At The Mesh Company, we’re often asked about mesh products that sit outside traditional woven or welded steel. Tension fabric mesh is one of those products that can look unfamiliar at first, but makes complete sense once you understand what it’s designed to do.

The PVC-coated tension fabric mesh made from galvanised tempered steel wire and polyester yarn is a good example. It isn’t trying to behave like rigid steel mesh, and it isn’t a decorative textile either. Instead, it sits somewhere in between, offering strength, airflow, and visual screening in applications where weight and substructure limitations rule out heavier steel solutions.

This guide explains what it is, how it works, and where it’s best used.

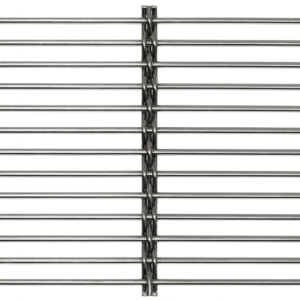

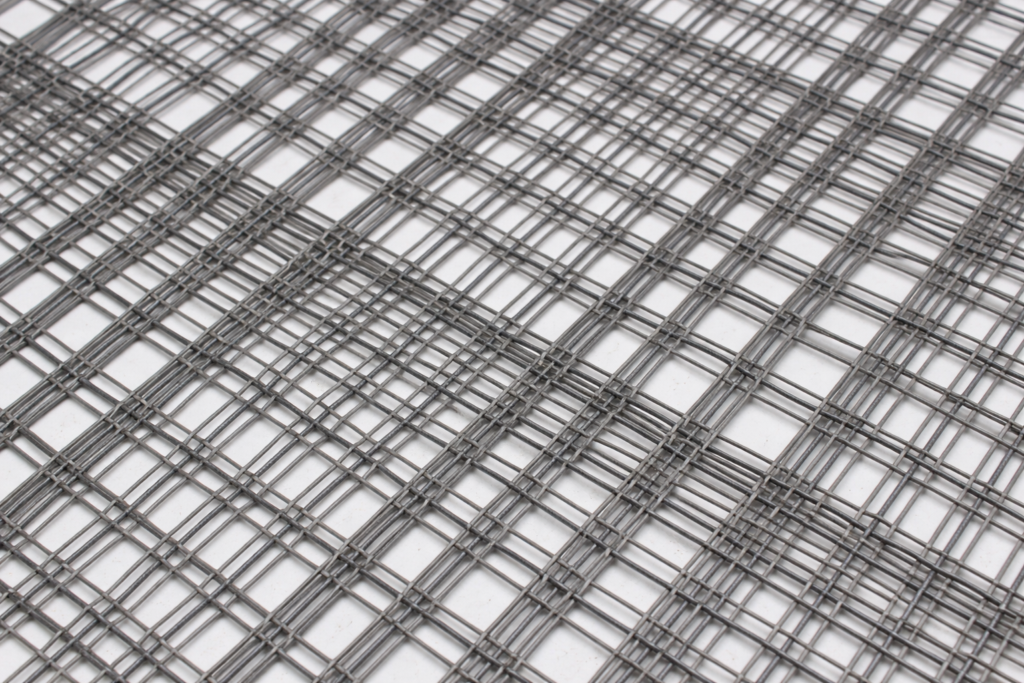

In simple terms, this product is a composite mesh made up of three key elements:

Galvanised tempered steel wire

Polyester (polypropylene) yarn

A protective PVC coating

These components are combined into a flexible net-like structure, rather than a rigid panel. The result is a mesh that only performs properly when installed under tension.

Each element plays a specific role. The galvanised steel wire provides cut resistance and long-term strength, while the polyester yarn keeps the mesh lightweight and contributes tensile performance. The PVC coating protects the entire structure from weathering, corrosion, and UV exposure, while also giving the mesh a consistent colour and finish.

Although the construction may sound complex, the intention is simple: to deliver strength and durability without the weight or rigidity of solid steel mesh.

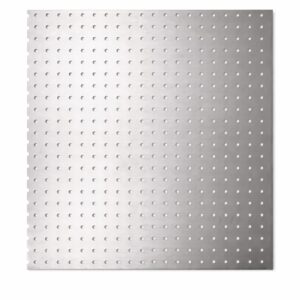

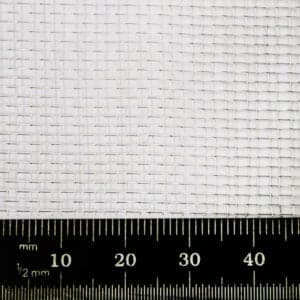

One of the defining characteristics of this tension fabric mesh is its high open area, typically around 50–55%. This means roughly half of the surface area allows air to pass through.

In practical terms, this makes it particularly effective for ventilation. When used on building facades, plant enclosures, or screening panels, it allows a significant amount of airflow without leaving spaces completely open.

Visual screening depends heavily on contrast. When the mesh is supplied in a light colour and installed in front of darker backgrounds, it provides a noticeable visual barrier. If the colour contrast is reversed, the mesh becomes less visually dominant. This is why colour choice and surrounding materials should always be considered at the design stage.

At approximately 0.55 kg per square metre, this mesh is far lighter than traditional steel alternatives. That low weight is one of its biggest advantages.

Because it doesn’t require a heavy supporting structure, it can be used to create large-area panels with minimal fixing. This makes it particularly suitable for facades and lightweight architectural applications where the substructure cannot support the weight of rigid steel mesh or perforated sheet.

In real-world use, this also makes handling and installation easier, especially on large projects where panel size and access are limiting factors.

Although it is flexible, this mesh is not fragile. The tempered steel wires provide resistance to cutting and casual vandalism, while the polyester yarn contributes tensile strength and impact resistance.

It can be cut with appropriate cutters when required for installation, but it is not easily damaged through everyday contact. What it does not offer is noise reduction; this is a ventilated screening product, not an acoustic solution.

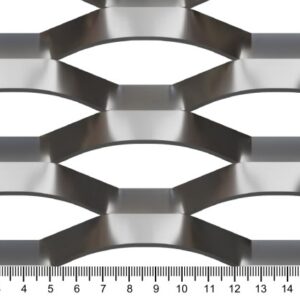

Because there is no inherent rigidity, the mesh must be installed under tension to perform correctly. Unlike rigid meshes that rely on frames, this product requires a defined edge detail that allows it to be tensioned evenly across the opening.

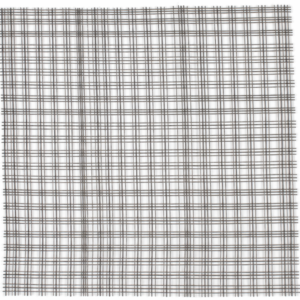

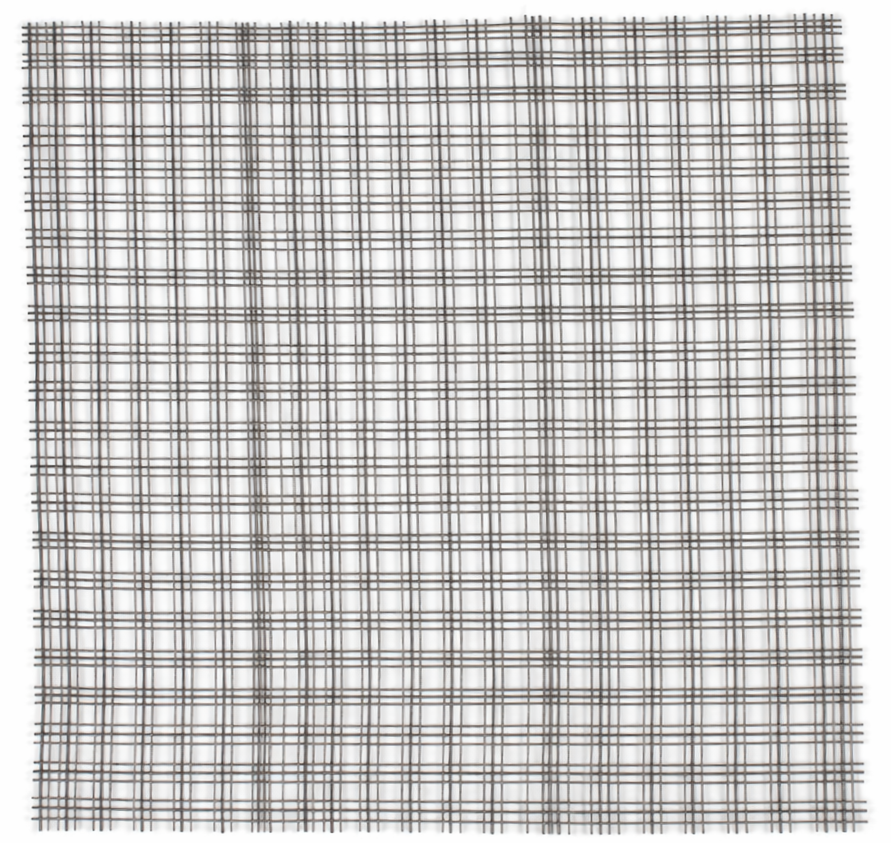

Rather than being defined by hole size or wire count, this mesh uses a repeating pattern layout. The pattern repeats across the surface and becomes more apparent over larger areas, rather than at close range.

This is one reason it isn’t specified in the same way as traditional mesh products. It is better thought of as a continuous surface, rather than a grid of defined apertures.

Care needs to be taken during installation to ensure patterns align across adjacent panels. Misalignment can be visually obvious, particularly on large facade installations.

This PVC-coated tension fabric mesh is designed for long-term outdoor use. The PVC coating protects the internal structure from corrosion, UV exposure, rain, and temperature fluctuations.

In typical environments, it is supplied with a 10-year guarantee and an expected service life of around 20 years. It performs well in exposed conditions, including coastal environments, provided it is installed and maintained correctly.

Because the mesh only works under tension, fixing details are critical. Common methods include clamping systems or the use of a cabled or keder-type edge that allows the mesh to be tensioned evenly.

The lightweight nature of the material allows for larger spans and reduced structural demands, but it also means accuracy during installation matters. Poor alignment or uneven tensioning can affect both appearance and performance.

Maintenance is relatively straightforward but should not be ignored. Periodic retensioning every three to four years is recommended, particularly on larger installations or in exposed environments.

Cleaning is typically limited to jet washing to remove surface contaminants. The exact maintenance schedule will depend on location, exposure, and environmental conditions.

This tension fabric mesh is best suited to applications such as ventilated facades, architectural screening, ceilings, and lightweight enclosures. It is commonly specified where airflow and weight reduction are critical, and where the supporting structure cannot accommodate heavy steel.

It is not suitable for high-traffic or high-wear areas, and it should not be used where rigidity, load-bearing performance, or abrasion resistance are required. Understanding this distinction is key to specifying it successfully.

PVC-coated tension fabric mesh offers a genuinely different approach to screening and facade design. It trades rigidity for flexibility, weight for span, and heavy structure for tensioned performance.

Used for the right reasons, it provides a durable, ventilated, and visually controlled solution that sits comfortably between traditional metal mesh and lightweight fabric systems.

Naomi O’Toole – Development Manager