£18.99 – £44.99 inc VAT

This website is secured:

✔ The UK’s Largest Range Of Mesh Products

✔ FREE UK Delivery Included

✔ Immediate Express Dispatch From Stock

✔ Tracked Delivery with Order Updates

✔ 30-Day Returns Accepted

£ Check Out Our Clearance Listing For Savings

@ ☏ Bespoke Sizes & Larger Sheets Available

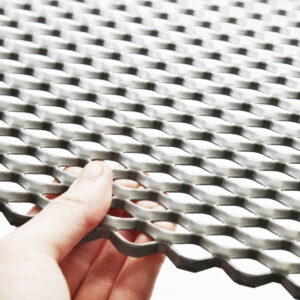

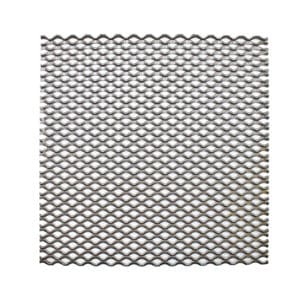

This durable and lightweight grey-coated aluminium expanded mesh offers a practical and aesthetic solution for various applications. With a 20mm x 14mm diamond-shaped design, 2mm thickness, and a weight of just 3.1 kg/m2, it provides a blend of visual appeal with 34% open area, ideal for scenarios requiring light filtration and airflow. Its versatility makes it suitable for both industrial and architectural uses.

Expanded metal mesh, finished with a grey coating, stands out for its versatility and unique properties suitable for various applications. This grey-coated aluminum mesh is crafted by the careful stretching of aluminum metal, resulting in a mesh with a distinctive diamond pattern. The diamond apertures measure 20mm along the longer axis and 14mm along the shorter axis, providing an aspect of symmetry and aesthetic appeal.

The mesh is characterized by a solid 2mm thickness, which reinforces its strength and longevity, making it apt for an array of uses that range from structural support to decorative embellishments. Its strength is complemented by a relatively modest weight of 3.1 kg/m2, which ensures that it can be handled and installed with ease, without sacrificing robustness.

A prominent feature of this grey-coated aluminum mesh is its open area percentage of 34%, which contributes to its visual appeal and allows for significant passage of light and air. This characteristic is particularly beneficial in environments where proper ventilation and natural light are required. The combination of visual openness and durability makes this mesh an advantageous component for use in HVAC systems, architectural facades, and numerous industrial settings.

The integration of specific attributes such as pitch sizes, thickness, weight, and open area percentage makes this grey-coated aluminum expanded metal mesh a sought-after product. It fulfills a wide range of needs, from improving security and sturdiness in industrial applications to providing a visually pleasing element in architectural designs.

You may be interested in 10mm round or square aluminium perforated mesh as an alternative to this product.

Our group have been in the mesh industry for over 150 years. We are one of the UK’s most trusted metallic mesh suppliers because:

We also offer a massive range of perforated metal sheet options from immediate stock. In order to perforated mesh, flat sheet metal is punched with round or square holes. Perforated sheets are commonly often used in applications where the passing of air is required. Because the holes are punched, it is possible to have a far stronger finished metal product than it would be for the equivalent thickness in woven or welded mesh. It is an extremely popular alternative to expanded metal mesh.

Different applications require raised and flat aluminum expanded mesh sheets. Standard or unflattened aluminum expanded mesh is created by slitting and stretching the aluminum into an open diamond pattern and then leaving it in its raised state. As a result, the mesh has a bumpy and textured surface with each strand of the mesh at a different height, providing a high grip surface that is especially useful for catwalks, walkways, and anti-slip surfaces in industrial settings.

Flat aluminum expanded mesh sheets, on the other hand, undergo a rolling process that flattens the mesh, creating a smooth and level surface. In architectural applications where a sleek, uniform appearance is desired, flattening the mesh makes it thinner, wider, and provides a more consistent appearance. Flat mesh is often used for cladding, decorative screens, or anywhere a flat, smooth surface is needed. There is no difference in strength-to-weight ratio between raised and flat meshes, but the choice between them depends largely on if texture and a three-dimensional appearance (raised mesh) or a flat, two-dimensional appearance (flat mesh) are more suitable for the project.

Aluminum expanded mesh sheets are manufactured through a series of steps that transform aluminum sheet metal into expanded mesh. Initially, a solid sheet of aluminum is slit and stretched simultaneously. In this process, a knife is used to make precise cuts in the metal, which are then stretched apart to form diamond-shaped openings. Instead of punching the metal, slits create the open areas, making it a highly economical process. Lattice-like pattern has strands and bonds that form diamonds, which provide structural integrity and rigidity.

Mesh can be left in its raised state after stretching, which is ideal for certain applications, or it can be passed through heavy rollers to produce flat mesh. It is possible to adjust the thickness of the strands and the size of the openings. Following expansion, the mesh may be cut to size, bent, and powder coated or anodized to enhance its durability and aesthetic appeal. The result is a lightweight yet durable material with a wide range of industrial, architectural, and security applications.

The strength, durability, and corrosion resistance of aluminum expanded mesh sheets make them an ideal choice for security grilles. Due to the way aluminum strands intersect in expanded mesh, it can provide a formidable barrier that is difficult to penetrate, offering a greater resistance to cutting and deformation than wire mesh or bars. Because expanded aluminum mesh has an inherent rigidity, along with its ability to be secured firmly to frames and substrates, it makes an excellent material for window, door, and gate grilles.

Moreover, aluminum expanded mesh allows for airflow and visibility, so it serves as a security feature without completely blocking light and air circulation. Maintaining the aesthetics and functionality of a building’s design without compromising safety is particularly important. In addition, manufacturers can customize the size and thickness of the openings to meet specific security requirements. In addition to these functional advantages, aluminum expanded mesh can be finished with a variety of colors and coatings, increasing its visual appeal and further increasing its resistance to environmental factors.

Check out our blog ‘everything that you need to know about expanded metal mesh’ for more information on this large range of materials.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

We also offer similar products through our highly popular eBay store, check us out there too.

| 20 x 14mm Expanded Sheet Sizes | 300mm x 300mm, 300mm x 600mm, 300mm x 900mm, 300mm x 1200mm |

|---|

In 2008 Locker Wire Weavers launched The Mesh Company to bring our enormous range of wire mesh products to the general public for the first time. Previously wire mesh was only available for trade customers.

We continue to extend our range, and now proudly offer many forms of mesh and metal products for the best possible prices. We specialise in woven wire mesh. As a group we work closely with architects and designers to develop ground-breaking new applications for our multifunctional range of materials. We also offer state of the art fabrication and engineering for projects of all sizes.

Strong ties with the Warrington community continue to be at the very core of our business. We are proud to invest in the training and developing our staff of all levels in line with the traditions set by Thomas Locker, who founded our group 150 years ago when he invented the electronic loom. We continue to bring ingenuity and strong ethics to our day to day business.

The Mesh Company continues Warrington’s historic role in the wire industry. For more than 140 years, our group has been a leader in the supply and manufacture of woven wire mesh and wire cloth. Having been founded in Warrington, UK in 1878, Locker mesh products still retain the quality craftsmanship and spirit of innovation that were so characteristic then.

Available Options

You will find full rolls of this insect netting here. Please be advised that the majority of woven mesh is usually available in a maximum roll size of 30 metres by 1200mm. Please email us if you wish to discuss purchasing this mesh in any size – sales@themeshcompany.com.

Feel free to call us if you wish to discuss any of our products – (+ 44) 01925 406 602. We are always happy to help in any way that we are able to.

We also offer this product through our highly popular eBay store, check us out there too.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions

Reviews

There are no reviews yet.