From filtration and separation to ventilation and light transmission, woven wire mesh plays an essential role in the vast world of industrial design and manufacturing. A key characteristic of woven wire mesh is its open area percentage. A mesh’s effectiveness, efficiency, and suitability for a given task are directly influenced by this metric.

A woven wire mesh’ open area percentage measures how much void space there is within the structure, showing how easily air, liquid, and light can pass through. For designers, engineers, and project managers, calculating this percentage isn’t just an academic exercise, it’s a necessity.

Mesh selection can be tailored to the specific project requirements, so the mesh chosen supports the intended function, whether it’s maximising flow rate in a filtration system, ensuring adequate ventilation in a building, or optimising light diffusion in an architectural project.

We hope that this article is of use to you to understand this vital mesh metric. Let’s get into it…

In spite of its simplicity, the open area percentage holds profound implications for the performance and application of woven wire mesh. Based on the area of the apertures (or openings) divided by the area of the mesh, this percentage can significantly affect the mesh’s functionality. An increased open area percentage means that a greater proportion of the mesh is composed of voids rather than wire, facilitating greater flow or passage.

When air, fluids, or even light must flow freely, this characteristic is particularly important. In filtration applications, for example, a higher open area allows for more efficient liquid or gas processing, thus reducing pressure drop and energy consumption. Additionally, a mesh with a high open area can provide effective shading while still allowing substantial light penetration in architectural designs that value natural light.

Thus, calculating the open area percentage becomes a crucial step in selecting woven wire mesh.Project leaders can align mesh characteristics with the specific requirements of their applications by precisely determining this value.

Whether optimising for filtration efficiency, ventilation capability, or light transmission, the open area percentage offers a quantifiable metric to guide the selection of woven wire mesh, ensuring that the final installation performs as intended, enhancing the aesthetics and utility of the project.

The open area percentage of woven wire mesh is crucial for applications that require precise filtration, airflow, or light penetration. A mesh’s open area percentage indicates how much space is available for material to pass through, directly affecting its functionality. Weaved wire mesh selection relies on the standard equation to calculate this percentage.

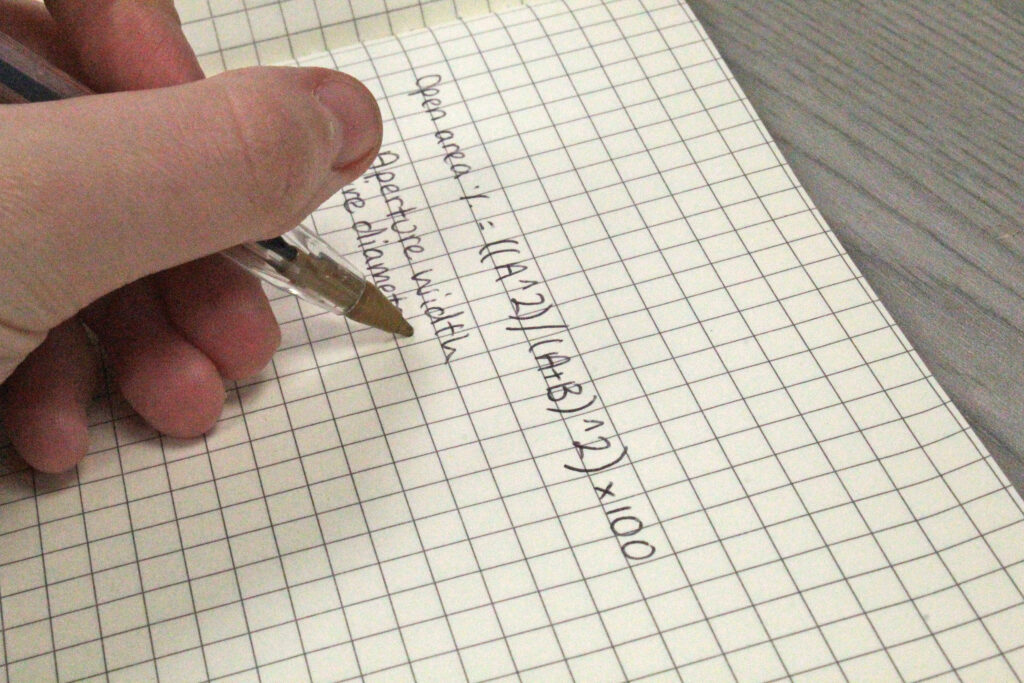

The open area percentage can be calculated using the following formula:

Open Area % = ((A^2) / (A + B)^2) × 100

Where:

This equation provides a way to quantitatively assess how much of the mesh area is open versus occupied by the wire itself.

Mesh openings are determined by this measurement. A precision tool like calipers can be used to measure the aperture width accurately. To get the most accurate reading, measure from the centre of one wire to the centre of the adjacent wire. To maintain accuracy, ensure that the same unit is used throughout the calculation, whether it is millimeters or inches.

Mesh wire thickness is measured with this device. To measure the diameter of the wire, precision tools such as calipers should be used. Mesh strength, flexibility, and open area percentage are all affected by wire diameter.

To calculate the open area percentage accurately, aperture width and wire diameter must be measured consistently. To avoid discrepancies in the final result, you must use the same unit consistently throughout the equation, whether it is millimeters, inches, or any other unit.

Calculating the open area percentage has practical implications across a wide range of applications. In filtration, a higher open area allows for greater fluid flow rate, reducing pressure drop across the mesh. Light diffusion and airflow can be influenced by the open area percentage in architectural applications.

When choosing woven wire mesh for specific applications, designers, engineers, and fabricators can use this equation to make informed decisions. A mesh selection can be tailored to meet the precise requirements of their project by accurately calculating the open area percentage.

To illustrate how to calculate the open area percentage, let’s apply the formula to three different woven wire mesh specifications. These examples will help elucidate the process and its implications for selecting the right mesh for various applications.

Open Area % = ((1^2) / (1 + 0.5)^2) × 100 = (1 / 2.25) × 100 ≈ 44.44%

Open Area % = ((2^2) / (2 + 1)^2) × 100 = (4 / 9) × 100 ≈ 44.44%

Open Area % = ((0.5^2) / (0.5 + 0.25)^2) × 100 = (0.25 / 0.5625) × 100 ≈ 44.44%

These examples reveal that despite the differences in aperture width and wire diameter, the open area percentage can be similar. This demonstrates the versatility of the formula and underscores the importance of considering both dimensions in mesh selection.

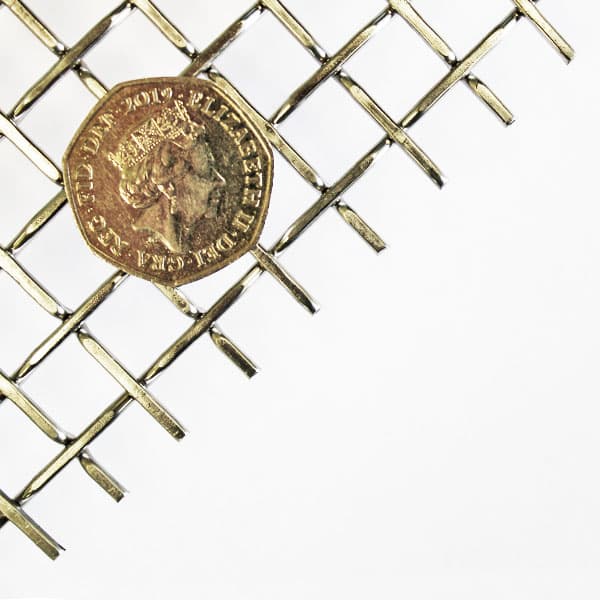

The images below show a mesh with 2 holes per linear inch and another with 200. Note the massive difference in hole size. Both are woven wire mesh. The same grade and the same pattern. One much finer than the other:

| Mesh Description | Aperture Width (mm) | Wire Diameter (mm) | Open Area % |

|---|---|---|---|

| 4.75mm Hole SS304 Mesh | 4.75 | 1.6 | 67.8% |

| 3mm Hole Heavy Duty Mesh | 3 | 1.2 | 64.1% |

| 2.47mm Hole Rodent Proof Mesh | 2.47 | 0.71 | 77.1% |

| 1.67mm Hole Coarse Mesh | 1.67 | 0.45 | 80.6% |

| 1.36mm Hole Woven Mesh | 1.36 | 0.45 | 76.1% |

| 0.87mm Hole Strainer Mesh | 0.87 | 0.4 | 72.6% |

| 0.70mm Hole Sieve Mesh | 0.70 | 0.35 | 71.4% |

| 0.223mm Hole Fine Wire Mesh | 0.223 | 0.14 | 75.2% |

| 0.154mm Hole Fine Mesh | 0.154 | 0.1 | 73.8% |

| 0.104mm Hole Screen Mesh | 0.104 | 0.05 | 80.4% |

| 0.043mm Hole Metal Wire Mesh Cloth | 0.043 | 0.035 | 57.3% |

| 0.034mm Hole Fine Mesh | 0.034 | 0.03 | 52.8% |

The calculations are based on the formula that is provided. Using the open area percentage you can gain a quantifiable understanding of how much of the mesh is void space, which is crucial for applications requiring careful control over how material passes through, such as filtration, ventilation, or light transmission, which require a precise control over material passage.

When selecting the optimal woven wire mesh for a specific application, the open area percentage is crucial. By applying the formula to various mesh sizes, we can determine the best mesh for flow rates, filtration efficiency, or light and air passage. Users can use this chart to guide them through the selection process by comparing the open area provided by different mesh specifications.

Consult with mesh suppliers and experts for accurate project planning and mesh selection, using precise calculations and considering the specific requirements of each application.

Please contact us if you have any questions regarding open area % of mesh, or anything for that matter. We are always really keen to assist in any way that we can.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explores how to build a chicken coop.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions