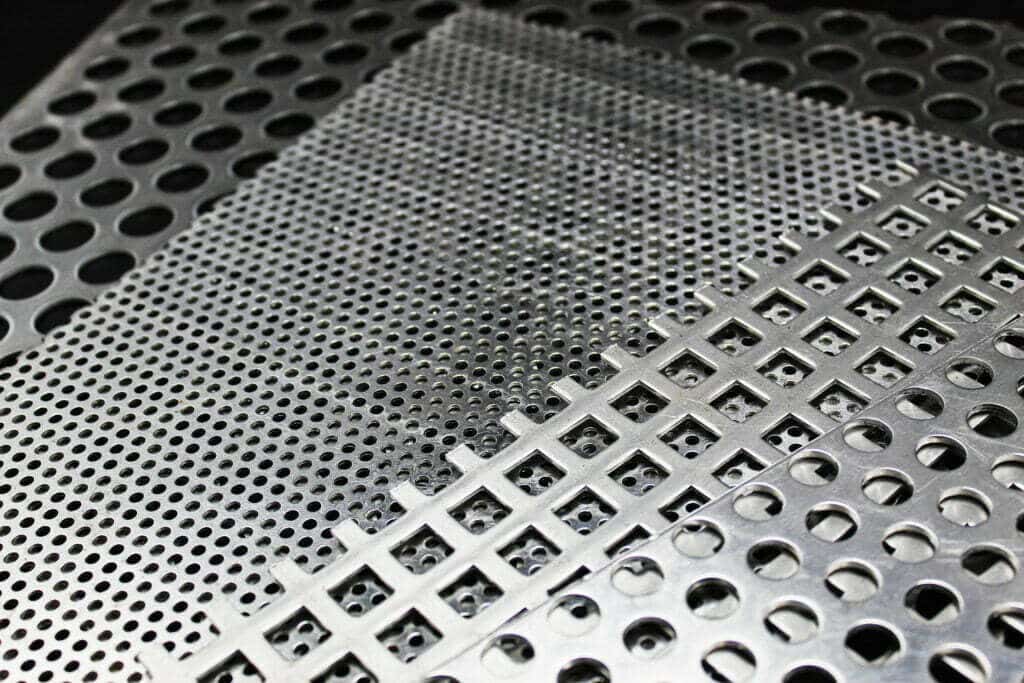

Metal can be perforated with a variety of shapes and patterns, including squares, circles, slots, and rectangles. The process can be used with a variety of materials, including steel, aluminium, stainless steel, and brass.

This guide focuses on aluminium perforated metal sheet. We carry large stocks of this wonderfully useful material in round and square-hole options.

But how is it made? What is it used for? How strong is it?

We will answer these questions and more in this helpful guide. First of all, we will answer the immediate question that you may have…

Aluminium perforated sheet metal is a type of sheet metal that has been punched or stamped with a pattern of holes or other shapes.

The perforations can be in a wide variety of shapes and sizes, depending on the desired functionality and aesthetic appearance. Perforated aluminium sheet metal is commonly used in architectural applications such as building facades, as well as in industrial applications such as ventilation systems, acoustic panels, and filtration devices. It is valued for its lightweight, corrosion-resistant properties and ability to be formed into a variety of shapes and sizes.

Aluminium perforated metal sheet is produced by a process called punching or perforation. The process involves the following steps:

The punching process can be performed using a variety of techniques, including mechanical punching, laser cutting, and water jet cutting, depending on the specific requirements and capabilities of the manufacturer. The resulting perforated aluminium sheet can be used in a wide range of applications, such as architectural facades, acoustic panels, filtration systems, and more.

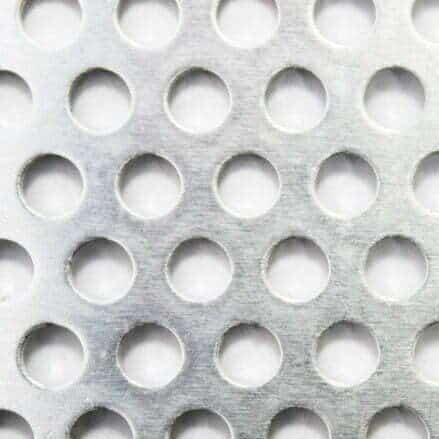

The most common perforated mesh shape is the round hole pattern. This is because round holes offer a good balance between open area and strength, making them suitable for a wide range of applications. Round hole perforated mesh can be used for filtration, ventilation, decorative purposes, and more. Other common perforated mesh shapes include square, rectangular, and slotted patterns. The choice of shape depends on the specific application and the desired aesthetic appearance.

Our best-selling option has a 3mm round hole.

