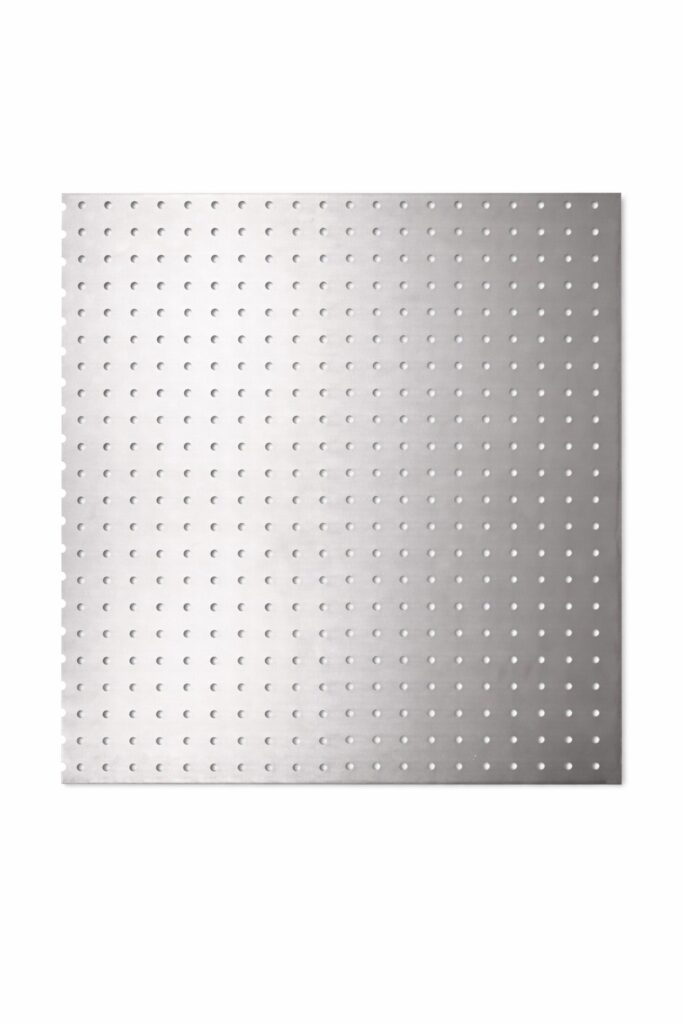

In the world of industrial design and manufacturing, versatility and reliability are paramount. Round hole mild steel perforated metal mesh is a testament to both.

From construction to architecture to automotive to agriculture, this material isn’t just a component, but a foundational element that shapes the efficiency and effectiveness of countless applications. Our company’s diverse range of round hole mild steel perforated mesh sheets is crafted to meet the varied needs of these industries with precision.

We offer specifications that bridge the gap between robustness and functionality. No matter whether the task at hand involves filtration, ventilation, structural support, or aesthetic enhancement, we have the exact specifications to meet the needs of the project in our catalog.

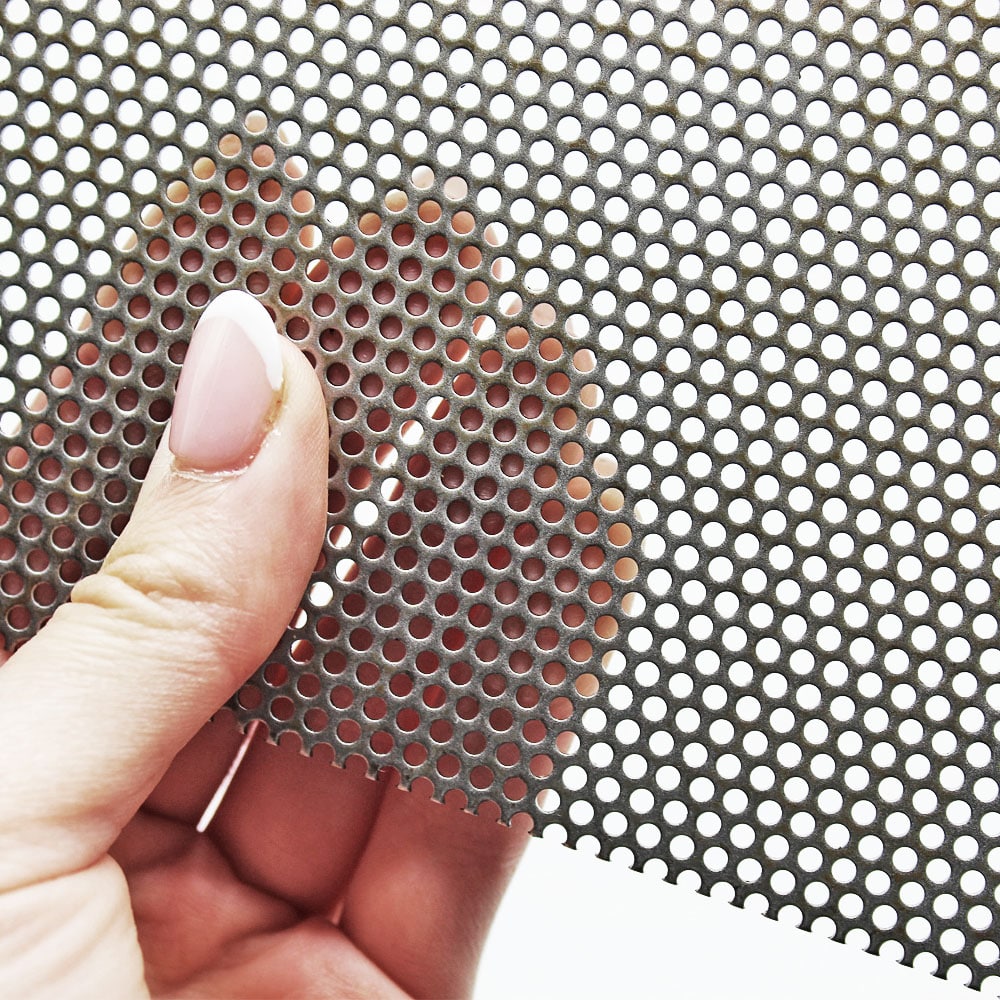

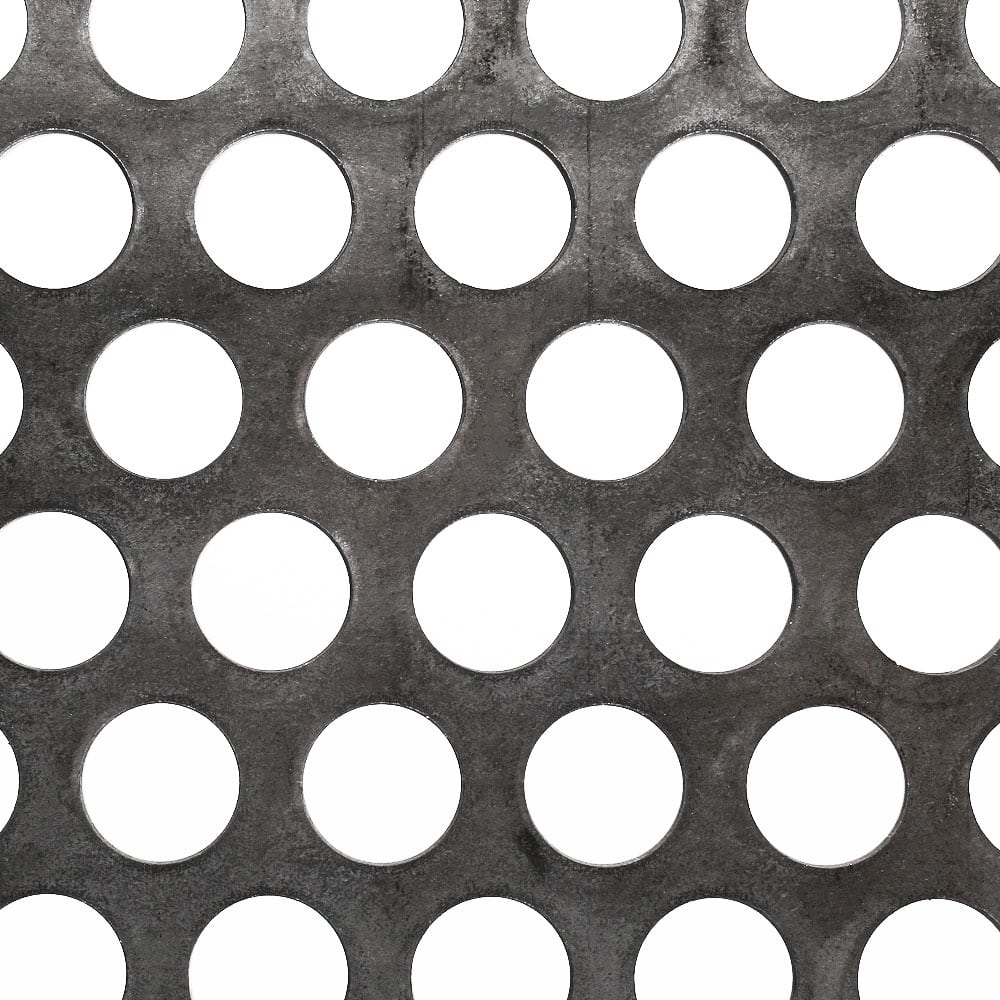

Our 3mm round hole mesh is as suitable for decorative applications as our 20mm variant is for heavy-duty industrial uses. With a vast assortment of pitches and thicknesses, our selection is engineered to deliver performance and adaptability.

This guide will navigate through the maze of options, helping you pinpoint the ideal mesh for your venture, backed by our assurance of quality and durability.

Let’s get into it…

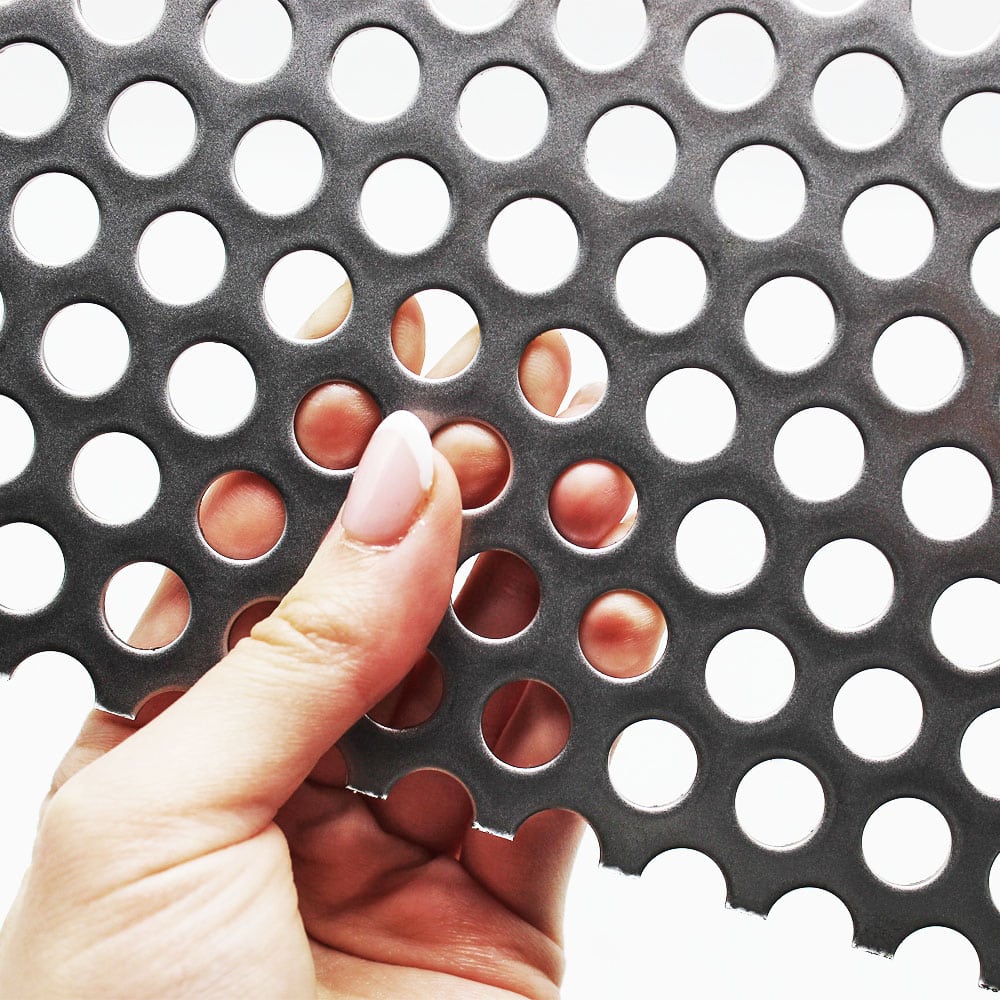

The outstanding characteristics of mild steel make it an ideal material for perforated mesh because it can be used in an array of applications. Its exceptional malleability is one of mild steel’s greatest advantages. As a result of this fundamental property, it can be shaped and customized with a high degree of precision without compromising its integrity. Because it is so pliable, it retains its overall strength and form when punctured to create the round holes characteristic of perforated mesh, making it ideal for structural and cosmetic applications.

Another inherent benefit of mild steel is its strength-to-weight ratio. Although it is relatively lightweight, it is extremely strong and durable, capable of withstanding considerable stresses before bending or breaking. As a result, it is suitable for applications that require support and endurance, such as barriers, guards, and large-scale architectural installations.

Another important factor is cost efficiency. Compared to many other metals, mild steel is more affordable without sacrificing quality or performance, making it a popular choice for large-scale projects and applications with limited budgets. When scaled to larger projects or larger production runs, mild steel’s economic advantage becomes even more apparent.

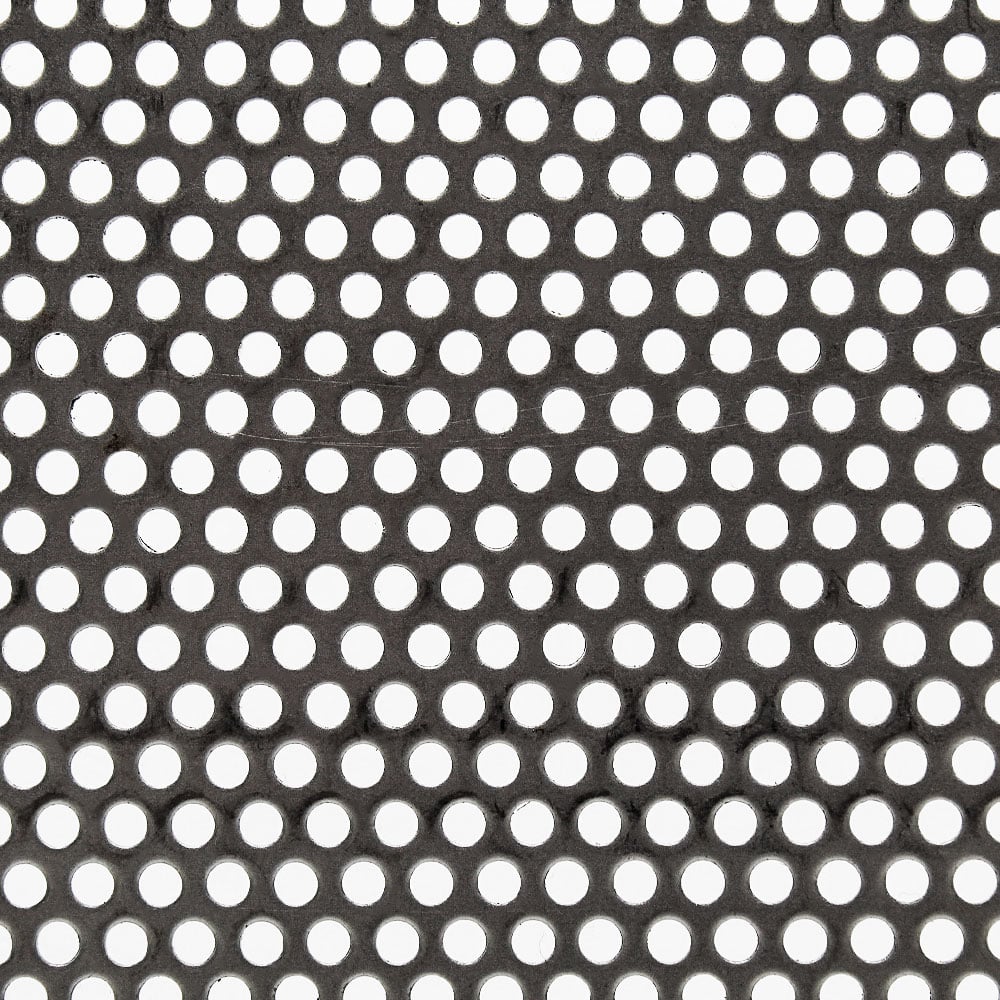

Finally, round hole perforations offer a unique combination of aesthetics and functionality. This pattern not only looks pleasing to the eye, but also provides consistent and reliable performance in terms of airflow, filtration, and light passage. As a result, round holes are easy to align and install, simplifying the construction process and allowing for seamless integration into a variety of applications, from industrial machinery to decorative building facades.

In the following section, we’ll dissect the specifics of a selection of our standard round-hole mild steel perforated mesh specifications to illustrate how these benefits translate into real-world applications, ensuring that you make an informed choice for your project’s requirements.

The round-hole mild steel perforated mesh range we offer is comprehensive, with each specification tailored to fulfill distinct requirements across a multitude of industries. Understanding the inherent traits of each variety aids in discerning which is the optimal choice for a specific application.

Here, we provide a deeper insight into our extensive selection, correlating each specification with its standard applications:

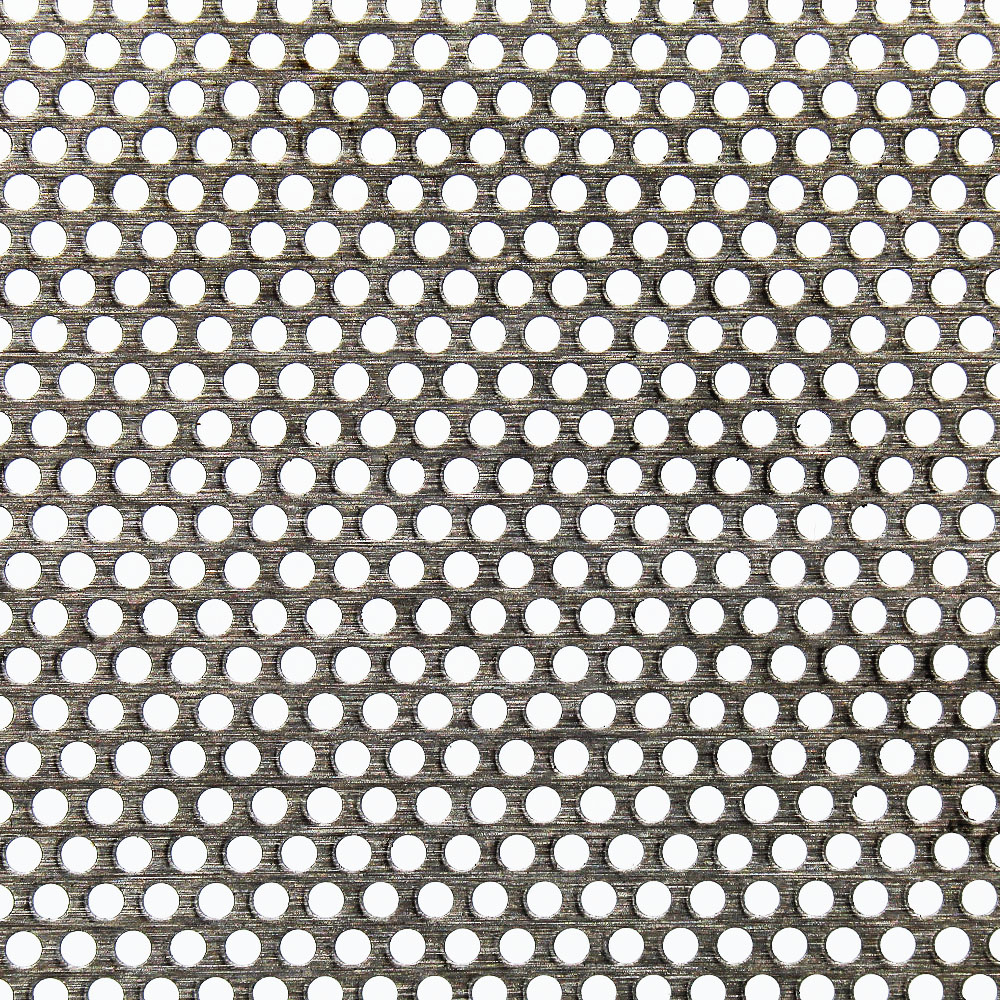

Providing excellent light filtration while maintaining material integrity, this specification has a well-balanced open area. As a furniture material, it is ideal for applications requiring both aesthetics and durability. Lampshades and radiator covers can benefit from this mesh because it allows light and air to pass through while providing a stylish, modern look.

Designed for heavy-duty applications, this specification is robust. This material is ideal for creating safe, durable walkways or platforms in construction and industrial settings. Additionally, it provides reliable protection when used as machinery guards, creating a sturdy barrier that does not restrict airflow or light, keeping the working environment well-ventilated and bright.

In sectors such as automotive manufacturing and electronics, where consistent ventilation is essential, this mesh provides the ideal balance between open spaces and material strength. A popular choice for architectural features, this perforation size has an appealing pattern that can enhance facades, claddings, or balustrades.

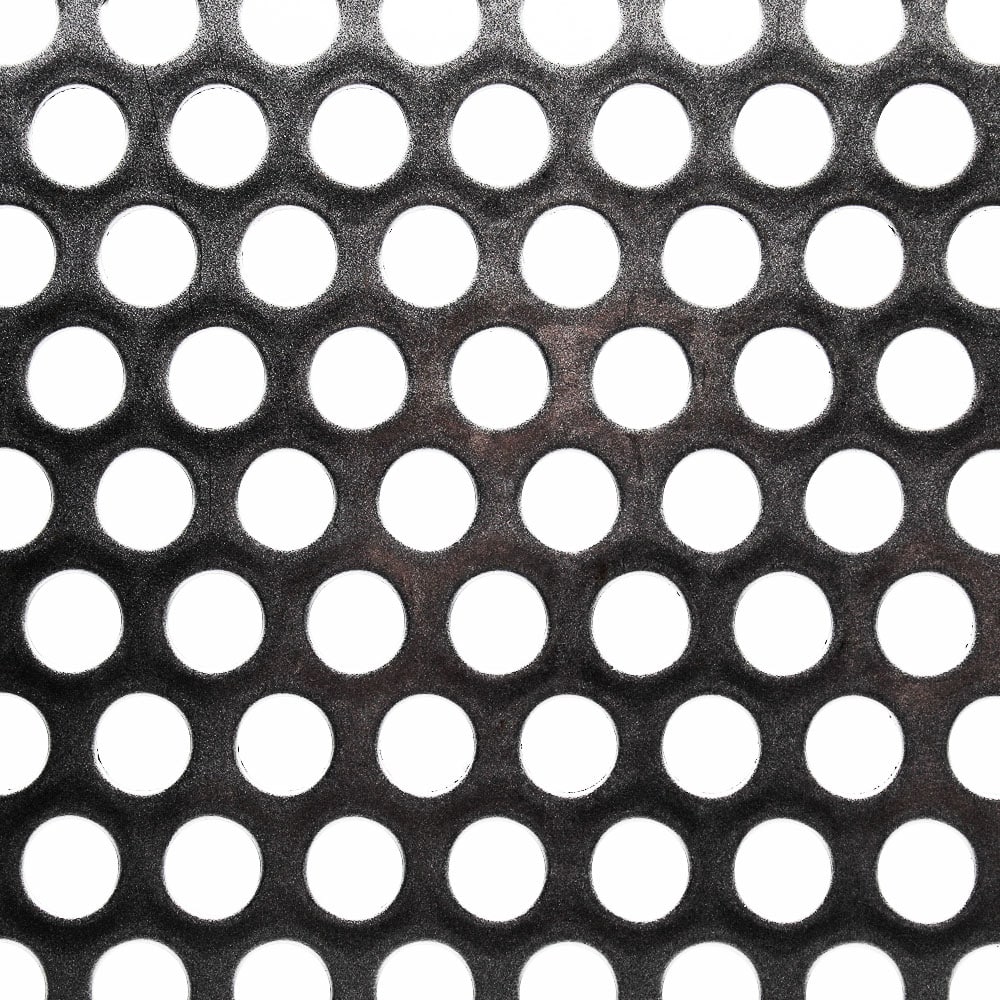

This mesh is ideal for applications requiring larger pass-through areas without compromising the mesh’s structural strength. In recycling centres or agricultural settings, where larger debris needs to be separated from finer materials, it is ideal for material sorting.

This specification finds its niche in precision-based applications. Acoustical panels, for instance, benefit from the high open area to metal ratio, which aids in sound management without hindering acoustic integrity. It’s also suitable for technical applications in the audio equipment industry, where sound permeability is paramount.

Mesh such as this excels in intricate filtration and separation processes, particularly in pharmaceutical, chemical, and food and beverage industries. As a result of its fine perforations, it allows for precise separation of materials, which is crucial to ensuring the quality and purity of the final product.

This medium-sized perforation can be used in a variety of applications, including outdoor furniture, custom car grilles, and safety barriers. As a result, it provides a substantial protective surface while allowing material to pass through.

Decorative and functional, this size can be used on building facades to create a modern look that regulates sunlight and airflow. Due to its durability and airflow properties, it is also suitable for HVAC systems and filters.

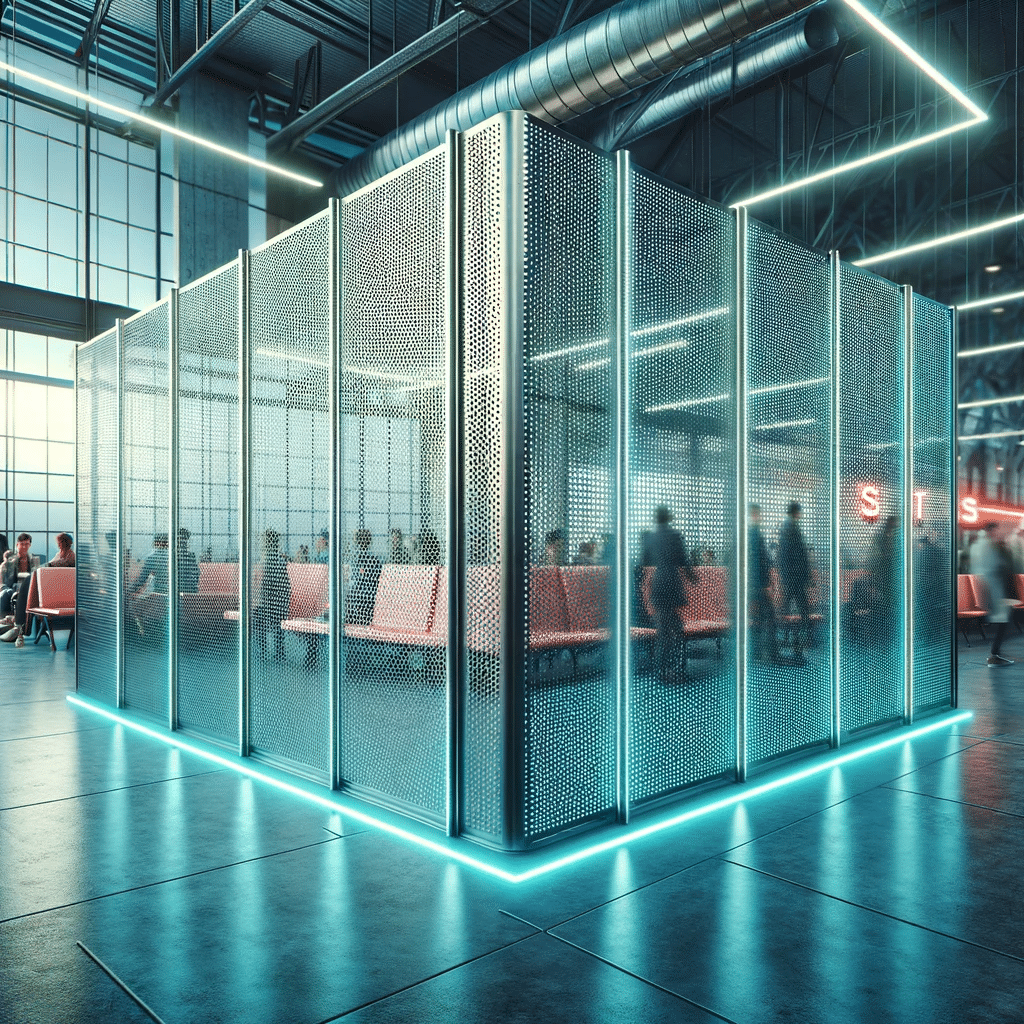

This variant is versatile and can serve in both industrial and artistic capacities. It’s an excellent choice for interior design elements, such as partition screens, that require a blend of privacy and open space. It’s equally functional in engineering applications where material ventilation and particle sizing are necessary.

This specification can handle significant structural demands for more substantial applications. Large perforations can be used for aesthetic purposes in architectural applications, as well as for particle separation in industrial settings.

In architectural designs and in the manufacture of electronics, where controlled air passage is necessary to maintain device temperature without allowing dust and debris in, this mesh is particularly useful due to its precise perforation.

The longevity and performance of perforated metal mesh are highly dependent on proper installation and maintenance. To prevent wear, make sure the mesh is securely fixed in place during installation. It’s essential to use the correct fixtures for the type of substrate it’s being attached to. Maintaining the appearance and integrity of the mesh requires regular cleaning with non-corrosive cleaners. Be gentle to avoid denting the material.

Consider thermal expansion rates and environmental factors when integrating mesh with other materials.

Perforated metal mesh will continue to perform flawlessly for years to come with the right care.

Choosing the right round hole mild steel perforated metal mesh specification is crucial to the success of any project. For the application it is designed for, it ensures efficiency, aesthetic value, and structural integrity. There is a solution for every challenge with our extensive range of options and customisation possibilities. Feel free to contact our team if you need further assistance or expert guidance through our full range of mesh options.

If you’re ready to elevate your project with the highest quality mild steel perforated metal mesh, contact us today. Request samples, ask for additional information, or place your order now.

We’re committed to providing outstanding quality and exceptional customer service, and we’re looking forward to working with you to fulfill all your project needs.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog COMPARING MESH MATERIALS: ALUMINIUM VS. STEEL PERFORATED SCREENS. This article aims to provide all the help that you might need to decide between these two highly popular metals.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.