Lattice weave mesh is a structural design that blends aesthetics with practicality by weaving materials into intricate patterns. This age-old technique has evolved from ancient craftsmanship to modern engineering, finding use in a variety of fields, including architecture, art, design, engineering, and gardening. It offers versatile solutions that are both visually appealing and robust.

In this blog, we’ll delve into the concept of lattice weave mesh, exploring its historical roots, the process of its creation, its diverse applications, and its growing popularity in today’s world. By the end, you’ll gain a thorough insight into its significance across various industries.

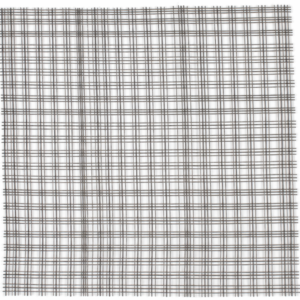

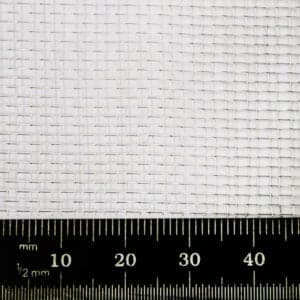

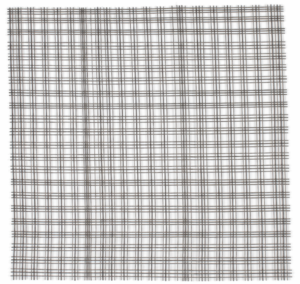

Lattice weave mesh refers to a specific type of mesh that is created through the interlacing or weaving of materials in a crosshatched pattern. The term “lattice” refers to a criss-cross pattern, while “weave” indicates the method of construction. Mesh, in this context, is a grid-like structure that is formed by the intersection of materials at right angles.

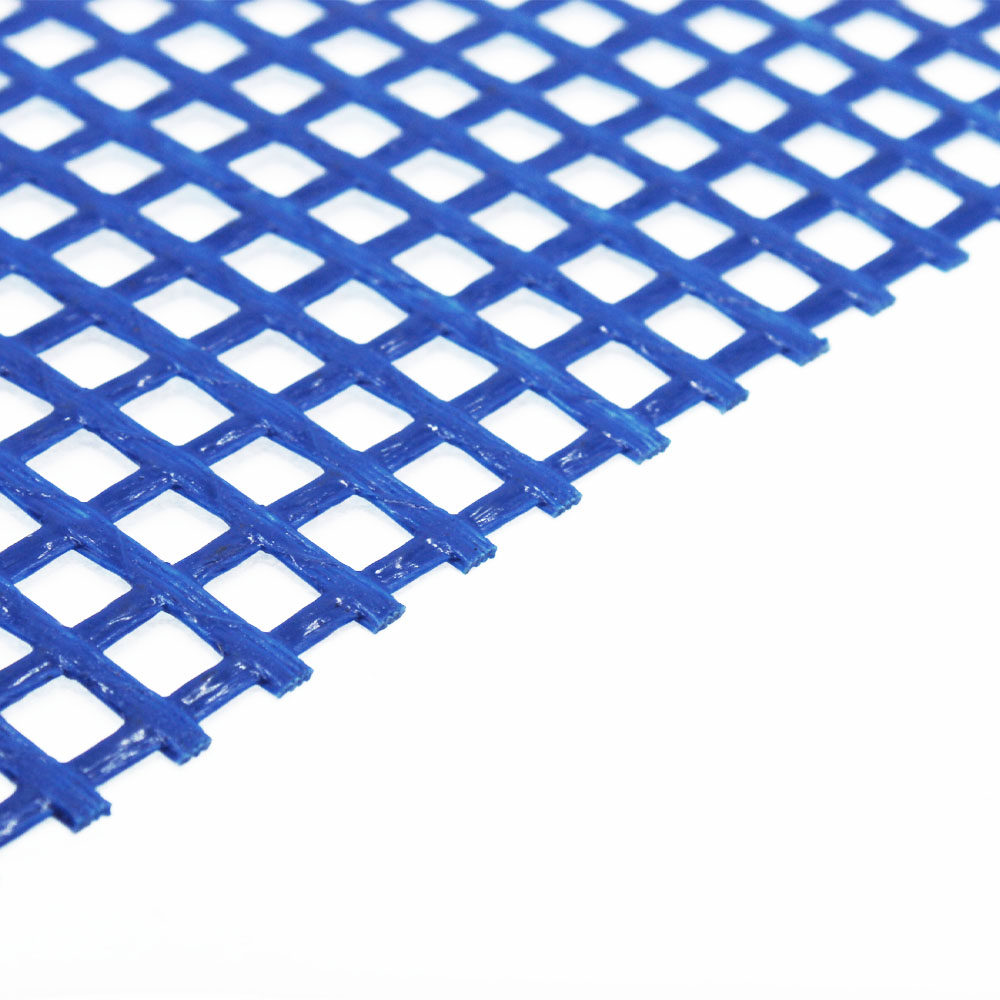

The materials used in lattice weave mesh can vary widely, depending on the intended application. Common materials include metals (such as steel, aluminium, and brass), plastics, natural fibres (such as bamboo or rattan), and even fabrics. The key feature of lattice weave mesh is the way the materials are arranged: they are interwoven in a manner that creates a series of evenly spaced openings. This results in a structured, often symmetrical, mesh.

The size of the openings in lattice mesh can also vary. In some cases, the gaps between the materials are large, creating an open, airy structure that allows for excellent ventilation and visibility. In other cases, the gaps are much smaller, resulting in a denser and more closed-off appearance.

The concept of latticework is ancient, dating back thousands of years. The Egyptians, for instance, used simple forms of latticework for everything from furniture to fencing. In Medieval Europe, lattice weave designs were seen in architecture, particularly in timber-framed houses where wood was interlaced to create walls, screens, and even windows.

Latticework also played an important role in Asian cultures. In Japan and China, intricate lattice designs were used for both practical and decorative purposes in gardens, architecture, and interior design. The natural aesthetic appeal of lattice weave, combined with its structural integrity, made it an ideal choice for everything from gates to room dividers.

In the 19th and 20th centuries, the Industrial Revolution saw the development of machinery that could mass-produce lattice mesh, particularly from metal and synthetic materials. This led to its widespread use in industries such as construction, manufacturing, and design.

Lattice weave mesh can be produced in several ways, depending on the materials being used and the desired outcome. Here are some of the common methods:

For smaller, bespoke projects, hand-weaving is still a popular technique. This method is particularly prevalent in artisan crafts, furniture making, and decorative art. The materials are manually interlaced, ensuring that the pattern is precisely followed. Hand-weaving allows for a high degree of customisation, enabling creators to adjust the size of the openings, the tightness of the weave, and the overall pattern to suit their specific needs.

Hand-weaving is commonly used with natural materials such as wood, bamboo, or rattan. The process is time-consuming but results in a high-quality, unique product.

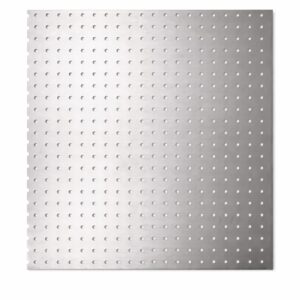

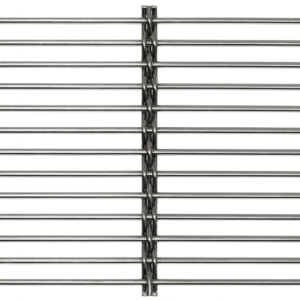

For larger-scale production, machine weaving is far more efficient. Machines are capable of weaving materials such as metal wires, plastics, and synthetic fibres into lattice weave meshes at a much faster rate. Machine weaving is used in industries where precision, uniformity, and strength are critical, such as in the manufacturing of metal mesh for construction or plastic mesh for industrial applications.

In machine weaving, the materials are fed through a loom-like device that interlaces them in a precise, predetermined pattern. The size of the openings and the tightness of the weave can be controlled by adjusting the settings on the machine.

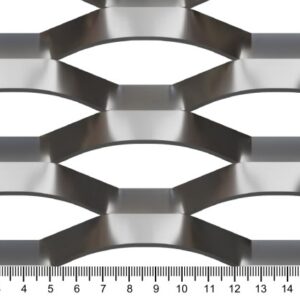

In some cases, particularly when working with metals, lattice mesh may be created by welding or soldering materials together. Instead of weaving the materials, they are arranged in a criss-cross pattern and then bonded at the points where they intersect. This creates a very strong, durable mesh that is often used in construction, fencing, and industrial applications.

The welding method is commonly used with metals such as steel, iron, and aluminium, and results in a rigid mesh that can withstand significant amounts of pressure and weight.

Lattice weave mesh is highly versatile and is used in a wide range of industries. Its applications can be grouped into three main categories: architectural, functional, and decorative.

