Welded wire mesh is a type of metal mesh that is used for a variety of applications in multiple industries.

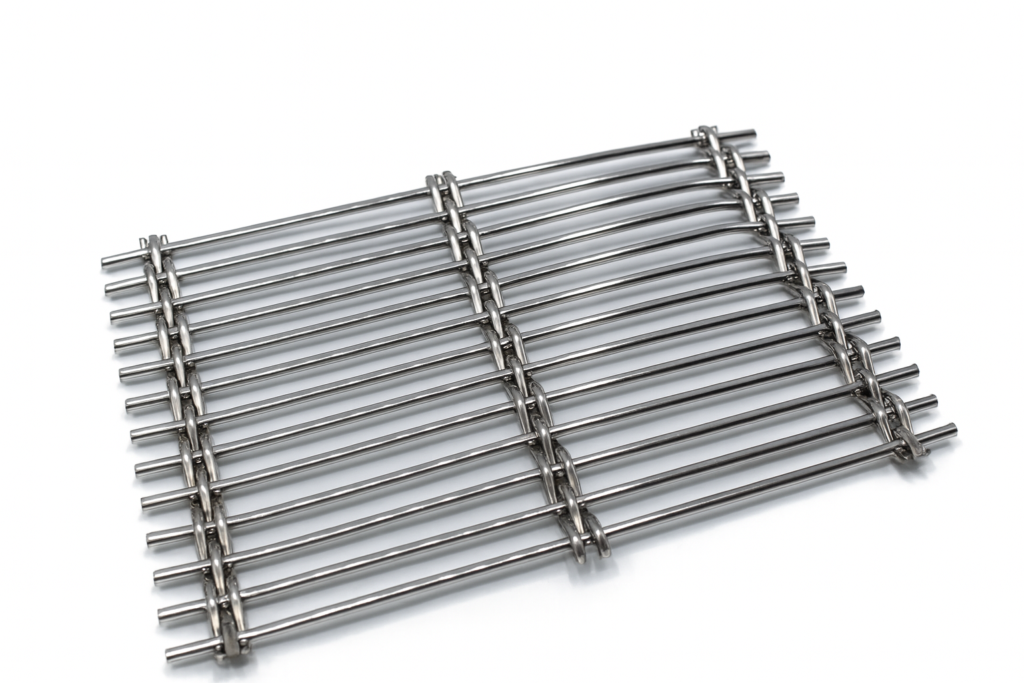

It is made up of cross-sectioned wires that are welded together at each intersection to form a strong, durable material. This versatile material can be used in a variety of ways and is sought after for its strength and reliability.

This article aims to better explain this popular material.

Let’s get into it….

Welded wire mesh is strong, durable, and can be used for multitudinous industrial and domestic applications. Commonly found in construction, farming, manufacturing, and other industrial settings, the material can be used to build enclosures, cages, fences, barriers, shelves, benches, grates and so much more. Our range is many roll size options, so it is easy to find one that will suit your requirements.

In the home it can be used to secure windows or doors as part of an anti-theft system or as part of an anti-intrusion system on commercial buildings. It’s also great for reinforcing walls or floors in buildings or homes since it adds structural stability while still allowing air circulation through the mesh. The mesh can also be used as a decorative element in outdoor or indoor areas; it looks great when installed around flower beds or garden paths!

A couple of years ago, we used 1/2″ welded mesh as the underground fox prevention in our trial chicken coop “Cluckingham Palace”.

We also used 1/2 x 1″ for the entrance to the coop. This has proven to work perfectly.

Installing a welded mesh fence involves several steps, including planning, preparation, and installation. Here are the general steps you can follow to install a welded mesh fence:

Planning: Start by determining the location and layout of your fence. Consider factors such as property lines, terrain, and any obstacles that may affect the installation.

Materials: Purchase the necessary materials, including welded mesh rolls, fence posts, cement, brackets, screws, and tensioning wire.

Preparation: Before you begin the installation, prepare the area by removing any obstacles, levelling the ground, and marking the fence line. Dig post holes at regular intervals along the fence line, making sure they are deep enough to support the height of the fence.

Installation: Begin by installing the corner and end posts first, using cement to secure them in place. Attach the panels to the posts using brackets and screws, ensuring that they are level and secure. Continue installing the remaining posts and panels until the fence is complete.

Finishing: Once the fence is installed, add any necessary finishing touches, such as post caps or a gate. Also, make sure to clean up the area and remove any excess materials or debris.

We will add a more detailed article on this process in the near future.

In the meantime you may be interested in our guide to building a chicken coop.

There are several common types of welded mesh, each of which has different characteristics and applications. Here are some of the most popular:

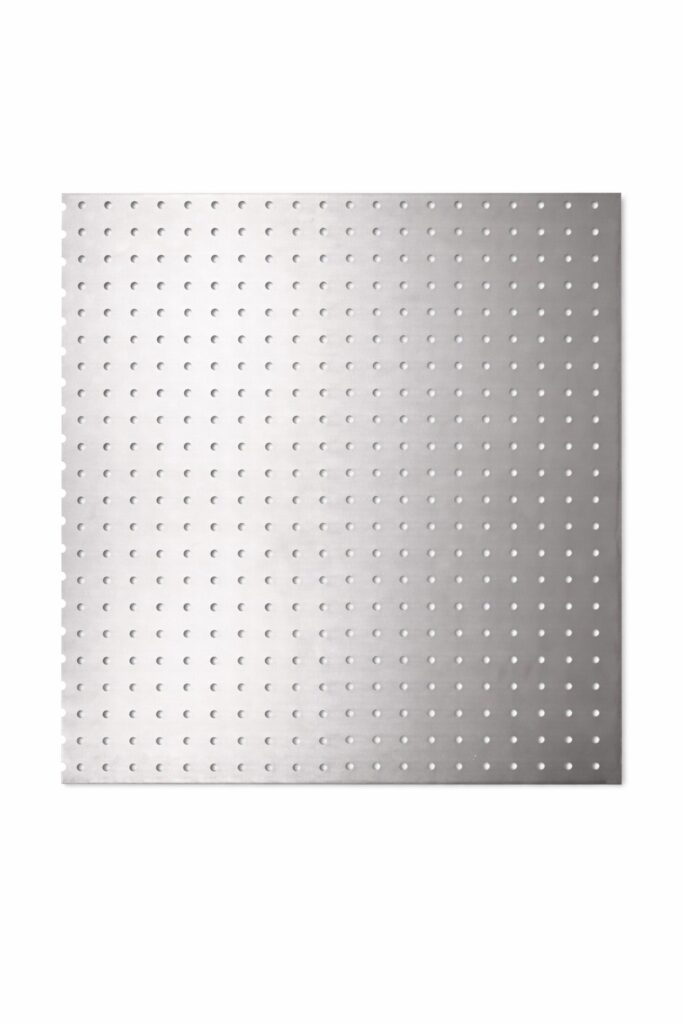

Square mesh: Square mesh is a type of welded mesh that has evenly spaced wires that intersect at right angles. It is commonly used in fencing, construction, and industrial applications. Square weld mesh is by far the most common type of mesh on the market.

Rectangular mesh: Rectangular mesh is similar to square mesh, but the wires are spaced farther apart in one direction than the other. This makes it ideal for applications where greater strength is needed in one direction, such as reinforcement in concrete structures.

Wire mesh panels: Wire mesh panels are pre-fabricated panels of welded mesh that are used for a wide range of applications, including fencing, machine guards, and decorative screens.

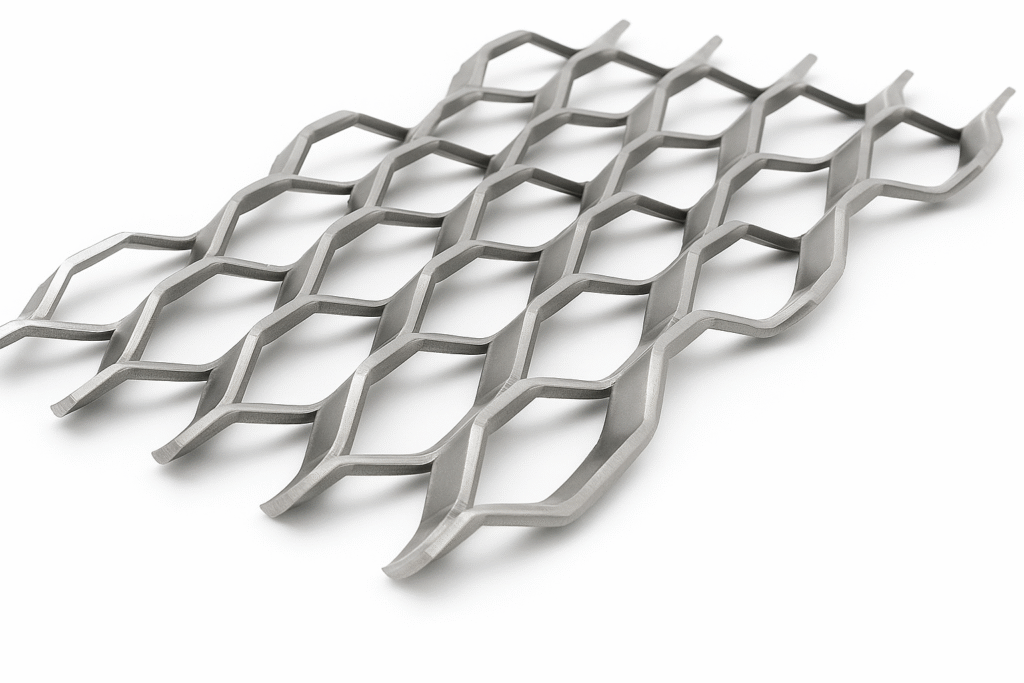

Welded wire fabric: Welded wire fabric is a type of welded mesh that is used as reinforcement in concrete structures, such as slabs and walls. It is made of high-strength steel wire and is available in a variety of sizes and configurations.

PVC coated mesh: PVC coated mesh is a type of welded mesh that has a layer of PVC coating over the wires. This provides additional protection against corrosion and weathering, making it ideal for outdoor applications.

Stainless steel mesh: Stainless steel mesh is a type of welded mesh that is made from high-quality stainless steel wire. It is corrosion-resistant and is used in applications where hygiene and durability are important, such as in the food industry and medical settings.

