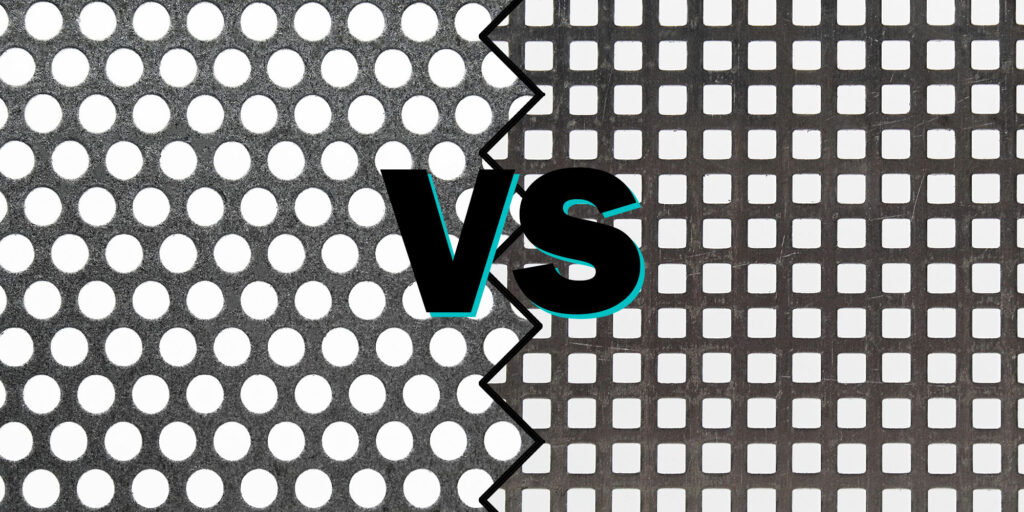

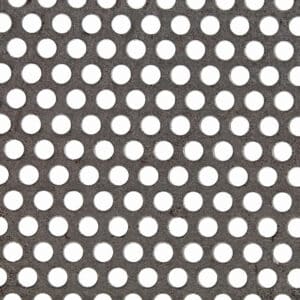

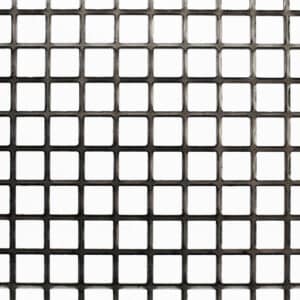

The choice between round hole and square hole perforated metal can have a big impact on a project’s outcome. It will examine factors like structural integrity, acoustic performance, aesthetic flexibility, and cost-efficiency when using round hole vs square hole perforated metal.

You can make more informed decisions tailoured to your specific needs when you understand these differences, whether you’re an architect, designer, or manufacturer.

One of the most crucial aspects to consider when choosing between round hole and square hole perforated metal is structural integrity. The shape of the perforation affects the distribution of stress and strain across the material.

Round Hole Perforated Metal: Stress is generally distributed more uniformly in round holes. Without sharp corners, there are fewer chances of stress concentrations, which are a common precursor to cracks and structural failures. Because of this, round hole perforated metal is an excellent choice for applications requiring varying loads or environmental conditions.

Square Hole Perforated Metal: However, square holes, on the other hand, can introduce stress concentrations at the corners of the holes, thereby compromising the material’s structural integrity under certain conditions depending on how they are cut or drilled. Despite this, square perforations can provide better material retention, which can be an advantage in applications where a more rigorous screening process is required or in filtration systems where particle sizes are very close to those of the holes.

A perforation’s shape also influences its acoustic properties. Depending on the application, both round and square perforated metals are used in architectural acoustics for sound absorption and noise reduction.

Round Hole Perforated Metal: Round perforations are more effective at diffusing sound waves and reducing their energy more uniformly. In environments where ambient noise is crucial, such as auditoriums, manufacturing plants, and large public spaces, round hole perforated metal is a popular choice.

Square Hole Perforated Metal: The sharp edges of square hole perforated metal can cause sound waves to be absorbed differently, which might be beneficial in specialised acoustic applications. Depending on the spacing and depth of the perforations, the unique patterning can also tune specific frequencies.

Especially in architectural and design applications, aesthetics play an important role in choosing the type of perforated metal. Round versus square holes can have a dramatic impact on a project’s overall appearance.

Round Hole Perforated Metal: In architectural designs, round holes provide a softer, more uniform appearance. In both modern and traditional settings, they provide a classic appearance, making them a versatile choice.

Square Hole Perforated Metal: A square hole provides a more geometric, angular aesthetic that can complement contemporary designs. Placing them in various patterns creates unique visual effects, adding a distinctive element to facade cladding, decorative panels, and privacy screens.

The cost of manufacturing perforated metal can vary based on the hole shape due to differences in the production process and material waste.

Round Hole Perforated Metal: It is generally easier and faster to punch round holes, which can lower production costs. In addition, round hole tooling tends to wear less quickly than square hole tooling, which can further reduce long-term manufacturing costs.

Square Hole Perforated Metal: Square hole punching can be more complex, resulting in higher tool wear and higher production costs. Despite the higher tooling costs, the ability to fit more square holes in the same space can reduce material waste.

Here’s a table outlining the pros and cons of round hole vs square hole perforated metal:

| Feature | Round Hole Perforated Metal | Square Hole Perforated Metal |

|---|---|---|

| Structural Integrity | Pros: | Pros: |

| – Uniform stress distribution | – Better material retention | |

| – Reduced likelihood of cracks | ||

| Cons: | Cons: | |

| – Less effective for specific filters | – Higher stress concentrations | |

| – Increased risk of structural failure at corners | ||

| Acoustic Performance | Pros: | Pros: |

| – Effective sound diffusion | – Can tune specific frequencies | |

| – Reduces ambient noise uniformly | ||

| Cons: | Cons: | |

| – Less control over frequency tuning | – Non-uniform sound absorption | |

| Aesthetic Flexibility | Pros: | Pros: |

| – Soft, uniform look | – Geometric, angular aesthetic | |

| – Versatile for various designs | – Creates unique visual patterns | |

| Cons: | Cons: | |

| – Limited to circular patterns | – Can be too bold for some designs | |

| Cost Efficiency | Pros: | Pros: |

| – Lower production costs | – Efficient material usage | |

| – Less wear on tooling | ||

| Cons: | Cons: | |

| – Potential for higher material waste | – Higher tool wear and production costs |

Here’s a straightforward table focusing on the typical applications for round hole vs square hole perforated metal:

| Applications | Round Hole Perforated Metal | Square Hole Perforated Metal |

|---|---|---|

| Architectural Design | Used in facades, exterior and interior panels for aesthetic uniformity | Ideal for modern designs with geometric themes, facades, and panels |

| Industrial Filtration | Common in applications requiring uniform stress distribution, such as screens and vents | Preferred for precise size-based filtration, like in material grading systems |

| Acoustic Engineering | Utilised for sound diffusion in auditoriums, theaters, and public spaces | Used for specific acoustic tuning, especially in recording studios and sound-sensitive environments |

| Agricultural Uses | Employed in machinery for uniform seed sorting and small particle applications | Used for sorting larger particles or seeds, where precise size retention is crucial |

| Decorative Elements | Popular in furniture, lighting fixtures, and decorative panels offering a soft aesthetic | Utilised in bold, distinctive decorative art, privacy screens, and modern décor elements |

Consider your project’s specific requirements when choosing between round hole and square hole perforated metal. In terms of structural integrity, acoustic performance, aesthetic flexibility, and cost-efficiency, each type offers distinct advantages. You can choose the most suitable perforated metal for your needs by understanding these differences.

You should now be able to make an informed decision about whether round hole vs square hole perforated metal is best for your application based on the results of this performance analysis. No matter what your priorities are, choosing round or square can make a significant difference in the success of your project, whether it is durability, sound management, visual impact, or budget.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores hexagonal vs square hole perf mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions