Chicken wire is a versatile and flexible material that is used for a variety of purposes in the UK.

From garden enclosures to temporary fencing and plant support, chicken wire can help you achieve a wide range of projects and goals.

But how is it made? Is it right for my project? How do I dispose it when I am done?

This article aims to answer these questions and many more.

Chicken Wire vs. Welded Wire: Chicken wire has a hexagonal pattern and is flexible, making it easy to form and fit to varied landscapes. It is ideal for fences for small animals or for enclosing gardens. With its rigid grid pattern, welded wire provides a more uniform and durable barrier, making it better suited to high-security areas such as commercial properties or animal enclosures.

Chicken Wire vs. Wood: In agriculture or temporary fencing, chicken wire offers a lightweight solution that allows visibility and airflow. As a contrast, wood fencing provides a solid barrier, providing more privacy and a classic look, making it an excellent choice for residential property boundaries as well as decorative garden sections.

Chicken Wire vs. Vinyl: Known for its longevity and low maintenance, vinyl fencing withstands weather elements better than chicken wire. For curved surfaces or irregularly shaped areas, chicken wire is more adaptable and easier to work with than steel wire.

Galvanised steel chicken wire is manufactured by a process that involves coating steel wire with zinc to protect it from rust and corrosion. Here are the steps involved in the making of galvanised steel poultry netting:

The choice between galvanised steel and green PVC chicken wire will depend on your specific needs and preferences.

Galvanised steel is durable and long-lasting, and is often used for applications that require a strong, sturdy material. It is also rust-resistant, making it ideal for outdoor use.

Green PVC chicken mesh, on the other hand, is a plastic material that is coated in green pigment. It is lightweight, easy to handle and can be used for a variety of purposes, including garden enclosures, plant support and temporary fencing.

One advantage of green PVC over galvanised steel is that it is more visually appealing and less obtrusive, making it a popular choice for garden applications. However, it may not be as durable or long-lasting as galvanised steel.

The choice between galvanised steel and green PVC chicken wire will depend on your specific needs and preferences. Galvanised steel is strong and rust-resistant, making it ideal for outdoor use, while the green PVC version is lightweight and visually appealing, making it a popular choice for garden applications.

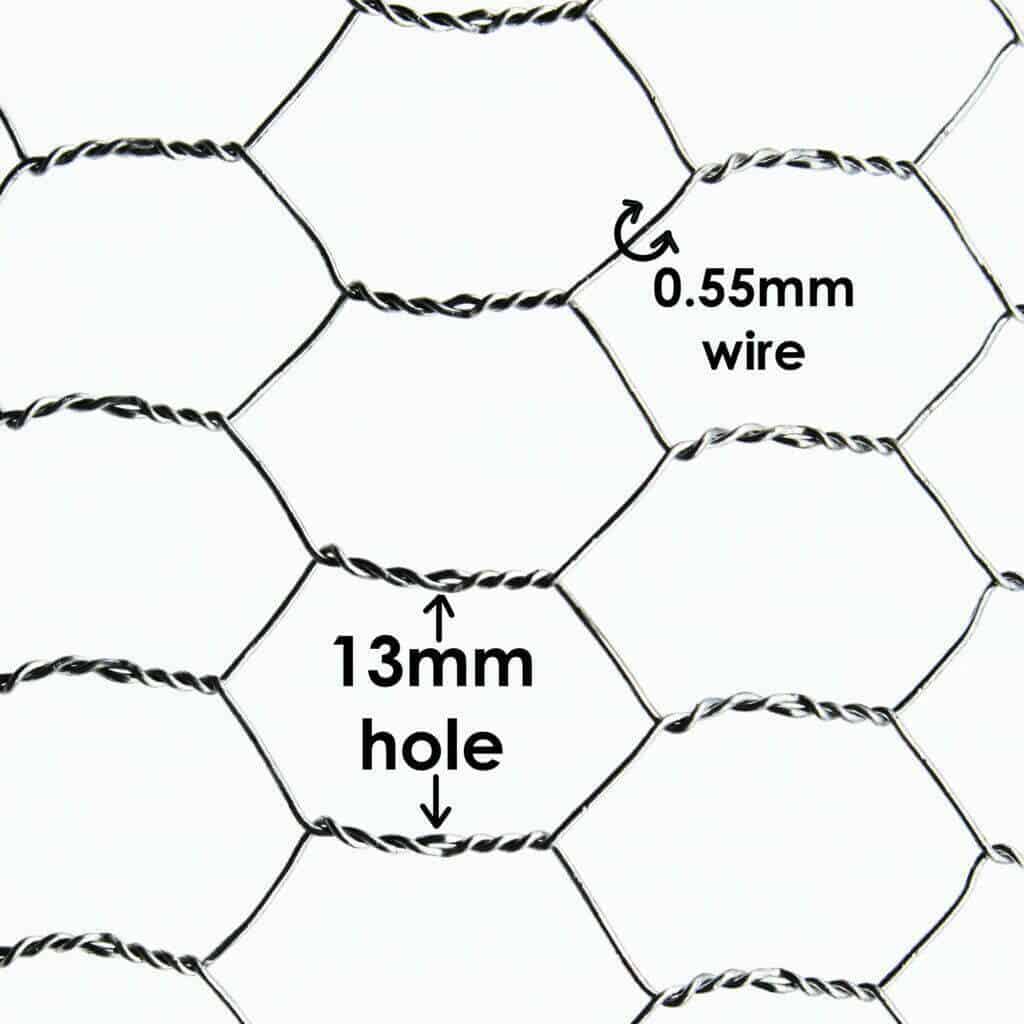

Ideal for smaller applications, this size offers tighter security against small animals and is often used in crafting and intricate garden work.

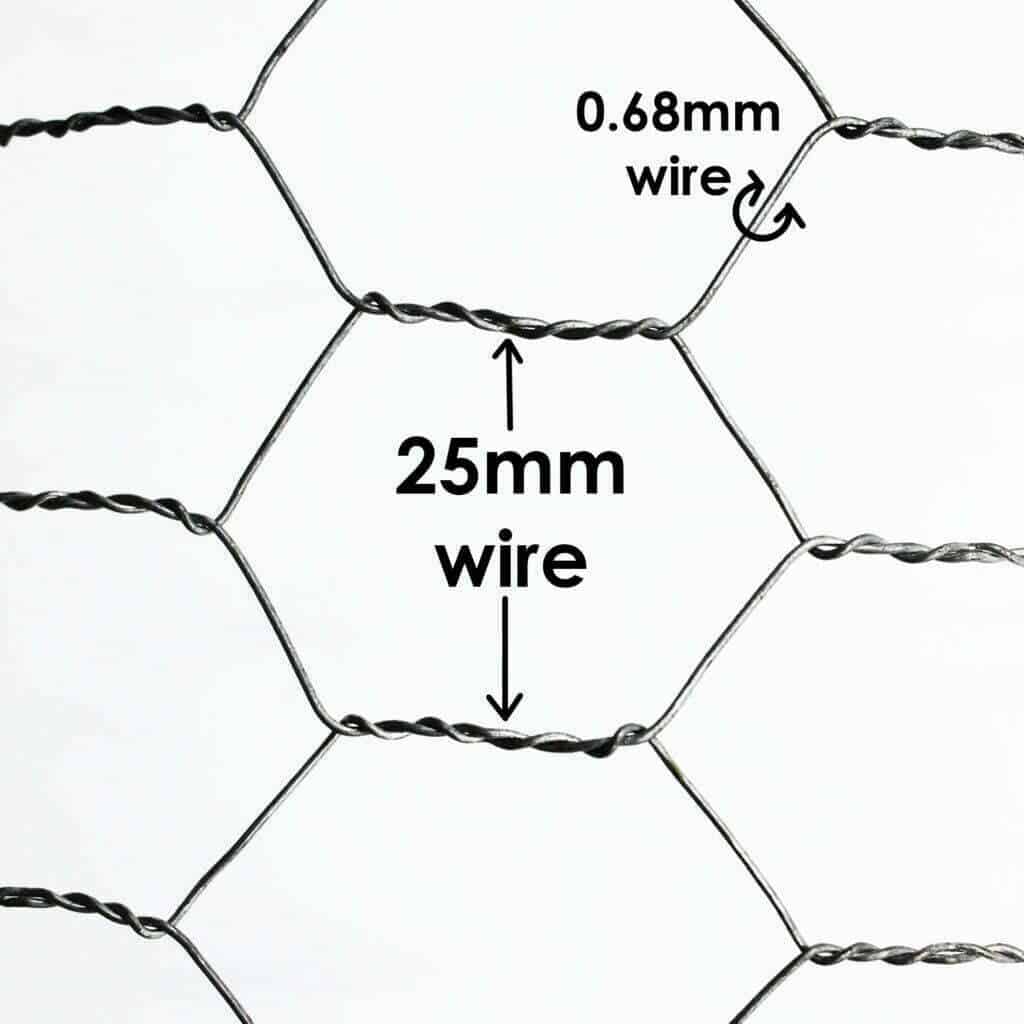

A versatile middle-ground option, suitable for a variety of garden and home uses, balancing flexibility and protection.

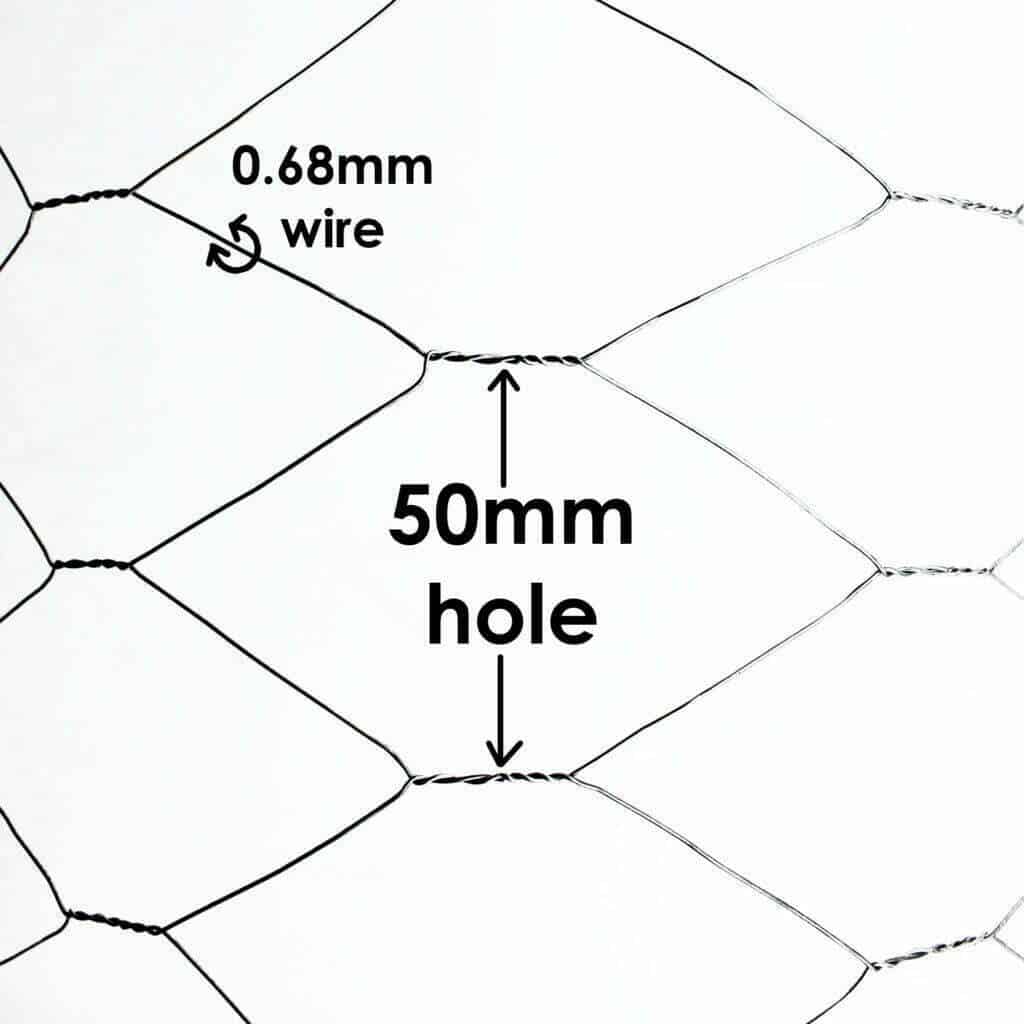

This larger size is perfect for more extensive fencing needs, such as agricultural enclosures, where broader coverage is required.

