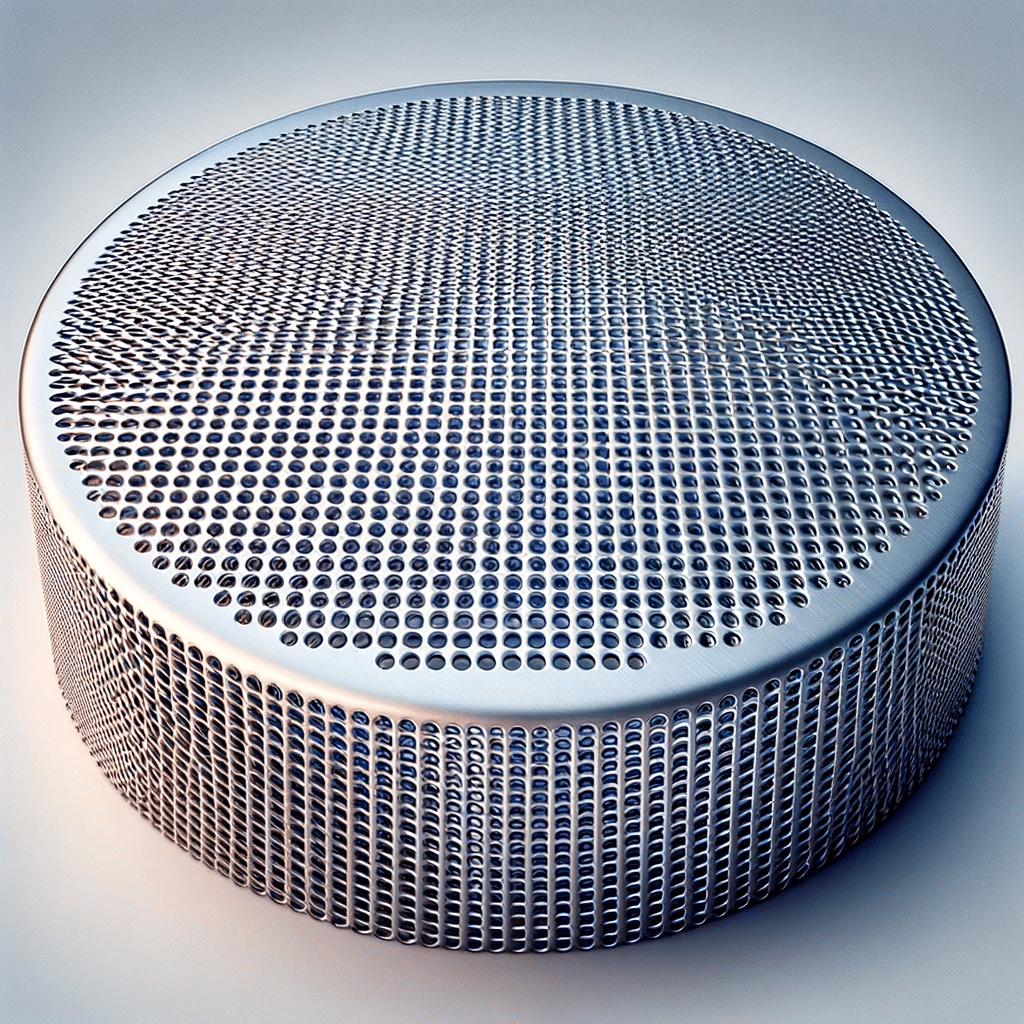

Stainless steel perforated metal mesh is a material that beautifully marries functionality with aesthetic appeal, making it an ideal choice for ventilator grilles.

The versatility of this product lies in its ability to provide effective ventilation while simultaneously enhancing an area’s visual appeal.

Besides industrial settings, this mesh is also used in residential and commercial buildings for practical and aesthetically pleasing solutions.

Its inherent properties make it suitable for a wide range of applications – it is robust, resistant to environmental factors, and can be customized.

This article will delve into the multifaceted role of stainless steel perforated metal mesh in ventilation systems, underscoring its importance and versatility.

