When it comes to DIY projects, the choice of materials can make or break your final product.

This is especially true for fly nets, where the metal used plays a pivotal role in both functionality and longevity.

Choosing the best metal for your DIY fly net is not just about aesthetics; it’s about finding a balance between durability, ease of handling, and effectiveness.

In this comprehensive guide, we at The Mesh Company will walk you through the nuances of selecting the ideal metal for your fly net project. We’ll dive into the properties of various metals and how they contribute to the overall quality of your fly net. Whether you’re a seasoned DIY enthusiast or a beginner, our insights will help you make an informed decision, ensuring your fly net stands the test of time and elements.

Let’s go…

What is a Fly Net?

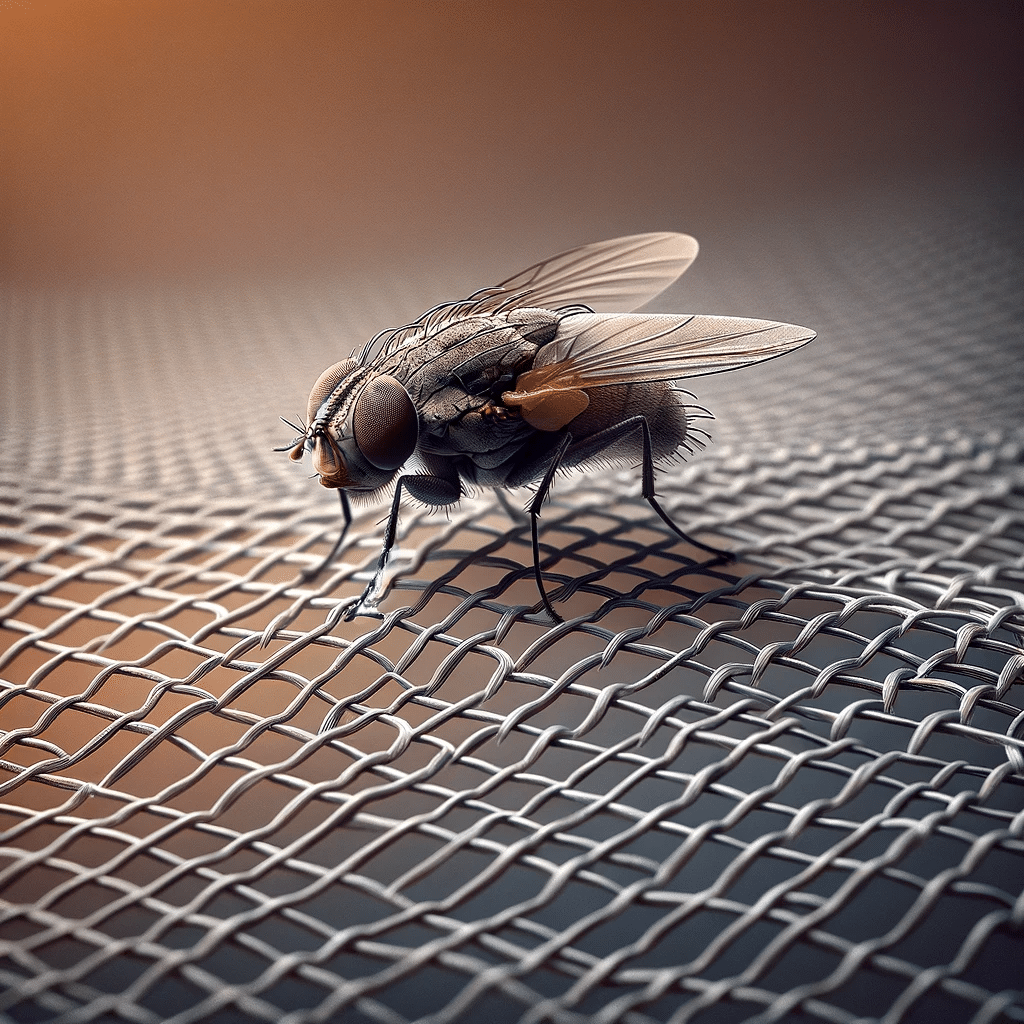

Insect screens, also known as fly nets, cover the openings of a structure, such as windows or doors, to prevent insects from entering while allowing air flow. Nets provide a barrier without compromising ventilation in areas where flying insects are a nuisance or health hazard.

Primary Uses of Fly Nets

Significance of Material Choice

Material plays a significant role in the effectiveness of a fly net. The right metal determines the net’s strength and durability, as well as its visibility and aesthetics. A net’s choice of metal determines its weather resistance, maintenance requirements, and longevity.

Any of the metal mesh options mentioned in the blog would be suitable. But which would work best for your project?

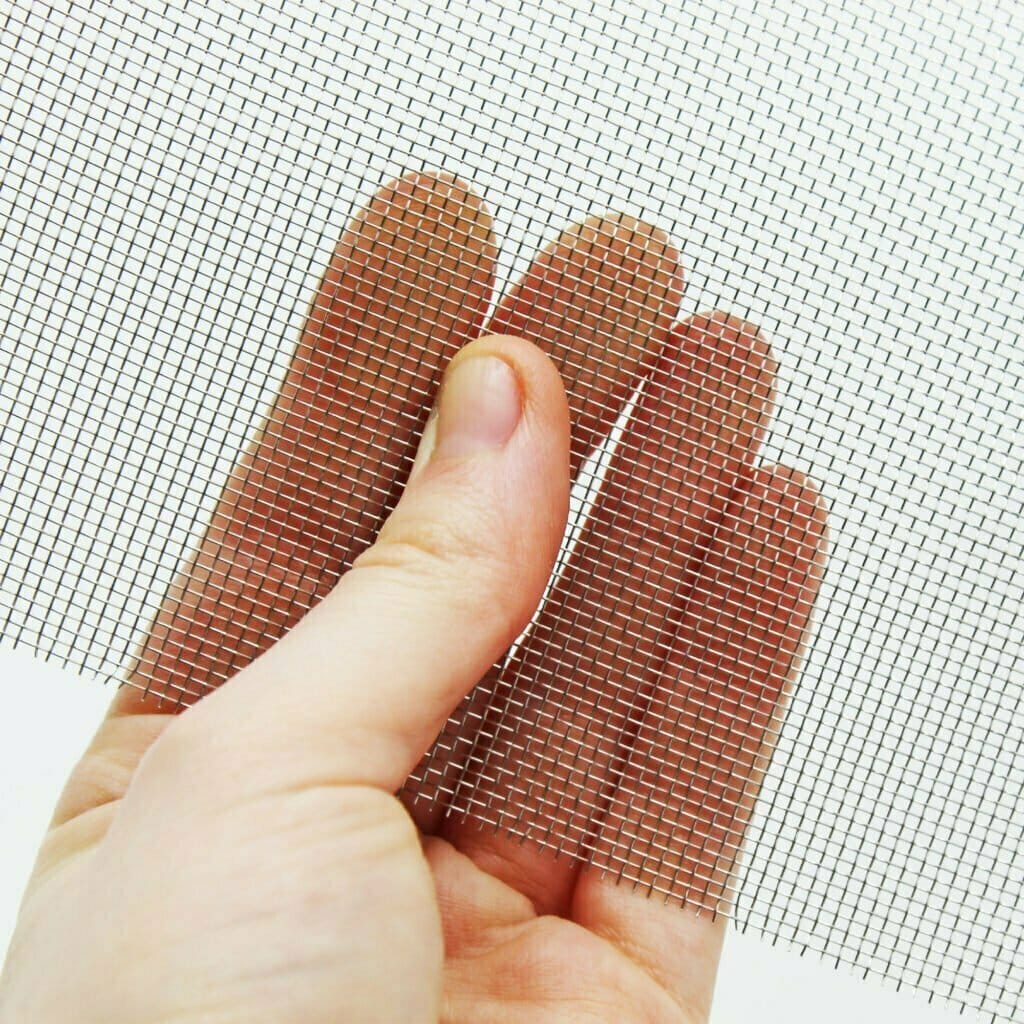

Common Metals Used in Fly Nets

Durability

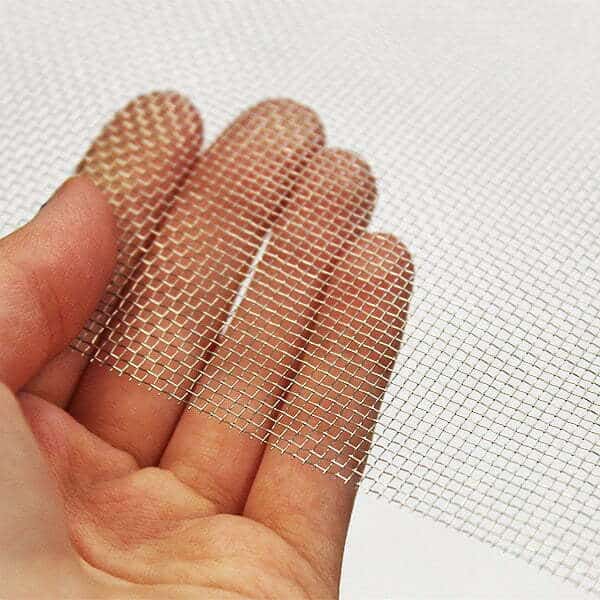

Rust and corrosion resistance are closely related to the longevity of a fly net. Due to their high rust resistance, metals such as stainless steel and aluminum are ideal for long-term outdoor use. A product must also be able to withstand physical stress without deforming or breaking as part of its durability.

