The Mesh Company are broadening our range ever further in 2023. One material that we are delighted to now offer is expanded metal mesh (EXP). We will be launching new options across the year, and we have written this handy guide to hopefully answer any question that you may have.

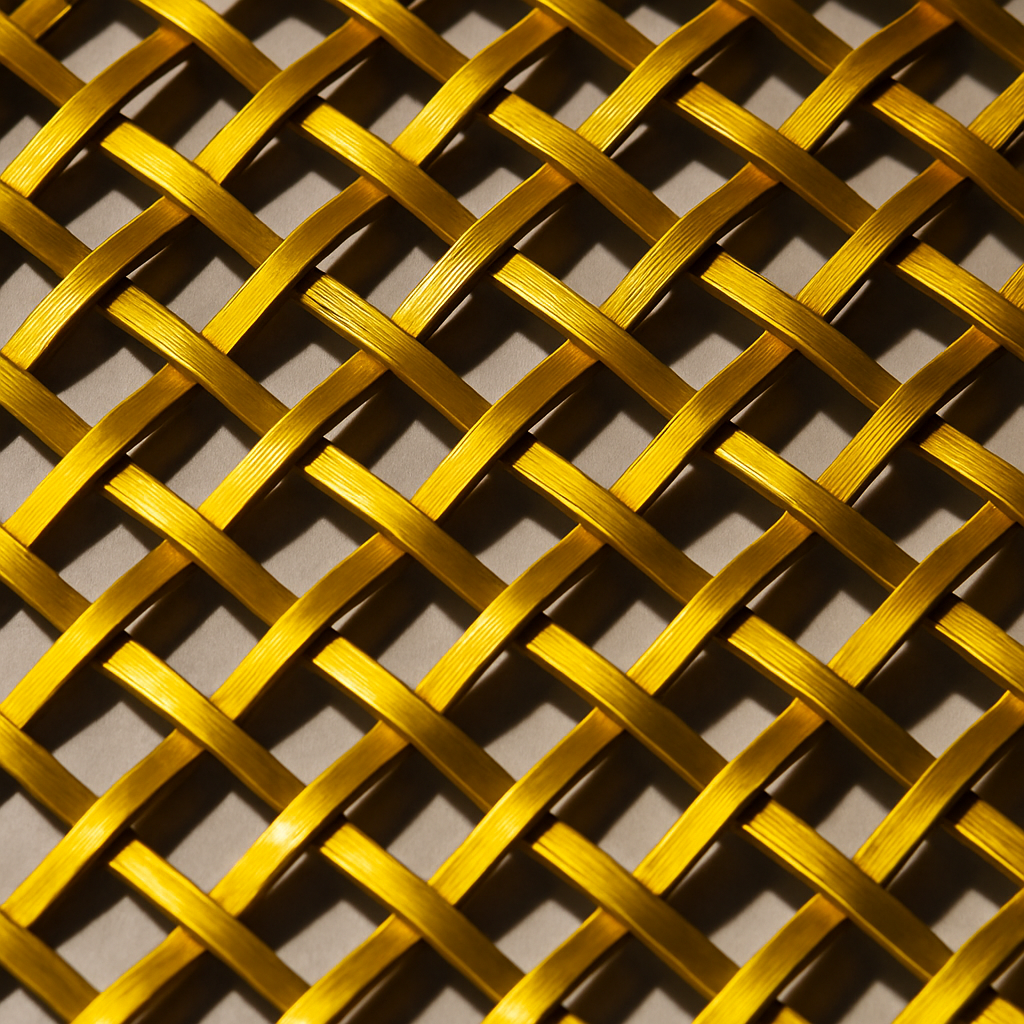

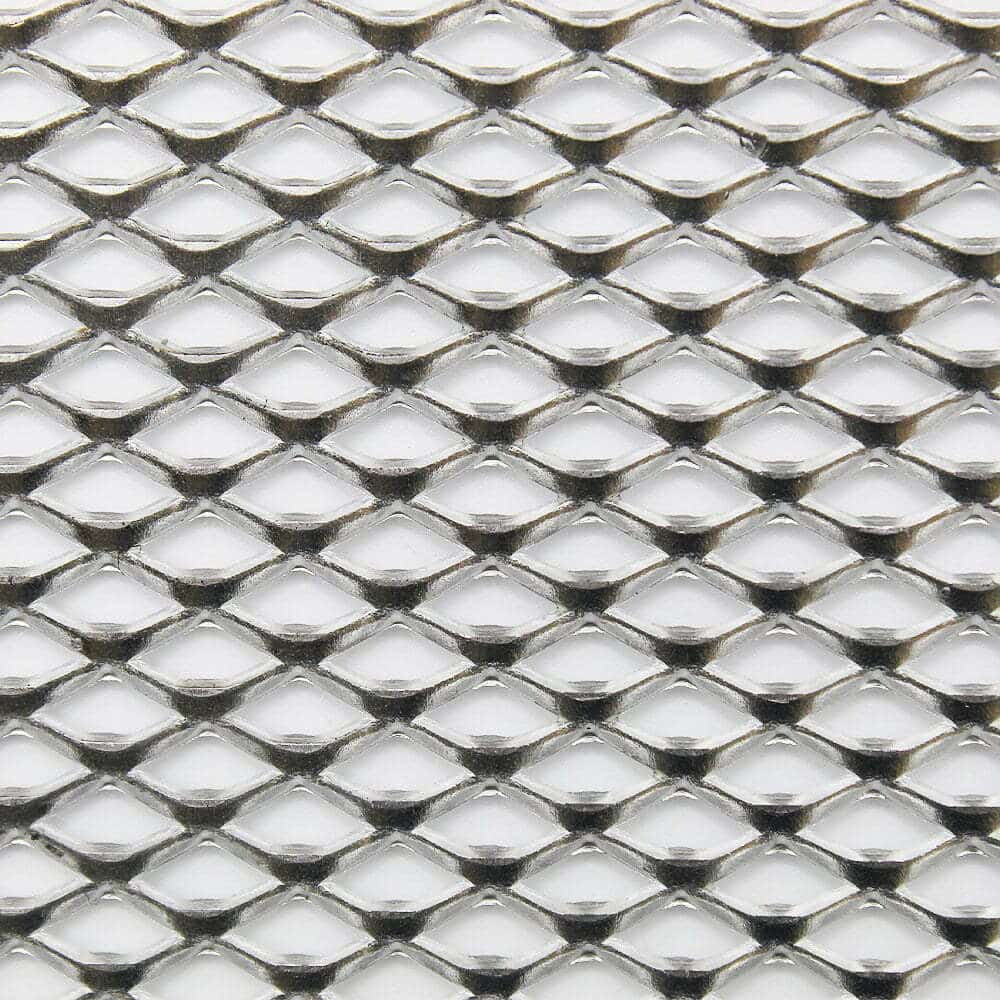

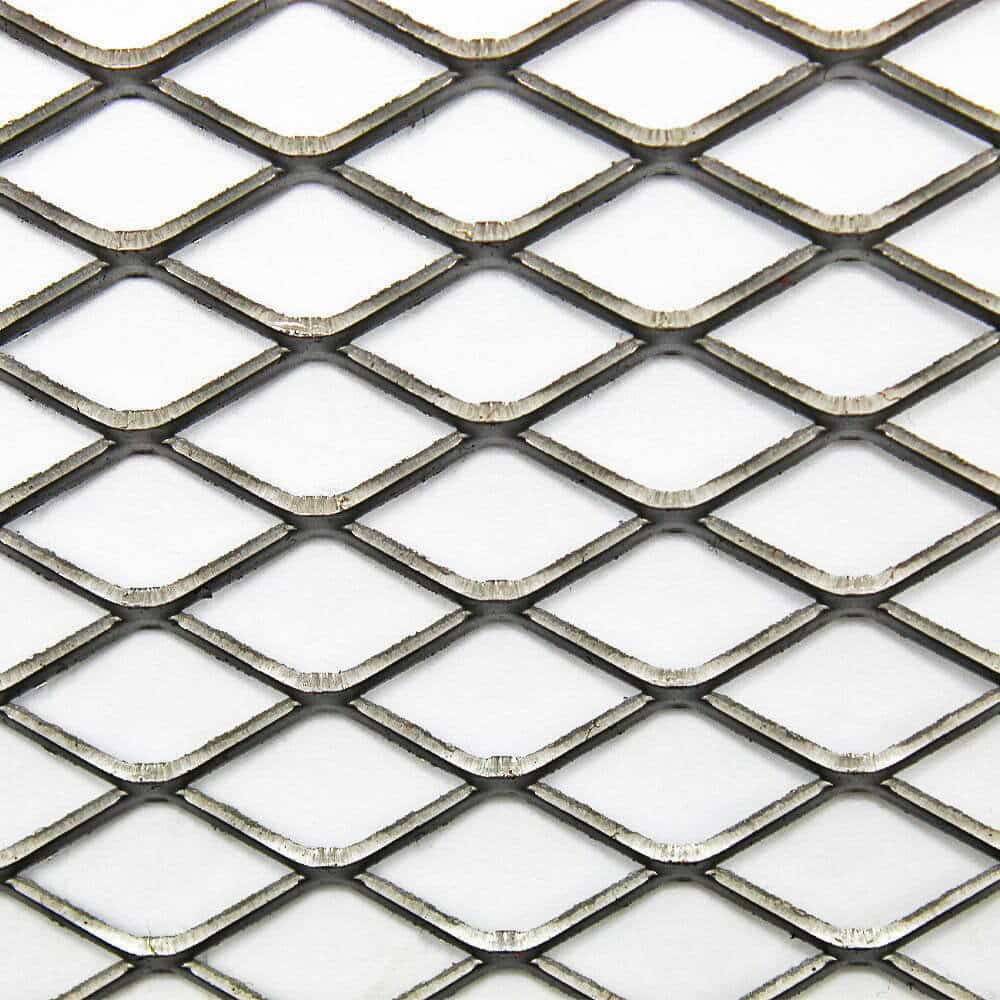

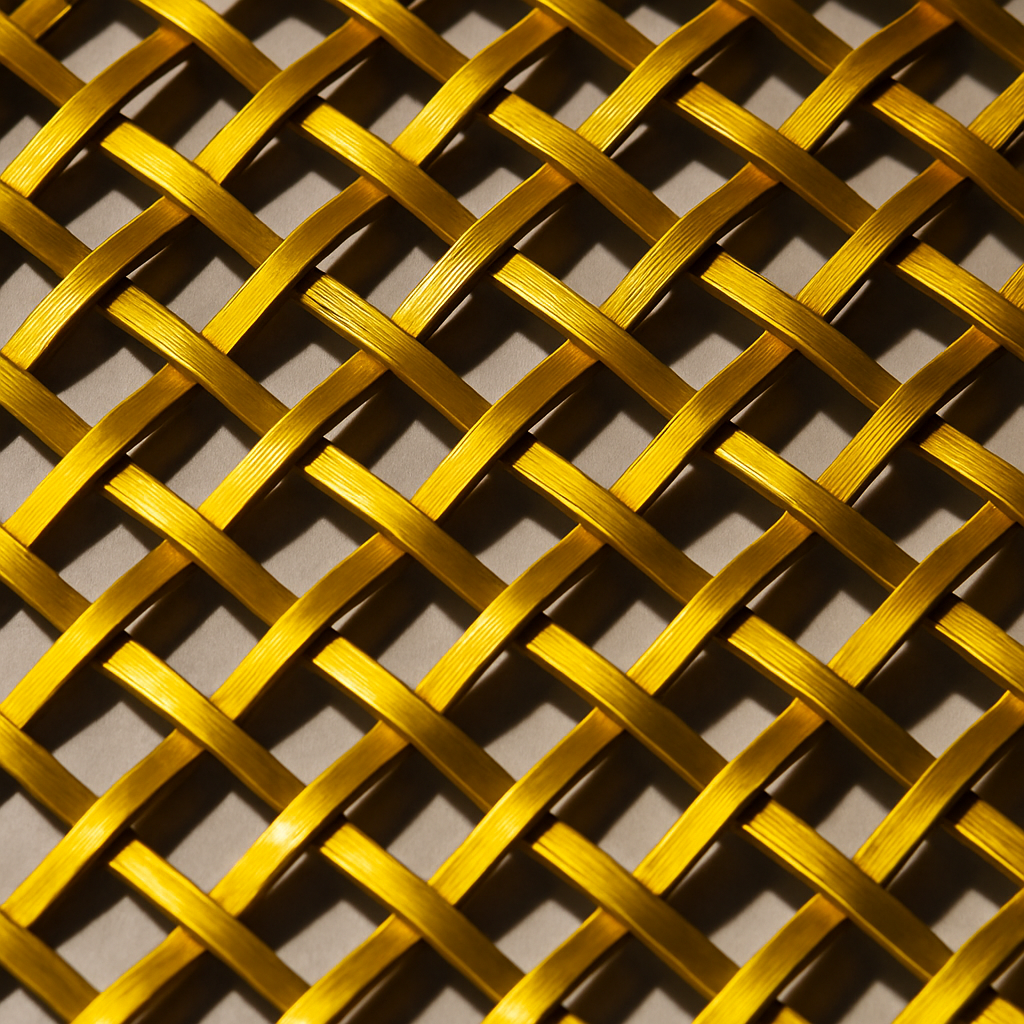

Expanded metal is also known as expanded sheet metal, or just expanded metal. It a type of sheet metal that has been cut and stretched to create a diamond-shaped pattern. This process increases the surface area of the metal, making it more durable and versatile. Expanded metal mesh is commonly used for architectural and industrial applications, such as building facades, security fencing, and machinery guards. It is available in a wide range of materials, including steel, aluminium, and stainless steel, and can be customized to meet specific structural, aesthetic, or functional requirements.

Perforated metal sheet may also be of interest as it is a similar product type. It is totally flat however, which may suit some applications better.

There are several types of expanded mesh available, which vary based on the manufacturing process and the characteristics of the finished product. Some of the most common types include:

Expanded metal mesh has a wide range of uses due to its strength, durability, and versatility. Some of the most common uses for expanded metal mesh include:

Metal mesh can also be used in various other applications such as reinforcing concrete, protecting underground utilities and as a guard in electrical substations, etc.

Yes. Expanded metal ceiling tile can be used in a variety of applications, including commercial and industrial buildings, as well as in residential settings. They are suitable for high traffic areas, such as airports, shopping centres, and other public spaces. These tiles are easy to install and can be suspended from a ceiling grid system. They are also lightweight, which makes them easy to handle and install. Additionally, Expanded metal replacement ceiling tiles are fireproof, soundproof and heat insulation. They also offer high ventilation and light transmission, making them an energy-efficient solution for lighting and HVAC systems.

Expanded metal mesh can be used as a reinforcing material for rendering, also known as a “scratch coat”, which is the first layer applied to a surface before the final render is applied. The expanded metal mesh is typically embedded in the wet rendering material and provides additional strength and stability to the surface, preventing cracking and other issues. It also helps to bridge any cracks or holes that may exist in the surface, providing a smooth and even surface for the final render.

It is used in the external insulation and finish systems (EIFS) in the construction industry as a reinforcement for the insulation layer. It is applied to the insulation layer which is then covered with a finish coat, this helps to increase the strength and durability of the insulation, preventing cracking and other issues.

Additionally, expanded metal mesh is also used in the construction of stucco walls, which is a traditional form of wall finish made of cement, sand, and water. The expanded metal mesh is embedded in the wet stucco mixture and helps to reinforce the wall and prevent cracking.

It can be cut using a variety of tools, such as tin snips, bolt cutters, or power saws. Tin snips are a manual tool that work well for cutting small pieces of expanded metal, while bolt cutters can handle larger pieces. Power saws, such as a metal-cutting band saw or a plasma cutter, can also be used to cut expanded metal, but they require a high level of skill and experience to operate safely.

It all depends on the thickness of the product. There are cutting guides on every product page depending on the material itself. We also offer a free cutting service if you require a bespoke size.

Yes, it is possible to weld expanded metal, but it can be more difficult than welding solid sheet metal due to the open structure of the material.

When welding expanded metal, it is important to use the correct type of welding process and filler metal. The most common welding process used for expanded metal is Gas Tungsten Arc Welding (GTAW), also known as Tungsten Inert Gas (TIG) welding, which is a precise and clean process that allows for control of the welding heat.

Another option is Gas Metal Arc Welding (GMAW) also known as Metal Inert Gas (MIG) welding, which is a faster process that also produces a clean weld.

To ensure a strong weld, it is also important to use a filler metal that is compatible with the expanded metal and the base metal. The base metal should be cleaned thoroughly before welding to remove any dirt, grease, or oil to ensure a good weld.

In general, welding expanded metal is a challenging task that requires skill and experience. It is always recommended to consult with a professional welder and make sure to follow safety guidelines when welding.

Yes, you can paint expanded metal. However, the open structure of the material can make it more difficult to paint than solid sheet metal. Also, some metals do not take paint. Plain steel is the best for painting.

Before painting expanded metal, it is important to clean it thoroughly to remove any dirt, grease, or oil. This will ensure that the paint adheres properly to the surface. A wire brush or sandpaper can be used to remove any loose rust or debris.

It’s a good idea to use a high-quality, rust-inhibiting primer before applying the final paint coat. This will help to prevent rust and protect the metal from the elements.

When applying the paint, it’s important to use a brush or roller with synthetic bristles or foam, as natural-bristle brushes can leave brush marks on the surface of the expanded metal.

It’s also important to use paint that is suitable for metal surfaces and to apply it in thin, even coats. Avoid applying too much paint in one area, as this can cause drips and runs.

It’s highly recommended to use a paint with a good quality and with the ability to withstand the elements, like a epoxy paint, or a polyurethane paint.

It’s also important to follow safety guidelines when painting, as some paints may contain harmful chemicals.

Yes, it is possible to bend expanded metal, but it can be more difficult than bending solid sheet metal due to the open structure of the material.

The process of bending expanded metal typically involves using a brake press or a press brake. This is a machine that uses a punch and die to bend the metal to a specific angle. The punch pushes the metal against the die, which shapes the metal as it is bent.

It’s important to note that the open structure of the expanded metal can make it more prone to tearing or cracking. To avoid this, the metal should be bent gradually and at a slow speed, and the punch and die should be adjusted to the appropriate size and shape for the metal being bent.

Also, it’s important to use a lubricant to reduce friction and heat during the bending process to avoid cracking.

It’s highly recommended that the metal should be bent at the manufacturer or by a professional metal bender with experience working with expanded metal. As the process can be complex and requires specialized equipment, and knowledge of the metal properties to avoid any damage.

Bending expanded metal can be challenging and it’s important to follow safety guidelines when working with metal and equipment.

As always, thank you for checking out our blog. We hope that this helps you with your project.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions