It is often the case that when it comes to choosing a mesh material for any application, be it fencing, gardening, crafting, or construction, the choice boils down to whether it is plastic or metal. In both cases, both materials have a unique combination of advantages and disadvantages that are unique to them. Throughout this article, we will provide a comparative analysis of both plastic mesh and metal wire mesh, as well as discuss some of their characteristics, applications, advantages, and disadvantages.

Let’s get into it…

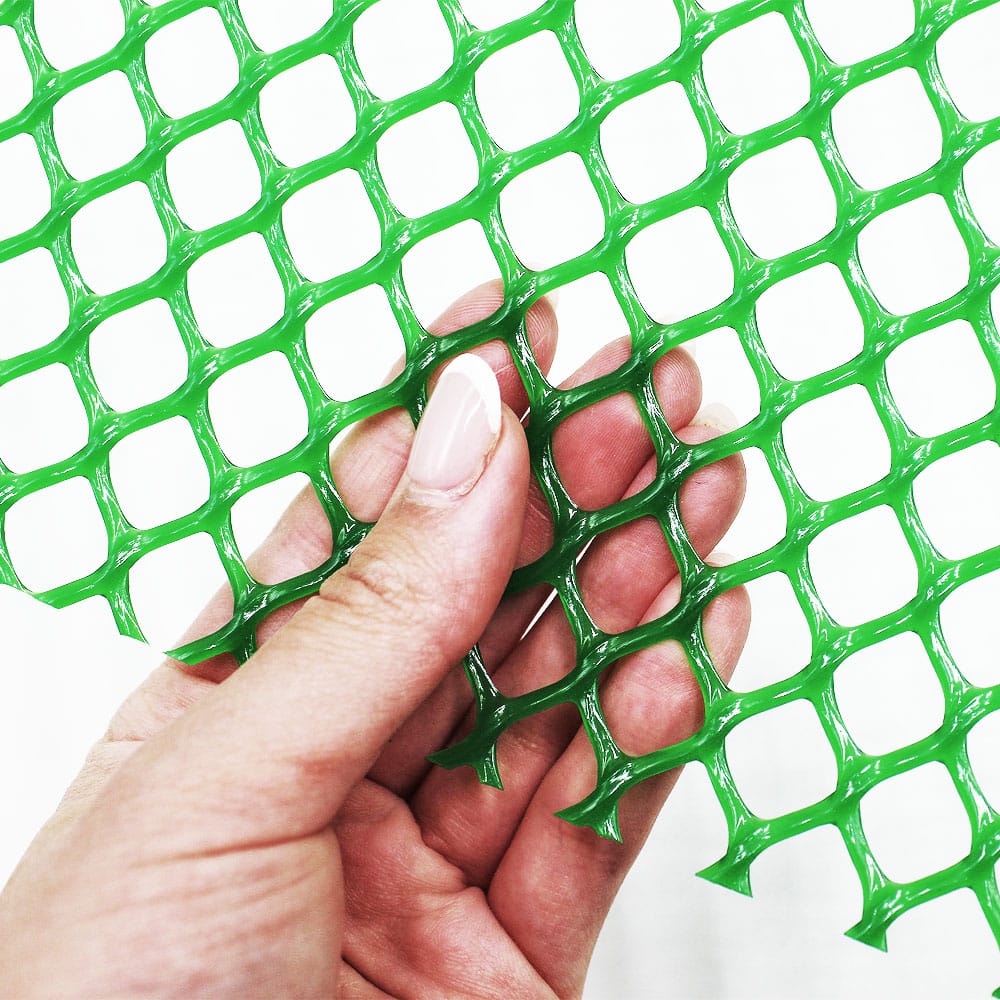

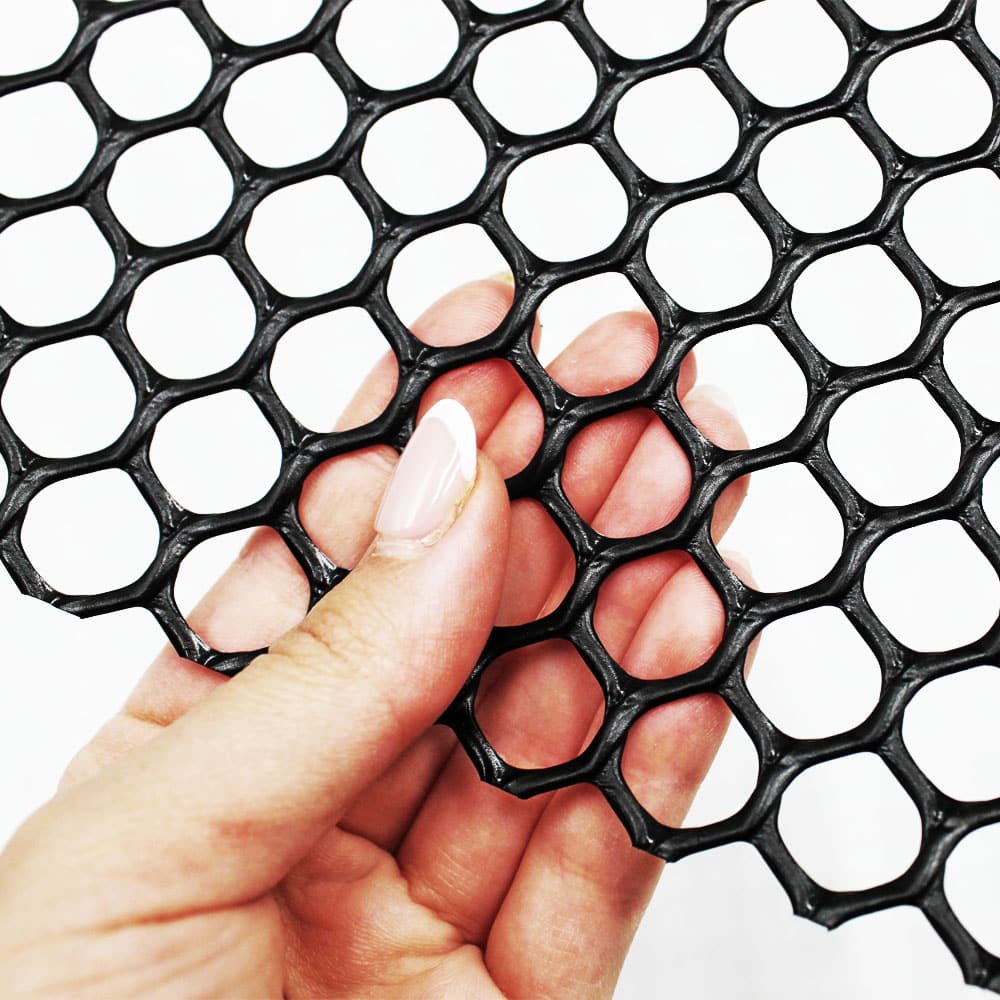

Plastic mesh is a versatile material that is made from synthetic polymer materials such as polyethylene, polypropylene, and polystyrene. In addition to its lightweight design and ease of handling, this product is also available in a variety of colors and sizes.

For example, we stock our balcony mesh in black, green and white.

As well as balcony fencing, plastic mesh is widely used in various applications. It can also be used in gardening to provide support for plants or to create a barrier against insects and other pests. There is also a use for it in construction safety, where it is used as a temporary fence around construction sites to ensure the safety of those working there. Despite its versatility and ease of use, plastic mesh is also commonly used in crafting and DIY projects due to its flexibility and ease of use.

Affordability: Plastic mesh is generally less expensive than metal wire mesh, making it a cost-effective solution for large-scale projects.

Versatility: It’s available in a wide range of colors, sizes, and designs, making it adaptable to numerous applications.

Corrosion Resistance: Unlike metal, plastic does not rust, making it suitable for use in wet and corrosive environments.

Easy Installation: Plastic mesh is lightweight and easy to cut and install without the need for specialized tools or equipment.

Durability: While plastic mesh is relatively durable, it may not withstand heavy stress or impact as well as metal wire mesh.

UV Resistance: Prolonged exposure to sunlight can cause some types of plastic mesh to become brittle and degrade over time.

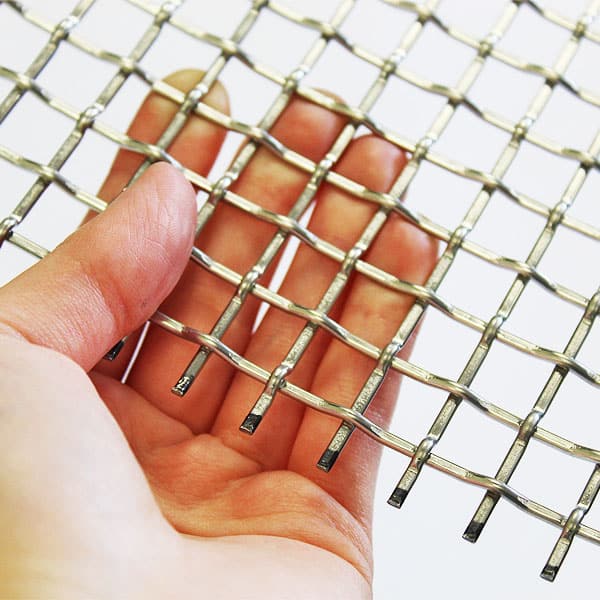

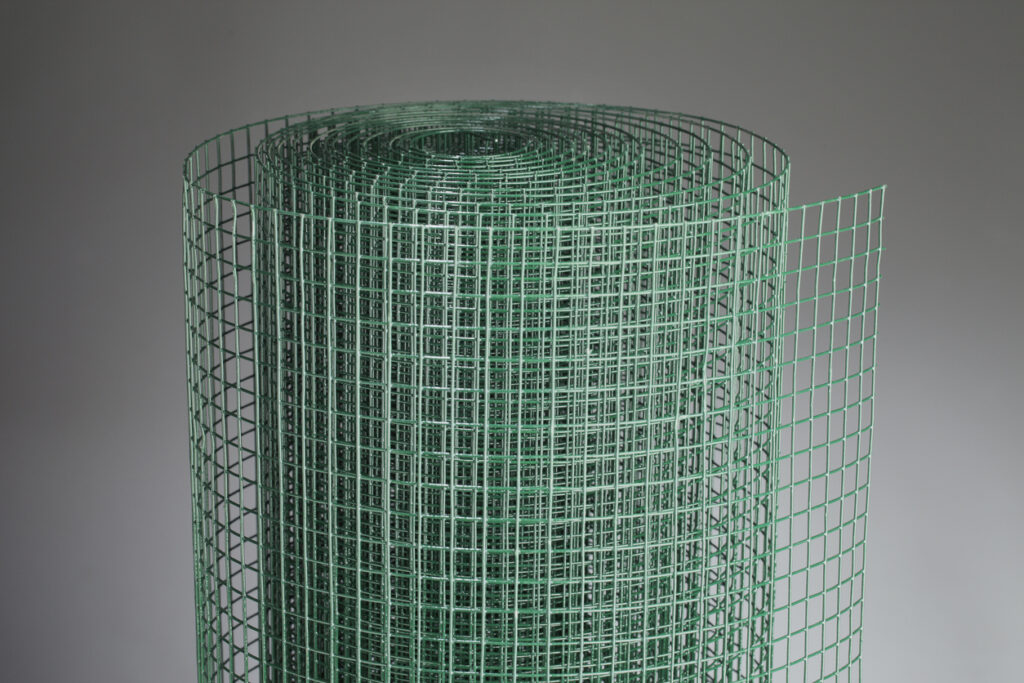

Metal wire mesh, also known as wire cloth or wire fabric, is a versatile product made from intertwined rows of metal wire. A grid-like pattern is woven or welded at the intersections of these wires to create a grid-like pattern at their intersections. This mesh can be produced from a variety of metals and metal alloys, including stainless steel, copper, brass, aluminium, and more. The particular material used will determine the mesh’s properties and most suitable applications.

It is important to note that the size of the openings in the mesh (known as mesh count) can vary significantly, which allows for a wide range of applications to be made with it. The more mesh counts there are, the greater the openings and the coarser the mesh is, while the more mesh counts there are, the smaller the openings and the finer and more delicate the mesh becomes.

Metal wire mesh is commonly used in industrial applications due to its strength. It’s used in fencing, screening, and filtration processes in various industries. In the home, it’s used for window screens, garden fences, and even in arts and crafts.

Pros of Metal Wire Mesh

Durability: Metal wire mesh is exceptionally durable and resistant to physical impact. This makes it ideal for applications that require a higher level of security or resistance to wear and tear.

Heat Resistance: Unlike plastic, metal wire mesh can withstand high temperatures, making it suitable for use in applications where heat resistance is necessary.

Longevity: With proper care and maintenance, metal wire mesh can last for many years.

Cons of Metal Wire Mesh

Cost: Metal wire mesh is typically more expensive than plastic mesh. The cost can increase further depending on the type of metal used.

Corrosion: Some metal meshes, particularly those made from iron or steel, can rust when exposed to moisture. However, this can be mitigated by using galvanized or stainless steel mesh.

Weight: Metal wire mesh is heavier than plastic mesh, which can make installation more challenging and may require specialized tools or equipment.

The choice between plastic mesh and metal wire mesh ultimately depends on the specific requirements of your project. If you need a cost-effective, versatile, and lightweight solution, plastic mesh could be the right choice. However, if durability, heat resistance, and longevity are more important, metal wire mesh might be a better fit.

Before making a decision, it’s crucial to assess your project’s needs, budget, and the environmental conditions where the mesh will be used. Whatever you choose, remember that both plastic and metal wire mesh have proven their worth in countless applications worldwide.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions