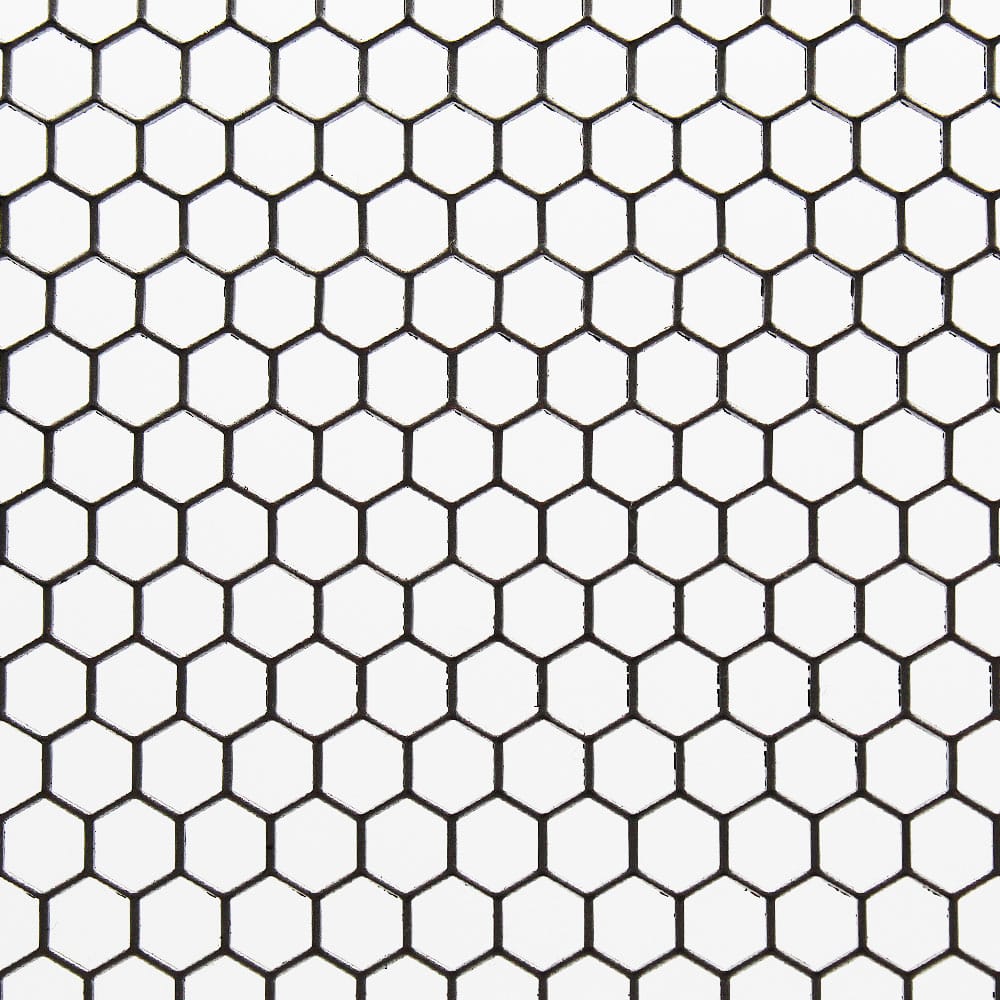

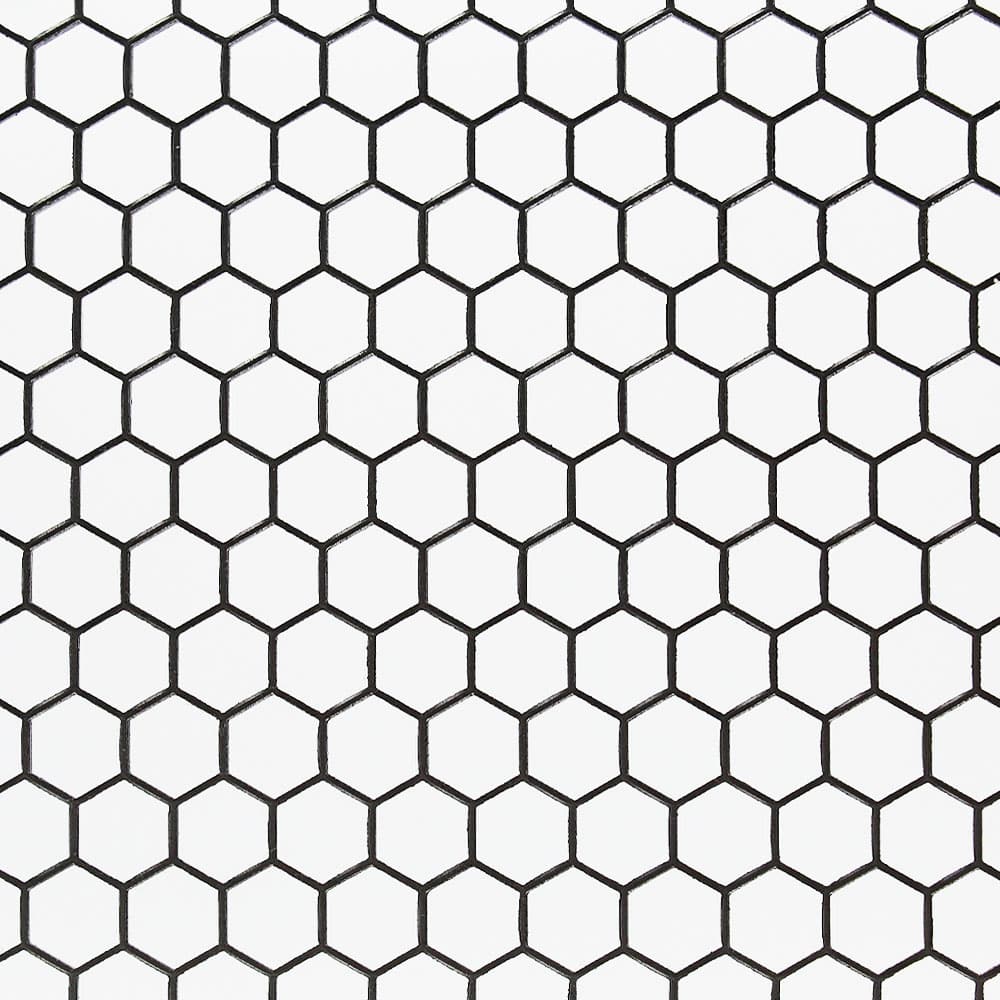

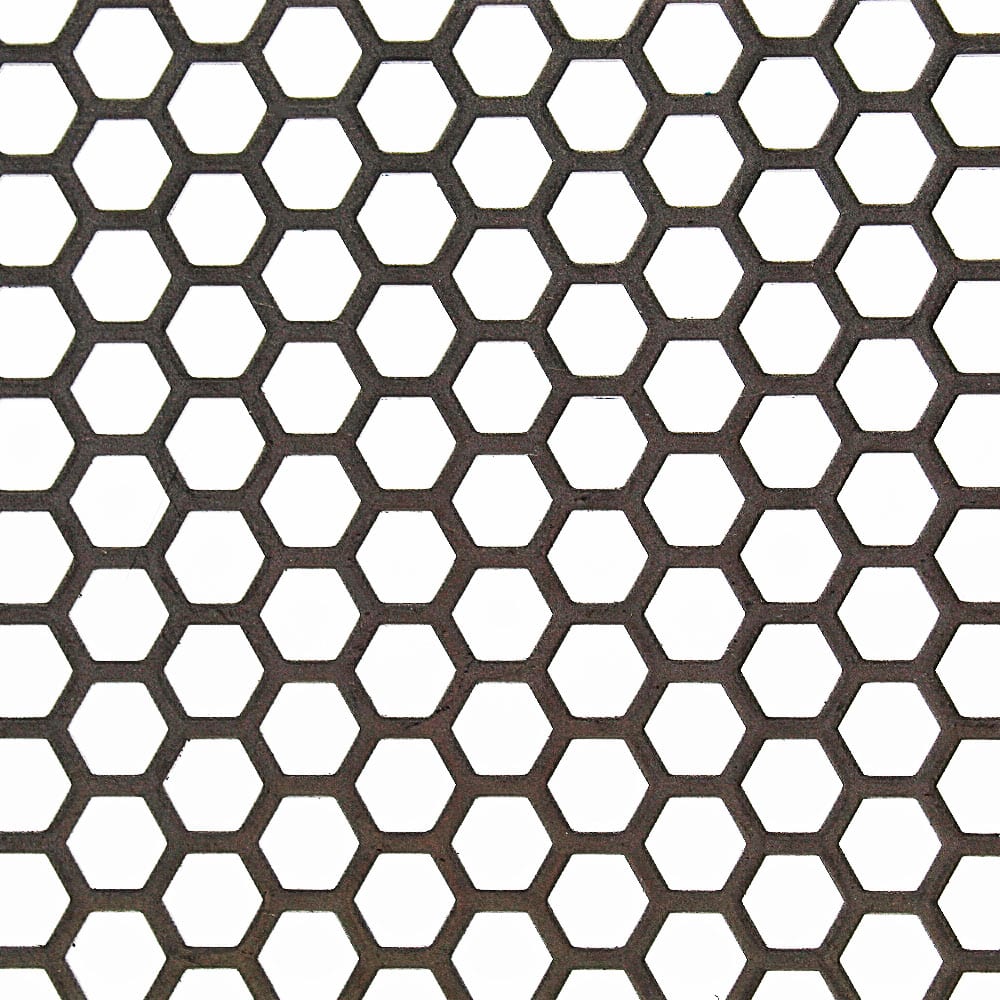

Perforated metal mesh with hexagonal holes offers a unique aesthetic and functional appeal. As a result of its six-sided shape, this pattern provides a unique visual aspect that can enhance a design. With a 6.7mm pitch and 1mm thickness, our 6mm hexagonal hole patterned mild steel metal sheet demonstrates the versatility of this pattern.

Hexagonal holes are known for their efficient use of space. Geometric holes have a higher open area percentage than square holes of similar size. As a result of this increased open area, hexagonal hole mesh is particularly suitable for applications requiring efficient ventilation, such as radiator covers or air conditioners.

Another advantage of hexagonal holes is that they distribute stress evenly. By evenly distributing forces across the mesh, the angular design enhances its overall strength and durability. The mesh’s mechanical strength and ability to support weight make it a preferred choice in settings where mechanical stresses are present.

Hexagonal hole mesh is often chosen for its aesthetic appeal when it comes to applications. Adding visual interest to facades, partitions, or ceilings with the unique pattern can enhance architectural designs. The 11mm hexagonal hole mild steel perforated mesh sheet with a 14mm pitch and 1mm thickness from our range is an example of how this mesh can be used to create striking visual effects while maintaining functionality.

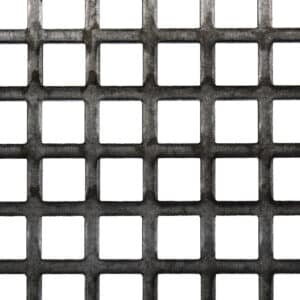

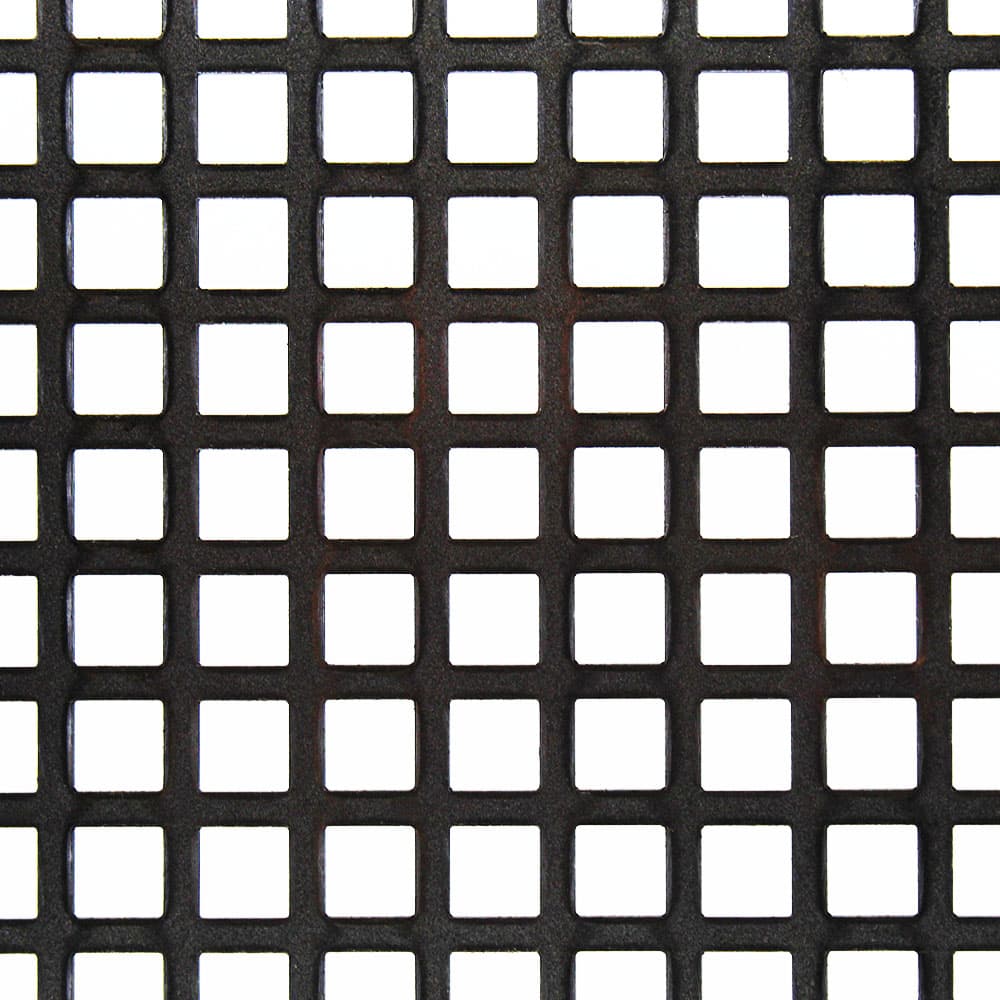

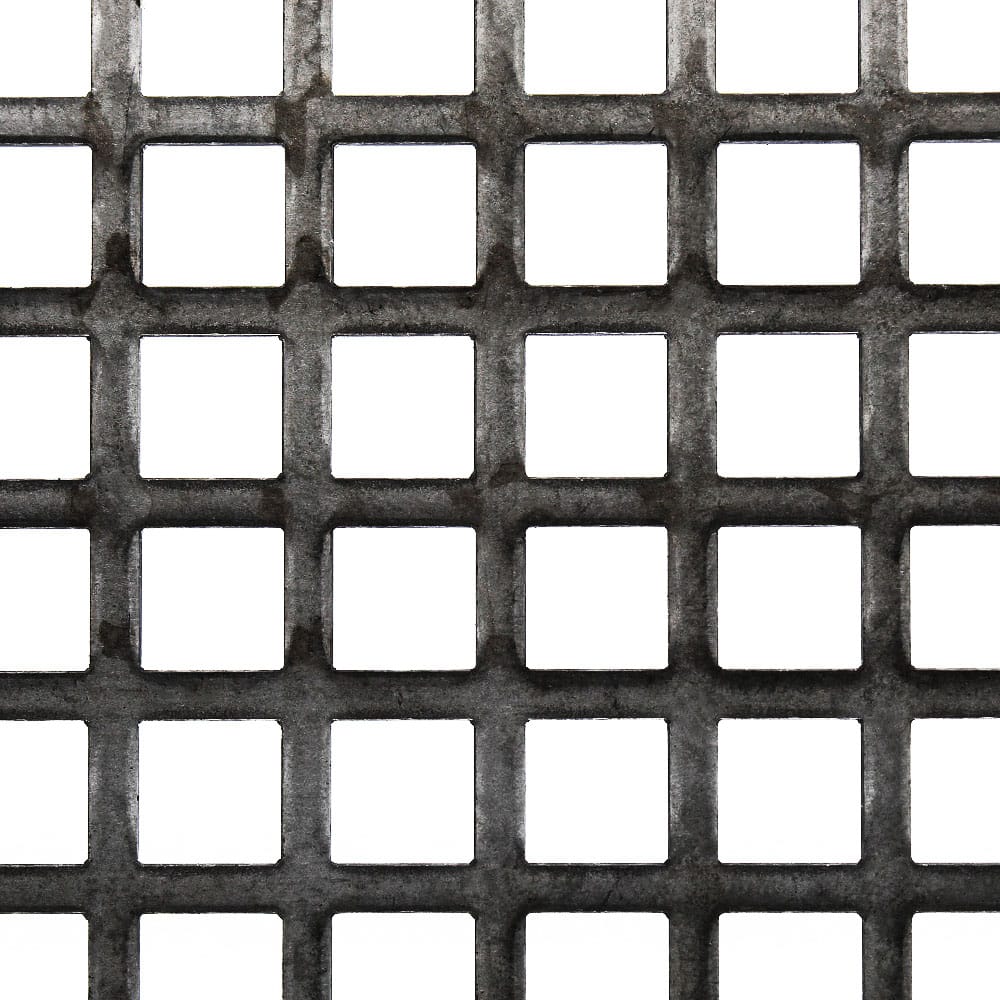

Perforated metal mesh with square holes combines traditional design with functional efficiency. They offer a classic aesthetic that can seamlessly integrate into a variety of design contexts thanks to their straight edges and uniform appearance. With options like 10mm Square Hole Mild Steel Perforated Steel Sheet with a 14mm pitch and 1.5mm thickness, we demonstrate the versatility of square hole mesh.

In terms of sizes and thicknesses, square hole meshes are available in a variety of dimensions to suit specific requirements. The finer 3mm square hole mild steel perforated mesh sheet metal comes with a 5mm pitch and 1mm thickness while the more robust 15mm square hole variant comes with a 20mm pitch and 2mm thickness.

Square hole patterns are particularly useful in applications requiring uniformity and straight-line aesthetics. Architectural designs, industrial machinery guards, and fencing use them to ensure consistent airflow and effective ventilation. A square hole’s uniformity also makes alignment and installation easier, especially in projects requiring precise measurements and patterns.

Square hole meshes also offer the advantage of a straightforward manufacturing process, which often results in a more cost-effective solution, especially for larger projects.

In applications requiring structural stability, the simple shape ensures uniform strength distribution across the mesh.

2mm Hexagonal Hole – 2.5mm Pitch – 1mm Thick

There are many applications where this fine mesh is excellent, such as radiator covers, cabinet door inserts, decorative panels, and other applications that require subtle ventilation and aesthetic detail.

This tile provides a unique visual texture that can enhance both residential and commercial spaces due to its hexagonal pattern.

3mm Square Hole – 5mm Pitch – 1mm Thick

The fineness of this mesh makes it ideal for finer applications in which a balance between strength and open area is required. The use of this material is excellent for protective screens, ventilation panels, and in electronic applications that require heat dissipation.

4.5mm Hexagonal Hole – 5mm Pitch – 1mm Thick

The mesh is used in areas requiring moderate ventilation and a decorative touch. As an interior design element, it is perfect for room dividers and ceiling panels, as well as exterior elements like architectural accents and facades.

6mm Hexagonal Hole – 6.7mm Pitch – 1.5mm Thick

In spite of its slightly larger hole size, this mesh is versatile enough to be used both in industrial and architectural contexts, since it can be used for medium-duty applications.

It is ideally suited for protecting barriers, outdoor furniture, and decorative architectural elements, providing both durability and a distinct style at the same time.

8mm Hexagonal Hole – 8.7mm Pitch – 1mm Thick

Often used in outdoor furniture, architectural features, and the design of gardens, this mesh is ideal for both decorative and functional applications.

A hexagonal pattern adds a contemporary touch to the piece, while also offering sufficient strength and open space for a variety of uses.

10mm Square Hole – 14mm Pitch – 1.5mm Thick

I would recommend this mesh for architectural applications, including building facades and cladding, where both ventilation and aesthetic appearance are of great importance. As a result of the 10mm square holes on the top, this design provides a modern look and allows for efficient air circulation.

As a result of its robustness as well as its visual appeal, this mesh is also suitable for outdoor furniture and garden screens.

11mm Hexagonal Hole – 14mm Pitch – 1mm Thick

There are eleven hexagonal holes in this pattern of 11mm that provide a unique pattern suitable for large-scale architectural applications, such as building facades and outdoor screens.

As well as offering effective ventilation and light filtration, this mesh combines a visual appeal with a high level of functionality.

15mm Square Hole – 20mm Pitch – 2mm Thick

With larger 15mm square holes, this mesh is ideal for heavy-duty screens and machine guards. While maintaining strength, it provides an open area for air and light to pass through.

Architects can also use this mesh for bold, statement-making features in their designs.

When comparing the aesthetic appeal and design flexibility of hexagonal and square-hole mild steel meshes, it’s clear that each pattern offers a unique visual language. With their angular lines and geometric appearance, hexagonal holes give any project a modern and dynamic appearance. Adding depth and visual interest to architectural designs, they create intriguing patterns and shadows. Square holes, in contrast, offer a more classic and orderly aesthetic, appealing to traditional design sensibilities. From contemporary to industrial, their uniformity and simplicity make them versatile.

Architecture and design projects can take advantage of the design flexibility of both patterns. Hexagonal meshes, such as the 4.5mm Hexagonal Hole Perforated Steel Metal Sheet with a 5mm pitch and 1mm thickness, can be used to create stunning feature walls, ventilated facades, or decorative panels that act as focal points. Hexagonal patterns elevate the design of a building or interior space, making a bold statement.

Square hole meshes, on the other hand, are ideal for applications where the design needs to blend in rather than stand out. In functional applications such as grilles, screens, and partitions, uniformity and consistency are important. Providing a balanced and orderly appearance, the square pattern can also be used for flooring, ceilings, and furniture design.

The choice between hexagonal and square hole patterns in mild steel perforated metal mesh largely depends on the aesthetic goals and functional requirements of the project. Hexagonal patterns are ideal for creating visually striking designs with a modern twist, while square holes are best for more traditional, uniform applications. They are both popular choices in the fields of architecture and industrial design since they offer a wealth of design possibilities.

The shape of the holes has a significant impact on the functional performance of perforated metal mesh, especially when it comes to airflow, strength, and durability. In these respects, hexagonal and square hole patterns each have their own benefits and limitations.

Shape plays a crucial role in airflow and ventilation. As a result of their geometric efficiency, hexagonal holes, such as those found in the 6mm Hexagonal Hole Patterned Metal Sheet Mild Steel, often provide more efficient airflow. For applications requiring high levels of ventilation, such as HVAC systems and industrial filters, this can be especially beneficial.

Square holes, such as those in the 10mm Square Hole Mild Steel Perforated Steel Sheet, offer a more direct, uniform path for airflow, which can be advantageous in systems that require a steady, unidirectional flow. Compared to hexagonal patterns, the total open area may be slightly smaller, potentially reducing ventilation efficiency.

A mesh’s hole pattern also affects its strength and durability. In applications where structural integrity is a primary concern, square holes can be advantageous due to their uniformity in distributing stress evenly across the material. Furthermore, hexagonal holes, with their angular intersections, are very strong, particularly when it comes to resisting lateral forces.

Hexagonal and square hole patterns in mild steel perforated mesh provide a range of customization and fabrication possibilities. Hole size, pitch (distance between holes), and pattern arrangement can be customized.

Fabricating hexagonal patterns, such as those found in our 4.5mm Hexagonal Hole Perforated Steel Metal Sheet, can sometimes be more complex due to the angular intersections. When aligning and joining multiple sheets or creating complex shapes, this complexity can require more precision in the manufacturing process.

Due to their straight lines and uniformity, square hole patterns, such as those found in our 3mm Square Hole Mild Steel Perforated Mesh Sheet Metal, are easier to fabricate. The material can be cut, shaped, and joined more easily, potentially reducing fabrication time and cost.

The versatility of both styles allows them to be customized for a wide range of applications, from industrial to decorative.

Both hexagonal and square hole patterns in mild steel perforated metal mesh have unique characteristics. In applications requiring high ventilation and a modern design touch, hexagonal holes provide efficient airflow and a distinct aesthetic. With their uniformity and straightforward fabrication, square holes are ideal for applications that require structural integrity and traditional aesthetics.

Choosing the right hole pattern for your project requires both consideration of functional requirements, such as airflow and strength, as well as aesthetic considerations. The versatility of hexagonal and square hole patterns ensures that there is a solution for every application, whether in industrial settings, architectural designs, or custom projects. It is important to weigh the unique properties of each pattern to make an informed decision that aligns with the specific goals and needs of your project.

Please feel free to contact our team if you require any assistance or information. Our guys are always happy to help.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog articles that explore aluminium and stainless steel perforated metal mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.