In the world of construction and metalworking, understanding the different types of materials available is key to ensuring successful projects.

One such is metal lath. We are often being asked to clarify what this term refers to. Which is why we took a moment to create this article.

How does it differ from metal mesh? While they may seem similar, each serves distinct purposes and offers unique benefits.

In this quick article, we’ll explore what metal lath is, how it differs from metal mesh, and look at some practical examples of each available from The Mesh Company.

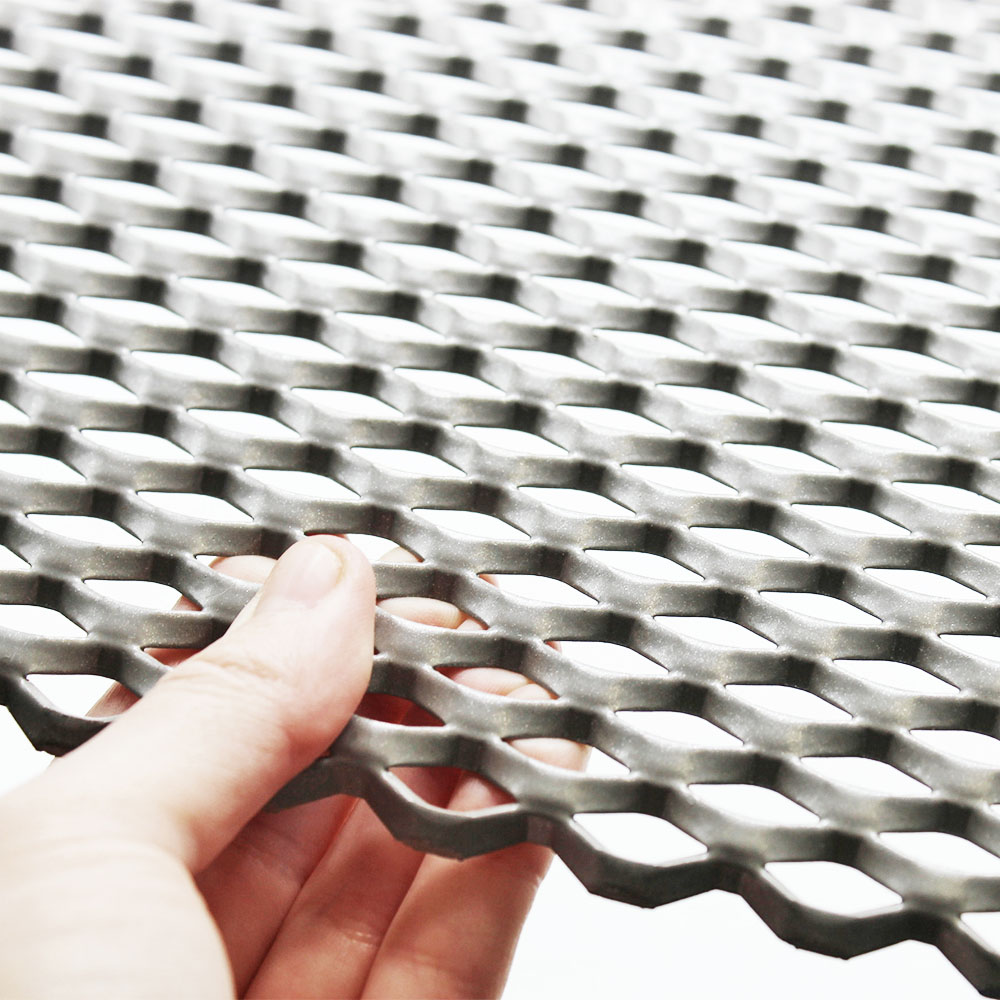

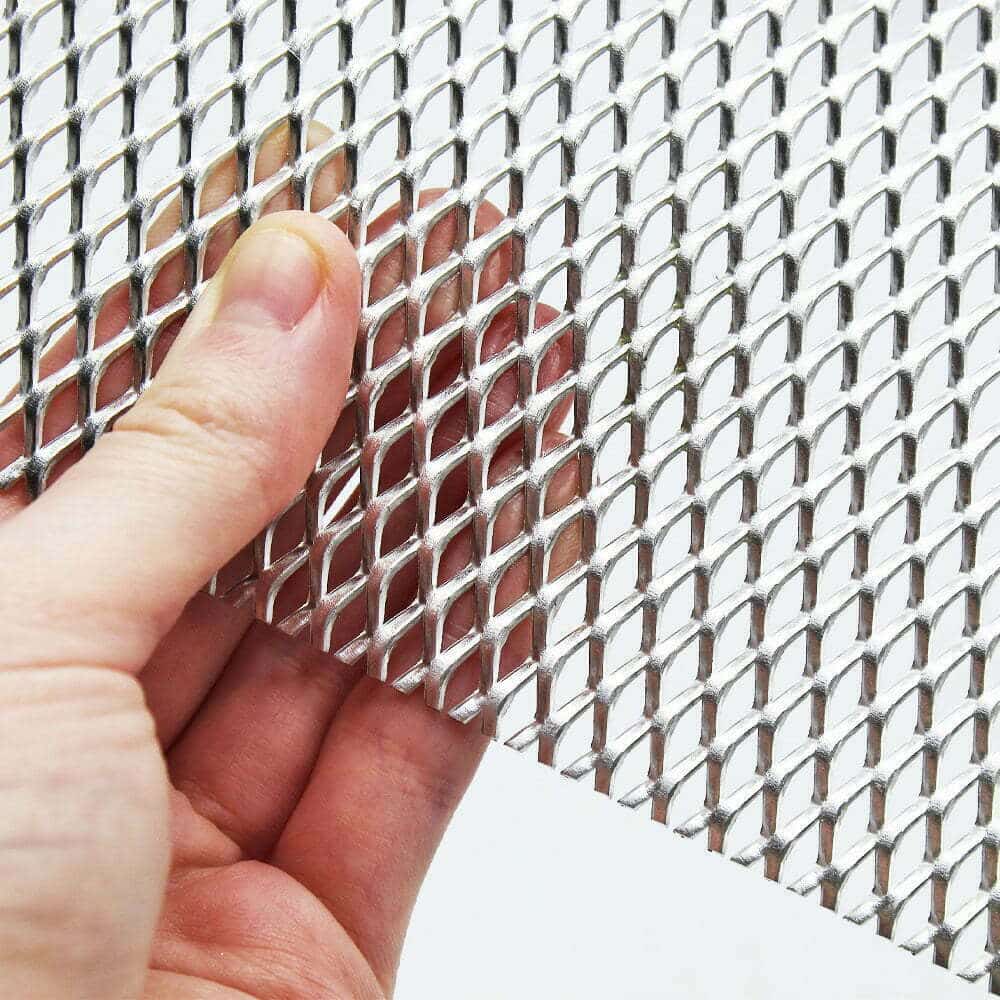

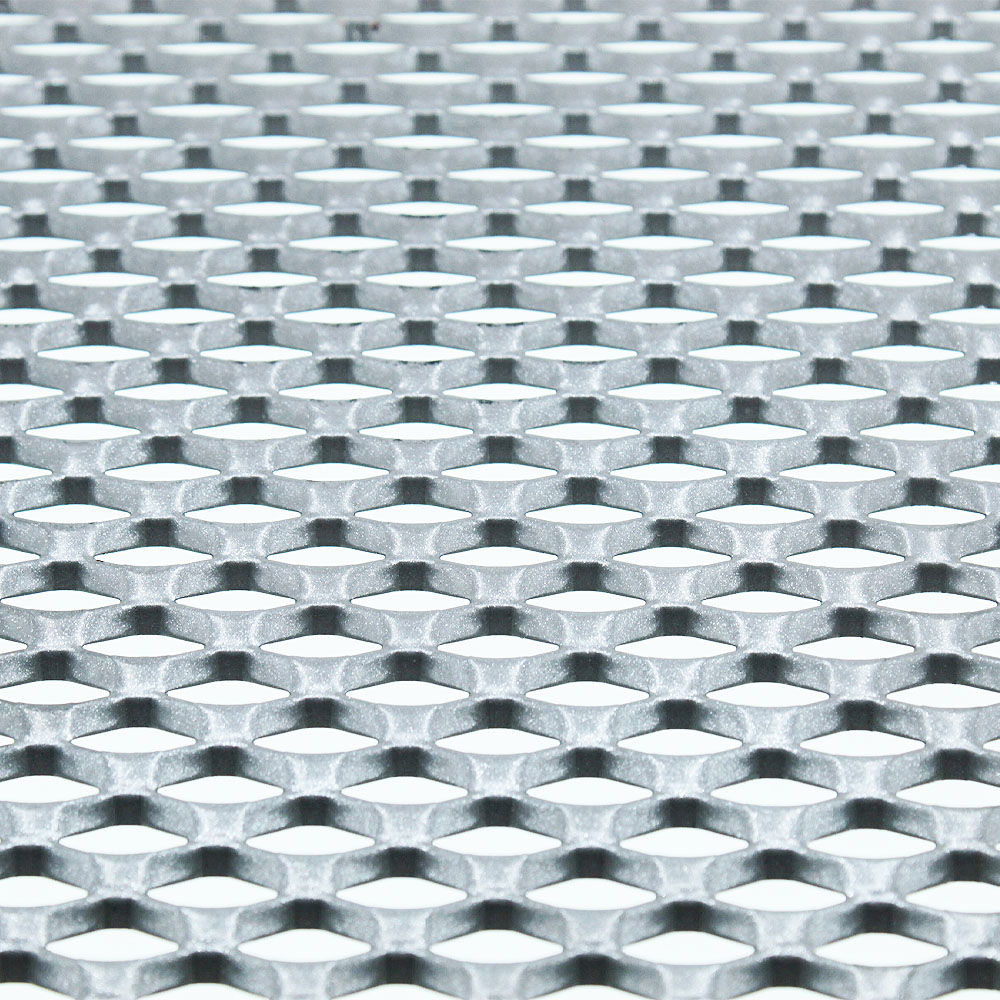

Metal lath is a versatile building material, commonly used as a base for plaster or stucco applications. It is made by expanding, perforating, or pressing metal sheets to create a network of small, uniform openings. This rough texture allows materials like plaster or stucco to adhere securely, making it ideal for reinforcing walls, ceilings, and other surfaces.

Types of Metal Lath: There are several types of metal lath, each suited to specific applications:

Why Use Metal Lath?

The main purpose of metal lath is to act as a supportive base for plaster or stucco. The open design ensures that the plaster bonds firmly, reducing the risk of cracks or detachment. It is typically made from galvanized steel to prevent rusting, ensuring longevity even in outdoor environments.

Example from The Mesh Company:

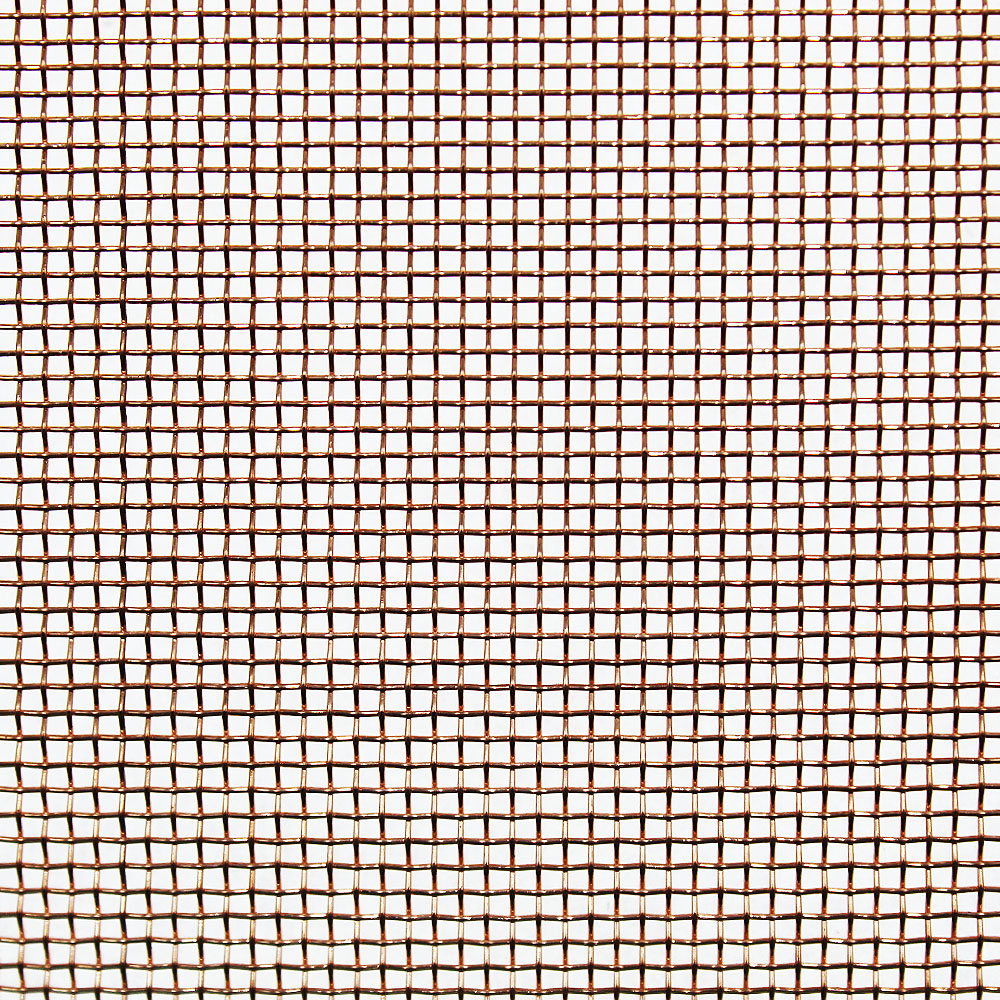

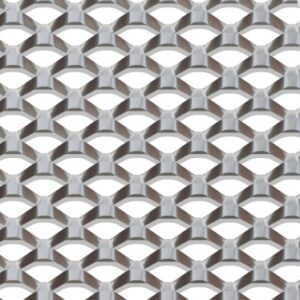

Unlike metal lath, metal mesh is a broader category that encompasses various types of woven, welded, or perforated metal sheets. Metal mesh is designed with a range of hole sizes, wire thicknesses, and patterns, making it suitable for an array of industrial, commercial, and decorative uses. The structure of metal mesh can vary significantly depending on its intended purpose.

Types of Metal Mesh: The most common types include:

Why Use Metal Mesh?: The versatility of metal mesh makes it useful in a wide range of applications, from filtration and sieving to reinforcement and security fencing. Its strength and flexibility allow it to be shaped into various forms, while the open structure provides excellent airflow and drainage.

Example from The Mesh Company:

Understanding the distinctions between metal lath and metal mesh is crucial for selecting the right material for your project. Here are the key differences between the two:

Purpose and Use Case:

Structure and Design:

Strength and Durability:

Both metal lath and metal mesh have their place in construction and other industries, but choosing the right one depends on the application:

When to Use Metal Lath:

When to Use Metal Mesh:

Metal lath and metal mesh may look similar at first, but they each have unique properties and applications. Metal lath is ideal for providing a strong base for plaster and stucco, ensuring a smooth and durable finish. On the other hand, metal mesh offers a versatile solution for a range of needs, from filtration to decorative accents. By understanding the differences between these materials, you can choose the right one for your project and ensure a successful outcome.

Explore the range of metal lath and metal mesh available at www.themeshcompany.com to find the perfect material for your next project.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions