In today’s world, architects and designers are constantly searching for innovative materials that can enhance the functionality and aesthetics of a building. One such material that has gained popularity in recent years is stainless steel perforated mesh.

This versatile material is not only durable and visually appealing, but it also offers excellent sun control capabilities.

In this blog, we will explore the benefits of using stainless steel perforated mesh for sun control and how it can contribute to energy savings and create comfortable indoor environments.

One of the most crucial aspects of building design is controlling the amount of sunlight that enters the space. Too much sunlight can lead to glare, overheating, and increased energy consumption for air conditioning. On the other hand, insufficient sunlight can result in a dim environment, affecting the occupants’ mood and productivity. Stainless steel perforated mesh is an innovative material that addresses these challenges by providing excellent sun control capabilities.

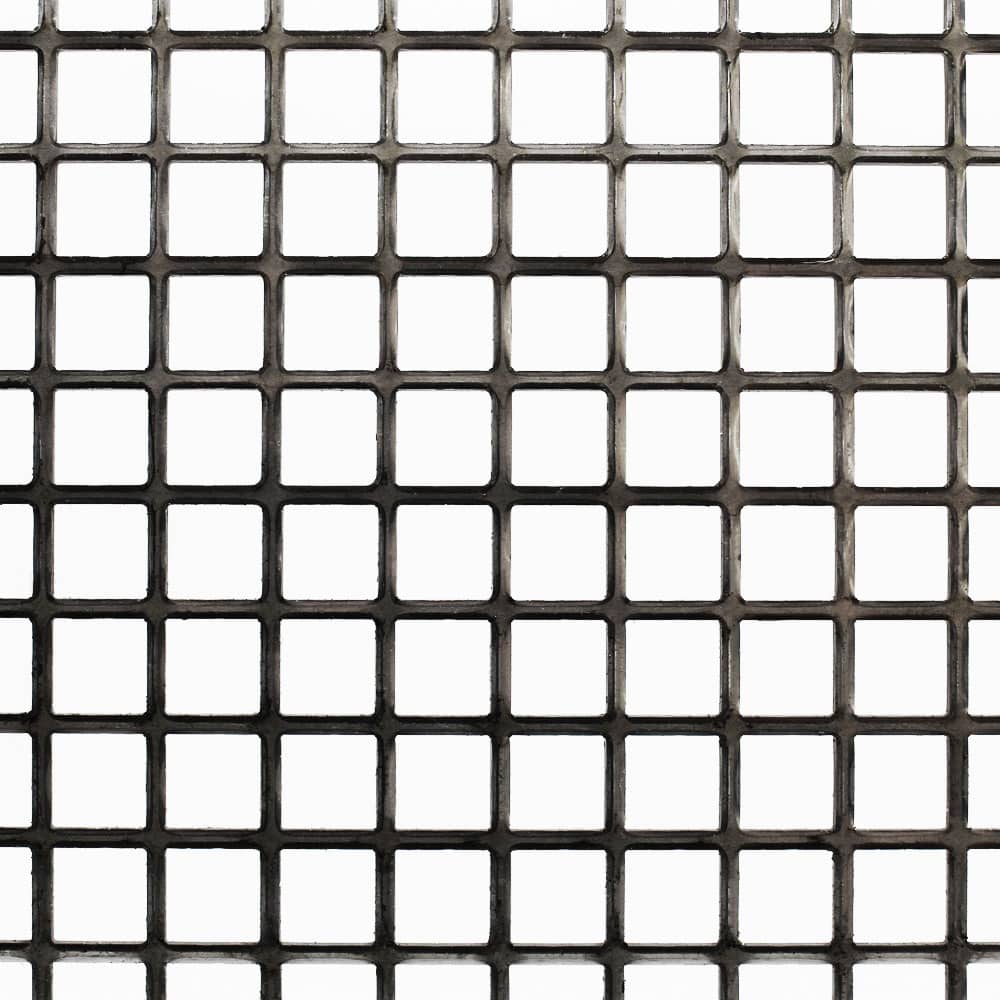

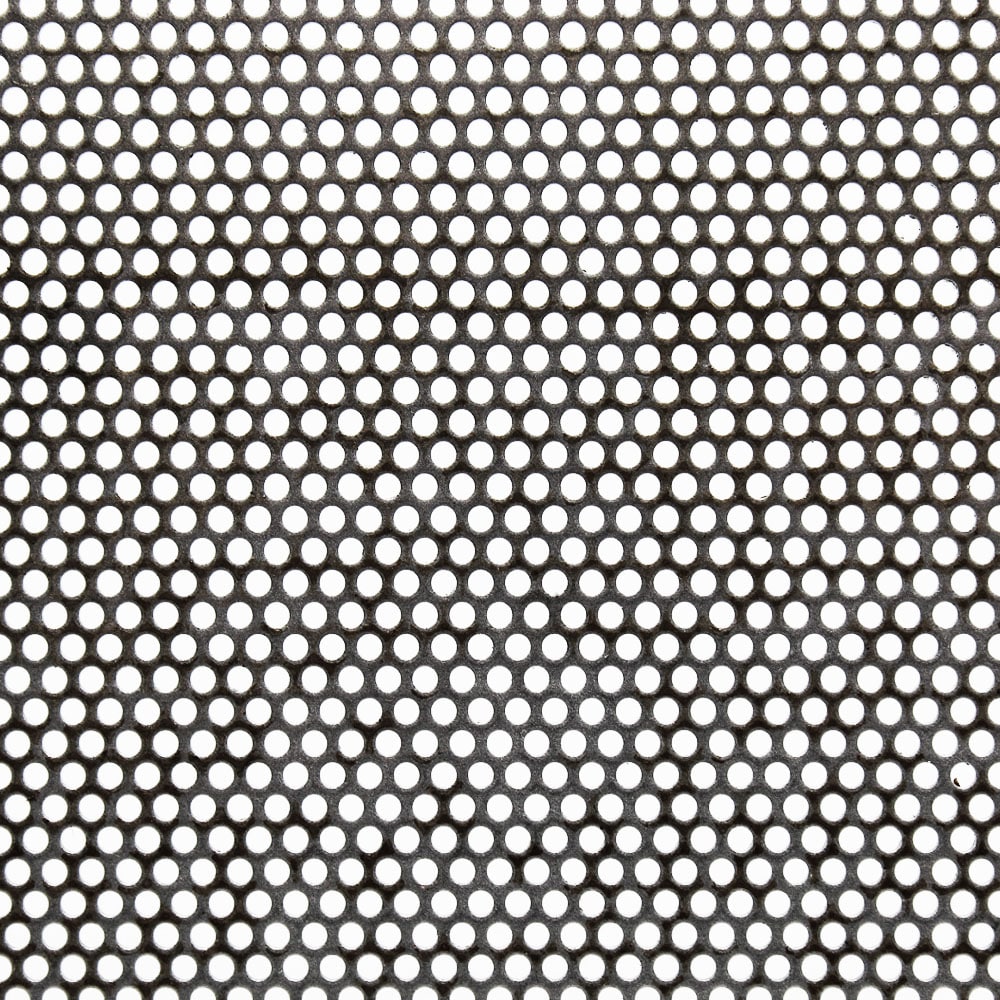

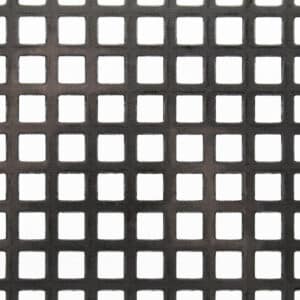

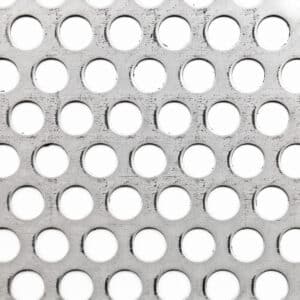

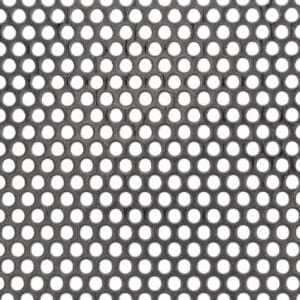

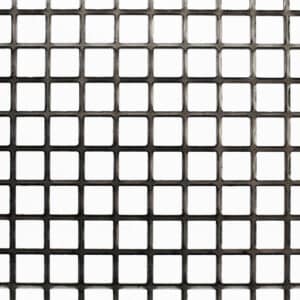

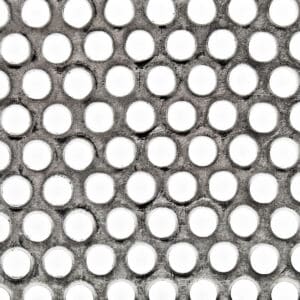

Stainless steel perforated mesh allows natural light to filter through its perforations, helping to illuminate the interior space while reducing the need for artificial lighting. This is particularly beneficial for creating bright and inviting environments while minimizing energy consumption. The size, shape, and pattern of the perforations can be customized to control the amount and direction of the sunlight entering the building. For example, smaller perforations can be used to block more sunlight and reduce glare, while larger perforations can be used to allow more light in and create a brighter space.

In addition to controlling the amount of light, stainless steel perforated mesh also helps to regulate the temperature inside the building. By blocking a portion of the sun’s rays, it reduces the amount of heat entering the space, thereby minimizing the need for air conditioning and contributing to energy savings. The perforations in the mesh allow for ventilation, enabling air to circulate and helping to dissipate heat.

The size and pattern of the perforations in the stainless steel mesh can be customized to optimize sun control at different times of the day or in different seasons.

For example, larger perforations will allow more light and heat to pass through, while smaller perforations will block more light and heat. The orientation of the perforations can also be customized to control the direction of the sunlight.

This mesh is made using a punch, which can be set to many sizes, shapes and patterns.

By controlling the amount of sunlight that enters a building, stainless steel perforated mesh can contribute to significant energy savings.

It reduces the need for artificial lighting during the day and helps to keep the interior cool, reducing the load on air conditioning systems.

In addition to its functional benefits, stainless steel perforated mesh also offers aesthetic appeal. It can be coated or painted in various colors to match the design of a building, and the perforations can create interesting patterns and visual effects when the light passes through.

Stainless steel is renowned for its exceptional durability, which is due to its unique composition. It is made of a mixture of iron and at least 10.5% chromium, along with other elements like nickel, manganese, and carbon. The chromium in stainless steel reacts with oxygen in the air to form a thin, invisible layer of chromium oxide on the surface of the metal. This layer is what makes stainless steel ‘stainless,’ as it prevents rust and corrosion by protecting the underlying metal from oxygen and moisture.

Another remarkable feature of stainless steel is its ability to ‘heal’ itself. If the surface of the stainless steel is scratched or damaged, the chromium oxide layer will quickly reform and repair itself, as long as there is oxygen present. This self-healing property makes stainless steel incredibly resistant to wear and tear, and helps to extend its lifespan even in harsh environments.

Stainless steel is also resistant to a wide range of environmental factors. It can withstand extreme temperatures, both hot and cold, making it suitable for use in all climates. It is also resistant to UV rays, which means it will not fade or deteriorate when exposed to sunlight. Additionally, stainless steel is resistant to chemicals, making it suitable for use in industrial environments where it may come into contact with corrosive substances.

Stainless steel requires very little maintenance to keep it in good condition. It does not need to be painted or coated, and its surface is easy to clean. Any dirt or stains on the surface of the stainless steel can be easily wiped away with a damp cloth, and it can be cleaned with mild detergent if necessary. This low maintenance requirement makes stainless steel a cost-effective choice in the long run.

Stainless steel perforated mesh is a versatile and effective material for sun control applications. It offers numerous benefits, including the ability to customize the size and pattern of the perforations, energy savings, aesthetic appeal, and durability.

By harnessing the power of this quality material, architects and designers can create buildings that are not only visually stunning but also functional and energy-efficient.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blogs that explore mild steel, aluminium and galvanised steel perforated metal mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions