If you are looking for a versatile product with many uses in industrial and commercial applications, look no further than mild steel woven wire mesh. This material is incredibly strong and can be used for anything from simple projects to complex safety barriers.

Here’s an overview of why mild steel woven wire mesh is the ideal choice for so many applications.

But first let’s discuss how it is produced….

Our group has been weaving since the days of Queen Victoria. The process has changed somewhat over the years. But the basics are the same.

Here are the general steps involved in making plain steel woven wire mesh:

Wire drawing: The first step is to draw the plain steel wire into the desired thickness, typically ranging from 0.5 mm to 5 mm.

Wire processing: The drawn wire is then processed by heat treatment and surface treatment to increase its strength, durability, and corrosion resistance.

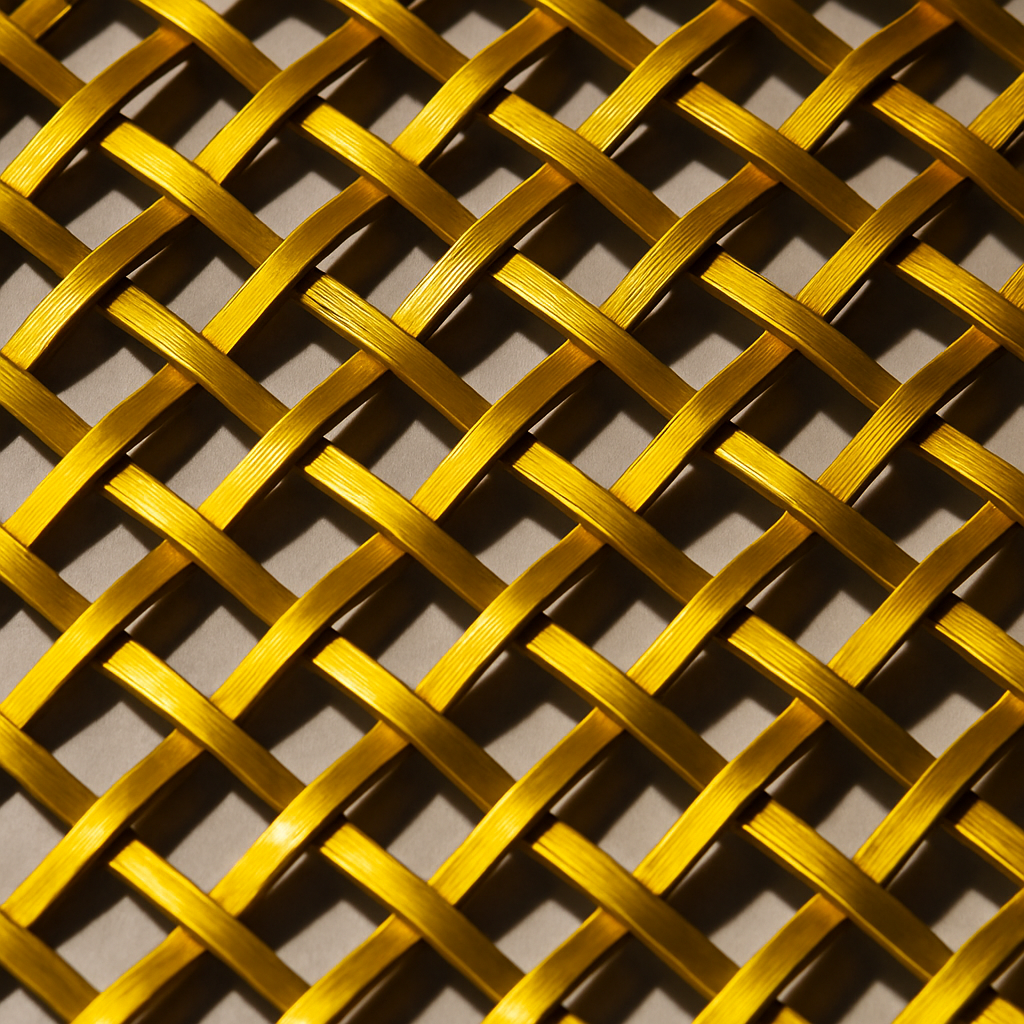

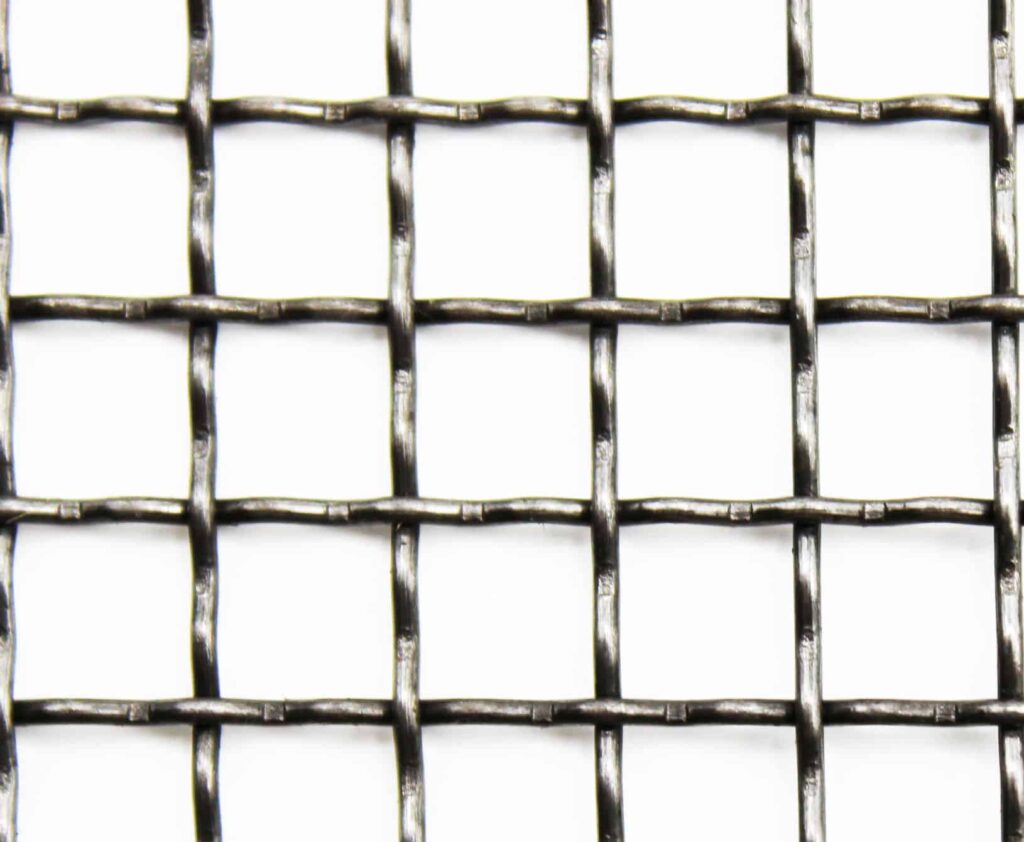

Weaving: The processed wires are then woven together on a loom in an interlocking pattern. The loom is typically set up to create a specific mesh size and wire diameter combination.

Cutting and finishing: Once the wire mesh sheet is woven, it is cut to the desired size and shape using cutting tools such as wire cutters or shears. The edges of the mesh are then finished to remove any sharp or rough edges.

Quality control: The finished plain steel woven wire mesh is inspected for quality to ensure that it meets the specified standards for mesh size, wire diameter, and aperture size.

Mild steel woven wire mesh can be used in a number of different ways, making it incredibly versatile. It can be used as security fences, safety barriers, sieves, filtration systems, ventilation ducts, guards against sparks or splashes of hot liquids, reinforcement structures – the possibilities are endless.

These are the main reasons we find our customers use plain steel rather than galvanised, or stainless:

Cost-effective: Plain uncoated steel mesh is relatively low-cost compared to other types of metal mesh, making it an ideal choice for large-scale projects or applications where cost-effectiveness is a priority.

Strength and durability: Plain uncoated steel mesh is strong and durable, making it suitable for various industrial and commercial applications where high strength is required. It can withstand exposure to harsh environmental conditions and can resist damage from heavy loads or impact.

Resistance to high temperatures: Plain uncoated steel mesh has a high melting point and can withstand exposure to high temperatures, making it suitable for use in high-temperature applications such as furnaces, ovens, and industrial processing.

Corrosion resistance: While plain uncoated steel mesh is not inherently corrosion-resistant, it can be treated with a rust inhibitor or protective coating to enhance its resistance to corrosion and extend its lifespan.

Easy to work with: Plain uncoated steel mesh is easy to cut, shape, and weld, making it easy to work with and suitable for a wide range of applications.

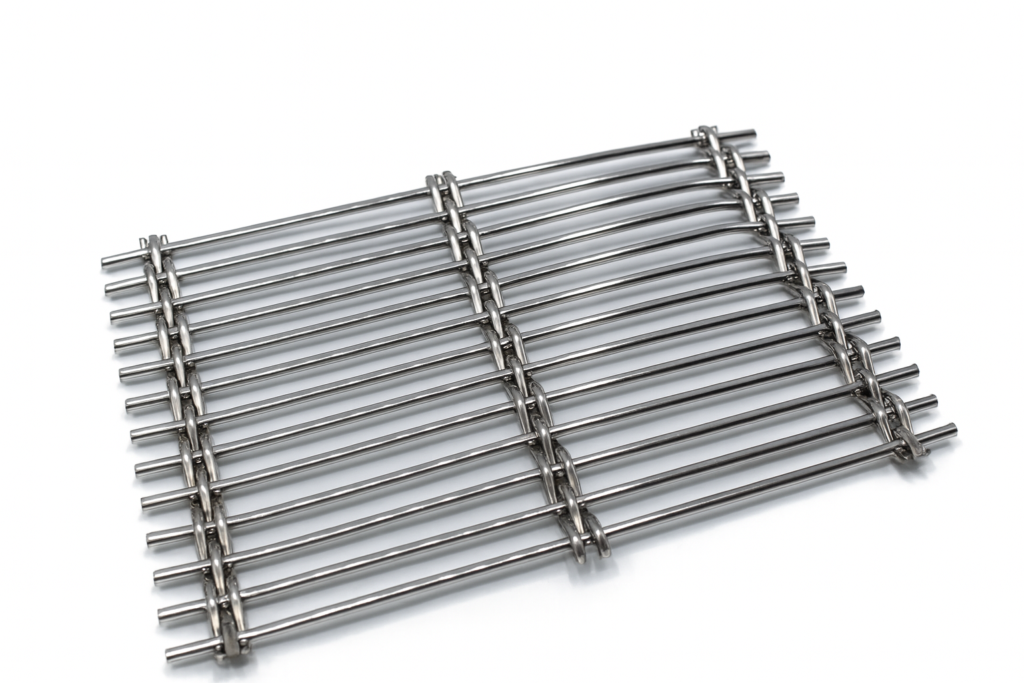

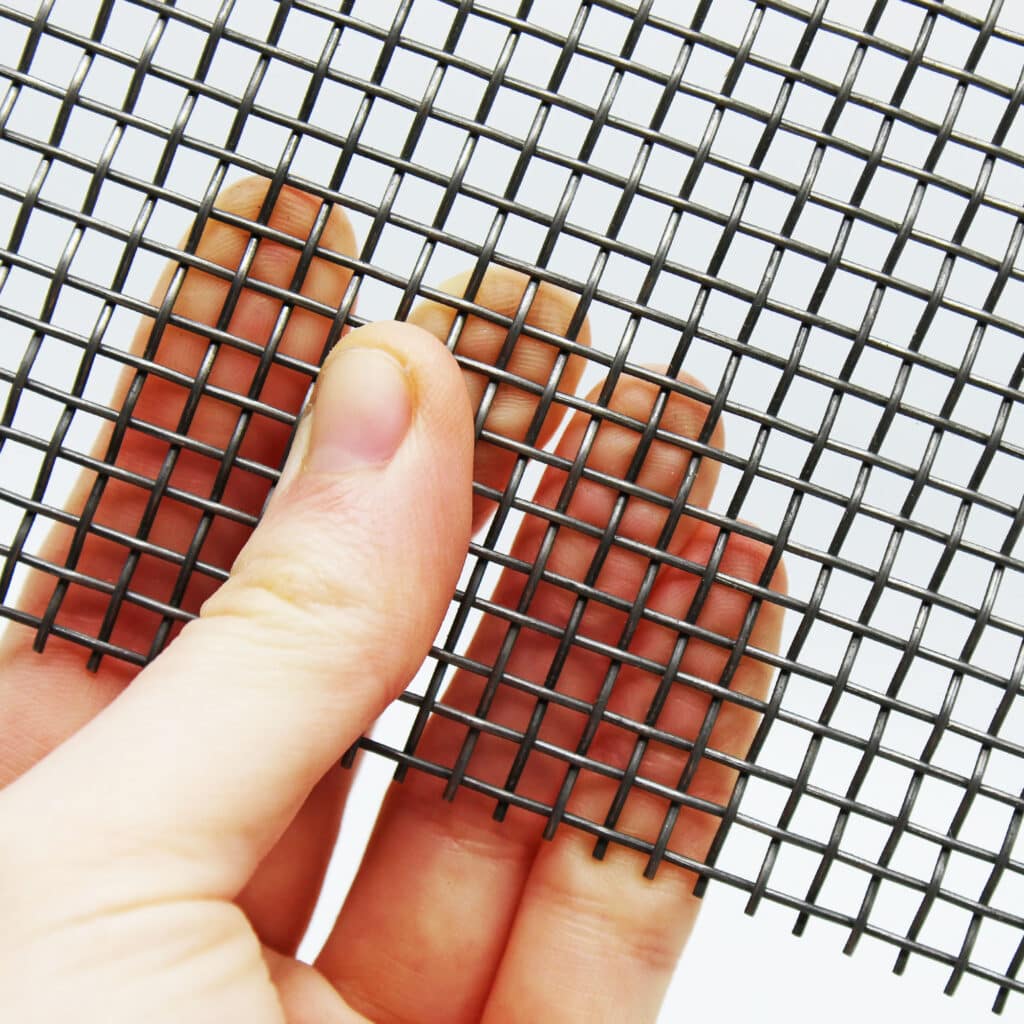

Woven wire mesh: Woven wire mesh is made from weaving mild steel wires together to create a pattern. It is available in different mesh sizes, wire diameters, and aperture sizes to suit different applications, from filtration to decorative purposes.

Welded wire mesh: Welded wire mesh is made from welding mild steel wires together to create a grid pattern. It is available in different wire thicknesses, mesh sizes, and aperture sizes to suit different applications, such as fencing, construction, and agriculture.

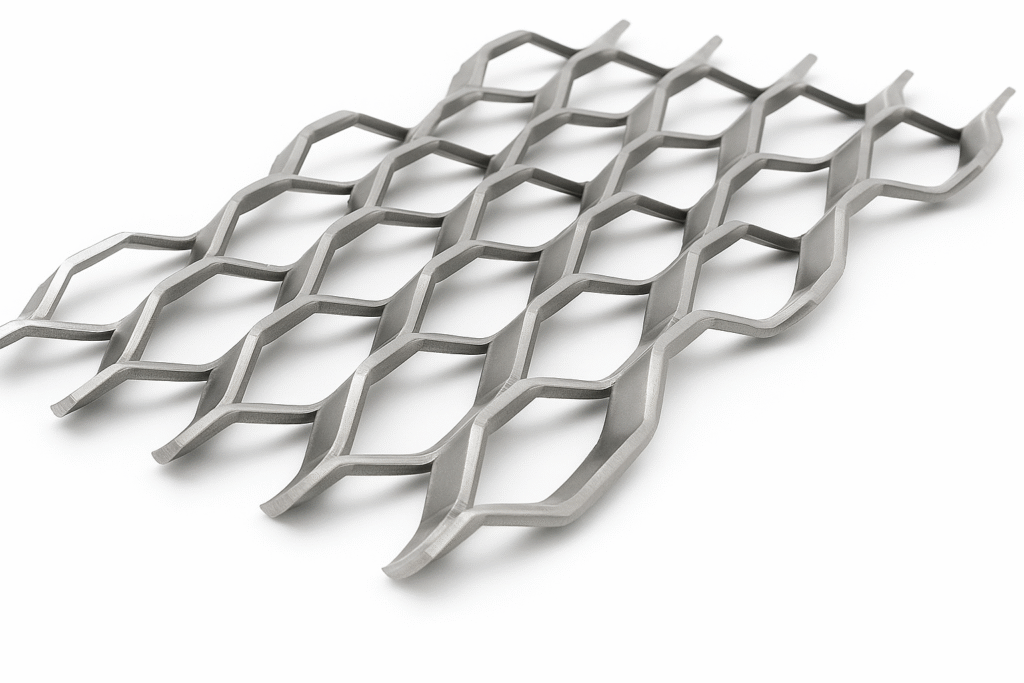

Expanded metal mesh: Expanded metal mesh is made from cutting and stretching a flat sheet of mild steel to create diamond-shaped openings. It is available in different sizes and thicknesses to suit different applications, such as safety and security, filtration, and industrial uses.

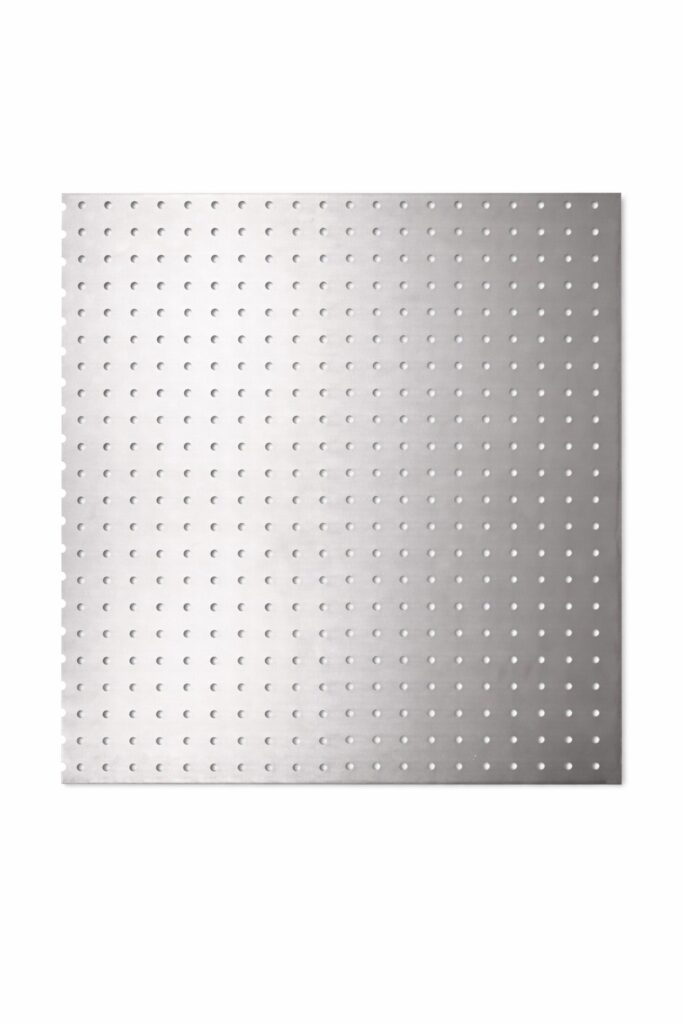

Perforated metal mesh: Perforated metal mesh is made from punching holes into a flat sheet of mild steel to create a pattern. It is available in both round and square hole options.

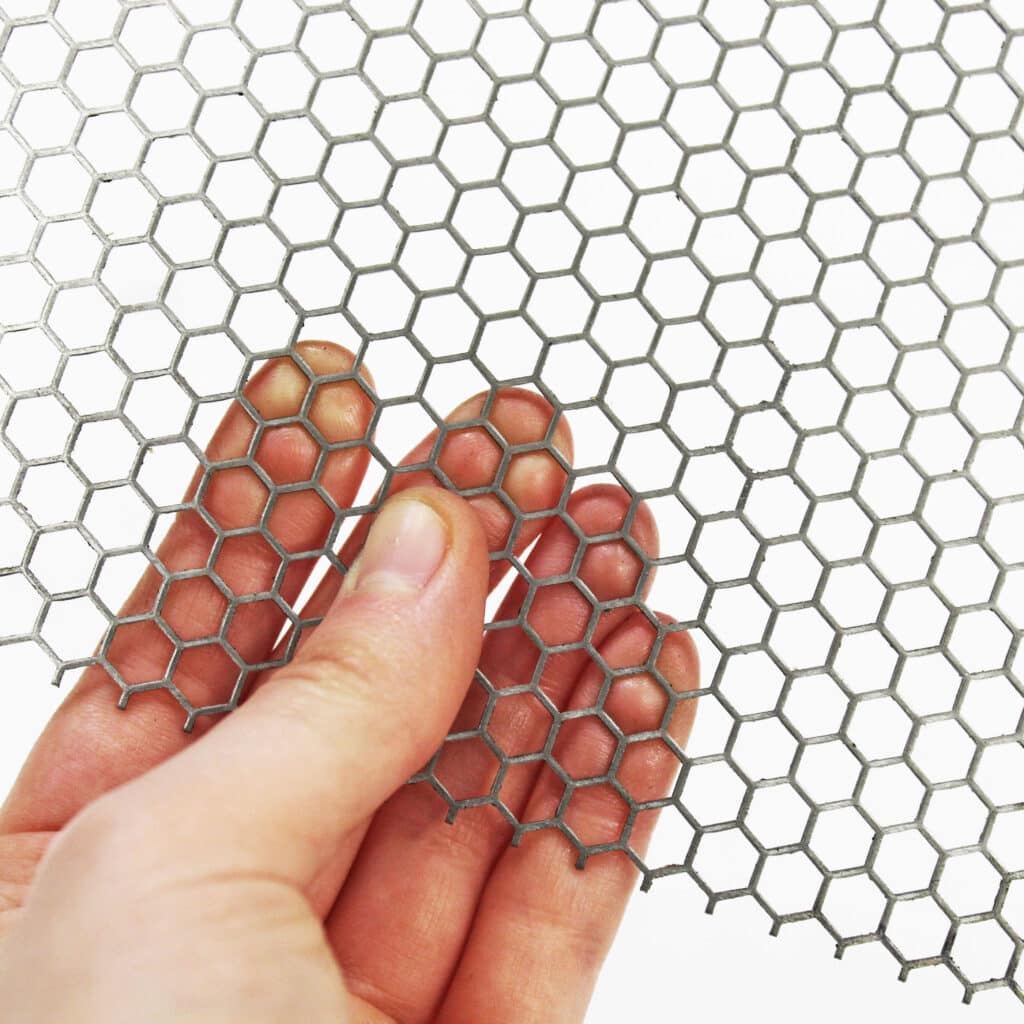

Hexagonal metal mesh: Hexagonal perforated metal is a type of perforated metal mesh that is designed with hexagonal-shaped holes punched into a flat sheet of metal. The hexagonal holes can be arranged in a regular or staggered pattern, depending on the desired look and function.

Overall, mild steel woven wire mesh is an excellent choice if you are looking for a strong and durable material with many versatile uses in both industrial and commercial settings.

It’s customisable nature means that you can find exactly what you need without having to settle for generic products from other suppliers – making it the perfect solution for any project! Whether you need something simple like security fences or something more complex like filtration systems – mild steel woven wire mesh has got you covered!

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.