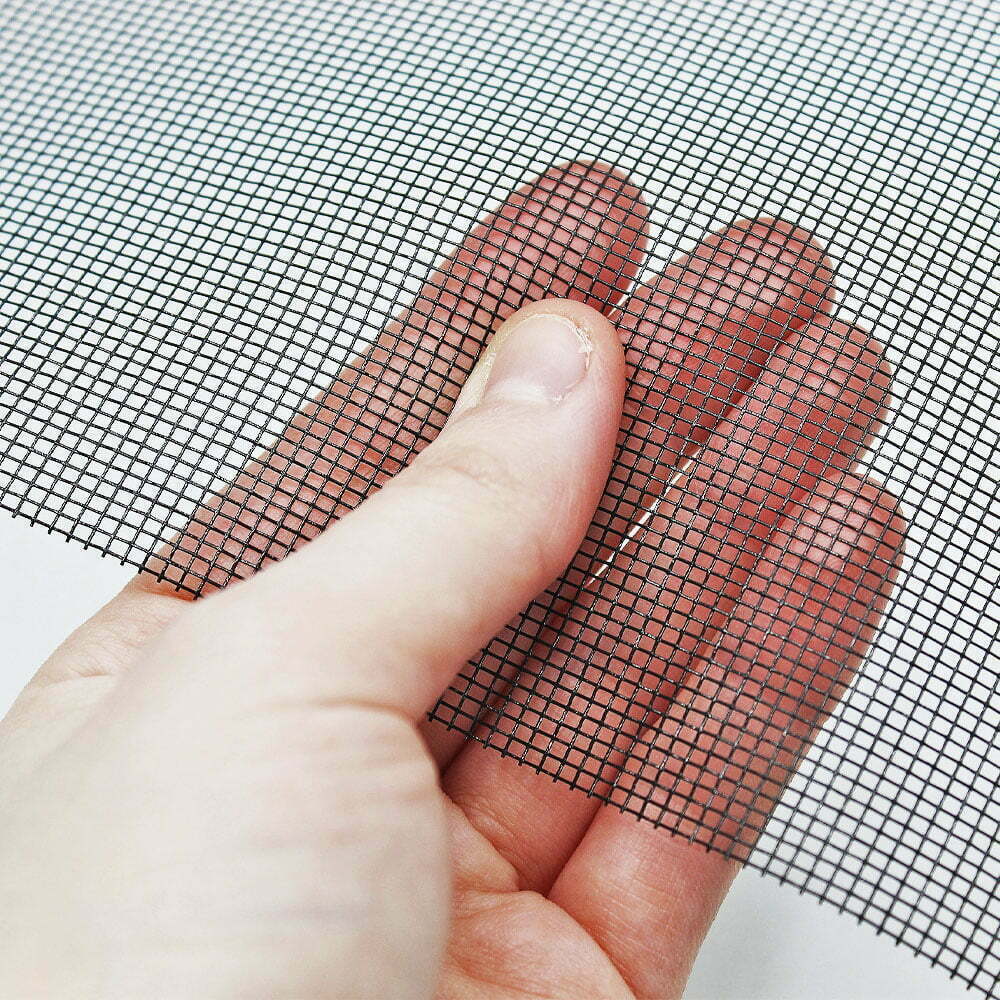

Mesh Size

An effective fly net depends on the mesh opening size. It is possible to weave or weld a variety of metals into various mesh sizes, affecting their ability to keep out insects of varying sizes. Choosing the right metal affects the precision with which mesh sizes can be maintained over time.

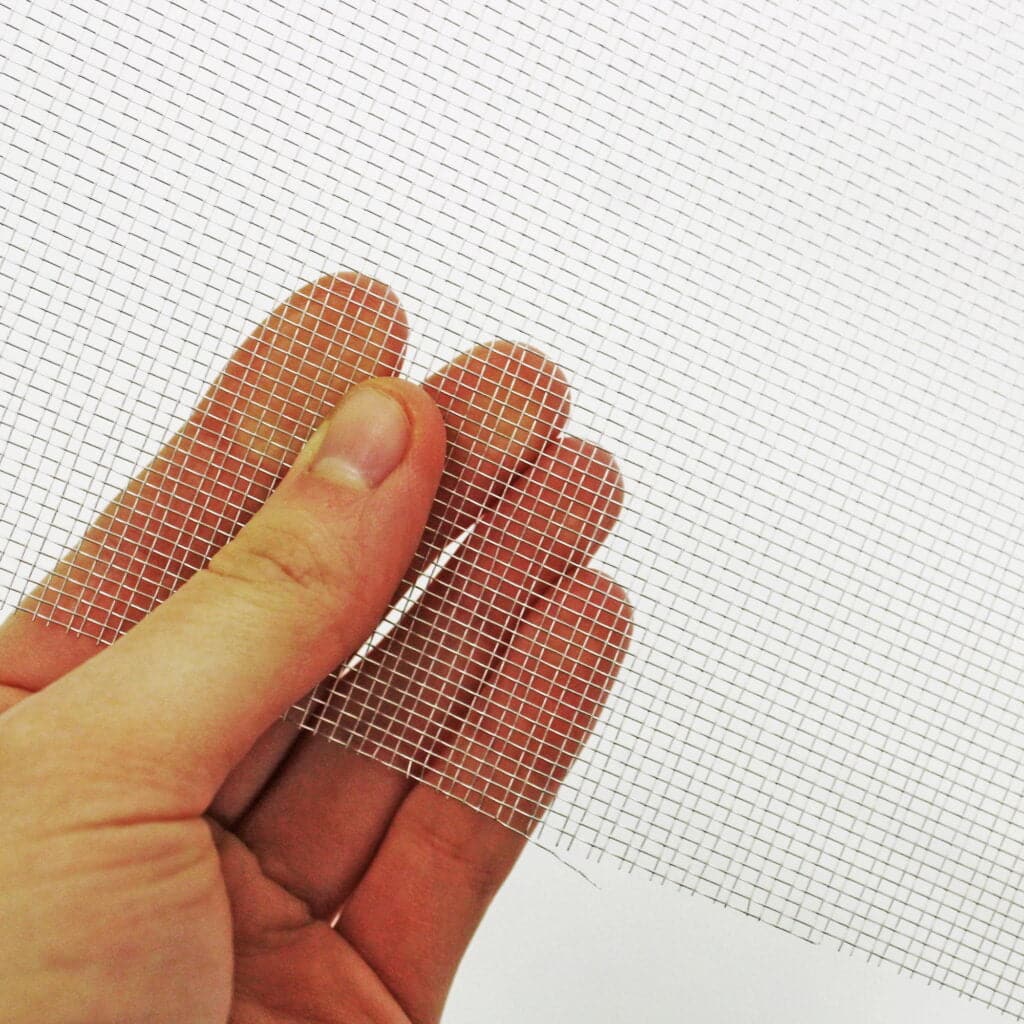

Ease of Handling

In DIY projects, the workability of the metal is crucial. Metals like aluminum are easier to cut and shape, making them ideal for home projects. Stainless steel, for example, may require more specialised tools and techniques.

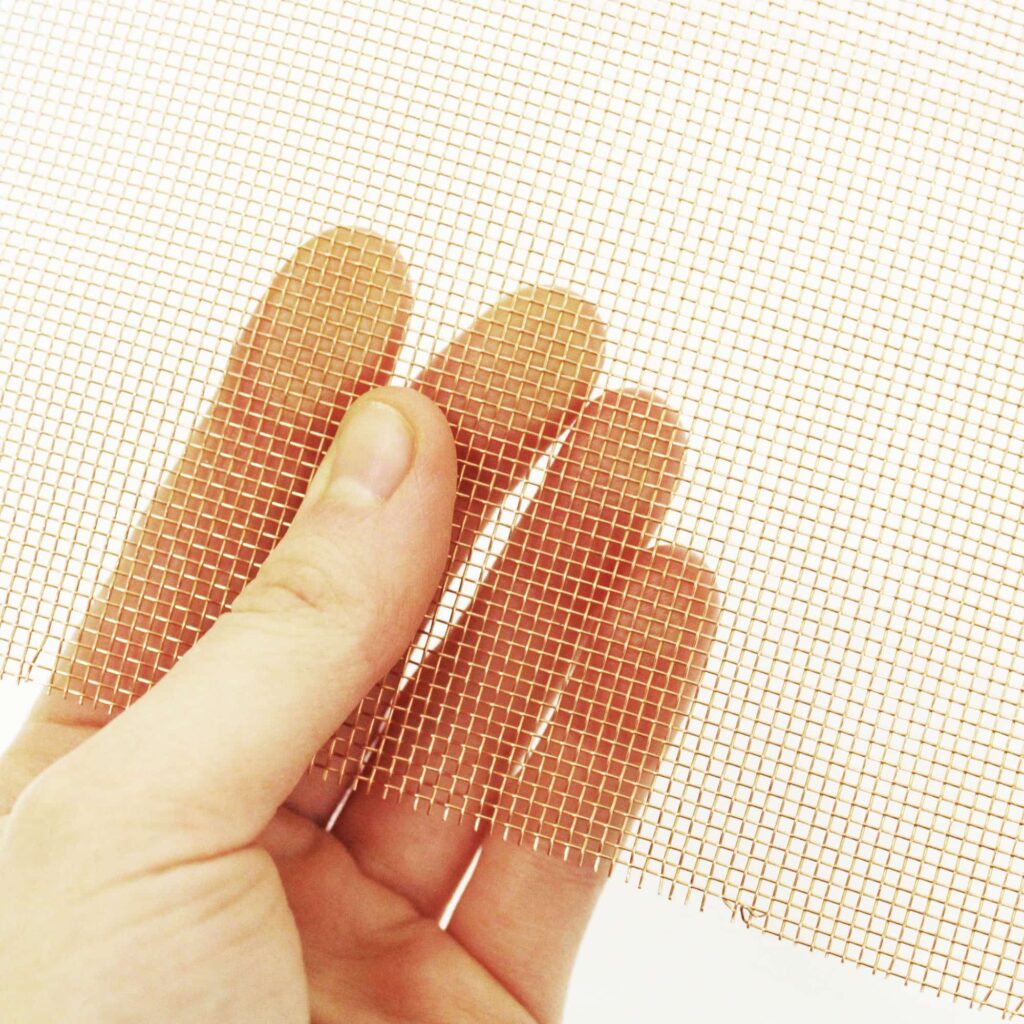

Aesthetic Appeal

The appearance of the metal is an important consideration, especially for residential applications. Metals like copper offer a distinct look that can add to the aesthetic value of a property. The metal’s ability to retain its appearance over time, resisting fading or discoloration, also plays a significant role.

Comparative Analysis

Ultimately, each metal has its own advantages. Galvanised steel and aluminum are cost-effective and easy to work with, making them ideal for DIY enthusiasts. Copper offers a unique aesthetic and natural antimicrobial properties, while stainless steel is known for its strength and durability. It depends on the individual’s budget, durability, appearance, and workability requirements.

Measuring and Cutting Metal Mesh

We recently produced a simple video showing how mesh of this kind of size can be cut easily with scissors.

Installation and Maintenance

Safety Precautions

Cost Implications

The cost of metal for fly nets varies significantly. For larger projects or those with limited funds, aluminum and galvanised steel are more budget-friendly. While stainless steel and copper are more expensive, they offer greater durability and aesthetic value, which may justify their higher price over time.

Sustainability Aspect

Metals’ entire lifecycle should be considered when assessing their environmental impact. Aluminum and steel are highly recyclable, reducing their environmental impact. While copper is less commonly recycled, its long lifespan can offset its initial environmental impact. Zinc coatings are responsible for galvanized steel’s sustainability. Choosing a sustainable option not only benefits the environment but can also be a selling point for environmentally conscious consumers.

To conclude, choosing the right metal for your DIY fly net requires balancing durability, functionality, aesthetic appeal, and cost-effectiveness. Many people choose aluminum due to its ease of handling and resistance to corrosion. While stainless steel stands out for its strength and longevity, copper has an aesthetic appeal and antimicrobial properties. Another viable option is galvanised steel, thanks to its robustness and affordability. Depending on your specific requirements, environmental conditions, and budget, each metal has unique advantages and potential downsides.

Consider these factors carefully when choosing a metal for your DIY fly net project. For more detailed advice, to explore our diverse range of high-quality metal meshes, or to benefit from our expert services, visit The Mesh Company’s website.

Our lovely team is dedicated to helping you make informed decisions and successfully complete your DIY projects.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to clean and maintain a fly screen.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.