In architecture, lattice weave mesh is used both for its structural integrity and its aesthetic appeal. Some common architectural applications include:

Fencing and Gates: Lattice weave mesh is often used in fencing and gate designs, providing a barrier that is both strong and visually appealing. The open nature of the mesh allows for airflow and light penetration, making it ideal for use in gardens, patios, and public spaces.

Façades and Cladding: In modern architecture, lattice weave mesh is sometimes used as cladding for buildings. This adds a textured, three-dimensional element to the exterior of the building while also offering practical benefits such as shading and ventilation.

Balustrades and Railings: Lattice mesh can be used in the construction of balustrades and railings, particularly in outdoor settings. The mesh provides safety without obstructing views. This makes it a popular choice for balconies, staircases, and decks.

Lattice weave mesh is also used in a variety of functional applications, particularly in industries such as construction, engineering, and manufacturing. Some of these applications include:

Reinforcement: In construction, lattice weave mesh made from steel or other metals is often used as reinforcement in concrete structures. The mesh helps to distribute weight evenly and adds strength to the overall structure, making it more resistant to cracking and other forms of damage.

Filtration: Lattice weave mesh is used in filtration systems where its evenly spaced openings allow for the passage of certain materials while blocking others. This can be seen in industrial filtration systems, as well as in domestic settings such as window screens and kitchen sieves.

Protective Barriers: Lattice weave mesh is often used as a protective barrier in both industrial and domestic settings. It can be found in machinery guards, safety fencing, and protective screens, where its strength and durability offer protection without completely obstructing visibility.

Lattice weave mesh has long been valued for its decorative potential, with its geometric patterns and intricate designs adding an elegant touch to a variety of settings. Some decorative applications of lattice weave mesh include:

Interior Design: Lattice mesh is often used in interior design to create room dividers, wall panels, and even ceiling treatments. Its open design allows for light and air to flow freely, while still providing a sense of separation and structure.

Furniture: Lattice weave mesh can be found in many types of furniture, particularly in outdoor or garden furniture. The mesh is often used for chair backs, tabletops, and storage units, where its airy design complements the overall aesthetic of the piece.

Art Installations: Lattice weave mesh is sometimes used in art installations, where its combination of form and function creates striking visual effects. Artists may use metal or fabric lattice mesh to create sculptures, light fixtures, or even entire installations that play with light, shadow, and transparency.

There are several reasons why lattice mesh has become such a popular choice in various industries:

Lattice mesh, particularly when made from metal or other strong materials, offers excellent strength and durability. This makes it suitable for use in a wide range of applications, from construction to safety barriers, where reliability is key.

Lattice weave mesh is prized for its aesthetic qualities. The repeating geometric patterns, combined with the natural beauty of the materials used, make it an attractive choice for both interior and exterior design. Whether used in a modern building façade or as part of a traditional garden fence, lattice weave mesh adds a touch of elegance and sophistication.

One of the biggest advantages of lattice weave mesh is its versatility. It can be made from a wide range of materials, in different sizes and patterns, to suit virtually any application. This versatility makes it a valuable resource in industries as diverse as architecture, manufacturing, and interior design.

The open nature of lattice weave mesh allows for excellent ventilation and light penetration, making it ideal for use in applications where airflow and visibility are important. For example, lattice mesh is often used in outdoor fencing, window screens, and building facades to allow for natural light and air to pass through while still providing protection and privacy.

Lattice mesh can also be a sustainable choice, particularly when made from renewable materials such as bamboo or recycled metals. The open structure of the mesh requires less material to create, reducing overall resource consumption, and the durability of the product means it has a longer lifespan, further reducing waste.

Lattice weave mesh is a versatile and time-tested material, used for centuries in a wide range of applications. Its blend of strength, durability, and aesthetic charm makes it a go-to option for everything from construction and architecture to interior design and artistic installations.

Whether you’re seeking to reinforce a concrete structure, craft an elegant room divider, or design a chic garden fence, lattice weave mesh offers a practical and visually appealing solution. With advancements in technology, the possibilities for its innovative use are expanding. This ensures that ancient technique continues to play a significant role in modern design and engineering.

By learning more about lattice weave mesh, how it’s made, and its various applications, you’ll be ready to leverage its many advantages for your projects. Whether you’re an architect, designer, or simply looking to elevate your home or garden, lattice weave mesh is a material well worth exploring.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may also be interested in our blog that explores plastic lattice mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.