At The Mesh Company, we spend a lot of time helping customers navigate the space between highly technical metal products and real-world requirements. Perforated sheet is a good example of where that guidance matters.

On paper, perforated metal looks simple: a flat sheet with holes punched through it. In practice, relatively small changes in hole size, pitch, thickness, and layout can completely change how a sheet behaves — structurally, visually, and functionally.

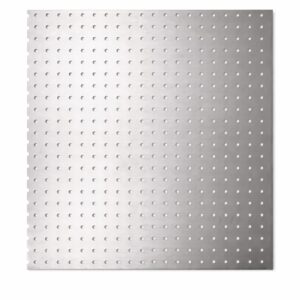

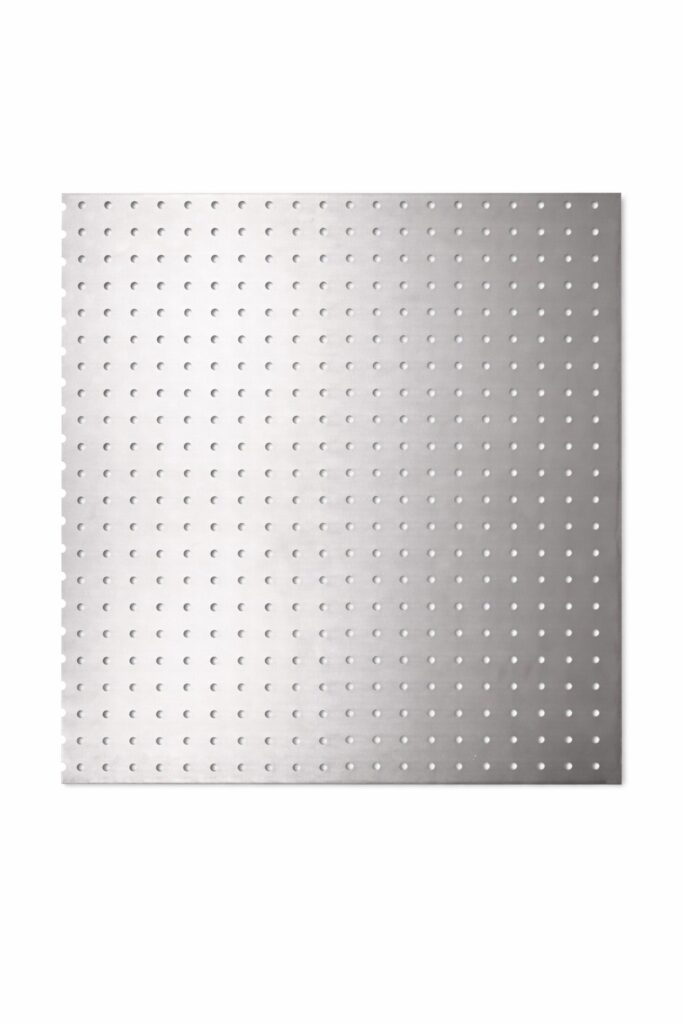

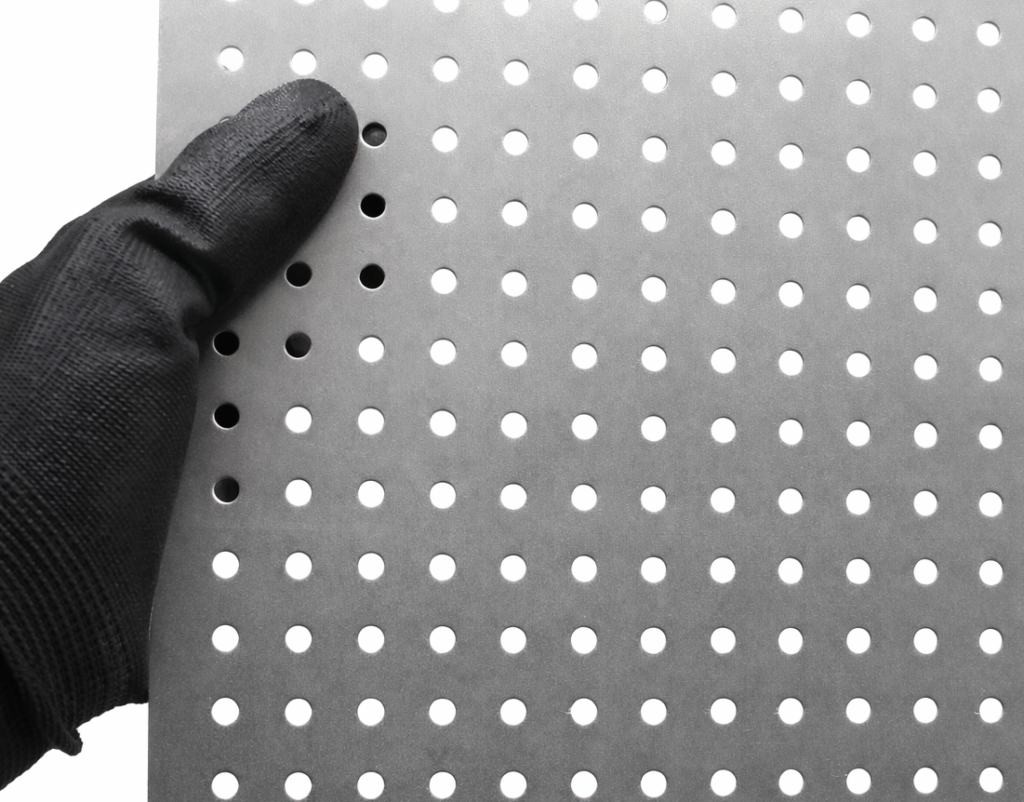

That’s why we’ve introduced a mild steel 4.5mm perforated sheet, manufactured with a 15mm square pitch in a 1.5mm thickness. This is not a lightweight, high-airflow product designed to disappear into the background. It is a purposeful, screening-led sheet that prioritises safety, strength, appearance, and cost control in equal measure.

This guide explains what it is, why it exists, and where it genuinely makes sense to use it.

Many perforated sheets are designed around maximising open area. Larger holes, staggered pitches, and thinner material all push airflow and light transmission higher. That approach is valid — but it isn’t always what customers actually need.

We regularly speak to customers who want something different. They need a perforated sheet that feels secure rather than open, that limits visibility rather than encouraging it, and that addresses safety concerns without resorting to a fully solid panel. At the same time, they want a product that is affordable, easy to fabricate, and available off the shelf.

A 4.5mm perforated sheet on a square pitch sits neatly in that space. It offers small enough holes to address finger-trap concerns, a low open area that provides visual screening, and enough remaining material to maintain strength and rigidity. Importantly, it achieves all of this in mild steel, keeping costs realistic for e-commerce buyers and smaller projects.

This product is defined by three key dimensions. Each one plays a specific role in how the sheet looks, performs, and behaves once installed:

Hole size: 4.5mm round

Material thickness: 1.5mm mild steel

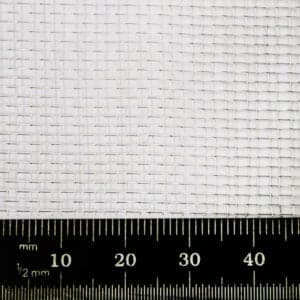

Pitch: 15mm square layout

Together, these details determine whether the sheet feels open or enclosed, flexible or rigid, decorative or functional.

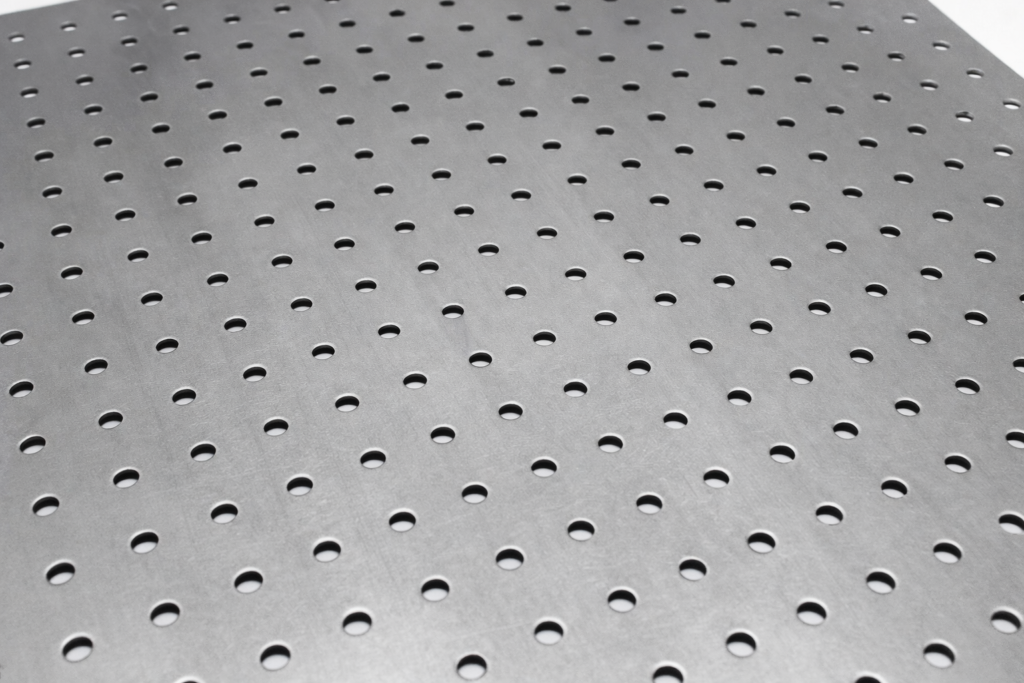

The 4.5mm round holes are small enough to limit finger access and help prevent the entry of birds or small animals, while still allowing a controlled amount of airflow. Round perforations are also familiar and predictable, which makes the sheet straightforward to cut, fold, and fabricate without unexpected behaviour.

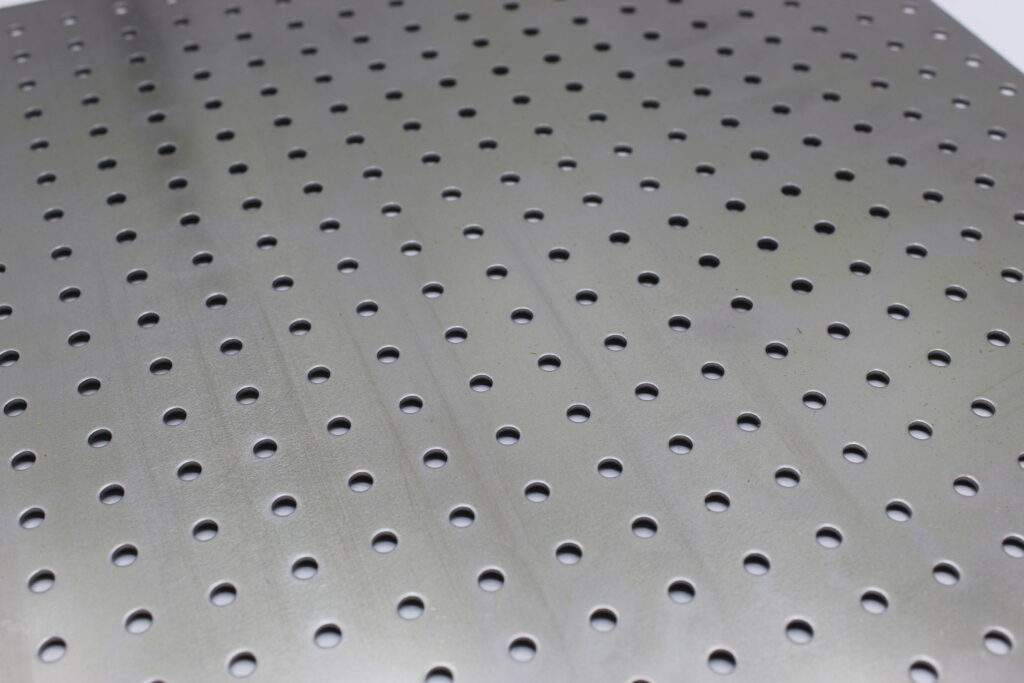

The 1.5mm mild steel thickness is a major contributor to the sheet’s overall performance. Despite the perforations, this thickness gives the material a solid, panel-like feel. It resists bending and distortion far more effectively than thinner perforated sheets and provides a reassuring sense of robustness once installed in a frame or fixed to a structure.

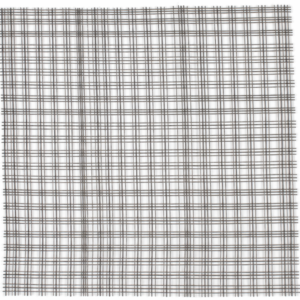

The holes are laid out on a 15mm square pitch, meaning they align directly both horizontally and vertically. This layout is chosen primarily for its appearance rather than maximum structural efficiency. The result is a clean, ordered pattern that works particularly well in visible installations, where the perforated sheet forms part of the finished design rather than being hidden away.

It’s worth addressing an important point directly. From a purely structural perspective, a staggered pitch distributes load more efficiently than a square pitch. That’s why staggered layouts are so common in industrial perforated sheets.

However, strength is not determined by pitch alone. In this case, the relatively thick 1.5mm mild steel compensates for the marginal strength difference between square and staggered layouts. Once the sheet is fixed into a frame, supported at its edges, or folded to increase rigidity, the practical difference becomes negligible for the applications this product is intended for.