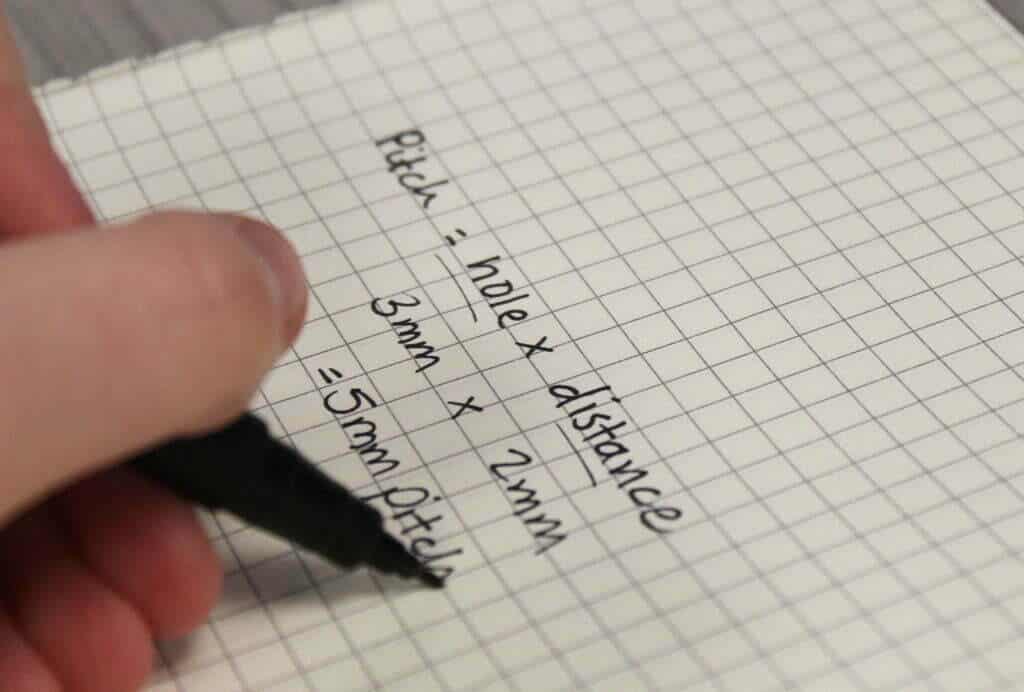

The most common question that we receive about perforated metal is: “what do you mean by pitch?”.

The pitch of perforated metal refers to the distance between the centres of adjacent holes in a perforated sheet. It is also known as the centre-to-centre spacing or the repeating pattern interval. The pitch is an important parameter in determining the open area of the sheet and the amount of material that needs to be removed during the punching process.

To calculate the pitch of perforated metal, follow these steps:

The strength of aluminium perforated mesh depends on a variety of factors, such as the thickness and pattern of the sheet, the size and shape of the holes, and the material properties of the aluminium alloy used. Generally, aluminium perforated mesh is relatively lightweight and has good strength-to-weight ratio, making it suitable for a wide range of applications where both strength and weight are important factors.

Aluminium alloys are known for their high strength, corrosion resistance, and durability, which makes them a popular choice for perforated mesh. The strength of aluminium perforated mesh can be further improved by selecting thicker sheets or smaller hole patterns, which can increase the amount of material in the mesh and reduce the size of the individual holes. The design of the mesh should also take into account the specific application and any load or stress requirements that may be present.

You may find stainless steel perforated mesh to be stronger, and perhaps better suited to your needs.

Yes, aluminium perforated metal sheet can be bent, but the extent to which it can be bent depends on the thickness of the sheet and the hole pattern. Perforated metal sheets that are thinner and have larger holes can be bent more easily than thicker sheets with smaller holes.

The bending process for aluminium perforated metal sheet is similar to that of solid aluminium sheets. The sheet is clamped to a bending brake, which is a tool used to bend the sheet to the desired angle. The bending brake applies pressure to the sheet at the point of the bend, causing the sheet to deform and form the desired shape.

It is important to note that bending aluminium perforated metal sheet can cause deformation or distortion of the holes, which may affect the performance or aesthetic appearance of the sheet. To minimize this effect, it is recommended to use a bending brake that has a wide clamping surface, and to avoid bending the sheet at the edges of the perforations. It is also advisable to test a small section of the sheet before attempting to bend the entire sheet to ensure that the desired results are achieved.

Yes, it is possible to weld aluminium perforated sheet, but there are some considerations to keep in mind.

Aluminium perforated sheet is typically made from aluminium alloy, which has a low melting point and high thermal conductivity. This can make welding aluminium perforated sheet challenging, as the heat from the welding process can easily deform or melt the sheet.

To weld aluminium perforated sheet, it is important to use a welding technique that can control the heat input and prevent distortion of the sheet. One common welding technique for aluminium perforated sheet is Tungsten Inert Gas (TIG) welding. TIG welding uses a non-consumable tungsten electrode to generate an arc that melts the aluminium and creates a weld bead. The process allows for precise control of the heat input, and can produce high-quality welds with minimal distortion.

It is also important to select the appropriate filler material for welding aluminium perforated sheet. Typically, a filler material that matches the alloy of the sheet is used, and care must be taken to avoid contamination from other metals or materials.

Yes, aluminium perforated metal sheet can be painted, but it is important to follow certain steps to ensure good adhesion and long-lasting results.

The first step is to clean the perforated sheet thoroughly to remove any dirt, grease, or other contaminants that may interfere with the paint adhesion. This can be done using a cleaning solution or degreaser and a clean cloth or sponge.

After cleaning, the sheet should be dried completely before painting. The choice of paint should be compatible with aluminium and the specific application, and it is important to select a paint that is designed for use on metal surfaces. It is recommended to use a primer designed for use on aluminium surfaces to improve adhesion and durability.

The paint can be applied using a spray gun, brush, or roller, depending on the desired finish and the size of the perforated sheet. It is important to apply the paint evenly and to follow the manufacturer’s instructions for application and drying times.

It is also important to note that painted aluminium perforated sheet may require periodic maintenance to ensure the paint remains in good condition. Regular cleaning and inspection can help identify any areas that may require touch-ups or repainting to maintain the appearance and performance of the sheet.

As always, thank you for checking out our blog. We hope that this helps you with your project. We try to launch a couple of new guides every week. Eventually we will have covered everything there is to cover about mesh.

Our goal for our blogs and help guides is to answer as many questions as possible to help to explain the possibilities of mesh to our customers. Contact our team today if you have any questions at all. We are always really keen to help in any way that we can.