304 stainless steel is renowned for its corrosion resistance, making it a material of choice in a myriad applications where both strength and longevity are critical.

This includes the manufacture of various forms of mesh, such as woven wire, welded, and perforated metal mesh, which serve countless industries from architecture to food processing.

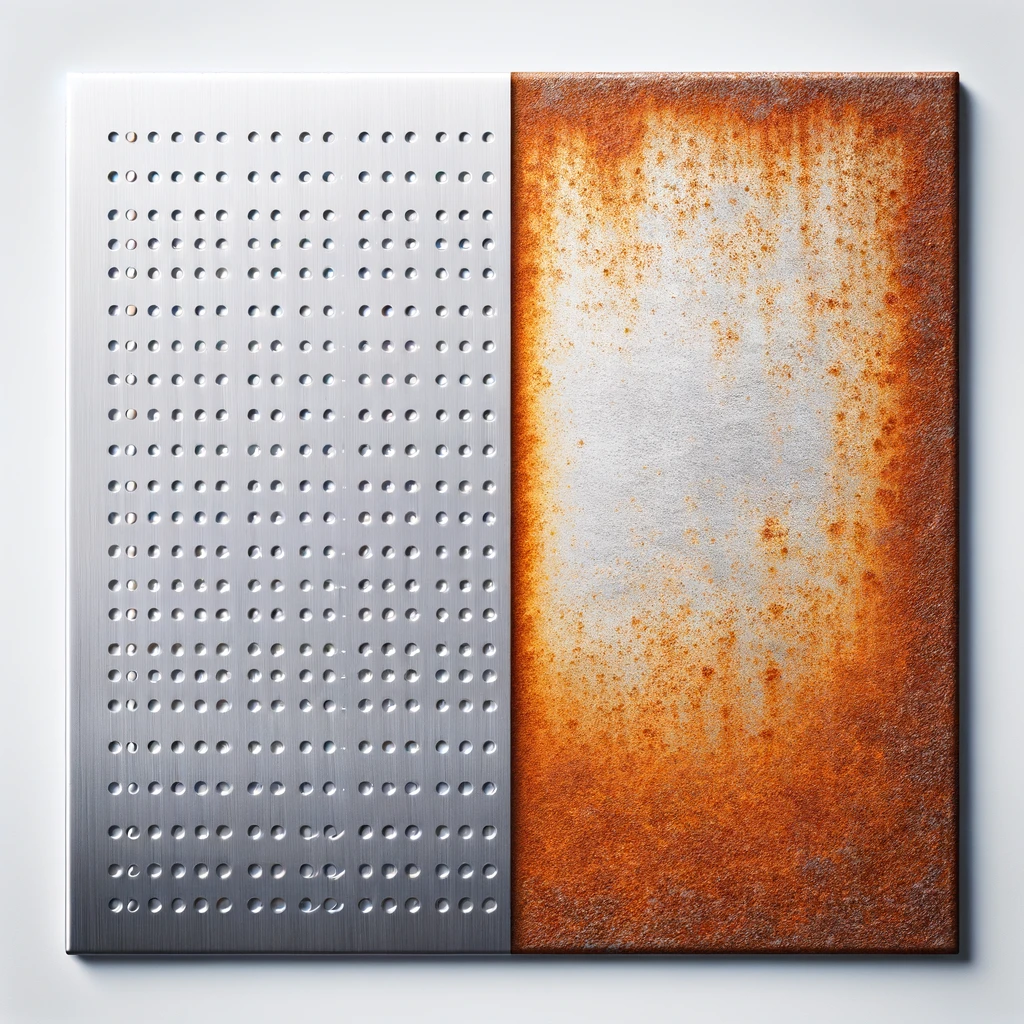

No material is completely impervious to corrosion, even 304 stainless steel, which is often considered virtually rustproof.

Users who rely on 304 stainless steel’s durability in challenging environments are concerned about its corrosion resistance, particularly in mesh form. Each setting demands a thorough understanding of how this material will perform over time, whether it is the harsh saline atmosphere of coastal regions, the acidic conditions of industrial processes, or the varying temperatures of outdoor applications.

We will examine 304 stainless steel’s resistance to rust in this comprehensive analysis. It will provide valuable insight into the material’s true rust-resistance by examining how it behaves in various forms of mesh under various environmental conditions. It is crucial to understand these considerations when selecting stainless steel mesh for a specific application.

Let’s get into it…

Composition and Properties

304 stainless steel, an alloy composed primarily of iron, 18% chromium, and 8% nickel, is designed to offer a high level of corrosion resistance.

A protective layer of chromium oxide forms on the surface of steel when chromium reacts with oxygen. In spite of its thinness, this passive layer effectively protects the underlying metal from further corrosion and oxidation.

