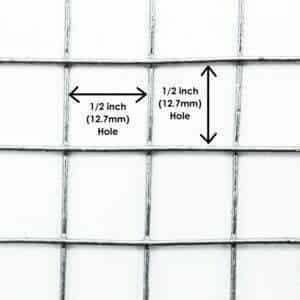

13mm welded mesh (1/2″) is a versatile and robust material that forms an integral part of various construction, industrial, and DIY projects.

Characterised by its uniform square or rectangular patterns, this type of mesh is renowned for its strength and durability. At The Mesh Company, we understand the critical role 13mm welded mesh plays in a myriad applications, from reinforcing concrete in construction projects to crafting sturdy garden trellises.

In this comprehensive guide, we delve into the nuances of 13mm welded mesh, offering our expertise and insights to help you make the most of this exceptional material. Whether you’re a professional builder, an industrial manufacturer, or a DIY enthusiast, this guide will equip you with essential knowledge and tips for choosing and using 13mm welded mesh effectively.

Let’s go…

Definition and Manufacturing Process

A 13mm welded mesh consists of individual steel wires that are welded at their intersections to form a rigid structure. “13mm” refers to the size of the openings between the wires, resulting in a grid pattern. It is typically manufactured using a mechanised process in which horizontal and vertical wires are precisely laid out and then welded together at each junction to ensure uniformity and strength.

Distinct Characteristics

As the intersections are firmly bonded, welded mesh maintains its shape and integrity even when cut. Grid size precision and robust welds distinguish it from other mesh types. Mesh of this type is also available in various wire gauges, which allow for different levels of strength and flexibility.

Common Uses

13mm welded mesh is widely used across several sectors:

Strength and Durability

13mm welded mesh is characterized by its strength. At each intersection, welding ensures that the mesh will not warp or break under significant weight and stress. Safety and durability are crucial in construction and industrial applications.

Versatility

The uniform structure of 13mm welded mesh makes it suitable for a wide range of applications. From reinforcing concrete in building foundations to crafting decorative items, its adaptability is evident. Both functional and creative projects benefit from its rigidity and ease of customisation (cutting to size).

Maintenance and Longevity

One of the key benefits of 13mm welded mesh is its low maintenance requirement. Coating or galvanizing it enhances its resistance to moisture and rust, and increases its lifespan. Because of its long-lasting nature, it ensures structural integrity over time and is also a cost-effective solution in the long run. Cleaning and occasional inspections are usually enough to maintain its condition, making it a practical choice for both permanent and temporary installations.

Construction and Building

13mm welded mesh plays a critical role in the construction and building industry. It is primarily used to reinforce concrete structures, such as foundations, floors, and walls, where it provides necessary tensile strength and distributes loads evenly. The mesh is also widely used to construct fences for security and demarcation. 13mm welded mesh is an ideal choice for creating sturdy and durable enclosures, such as in storage facilities or for machinery protection.

Gardening and Landscaping

Gardening and landscaping can benefit from 13mm welded mesh. In addition to providing a stable structure for climbing plants and vegetables, it is widely used in making plant supports and trellises. It can also be used to create animal barriers to protect gardens from pests and wildlife while maintaining airflow and visibility. Due to its durability, it is a long-term solution for gardeners and landscapers.

Industrial Uses

There are a wide range of applications for 13mm welded mesh in industrial settings. In manufacturing processes, it is used to create baskets and containers that require strength and ventilation. This mesh is commonly used for shelving or partitioning in storage solutions, providing secure and visible storage options. A 13mm welded mesh is also crucial to safety, since it is used to construct protective barriers around machinery or hazardous areas, ensuring worker safety without hindering visibility.

Creative and Decorative Uses

In addition to its functional applications, 13mm welded mesh can be used for creative and decorative projects. With its grid structure, it is suitable for use in home décor, such as wall panels, room dividers, or as a base for creative installations. In addition to its traditional uses, this mesh is a versatile medium for sculptures, mixed media art, and other artistic creations.

Factors to Consider

When selecting 13mm welded mesh for a project, several factors need to be considered to ensure the right fit:

Sourcing Quality Mesh

To ensure you’re getting a high-quality 13mm welded mesh, consider the following tips:

Step-by-Step Installation Guide

Maintenance Advice

Safety Precautions

Material Sourcing

It is estimated that the production of steel, the primary material in welded mesh, is responsible for a significant amount of energy use and can have a negative impact on the environment. Advances in production technology are, however, reducing these impacts, with many manufacturers focusing on more sustainable practices.

Recyclability

Recyclability is a key environmental benefit of 13mm welded mesh. Steel is one of the most recycled materials in the world, allowing for the reprocessing and reuse of mesh products, which reduces the need for new raw materials and minimises waste.

Long-term Sustainability

13mm welded mesh is highly sustainable due to its durability and long-term use. Providing a long-lasting solution reduces the frequency of replacements, thereby reducing the environmental footprint.

13mm welded mesh is a versatile, strong, and sustainable option for a number of applications, including construction, industry, gardening, and creative work. The installation and maintenance of this product are straightforward, and safety and longevity are key considerations. The recyclability of steel and the long-term sustainability of steel mesh mitigate the environmental impact of steel production. The strength, size, and environmental conditions of your project should be taken into consideration when choosing 13mm welded mesh.

The Mesh Company offers a range of high-quality 13mm welded mesh products. We offer a wide range of products and expertise to ensure you find the right solution for your project.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.