We value your privacy

We use cookies to enhance your browsing experience, serve personalised ads or content, and analyse our traffic. By clicking "Accept All", you consent to our use of cookies. Cookie Policy

We use cookies to help you navigate efficiently and perform certain functions. You will find detailed information about all cookies under each consent category below.

The cookies that are categorised as "Necessary" are stored on your browser as they are essential for enabling the basic functionalities of the site....

Necessary cookies are required to enable the basic features of this site, such as providing secure log-in or adjusting your consent preferences. These cookies do not store any personally identifiable data.

This cookie stores your consent preferences for cookies on this website.

Functional cookies help perform certain functionalities like sharing the content of the website on social media platforms, collecting feedback, and other third-party features.

No cookies to display.

Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics such as the number of visitors, bounce rate, traffic source, etc.

No cookies to display.

Performance cookies are used to understand and analyse the key performance indexes of the website which helps in delivering a better user experience for the visitors.

This cookie is used by Google Analytics and distinguishes unique visitors on the website.

This cookie is used by Google Analytics to track visitor activities on the website.

This cookie is used by Google Analytics and stores a unique value for each page visited and tracks page views.

This cookie is used by Google Analytics and tracks a visitors session.

Advertisement cookies are used to provide visitors with customised advertisements based on the pages you visited previously and to analyse the effectiveness of the ad campaigns.

This cookie is used by Doubleclick and contains information about a visitor's past visit to other websites that have advertisements from Doubleclick.

This cookie is used by Google AdSense for experimenting with efficiency across websites that use Google Ads.

This cookie is used by DoubleClick to check if a visitor's browser supports cookies.

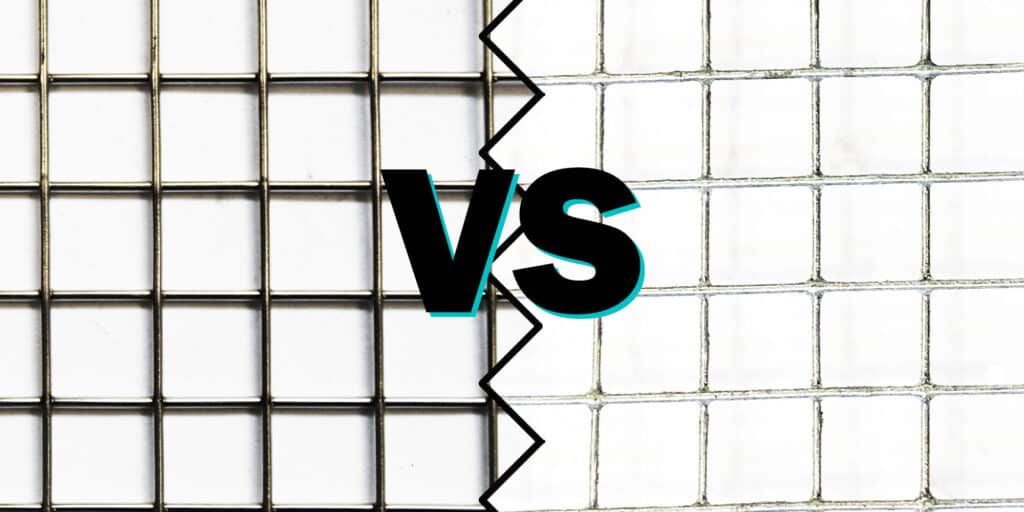

When it comes to selecting the right material for welded wire mesh, the decision can significantly impact the functionality, durability, and cost-effectiveness of your project.

Welded wire mesh, a versatile and widely used material, plays a crucial role in various applications ranging from industrial fencing and enclosures to decorative uses.

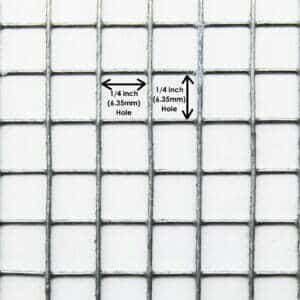

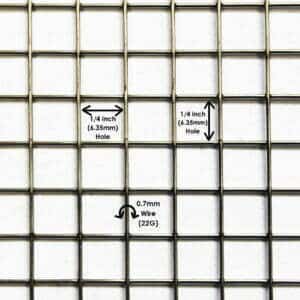

Among the myriad choices, stainless steel and galvanised steel are the most popular options, especially in the common 1/4″ size.

Both materials bring distinct properties to the table, influencing their suitability for different environments and uses.

Stainless steel, renowned for its sleek appearance and resistance to rust, offers a high-end solution for applications where both aesthetics and longevity are key.