By adding nickel to the alloy, the corrosion resistance, formability, and strength are enhanced, as well as the susceptibility to stress-corrosion cracking is reduced. Manganese and silicon may also be present in smaller amounts in the alloy, which contributes to its overall structural integrity and resistance to corrosion.

Mechanism of Corrosion Resistance

When chromium is exposed to oxygen in the air or water, the chromium oxide layer forms spontaneously, enhancing corrosion resistance of 304 stainless steel. As long as there is sufficient oxygen available for the chromium to react with, this passive film will quickly reform if damaged or removed.

Certain conditions, however, can compromise the effectiveness of this passive layer in providing rust resistance. Rust can develop as a result of factors such as low oxygen environments, exposure to certain chemicals, or high salinity. Additionally, the alloy’s composition can be tailored to suit specific environments, enhancing its resilience where standard stainless steel might not.

In the following sections, we will examine how the properties of 304 stainless steel play out in the production and use of woven wire, welded, and perforated metal mesh, along with the steps necessary to maximise the corrosion resistance and lifetime of these materials.

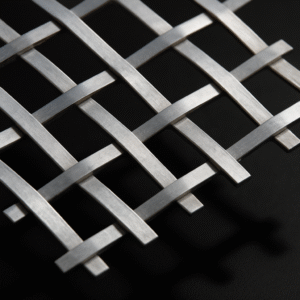

Manufacturing Process of Woven Wire Mesh

304 stainless steel woven wire mesh is produced by procuring high-quality, corrosion-resistant wire. Work-hardening can enhance the strength of this wire as it is drawn to the required diameter. The drawing process also helps in shaping the wire to the desired thinness without compromising the inherent rust-resistant properties of the alloy.

A meticulous weave is performed on industrial looms after the wire has been prepared. For standard meshes, warp and weft wires are interlaced in plain weave, while twill weave is used for denser meshes. Precision engineering ensures a consistent, tight, and uniform mesh that maintains structural integrity while providing excellent filtration.

Vulnerabilities to Rust

304 stainless steel woven wire mesh can encounter situations where rust can occur despite its inherent corrosion resistance. Due to salt’s corrosive properties, areas with high salinity, such as coastal regions, are challenging. Rust is also more likely to occur in environments that are acidic or alkaline or have low oxygen levels, which are critical for maintaining the passive oxide layer.

Mechanical damage can compromise the rust resistance of woven wire mesh, allowing the protective chromium oxide layer to be breached, and contact with iron particles, which can cause contamination and subsequent rusting.

Case Studies

Weaved wire mesh made of stainless steel 304 has been demonstrated to be resilient and to be vulnerable in numerous case studies. The consistent exposure to acidic solutions caused localised corrosion of mesh used as a filtration medium in an industrial setting. Over time, however, proper maintenance and routine cleaning preserved the mesh’s integrity.

The same type of mesh faced challenges in architectural applications for façade screens in a coastal project. To ensure the mesh’s longevity and aesthetic appeal, additional protective coatings were applied to prevent rust formation due to the high salinity in the atmosphere.

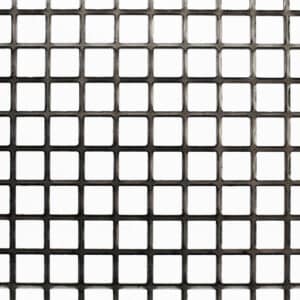

Welded Mesh Production

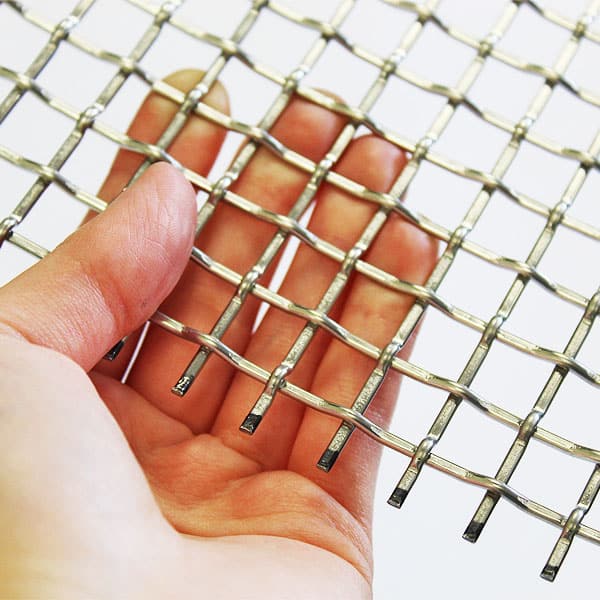

The intersections of 304 stainless steel wires are welded together to form welded mesh by laying them out in a grid pattern. By using electric resistance welding, the wire junctions are heated to the point of melting and fusing together by an electric current.

Impact of Welding on Corrosion

Welding can alter the microstructure of 304 stainless steel at the weld points, affecting its corrosion resistance. The intense heat can cause the chromium oxide layer to degrade, allowing rust to develop, a process known as weld decay or intergranular corrosion. Post-welding annealing is crucial for restoring corrosion resistance by allowing a new passive layer to form on the mesh.

Protective Measures

There are several measures that can be taken to mitigate these vulnerabilities. In post-weld annealing, the mesh is heated to a high temperature and then cooled, allowing the chromium oxide layer to reform. Powder coatings, for example, can provide a barrier against corrosive elements. High alloyed stainless steel grades, such as 316, with molybdenum added, may provide additional corrosion resistance, especially in harsh environments.

While 304 stainless steel is inherently corrosion-resistant, the manufacturing processes of woven and welded mesh may introduce factors that compromise this property. A thorough understanding of these processes, environmental factors, and the necessary protective measures is crucial to ensuring the longevity and effectiveness of 304 stainless steel mesh.

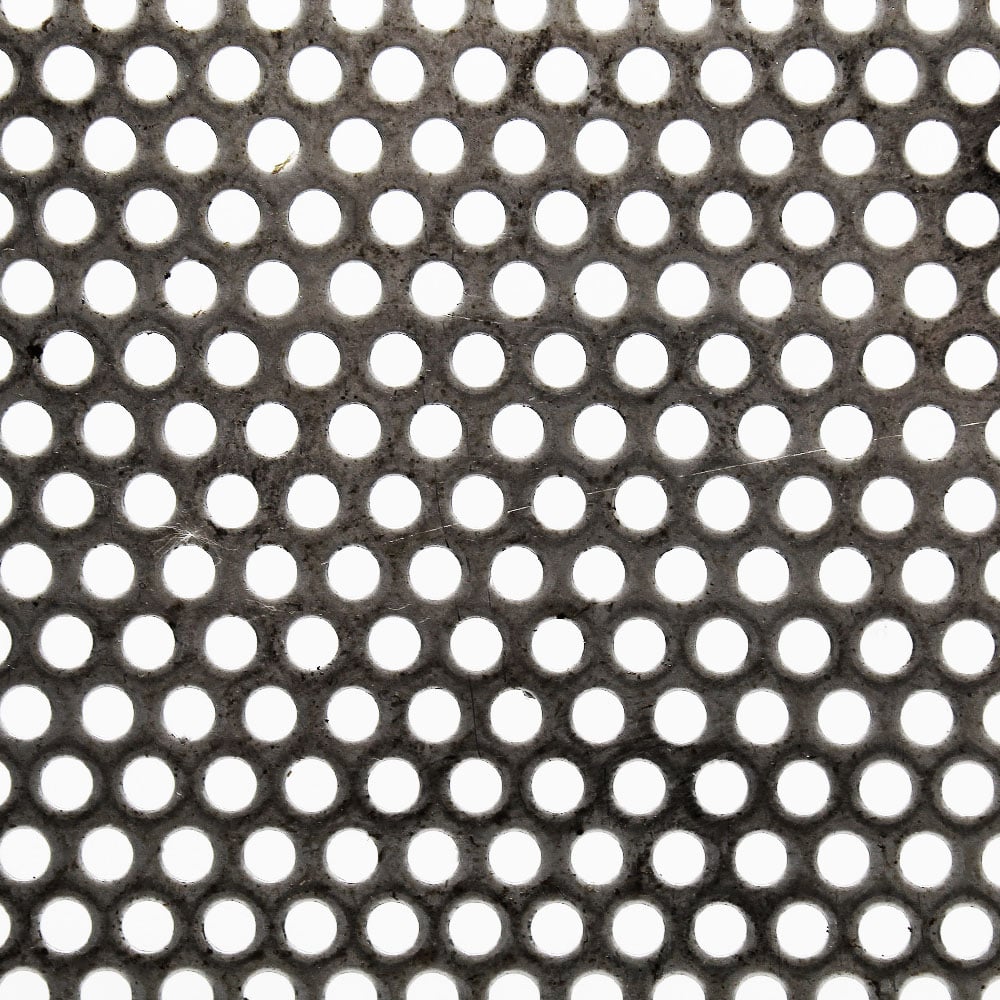

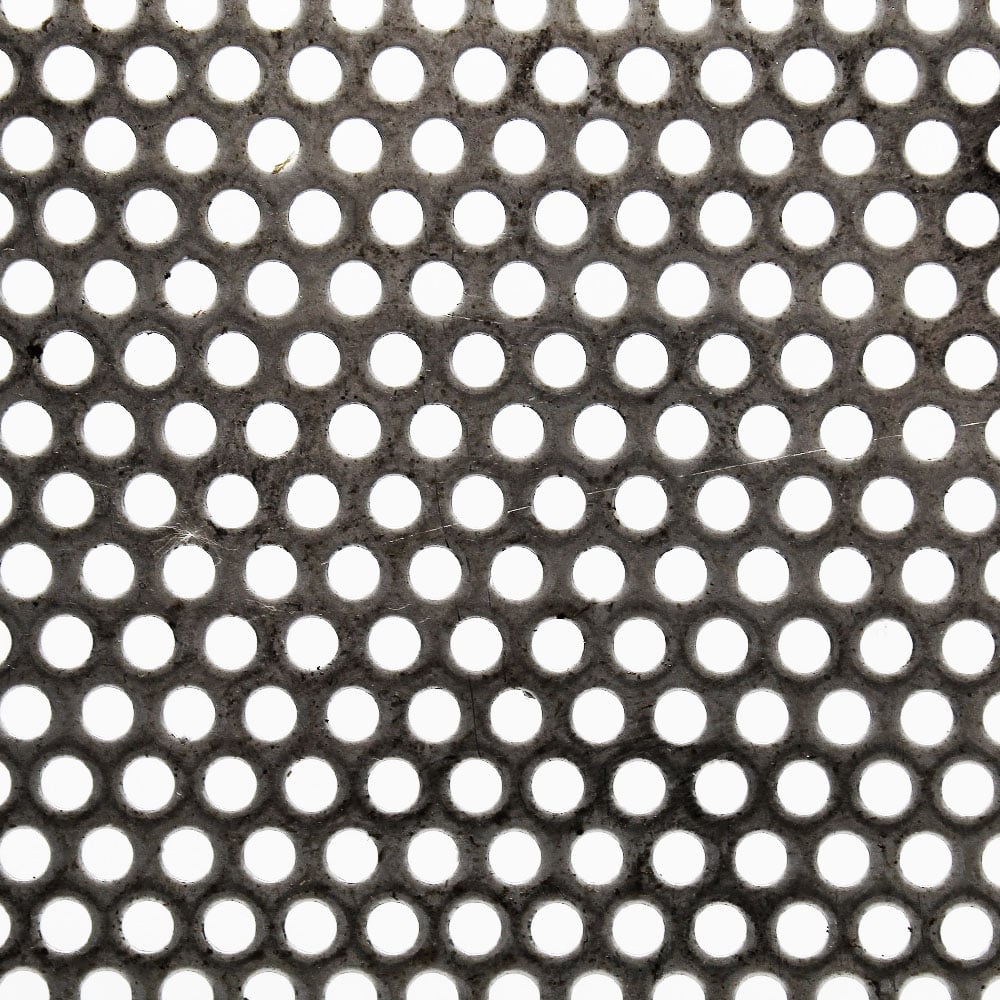

The production of perforated metal mesh from 304 stainless steel involves stamping or punching holes through a flat sheet of the metal, a process that inherently changes the dynamics of the material’s corrosion resistance.

Perforation Process

The protective oxide layer of stainless steel can be compromised during perforation. During punching, new surfaces are exposed to the environment, which may not have the same level of oxide layer formation as the original surface. When perforation causes significant heat or mechanical stress, “drill smear” can occur – a thin layer of deformed material around the holes that traps contaminants and interferes with the passive layer’s ability to reform.

Environmental Factors

Rust resistance of perforated mesh depends on the environment in which it is used. The risk of pitting and crevice corrosion increases significantly in marine or chloride-rich environments. Stainless steel can be aggressively attacked by industrial pollutants, such as sulfur compounds that can cause sulfuric acid to form on the surface.

Preservation Strategies

To mitigate these risks and extend the service life of 304 stainless steel perforated metal mesh, several preservation strategies can be employed:

304 stainless steel’s rust resistance across woven wire, welded, and perforated mesh forms reveals a complex interplay between material properties, manufacturing processes, environmental exposures, and maintenance practices. Although 304 stainless steel is known for its corrosion resistance, there are scenarios where it can’t handle rust.

Choosing the right mesh for a project requires understanding these nuances. Keeping stainless steel mesh in good shape over time requires considering environmental factors and doing proper maintenance. This will make the mesh last longer and perform better.

When it comes to 304 stainless steel mesh, it’s advisable to engage industry experts who can provide personalised recommendations based on specific project requirements. By making informed choices, you can make sure that the mesh will last for years, maintaining its functionality and aesthetic appeal.

We are here to help. Contact us if you have any questions about stainless steel mesh, or indeed any mesh question that you may have for us. We are always happy to help.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

You may be interested in our blog that explore round hole vs square hole perforated metal mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers.

The largest range of wire mesh, chicken wire, wire fencing, woven wire mesh and perforated metal products in Europe, delivered direct from our Warrington warehouse.

Website by: Beech Web Services | Terms and Conditions | Cookie Policy | Privacy Policy | Website Terms and Conditions