Let’s get into it…

Stainless steel is widely used in ventilation, especially for ventilator grilles. Due to its strength and resilience, it is an excellent material for withstanding environmental stresses while maintaining its integrity and appearance.

With stainless steel’s corrosion resistance, ventilator grilles remain effective and visually appealing for years to come, even when exposed to moisture or chemicals.

Furthermore, stainless steel complements a wide range of architectural styles, making it a popular choice for buildings that value aesthetics as well as functionality. The following section explores these properties in detail, highlighting why stainless steel is a preferred material for ventilator grilles.

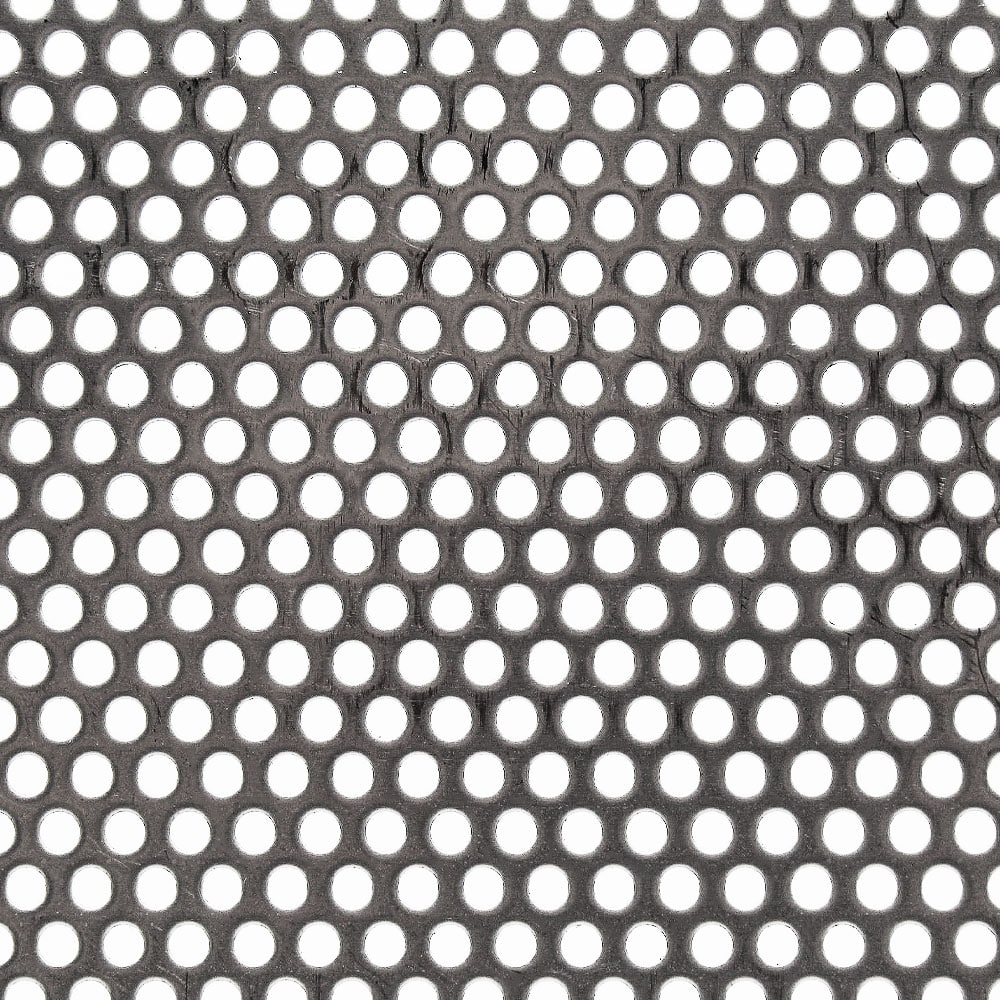

A ventilation system’s airflow and efficiency are significantly affected by the size of the holes in the perforated metal mesh.

A smaller hole can offer greater material strength and be ideal for spaces requiring subtle ventilation, while a larger hole provides greater air passage, which is essential for spaces requiring significant airflow.

Choosing the right hole size affects not only the functional aspect of ventilation, but also the acoustic properties and the overall appearance of the grille.

In the section below we will outline a selection of some of our most popular stainless steel perforated metal options.

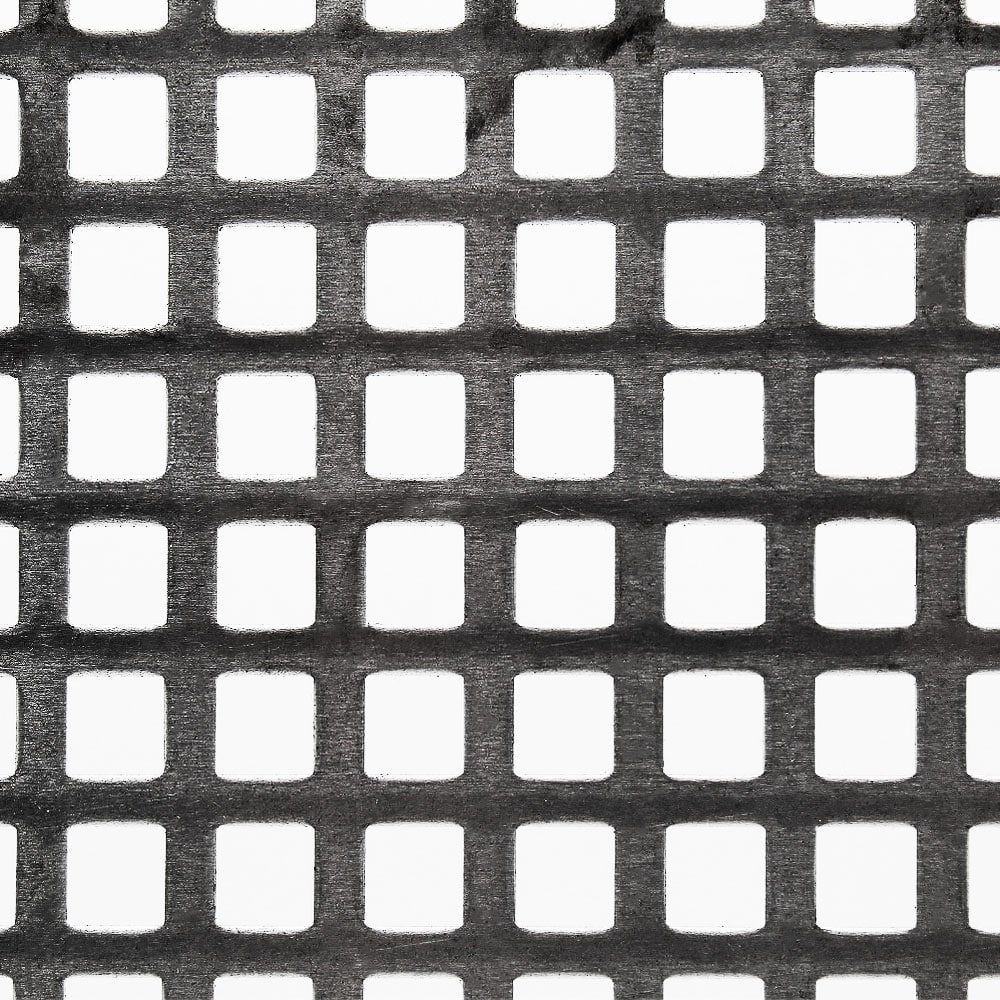

The choice between round, square, slotted, or other geometric shapes isn’t merely a matter of visual preference but has tangible effects on the grille’s performance and overall design impact.

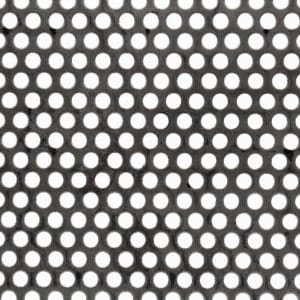

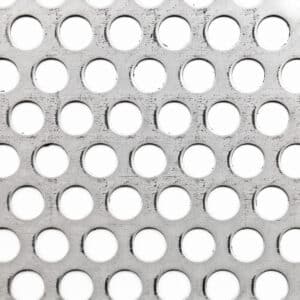

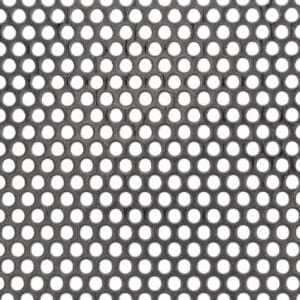

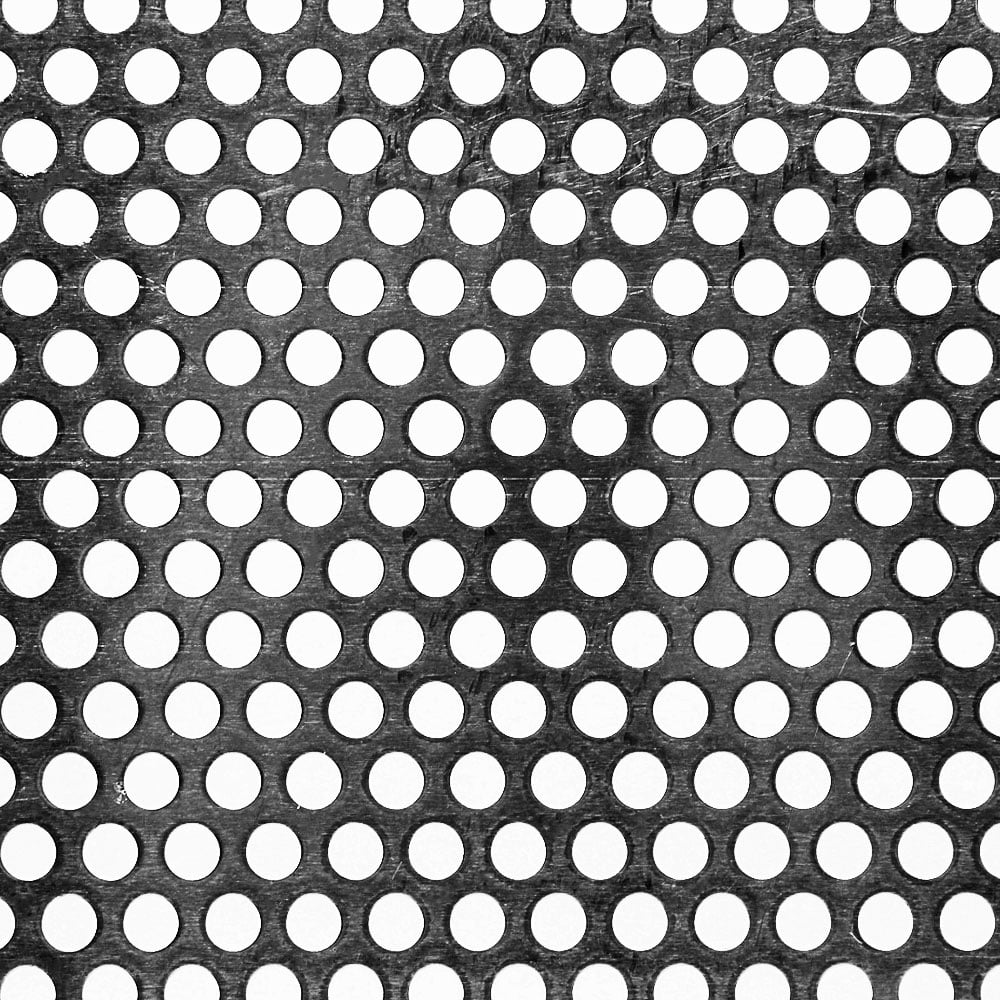

Round holes are a popular choice in ventilator grilles for several reasons. Due to its symmetrical shape, air is evenly distributed, reducing turbulence and improving airflow efficiency. Round holes also have a lower pressure drop, requiring less energy to move air through the grille. In terms of aesthetics, round holes lend the design a sense of harmony and consistency.

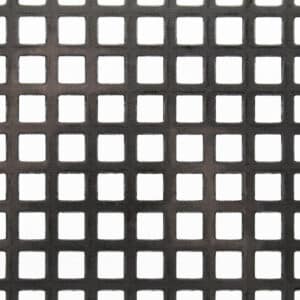

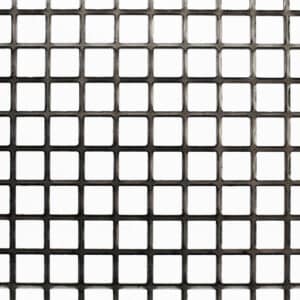

With their straight edges and sharp corners, square holes appear more modern and structured. Certain architectural styles with angular designs can benefit from them particularly. A square hole can provide a slightly larger open area than a round hole of the same size, which may facilitate greater airflow. It is important to consider, however, that they may also increase the pressure drop slightly, which is an important aspect of overall ventilation efficiency.

Slotted Holes

The slotted holes are elongated in shape and can be oriented horizontally or vertically, depending on the orientation of the slot. It is often the case that these ducts are chosen for their unique visual appeal, as well as their ability to direct airflow in a particular direction. There are several applications where slotted holes can be particularly useful, such as those when linear airflow is needed or where space constraints prevent the use of round or square holes. Their elongated shape can also create interesting light and shadow effects, adding to the decorative appeal of the grille.

The hole size and thickness of the material determine the suitability of ventilator grilles for specific applications. Here are ten options from The Mesh Company’s extensive range, each with unique uses and benefits:

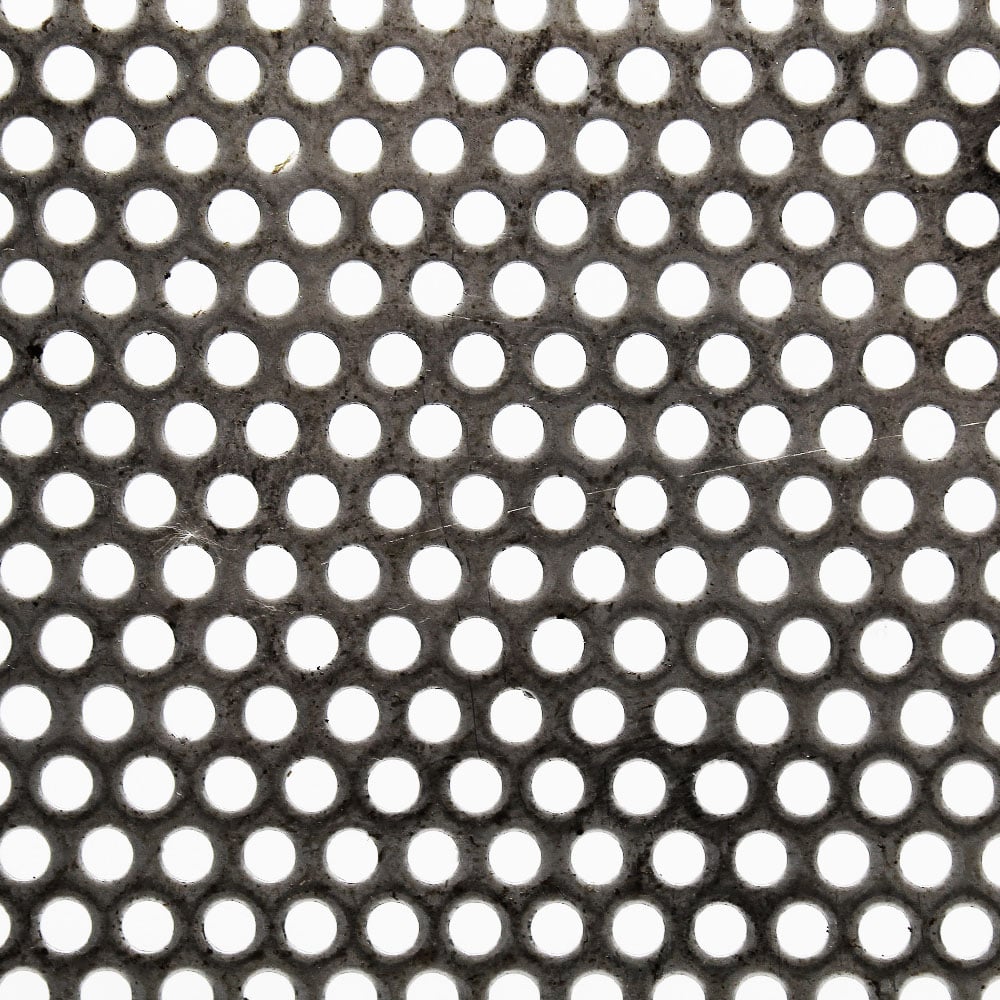

0.75mm Round Hole – 1.5mm Pitch – 0.6mm Thick

Ideal for fine filtration applications, offering subtle airflow with a sleek appearance.

1mm Round Hole – 2mm Pitch – 1mm Thick

A versatile choice for general ventilation in residential settings, balancing airflow with particle retention.

1.5mm Round Hole x 2.5mm Pitch x 0.6mm Thick

Offers precise air control, suitable for areas requiring detailed regulation of airflow.

3mm Round Hole – 5mm Pitch – 1mm Thick

This option provides ample air passage suitable for larger spaces requiring consistent ventilation.

4mm Round Hole – 6mm Pitch – 1.5mm Thick

Strikes a balance between protection and airflow, fit for both home and commercial use.

5mm Round Hole – 8mm Pitch – 2mm Thick

The added thickness ensures longevity, making it suitable for outdoor applications exposed to the elements.

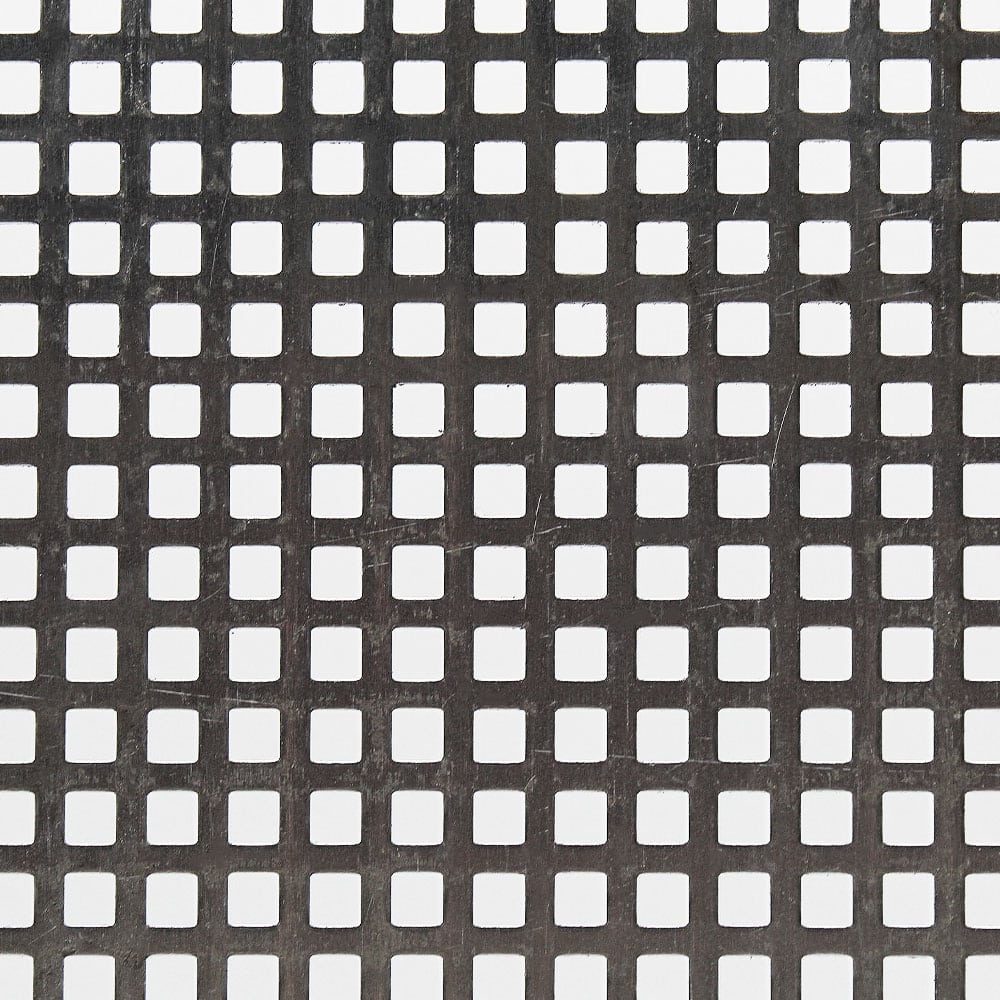

5mm Square Hole – 8mm Pitch – 1mm Thick

Offers excellent air circulation and is aesthetically pleasing, making it suitable for modern homes and offices.

10mm Square Hole – 12mm Pitch – 1mm Thick

Great for commercial and industrial environments where maximum airflow is necessary.

6mm Round Hole – 9mm Pitch – 1.5mm Thick

The increased thickness adds durability, perfect for high-traffic areas needing robust ventilation solutions.

20mm Round Hole – 28mm Pitch – 2mm Thick

Provides significant airflow, ideal for industrial applications where ventilation is paramount.

Each option serves different needs, from delicate air control in sensitive environments to robust airflow in industrial settings, ensuring you can find the perfect fit for your ventilator grille project.

A stainless steel perforated metal ventilator grille serves both a functional and aesthetic purpose. Designs range from simplistic and minimalist to intricate and bespoke. Grid patterns remain popular because of their timeless look and effective airflow management. Modern architecture often calls for custom-designed grilles that serve as focal points in design schemes.

A custom grille can incorporate a brand logo, geometric patterns, or organic shapes inspired by nature, depending on the ventilation requirements.

A custom design can also be tailored to meet specific airflow requirements. You can use slotted or diagonal patterns to direct airflow or to create a subtle visual effect that enhances the overall design of a room.

If you require a custom grille or image perf then please contact us and we will help you to find what you need.

It is very important to approach the installation of stainless steel ventilator grilles with precision and care. In most cases, the process involves measuring the vent area accurately, preparing the surface, and then attaching the grille to the vent area using fasteners or adhesives that are appropriate for the particular application. There is a need to ensure that the grille is installed flush against the surface in order to prevent any obstruction of airflow or issues with noise from occurring.

It is possible to integrate these grilles into a variety of architectural styles due to the versatility of stainless steel. Its sleek, modern appearance complements contemporary design schemes, while its durability and the possibility of using different finishes, such as powder coatings, allow it to be easily incorporated into more traditional or industrial aesthetic schemes. Stainless steel grilles can be designed to mimic historic patterns, thereby merging the old with the new in a harmonious manner in the case of buildings with specific architectural heritage. The adaptability of ventilation components ensures that they contribute positively to the overall design narrative of a building.

Checklist:

Perforated stainless steel metal needs to be maintained to maintain its longevity and performance as a ventilator grille. Dust and debris can be prevented by regularly cleaning with mild soap and water, followed by a thorough rinse. Check outdoor installations for signs of environmental wear and remove any surface rust with a soft brush.

Water spots and fingerprints can be removed with special stainless steel cleaners that polish the surface, leaving a protective layer that resists future marks. Airflow efficiency will also be maintained if the grille is free of obstructions.

Your ventilator grille’s stainless steel perforated metal mesh selection impacts not only the functionality of your ventilation system, but also the visual harmony of your space. A good choice balances practicality with aesthetic value, catering to specific ventilation needs while complementing the architectural design.

Perforated stainless steel offers a blend of style and efficiency for various applications, due to factors such as durability, maintenance, and design versatility.

We hope that this article proves to be of interest and please do feel free to contact us if you require any further assistance or information.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores the top 10 uses for stainless steel perforated mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.