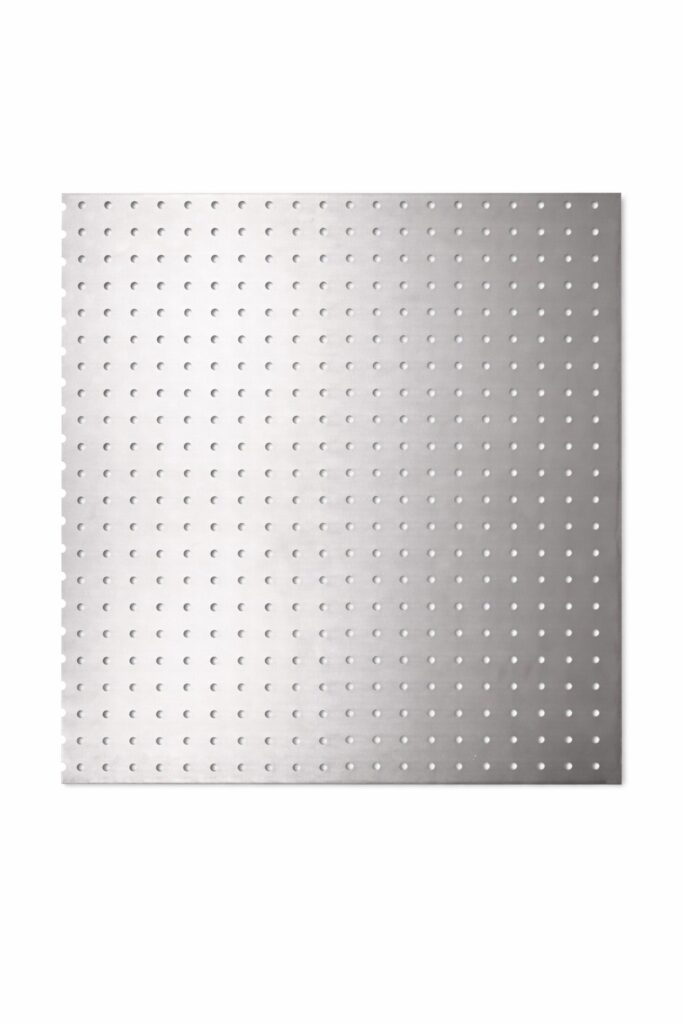

The square pitch is chosen because it looks better. The regular grid creates a calm, architectural appearance that suits screening, guarding, and infill panels where the sheet remains visible. For customers who care about how a perforated panel looks as much as how it performs, that visual order matters.

One of the most misunderstood aspects of perforated sheet is open area. Larger numbers are often assumed to be better, but that depends entirely on what the sheet is being asked to do.

With 4.5mm holes on a 15mm square pitch, this sheet has an open area of approximately 7%. That figure is deliberately low.

A low open area means the sheet feels more solid, provides better screening, and offers improved guarding performance. It also means airflow and light transmission are limited rather than maximised. This is not an airflow-first product, and it isn’t intended to be.

Understanding this balance is key to choosing the right perforated sheet. In many guarding and screening applications, unrestricted airflow or visibility would actually be a disadvantage.

The technical term for the way this sheet reduces visibility is visual occlusion. In simple terms, it describes how effectively a material interrupts sightlines.

With only around 7% open area, this 4.5mm perforated sheet provides a high level of visual occlusion. You can still achieve ventilation through the panel, but it is difficult to see clearly through it. Shapes and movement behind the sheet are softened rather than exposed, which gives a sense of privacy and enclosure without fully closing off the space.

This characteristic makes the sheet particularly useful for screening plant, services, and equipment, as well as for architectural infill where designers want separation without a solid barrier.

Safety is another key reason this perforation size makes sense. Round holes present a higher finger-trap risk than square or hexagonal openings, simply because fingers are round. For that reason, common guidance recommends keeping round perforations at 8mm or below where finger access is a concern.

At 4.5mm, this sheet sits well within that guidance. It is suitable for public-facing installations, shared environments, and any application where accidental finger access needs to be limited without resorting to mesh or solid panels.

Due to its combination of small holes, low open area, and solid thickness, this 4.5mm perforated sheet is particularly well suited to:

Guarding around machinery and equipment, where finger access needs to be restricted

Screening applications, providing privacy and protection without fully enclosing a space

Architectural infill panels, where a clean, uniform appearance is important

Areas requiring visual occlusion, rather than full transparency

It can also be used for:

Ventilation covers, where airflow is required but needs to be controlled

Filtration or separation applications, acting as a coarse or protective layer rather than a fine filter

As effective as this sheet is within its intended role, it is not a universal solution. If maximum airflow or light transmission is required, the low open area will be a limitation rather than a benefit. Larger perforations or a staggered pitch would be more appropriate in those cases.

Similarly, standard perforated sheet is not recommended for walkways or flooring without additional surface treatment to provide grip. These applications require products specifically designed for slip resistance.

Being clear about these boundaries helps ensure the sheet is used appropriately and performs as expected.

This 4.5mm perforated sheet is designed to balance strength, safety and visual screening, rather than maximise airflow or light transmission. The small round holes, low open area and 1.5mm mild steel thickness give it a solid, panel-like feel once installed.

With a clean square-pitch layout and good finger-trap performance, it is well suited to guarding, screening and architectural infill applications where controlled airflow and reduced visibility are required.

Naomi O’Toole – Development Manager