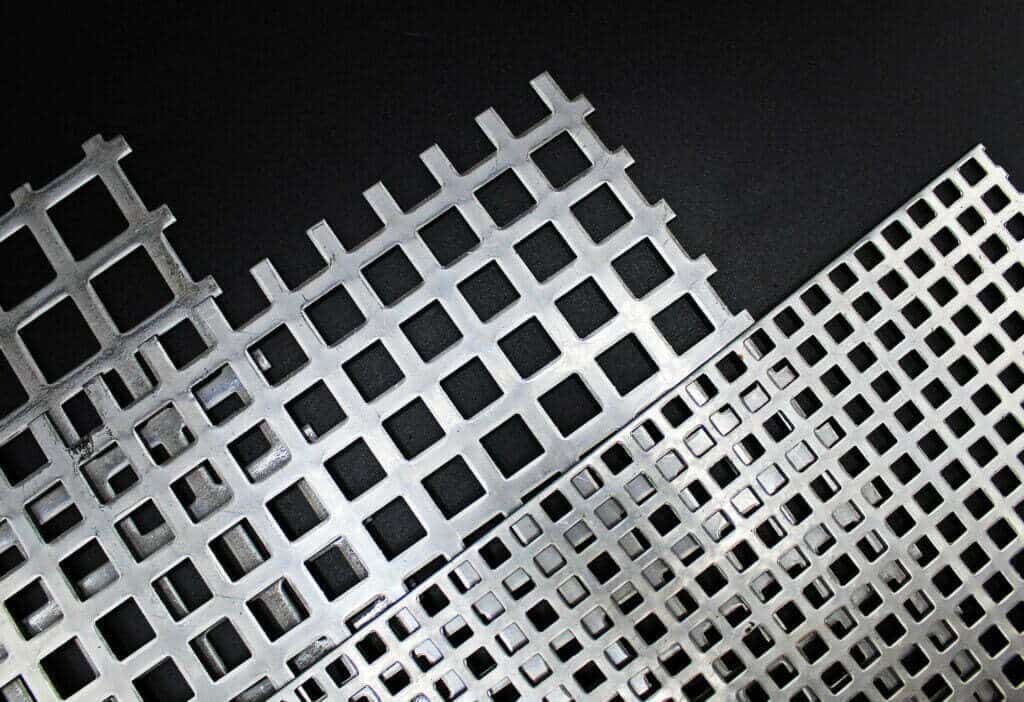

Metal can be perforated with a variety of shapes and patterns, including squares, circles, slots, and rectangles. The process can be used with a variety of materials, including steel, aluminium, stainless steel, and brass.

This guide focuses on square hole perforated metal. We offer it in stainless steel, galvanised steel, mild steel and aluminium.

But how is it made? What is it used for? How strong is it?

We will answer these questions and more in this helpful guide.

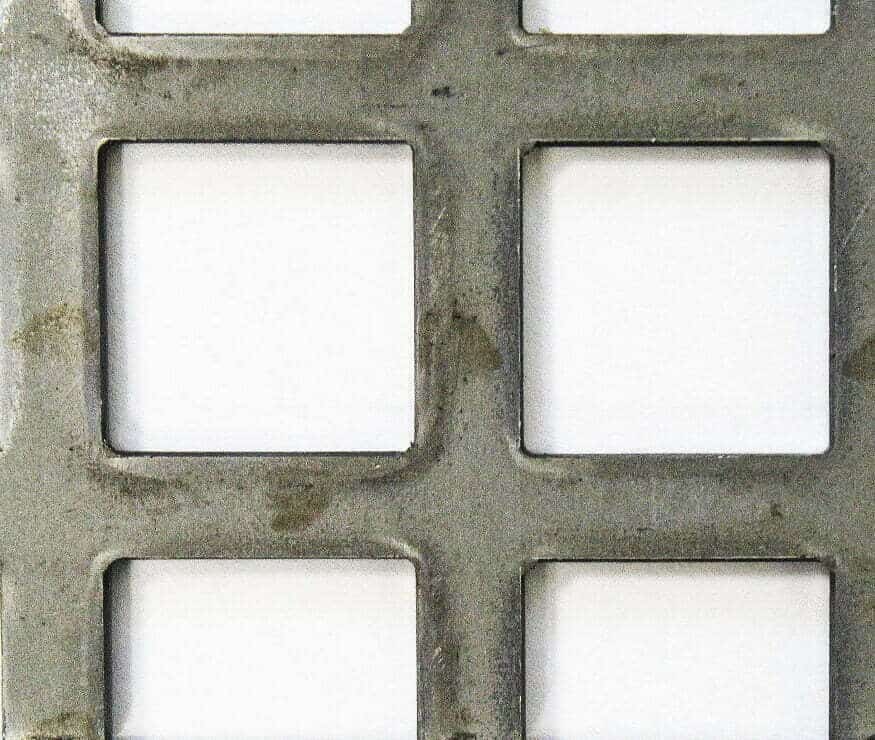

Perforated metal is a type of metal material that has been punched with a series of holes of various shapes, sizes, and patterns. The process of creating perforated metal involves using a press to punch the holes through a metal sheet. The result is a sheet of metal with a series of openings that can be used for a variety of purposes, including filtration, ventilation, soundproofing, and decorative applications.

Perforated metal can be made from a variety of metals, including aluminium, steel, stainless steel, and others, and can be finished with a variety of coatings, such as paint, plating, or anodizing. The size, shape, and pattern of the holes in the metal can be customized to meet the specific needs of a given application.

Square hole perforated metal is made by a process called perforation, in which a metal sheet or plate is punctured with a tool or machine to create regular, uniform holes in a pattern. The process involves feeding the metal sheet through a press that has a cutting die, which punctures the metal to create the desired pattern.

The mesh is perforated into a square hole pattern to suit the users requirements. We also stock a large range of round hole perforated metal too.

Square hole perforated metal is a versatile material that is used in a wide range of applications due to its solid pattern of holes and its strength and durability. Here are some of the most common uses for square hole perforated metal:

The strength of perforated metal depends on several factors, including the type of metal used, the size and pattern of the holes, and the thickness of the metal sheet. Generally, perforated metal is stronger than an equivalent solid sheet of metal, as the holes provide structural support and prevent the metal from stretching or tearing under stress.

However, the strength of square perforated metal can vary depending on the specific application and the properties of the metal used. For example, perforated steel is generally stronger than perforated aluminium, and perforated metal with larger holes will typically be weaker than metal with smaller holes.

If strength is a concern, it’s important to consider these factors and choose the right type of perforated metal for the specific application. Additionally, the strength of perforated metal can be further increased through the use of reinforcement, such as adding a backing or support structure.

Square perforated metal is available in a wide range of metal materials, including:

Steel: Steel is a strong and durable metal that is commonly used for perforated metal due to its high strength-to-weight ratio and resistance to corrosion.

Stainless Steel: Stainless steel is a popular choice for perforated metal due to its resistance to corrosion, staining, and rusting.

Aluminium: Aluminium is a lightweight metal that is easy to work with and has good resistance to corrosion.

Brass: Brass is a copper-zinc alloy that is often used for perforated metal due to its attractive appearance and resistance to corrosion.

Copper: Copper is a soft and malleable metal that is often used for perforated metal due to its good conductivity and resistance to corrosion.

Galvanised Steel: Galvanized steel is steel that has been coated with a layer of zinc to increase its resistance to corrosion.

Yes, you can cut perforated metal. The method used to cut perforated metal will depend on the size, thickness, and material of the metal, as well as the complexity of the cut required. Some common methods for cutting perforated metal include:

Yes, you can weld square perforated metal, but it is important to keep in mind that welding perforated metal can be challenging due to the presence of holes in the material. The holes can cause problems such as warping or burn-through during the welding process, and the type of metal used can affect the weldability of the material.

If you are planning to weld square perforated metal, it’s important to choose the right welding method and techniques to ensure a successful outcome. Some common welding methods used for perforated metal include:

Please make sure to select the correct metal for your purposes. Some are better for welding for others.

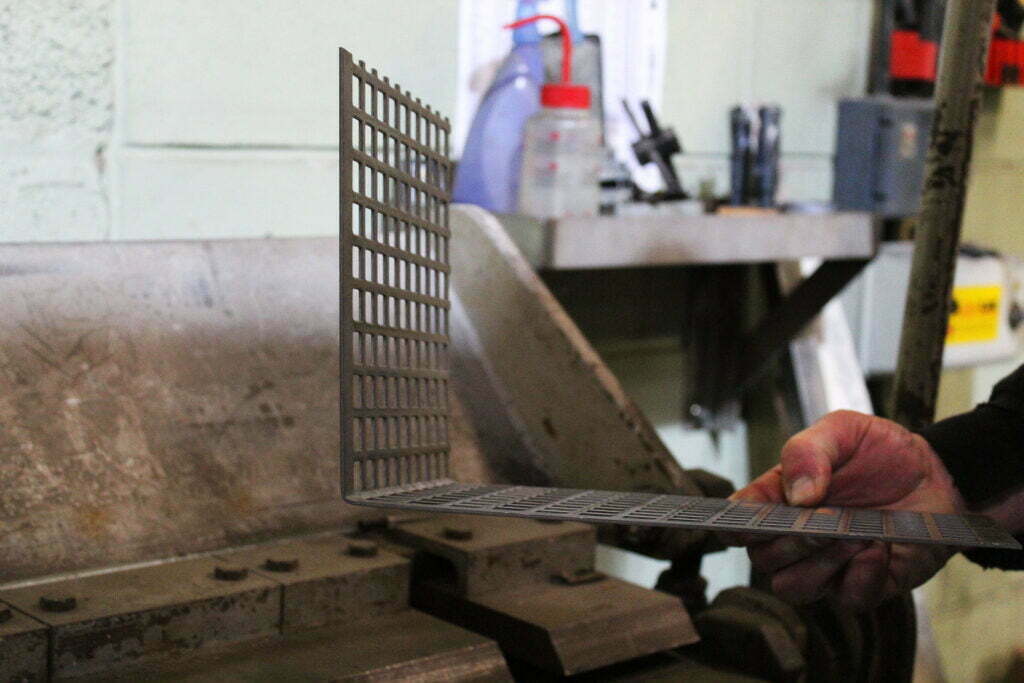

Yes, you can bend square perforated metal, but the process can be more complex than bending solid metal due to the presence of the holes in the material. The size, spacing, and material of the holes can affect the bendability of the metal and the quality of the final bend.

Some common methods used for bending square perforated metal include:

Press Brake Bending: Press brake bending is a metal fabrication process that uses a machine called a press brake to bend metal into a specific shape. This method is often used for bending square perforated metal into curves or angles.

Roll Bending: Roll bending is a metal fabrication process that uses a machine with three rolls to bend metal into a specific shape. This method is often used for bending large sheets of perforated metal into curves or cylinders.

Hand Bending: Hand bending is a manual metal fabrication process that uses hand tools to bend metal into a specific shape. This method is often used for small sheets of perforated metal or for making simple bends in the material.

When bending square perforated metal, it’s important to choose the right method and techniques to ensure a successful outcome and to minimize the risk of damaging the metal or the holes during the bending process.

Yes, you can paint perforated metal, but it is important to keep in mind that painting perforated metal can be more challenging than painting solid metal due to the presence of the holes. The holes can make it difficult to achieve an even and consistent coat of paint, and the type of paint and application method used can affect the final outcome of the paint job.

If you are planning to paint perforated metal, it’s important to choose the right paint and application method to ensure a successful outcome. Some common methods for painting perforated metal include:

Spray Painting: Spray painting is a popular method for painting perforated metal, as it allows for a quick and even application of paint. To achieve the best results when spray painting perforated metal, it’s important to use a paint that is designed for metal and to follow proper spray painting techniques, such as using multiple light coats of paint to build up a consistent finish.

Brush Painting: Brush painting is another option for painting perforated metal, but it can be more time-consuming and may result in an inconsistent finish due to the difficulty of evenly painting the holes in the metal. To achieve the best results when brush painting perforated metal, it’s important to use a high-quality brush and to apply multiple thin coats of paint to build up a consistent finish.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.