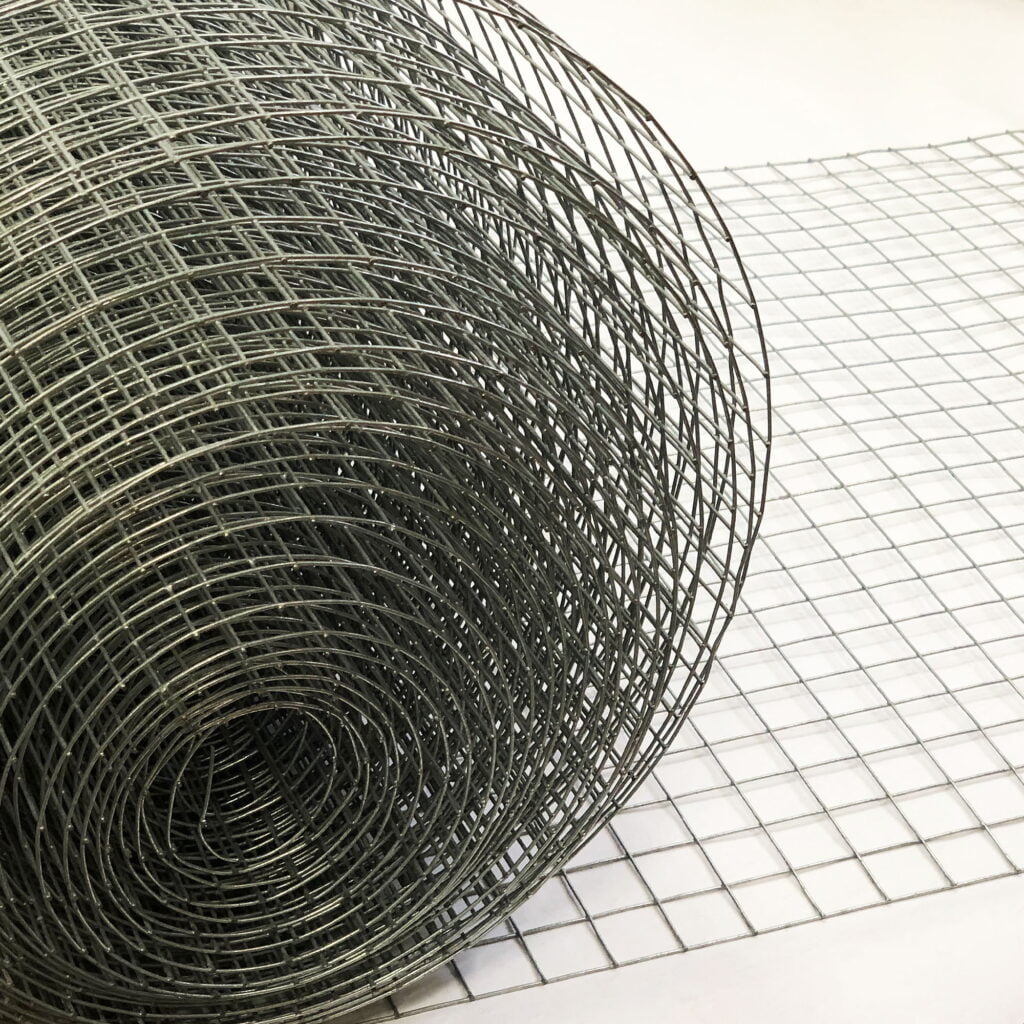

The image above shows a 13mm welded wire mesh and a 13mm chicken wire mesh side-by-side.

Here are some simple comparisons between the two:

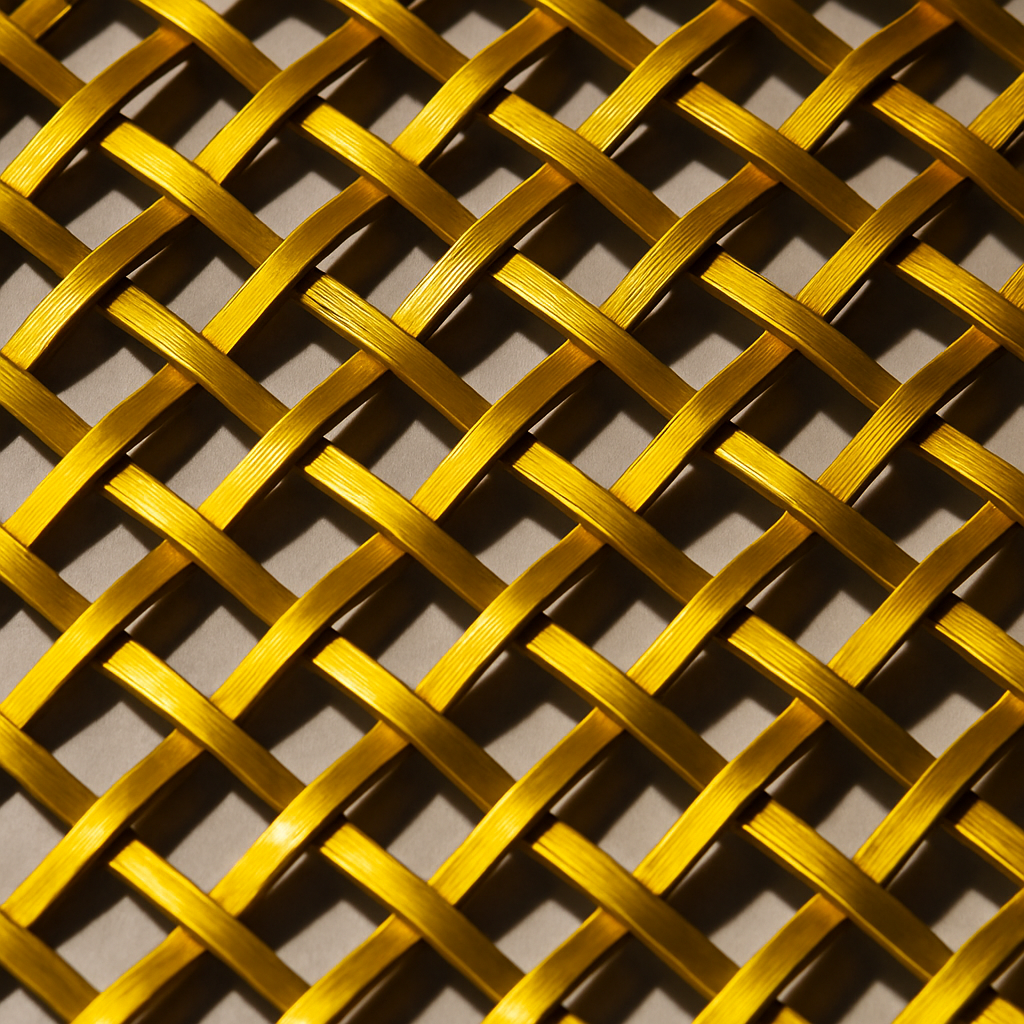

Strength: Welded mesh is generally stronger and more durable than chicken mesh. Welded mesh is made by welding the wire intersections, which creates a strong bond and prevents the wires from moving independently. Chicken mesh, on the other hand, is made by weaving the wires together, which can make it less strong and prone to unravelling.

Mesh size: Welded mesh is available in a wide range of mesh sizes, including larger sizes that are not available in chicken mesh. This makes welded mesh better suited for applications where larger openings are needed, such as in fencing or industrial applications.

Wire thickness: Welded mesh is available in a variety of wire thicknesses, which can provide greater strength and durability. Chicken mesh is typically only available in thinner wire gauges, which makes it less durable in applications where greater strength is required.

Price: Chicken mesh is generally less expensive than welded mesh, which makes it a more cost-effective option for certain applications.

Both are super popular mesh options. In terms of wire mesh, chicken wire is most commonly used overall perhaps, but it is closely followed by welded.

There are many benefits associated with using welded wire mesh over other materials like wood or plastic. One major advantage is its strength; due to the welding process during production, welded wire mesh is incredibly strong compared to other options on the market. This makes it ideal for any application where strength and durability are paramount requirements such as security fencing or flooring reinforcement in large buildings.

Additionally, welded wire mesh tends to have excellent corrosion resistance, which makes it perfect for outdoor use without having to worry about rusting over time Welded mesh is most commonly available in metals that perform well outdoors, to rusting is not normally an issue.

Overall, welded wire mesh offers an array of uses across several industries including construction and manufacturing but can also be used commercially as well. If you’re looking for something strong and reliable that will last you years down the road then this might just be what you need! With its strength and durability plus excellent corrosion resistance capabilities combined with its ease of installation and maintenance; welded wire mesh really is a useful material for so many projects.

Well, that about covers it. As always, thank you for checking out our blog. We hope that this helps you with your project.

If you do want to learn more about chicken wire then check out our other articles on the subject. We have written in detail on galvanised chicken wire and how to build a chicken coop. Both are very useful reads if you are planning on investing in some wire fencing.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.