£19.99 – £59.99 inc VAT

This website is secured:

✔ The UK’s Largest Range Of Mesh Products

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Sizes & Larger Sheets Available

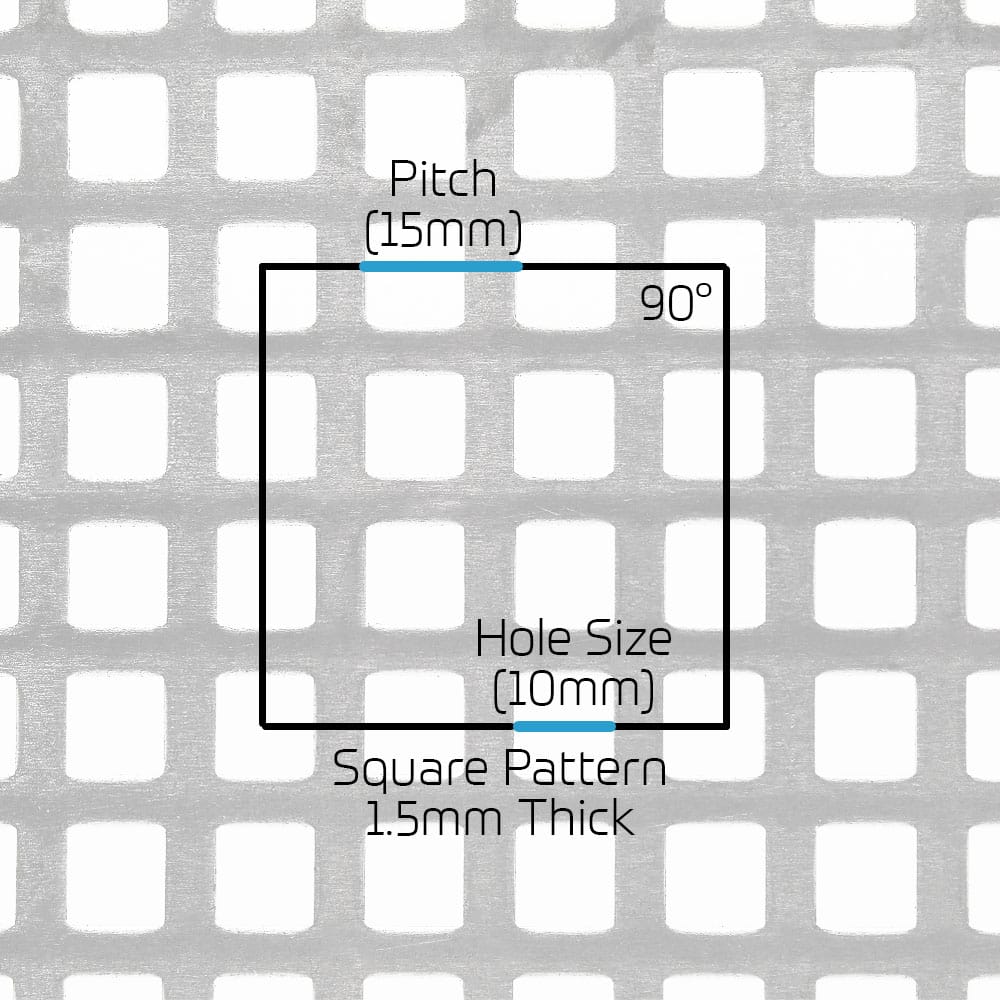

Perforated metal sheet with 10mm square holes is produced by punching a flat aluminium plate with a specific pattern. This strong and attractive material boasts a high strength-to-weight ratio, customisable design options, and excellent temperature stability. It’s perfect for applications such as partitions, furniture, air filtration systems, and acoustic control in busy environments.

Made from 1050 H14 grade aluminium, it offers excellent corrosion resistance and is suitable for MIG and TIG welding. This perforated metal is ideal for use on classic cars, commercial vehicles, trailers, and caravan

10mm square aluminium perforated metal sheet is produced by punching flat aluminium plate with a specific pattern. 10mm square perforated metal sheet is an effective, strong and attractive material used for myriad purposes.

Square punched metal has many advantages, including having a high strength-to-weight ratio, customisable design options and excellent temperature stability. This product is perfect for applications such as partitions, furniture and air filtration systems, and also has acoustic properties which makes it ideal for sound control in busy environments. See our detailed article on why perforated metal is so often used for acoustic applications.

Aluminium perforated metal is a punched sheet plate. Hole rows can be straight or staggered to increase the number of openings.

The 1050 H14 grade is at least 99.5% pure aluminium. Suitable for both MIG and TIG welding. We recommend this product to customers for use on classic cars, kit cars, and sports cars.

Aluminium 1050 H14 has excellent corrosion resistance, furthermore it is ideal for anodizing or powder coating. Often used in the manufacture of signs and curtain walls.

Can be applied to commercial vehicles, horse boxes, trailers, and caravans.

Our group have been in the mesh industry for over 150 years. We are one of the UK’s most trusted metallic mesh suppliers because:

We also offer a massive range of aluminium perforated metal sheet options from immediate stock. In order to produce aluminium perforated metal sheet, flat sheet metal is punched with round or square holes.

We also offer stainless steel, which is a more expensive option, but this is due to increased corrosion resistance and longevity.

Square aluminium perforated metal is made through a process of punching a flat sheet of aluminium using a machine known as a punch. The process involves placing the aluminium sheet onto a bed, clamping it down securely, and then using a punch press to create precise patterns of square-shaped holes in the metal.

The size, shape, and spacing of the holes can be customised to meet specific design requirements. Once the holes are punched, the remaining metal around the holes is left intact, forming a perforated metal sheet with square-shaped holes.

Square aluminium perforated metal can be made using a range of aluminium alloys, with the most common being 3003-H14 and 5052-H32. These alloys are known for their strength, durability, and corrosion resistance, thus they are ideal for a huge range of applications.

Cutting this metal mesh at home can be possible with the right tools and safety precautions. However, it’s important to note that cutting metal can be dangerous, and it’s recommended to have some experience with metalworking.

Here are some means of cutting that our customers have employed in the past:

We use our massive guillotine to cut all of our perforated metal sheets. Please reach out today if you have a specific requirement in mind. We will respond with prices or helpful advise very quickly.

See below for a quick summary of this mesh size:

Check out our blog aluminium perforated metal sheet for more information on that large range of materials. We have also written on square hole perforated metal.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

We also offer similar products through our highly popular eBay store, check us out there too.

| Sheet Size | 150 x 150mm, 300 x 300mm, 250mm x 500mm, 300mm x 500mm, 400mm x 500mm, 500mm x 500mm, 100mm x 500mm, 150mm x 500mm, 150mm x 1000mm, 200mm x 500mm, 200mm x 1000mm, 250mm x 1000mm, 300mm x 1000mm, 400mm x 1000mm, 500mm x 1000mm, 100mm x 1000mm |

|---|

In 2008 Locker Wire Weavers launched The Mesh Company to bring our enormous range of wire mesh products to the general public for the first time. Previously wire mesh was only available for trade customers.

We continue to extend our range, and now proudly offer many forms of mesh and metal products for the best possible prices. We specialise in woven wire mesh. As a group we work closely with architects and designers to develop ground-breaking new applications for our multifunctional range of materials. We also offer state of the art fabrication and engineering for projects of all sizes.

Strong ties with the Warrington community continue to be at the very core of our business. We are proud to invest in the training and developing our staff of all levels in line with the traditions set by Thomas Locker, who founded our group 150 years ago when he invented the electronic loom. We continue to bring ingenuity and strong ethics to our day to day business.

The Mesh Company continues Warrington’s historic role in the wire industry. For more than 140 years, our group has been a leader in the supply and manufacture of woven wire mesh and wire cloth. Having been founded in Warrington, UK in 1878, Locker mesh products still retain the quality craftsmanship and spirit of innovation that were so characteristic then.

Available Options

You will find full rolls of this insect netting here. Please be advised that the majority of woven mesh is usually available in a maximum roll size of 30 metres by 1200mm. Please email us if you wish to discuss purchasing this mesh in any size – sales@themeshcompany.com.

Feel free to call us if you wish to discuss any of our products – (+ 44) 01925 406 602. We are always happy to help in any way that we are able to.

We also offer this product through our highly popular eBay store, check us out there too.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions

Reviews

There are no reviews yet.