Galvanised chicken wire can be cut using a variety of tools, including:

When cutting galvanised chicken wire, it’s important to use caution and to wear protective gear, such as gloves and safety glasses, to protect yourself from sharp edges and flying debris.

Yes, galvanised chicken wire can be used to reinforce concrete. Chicken wire is often used as a reinforcement material in concrete due to its high tensile strength and ability to hold concrete in compression. This technique is called “wire mesh reinforcement” and it helps to reinforce concrete structures and improve their overall strength and durability.

When used to reinforce concrete, the chicken wire is typically laid in a grid pattern over the surface of the wet concrete. This allows the wire to bond with the concrete and create a strong, interlocking matrix. The concrete is then poured over the chicken wire, completely covering it. As the concrete cures and hardens, the wire mesh helps to hold it in place and resist any cracking or bending.

Mesh materials alone are not a guaranteed solution for stopping rats. The mesh size of most chicken wire is relatively large, typically 1 inch or larger, and rats are able to squeeze through small spaces, making it possible for them to get through the mesh.

However, if the netting is installed properly and with adequate tension, it can make it more difficult for rats to get through, and in some cases, it may be enough to deter them. To improve the effectiveness of chicken wire in stopping rats, it can be used in combination with other measures, such as:

It is important to note that preventing rat access to your property will require a comprehensive approach, including good sanitation practices and exclusion techniques. If you have a serious rat problem, it is best to consult with a professional pest control expert for advice on the best solution for your situation.

We do boast a huge range of rodent mesh products through our store from immediate stock. If you need to block rats, we will have the material for you.

Garden Trellises and Plant Supports: Chicken wire can be shaped into various forms for plant support structures, allowing for creative gardening solutions.

Home Decorations: From lampshade frames to wall art, chicken wire offers a rustic charm that can be incorporated into numerous home décor projects.

Storage Solutions: Create hanging baskets or pantry organizers using chicken wire for an aesthetic and functional storage option.

The strength of chicken wire depends on several factors, including the material it is made of, the gauge (or thickness) of the wire, and the spacing of the holes.

Chicken wire is typically made of galvanised steel, which is a strong and durable material. The wire is usually coated with a zinc layer to prevent rusting. The thickness of the wire, measured in gauge, is also a factor in its strength. Thicker wires have a higher gauge number and are generally stronger than thinner wires with a lower gauge number.

The spacing of the holes in the mesh also affects its strength. The closer the holes are together, the stronger the chicken wire will be. Chicken wire with smaller holes will be stronger than with larger holes, as long as the wire gauge remains the same.

In general, chicken wire is a relatively lightweight material that provides some strength and stability, but it is not typically used as a standalone support structure. Instead, it is often used as a reinforcement material, in combination with other building materials such as concrete or wood.

There are several ways to attach chicken mesh to a fence, including the following:

Regardless of the method used, it is important to make sure the chicken wire is attached securely to the fence so that it does not come loose or fall down. Additionally, the netting should be taut and without any sagging or loose areas to ensure its effectiveness.

The proper disposal of poultry netting depends on the material it is made of and the local regulations in your area.

Chicken wire is often made of galvanised steel, which is a recyclable material. If the chicken wire is in good condition and not contaminated with other materials, it can be taken to a recycling centre for proper disposal. Many recycling centres accept metal products, including chicken wire mesh.

Before disposing of the chicken wire, it is important to check with your local recycling centre or waste management facility to determine their specific guidelines for disposing of metal products.

If the mesh is rusty or damaged, it may not be recyclable. In this case, it should be taken to a landfill for proper disposal.

It is important to note that some local regulations may require special disposal procedures for metal products. Before disposing of galvanised steel mesh, it is important to check with your local authorities to determine the proper disposal method in your area.

Handling Precautions: Always wear gloves when working with chicken wire to prevent cuts and scratches. Eye protection is also recommended to safeguard against wire snaps.

Cutting Safely: Use appropriate wire cutters and ensure a stable working surface to avoid accidents when cutting chicken wire.

Installation Safety: When installing chicken wire, make sure to securely fasten it to prevent loose ends, and be aware of its tension to avoid snapping back.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.