Its natural corrosion resistance makes it a favored choice in environments prone to moisture or where a clean, professional look is desired. On the other hand, galvanised steel, known for its robustness and cost-effectiveness, is often chosen for outdoor and industrial applications where durability against physical impacts is a priority.

This article aims to provide a thorough comparative analysis of these two materials. We will delve into their inherent properties, such as strength, flexibility, and corrosion resistance, and evaluate their performance under various environmental conditions. By comparing their suitability in different applications, maintenance needs, and cost implications, we aim to conclude which material generally holds the upper hand in each aspect.

Whether you are an architect, a contractor, or a DIY enthusiast, understanding the nuances of these materials will empower you to make an informed decision for your specific welded wire mesh needs.

Let’s get into it…

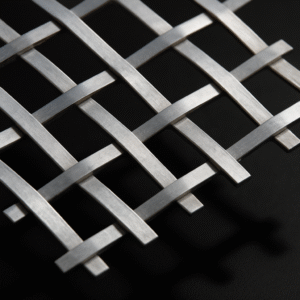

Although stainless steel and galvanised steel are both iron-based alloys, their performance in welded wire mesh applications differs. In addition to its excellent strength and flexibility, stainless steel is primarily composed of iron, chromium, and nickel. Chromium, at least 10.5%, gives stainless steel its hallmark feature – resistance to corrosion and rust. Featuring a unique combination of toughness and malleability, this alloy is suitable for both structural and decorative uses.

In contrast, galvanised steel is essentially carbon steel that has been coated with zinc. Zinc coatings give galvanised steel its corrosion resistance. Despite the steel’s high tensile strength, the zinc coating can wear away over time, especially under harsh conditions, potentially exposing the steel to rust. For applications requiring higher structural strength and lower corrosion risk, galvanised steel is often preferred.

Due to its ability to withstand bending and shaping without compromising its structural integrity, stainless steel often has an edge when it comes to flexibility. It is therefore a better choice for intricate designs or applications that require curved or molded mesh.

In terms of overall material performance for welded wire mesh, stainless steel emerges as the clear winner. Due to its superior corrosion resistance, excellent strength and flexibility, it is an excellent choice for a wide range of applications.

Result: Stainless Wins

Galvanised Steel

Stainless Steel

Choosing the right material for welded wire mesh is critical, especially in environments exposed to moisture, chemicals, or saline conditions. As a result of its high chromium content, stainless steel naturally forms a protective oxide layer that protects it from rust and corrosion. Because of its intrinsic resistance, it is ideal for applications in corrosive environments such as coastal areas, chemical plants, and food processing facilities. The ability to maintain integrity and appearance over time without additional coatings or treatments is a significant advantage.

Galvanised steel, though initially robust against corrosion due to its zinc coating, can become vulnerable over time. As the zinc layer wears or becomes damaged, the underlying steel becomes exposed to the elements. In environments with high salinity or frequent abrasion or impact, this is especially noticeable. However, for applications in less corrosive environments or where the mesh is not directly exposed to harsh elements, galvanised steel can be a cost-effective and durable option.

In terms of environmental resilience, stainless steel is the clear winner. Due to its unparalleled corrosion resistance, it is a more reliable choice for projects that require long-term durability and low maintenance. While galvanised steel is suitable in certain contexts, its susceptibility to corrosion under certain conditions limits its universal application.

Result: Stainless Wins

Galvanised Steel

Stainless Steel

Stainless steel and galvanised steel both have specific domains where 1/4″ welded wire mesh excels. Stainless steel welded wire mesh is highly sought after in scenarios where both strength and appearance are crucial. It includes architectural applications like facade cladding, decorative partitions, and certain types of fencing, particularly in urban or coastal areas. As a result of its inherent strength and aesthetic appeal, it is also a preferred material for creating animal enclosures in zoos, luxury pet habitats, and high-end retail displays.

On the other hand, galvanised steel finds extensive use in industrial and functional applications. Due to its robust nature and cost-effectiveness, it is widely used in agricultural settings for livestock fencing and in industrial settings for machine guards, security fencing, and other applications exposed to harsh conditions. It may not have the aesthetic appeal of stainless steel, but its strength and functionality make it ideal for heavy-duty, utilitarian applications.

The versatility of stainless steel’s applications makes it a clear winner. Durability, corrosion resistance, and aesthetic appeal make it suitable for a wide range of applications, from decorative to functional. For purely functional uses, galvanised steel is undoubtedly strong and cost-effective, but its limitations in aesthetic and corrosion-sensitive applications limit its use.

Result: Stainless Wins

For architectural and decorative applications, aesthetics play a significant role in material selection. Modern, sleek stainless steel welded wire mesh boasts a naturally shiny finish that appeals to contemporary design sensibilities. As a result, it maintains its appearance over time, resisting rust and discoloration. With its enduring aesthetic quality, it is ideal for visible applications in architecture, interior design, and high-end retail displays.

Although galvanised steel is practical and strong, it lacks aesthetic versatility. A new galvanised steel can appear bright and shiny initially, but over time it may dull and develop a patina from the zinc coating, especially if the coating begins to wear or corrode. Applications where the visual aspect is as important as functionality may find this aspect less desirable.

Stainless steel again leads the way in terms of design flexibility. Its ability to be easily fabricated into various shapes and designs without losing its aesthetic quality or structural integrity makes it an excellent choice for creative and intricate designs. Despite its ability to be shaped and molded, galvanised steel lacks the same level of finesse and elegance as stainless steel.

In terms of aesthetic value and design flexibility, stainless steel welded wire mesh is the best choice. Its combination of enduring beauty and adaptability to various design requirements makes it more suitable for projects that place a high priority on appearance.

Result: Stainless Wins

Welded wire mesh must be durable and long-lasting, especially when exposed to environmental elements and physical stress. As a result of its corrosion resistance and strength, stainless steel often has a longer lifespan than galvanised steel. Chromium forms a protective layer on stainless steel’s surface, preventing rust and corrosion, which is essential for outdoor or moist environments. Due to its inherent resistance to environmental factors, stainless steel mesh is less likely to degrade over time, reducing the need for replacement or repair.

While galvanised steel is initially robust, it can wear and tear over time, particularly if the zinc coating is damaged. Rust can significantly reduce the lifespan of steel once the underlying steel is exposed. Galvanised steel may need to be replaced or maintained sooner if it is exposed to harsh environments.

In terms of lasting durability, stainless steel is clearly the winner. Due to its ability to withstand diverse conditions without deteriorating, welded wire mesh is a reliable and long-term solution.

Result: Stainless Wins

In order to ensure the longevity of any material, maintenance is crucial. Due to its corrosion-resistant properties, stainless steel welded wire mesh requires relatively little maintenance. For maintaining its appearance and integrity, mild soap and water are usually sufficient. Neither indoors nor outdoors, it does not require additional treatments or coatings to prevent rust.

In contrast, galvanised steel may require more attention over time, especially in environments prone to corrosion. A rust inhibitor or re-coating may be necessary if the zinc coating is compromised. It is essential to regularly inspect the coating for signs of rusting or damage.

Stainless steel is the most maintenance-friendly and easy-to-care-for material. Because it requires less maintenance, it becomes a more convenient and cost-effective option over time, especially when compared to galvanised steel.

Result: Stainless Wins

Both the initial cost and the long-term expenses associated with maintenance and replacement must be taken into account when evaluating cost-effectiveness. Galvanised steel typically has a lower upfront cost compared to stainless steel. In large-scale or budget-sensitive projects, this can be an attractive feature. The initial savings may, however, be offset by higher maintenance costs and an earlier replacement due to wear.

Stainless steel offers greater longevity and requires less maintenance, despite being more expensive at first. Reducing the need for repair or replacement can result in long-term cost savings. In addition, stainless steel can add value to a project through its consistent aesthetic appeal and structural integrity.

In terms of both initial cost and long-term investment, stainless steel presents a better value. As a result of its durability and minimal maintenance requirements, it is a more cost-effective option for long-term projects.

Result: Stainless Wins

Several key points emerge from this comprehensive comparison of stainless steel and galvanised steel for 1/4″ welded wire mesh.

In terms of material properties, environmental resilience, aesthetic value, longevity, maintenance, and overall cost-effectiveness, stainless steel is superior to galvanised steel. Corrosion resistance, durability, and low maintenance requirements make it a reliable choice for a wide range of applications. In addition, its aesthetic appeal and design flexibility add value to visible or decorative projects.

It is true that galvanised steel is initially more cost-effective and robust, but it falls short when it comes to longevity and maintenance, particularly in harsh environments. Corrosion susceptibility and the need for more frequent maintenance reduce its long-term cost-effectiveness.

Considering all the factors evaluated, stainless steel generally appears to be a better choice for 1/4″ welded wire mesh, despite both materials having their merits. In addition to its strength, durability, and aesthetic appeal, it is an extremely versatile and cost-effective material. We urge readers to weigh these insights against their specific needs and choose the material that best aligns with their project requirements and long-term goals.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores 13mm galvanised welded mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions